Search results for: 'combin machine'

- Related search terms

- machine+tr

- Machine+c

- Machine+c'

- Machine+op

- Machine fe'

-

T-9600 XENON ARC LIGHT FASTNESS TESTERT-9600 XENON ARC LIGHT FASTNESS TESTER KEY SPECIFICATION: CHAMBER TEMPERATURE: 25-55℃; RESOLUTION: 0.1℃ CHAMBER HUMIDITY: LIGHT CYCLE: 10-70%RH; RESOLUTION: 0.1RH% DARK CYCLE: 30-95%RH; RESOLUTION: 0.1RH% BST: 40-85℃; ACCURACY: ±1℃; RESOLUTION: 0.1℃ BPT (OPTION): 40-80℃, ACCURACY: ±2℃; RESOLUTION: 0.1℃ TIME CONTROL RANGE: ≤10000H IRRADIANCE CONTROL RANGE: 0.80-1.20W/M²@420NM (OPTION: 340NM, 420NM, 300-400NM OR 280-800NM) ACCURACY: ±0.02W/M²@420NM. DIGITAL SETTING, CLOSED-LOOP AUTOMATIC COMPENSATION XENON ARC LAMP RATED POWER: 2500W SAMPLE HOLDER ROTATION SPEED: 2-7 RPM SAMPLE HOLDERS CAPACITY: ISO: 145 × 45mm 12PCS OR AATCC: 145 × 70mm 6PCS TIMING OF EACH SAMPLE HOLDER, RESPECTIVELY: ≤10000H LIGHT PERIOD: ≤1000H SPRAY PERIOD: ≤1000H POWER: AC220V ±10% 50Hz 6.5KW RATED POWER: 3.3KW DIMENSION: 920 × 650 × 1680mm WEIGHT: 180KG Learn More

T-9600 XENON ARC LIGHT FASTNESS TESTERT-9600 XENON ARC LIGHT FASTNESS TESTER KEY SPECIFICATION: CHAMBER TEMPERATURE: 25-55℃; RESOLUTION: 0.1℃ CHAMBER HUMIDITY: LIGHT CYCLE: 10-70%RH; RESOLUTION: 0.1RH% DARK CYCLE: 30-95%RH; RESOLUTION: 0.1RH% BST: 40-85℃; ACCURACY: ±1℃; RESOLUTION: 0.1℃ BPT (OPTION): 40-80℃, ACCURACY: ±2℃; RESOLUTION: 0.1℃ TIME CONTROL RANGE: ≤10000H IRRADIANCE CONTROL RANGE: 0.80-1.20W/M²@420NM (OPTION: 340NM, 420NM, 300-400NM OR 280-800NM) ACCURACY: ±0.02W/M²@420NM. DIGITAL SETTING, CLOSED-LOOP AUTOMATIC COMPENSATION XENON ARC LAMP RATED POWER: 2500W SAMPLE HOLDER ROTATION SPEED: 2-7 RPM SAMPLE HOLDERS CAPACITY: ISO: 145 × 45mm 12PCS OR AATCC: 145 × 70mm 6PCS TIMING OF EACH SAMPLE HOLDER, RESPECTIVELY: ≤10000H LIGHT PERIOD: ≤1000H SPRAY PERIOD: ≤1000H POWER: AC220V ±10% 50Hz 6.5KW RATED POWER: 3.3KW DIMENSION: 920 × 650 × 1680mm WEIGHT: 180KG Learn More -

V-1885 SAURER BD7 OPEN END, YEAR 2017, 480 ROTORS PER MACHINEV-1885 SAURER BD7 OPEN END, YEAR 2017, 480 ROTORS PER MACHINE QUANTITY: 3 Learn More

V-1885 SAURER BD7 OPEN END, YEAR 2017, 480 ROTORS PER MACHINEV-1885 SAURER BD7 OPEN END, YEAR 2017, 480 ROTORS PER MACHINE QUANTITY: 3 Learn More -

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More -

T-6969 EREMA RECYCLING LINE, CAPACITY 250 KG/HOUR, YEAR 2017T-6969 EREMA RECYCLING LINE, CAPACITY 250 KG/HOUR, YEAR 2017 DIAMETER SCREW(S): 70mm MATERIAL & MIN – MAX THICKNESS: FILM MAX. CAPACITY: 250 KG/HOUR QUANTITY: 1 Learn More

T-6969 EREMA RECYCLING LINE, CAPACITY 250 KG/HOUR, YEAR 2017T-6969 EREMA RECYCLING LINE, CAPACITY 250 KG/HOUR, YEAR 2017 DIAMETER SCREW(S): 70mm MATERIAL & MIN – MAX THICKNESS: FILM MAX. CAPACITY: 250 KG/HOUR QUANTITY: 1 Learn More -

SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2473 SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT THE MAJOR ADVANTAGE OF THIS MACHINE IS SCALABILITY, AS IT’S SUITABLE FOR BOTH PRODUCTION LINE AS WELL AS R & D PROJECTS. IT FUNCTIONS WITH 56 NOZZLES ENABLING HIGH PRODUCTIVITY FOR MASS PRODUCTION OF NANOFIBERS, HOWEVER IT CAN ALSO FUNCTION WITH A SINGLE WHEN WORKING ON R & D PROJECTS. ITS UNIQUE DESIGN ENABLES PRODUCTION OF NANOFIBERS AND COMPOSITES, IT ACCOMMODATES FOUR SYRINGE PUMPS AND FOUR HIGH VOLTAGE POWER SUPPLIERS, MAKING IT POSSIBLE TO WORK SIMULTANEOUSLY WITH UP TO FOUR DIFFERENT POLYMERS, INDEPENDENTLY CONTROLLED. MACHINE USES A UNIQUE PATENTED HYBRID ELECTROSPINNING TECHNOLOGY. THIS NEW TECHNIQUE COMBINES THE ADVANTAGES OF BOTH NEEDLE - BASED AND NEEDLE - LESS ELECTROSPINNING, WHICH ARE INCLUDING BUT NOT LIMITED TO: HIGH THROUGHOUT PRODUCTIVITY (FROM THE NEEDLE - LESS), WITH A VERY ACCURATE CONTROL OVER THE PROCESS AND THE FINAL PRODUCT (FROM NEEDLE - BASED ELECTROSPINNING). SPECIFICATIONS: CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 650 KGS DIMENSIONS: 1965 X 2095 X 2012 mm HIGH VOLTAGE POWER SUPPLY NUMBER OF HV GENERATORS: 4 UNITS (1 FOR EACH SOLUTION FEEDING ROD) VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP NUMBER OF PUMPS: 4 UNITS FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML AVAILABLE SYRINGES: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 14 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 56 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 15 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 50 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 30 TO 280 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 550 mm SUBSTRATE WINDING SPEED: 0,01 M/MIN TO 1 M/min REPETITIVE WINDING MODE (OPTIONAL) COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 10 MM TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 3000 X 3000 mm Learn More

SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2473 SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT THE MAJOR ADVANTAGE OF THIS MACHINE IS SCALABILITY, AS IT’S SUITABLE FOR BOTH PRODUCTION LINE AS WELL AS R & D PROJECTS. IT FUNCTIONS WITH 56 NOZZLES ENABLING HIGH PRODUCTIVITY FOR MASS PRODUCTION OF NANOFIBERS, HOWEVER IT CAN ALSO FUNCTION WITH A SINGLE WHEN WORKING ON R & D PROJECTS. ITS UNIQUE DESIGN ENABLES PRODUCTION OF NANOFIBERS AND COMPOSITES, IT ACCOMMODATES FOUR SYRINGE PUMPS AND FOUR HIGH VOLTAGE POWER SUPPLIERS, MAKING IT POSSIBLE TO WORK SIMULTANEOUSLY WITH UP TO FOUR DIFFERENT POLYMERS, INDEPENDENTLY CONTROLLED. MACHINE USES A UNIQUE PATENTED HYBRID ELECTROSPINNING TECHNOLOGY. THIS NEW TECHNIQUE COMBINES THE ADVANTAGES OF BOTH NEEDLE - BASED AND NEEDLE - LESS ELECTROSPINNING, WHICH ARE INCLUDING BUT NOT LIMITED TO: HIGH THROUGHOUT PRODUCTIVITY (FROM THE NEEDLE - LESS), WITH A VERY ACCURATE CONTROL OVER THE PROCESS AND THE FINAL PRODUCT (FROM NEEDLE - BASED ELECTROSPINNING). SPECIFICATIONS: CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 650 KGS DIMENSIONS: 1965 X 2095 X 2012 mm HIGH VOLTAGE POWER SUPPLY NUMBER OF HV GENERATORS: 4 UNITS (1 FOR EACH SOLUTION FEEDING ROD) VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP NUMBER OF PUMPS: 4 UNITS FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML AVAILABLE SYRINGES: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 14 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 56 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 15 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 50 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 30 TO 280 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 550 mm SUBSTRATE WINDING SPEED: 0,01 M/MIN TO 1 M/min REPETITIVE WINDING MODE (OPTIONAL) COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 10 MM TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 3000 X 3000 mm Learn More -

C-4005 PACTEC NAGEMA EW10 CUT & VIENNA FOLD TYPE BONBON WRAPPER, WIDTH 16 TO 18mm, YEAR 1990

C-4005 PACTEC NAGEMA EW10 CUT & VIENNA FOLD TYPE BONBON WRAPPER, WIDTH 16 TO 18mm, YEAR 1990C-4005 PACTEC NAGEMA EW10 CUT & VIENNA FOLD TYPE BONBON WRAPPER, WIDTH 16 TO 18mm, YEAR 1990

YEAR: 1990

300/MIN

WITH BATCH ROLLER & ROPE SIZER

REFURBISHED

PRODUCT DIMENSIONS

LENGTH: 25 TO 35mm

WIDTH: 16 TO 18mmQUANTITY: 1

Learn More -

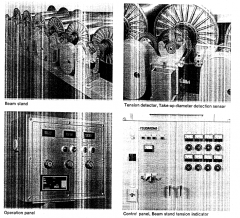

M-5202 KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMAREFERENCE NUMBER: M-5202 (1313VTYFXX12) L KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMA QUANTITY AVAILABLE: 1 Learn More

M-5202 KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMAREFERENCE NUMBER: M-5202 (1313VTYFXX12) L KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMA QUANTITY AVAILABLE: 1 Learn More -

M-2022 COMPLETE OPEN END PLANT YEARS 2006 – MACHINES ARE RUNNINGREFERENCE NUMBER: M-2022 (77052WHPOY6RL) COMPLETE OPEN END PLANT YEARS 2006 – MACHINES ARE RUNNING QUANTITY AVAILABLE: 1 Learn More

M-2022 COMPLETE OPEN END PLANT YEARS 2006 – MACHINES ARE RUNNINGREFERENCE NUMBER: M-2022 (77052WHPOY6RL) COMPLETE OPEN END PLANT YEARS 2006 – MACHINES ARE RUNNING QUANTITY AVAILABLE: 1 Learn More -

E-2896 CONVOLUTER

E-2896 CONVOLUTERE-2896 CONVOLUTER

MODEL: 2150

CONVOLUTING WIDTH MAX: W 2150 mm (84")

CONVOLUTING PIN DEPTH: 30 mm (1.18")

CONVOLUTING RUNNING SPEED: 0 TO 25 RPM

TOTAL POWER: 10.74 KW

CUTTING SPEED: 0 TO 25 METERS PER MINUTE

CUTTER BLADE TOTAL LENGTH: 9800 mm

BLADE WIDTH x THICKNESS: 50mm x 0.65mm

MACHINE WEIGHT: 2500 KG

MACHINE OVERALL DIMENSIONS: 15.4 FEET WIDE X 4.1 FEET DEEP X 5 FEET TALL

MAXIMUM HEIGHT OF FOAM: 200mm (8”)

THE HEADS ARE ROUND HEADS:

-THE DIAMETER OF EACH HEAD IS 16mm

-THE HEIGHT IS 30mm

-THE DISTANCE OF THE CENTER TO CENTER OF A PAIR HEADS IS 50mm.

Learn More

THIS MACHINE IS A COMBINATION CONVOLUTER-CUTTING MACHINE.

PRODUCES APPROPRIATE MATERIAL PACKAGING FOR ELECTRONICS, DELICATE INSTRUMENTS, FOR CAR SEATING AND MATTRESS INDUSTRY, AS WELL AS EXPENSIVE ARTICLE PACKAGING AND HIGH DENSITY FOAM. -

M-4136 SANTEX TENTER FRAME YEAR 2003-UP TO 3400mm – 3 ZONE – VERTICAL PIN – HOT OILREFERENCE NUMBER: M-4136 SANTEX TENTER FRAME YEAR 2003-UP TO 3400mm – 3 ZONE – VERTICAL PIN – HOT OIL TYPE: SANTEX TENTER FRAME YEAR: 2003 WORKING WIDTH: 800mm UP TO 3400mm SPEED: 2 UP TO 20 M/MIN CHAIN: VERTICAL PIN CHAIN DRYER: 3 COMPARTMENTS DRYER LENGTH: 6 METERS MAX. TEMP.: 230° C HEATING: DIATHERMIC OIL OIL BOILER: GARIONI NAVAL TH 500 CAPACITY: 581 KW, MAX. TEMP. 350° C, NITROGEN COVERED TOTAL LENGTH NEEDED: APPROX. 20,000mm TOTAL WIDTH OF MACHINE: 6,200mm TOTAL HEIGHT OF MACHINE: 3,100mm ENTRY COMBINATION GUIDING CHAIN FOR A-FRAMES CORRECT POSITIONING RUBBERIZED ROLLERS AS INFEED UNIT WECO IMPREGNATION UNIT, CONTROL AND TANK ROLLER WITH LOAD CELL MAHLO WEFT STRAIGHTENER, TYPE: RFMC-10A 6 MEASURING HEADS, WW 4200mm OPERATION PEDESTAL OPERATION PANEL, MONITOR 1 UPPER INFEED ROLLER + 1 BENDED ROLLER E+L FABRIC INFEED VERTICAL PIN CHAIN 3 SECTIONAL DRYER (6 M) COOLING UNIT AT EXIT 2 CAMERAS VIDEO CONTROL STRETCH WORK: 2 PRESSING ROLLERS 3 HEATED DRAG ROLLERS WITH SINGLE DRIVE TEMPERATURE 80° C TO 250° C ON-WINDING UNIT FOR A-FRAMES ELECTRICAL CABINET QUANTITY AVAILABLE: 1 Learn More

M-4136 SANTEX TENTER FRAME YEAR 2003-UP TO 3400mm – 3 ZONE – VERTICAL PIN – HOT OILREFERENCE NUMBER: M-4136 SANTEX TENTER FRAME YEAR 2003-UP TO 3400mm – 3 ZONE – VERTICAL PIN – HOT OIL TYPE: SANTEX TENTER FRAME YEAR: 2003 WORKING WIDTH: 800mm UP TO 3400mm SPEED: 2 UP TO 20 M/MIN CHAIN: VERTICAL PIN CHAIN DRYER: 3 COMPARTMENTS DRYER LENGTH: 6 METERS MAX. TEMP.: 230° C HEATING: DIATHERMIC OIL OIL BOILER: GARIONI NAVAL TH 500 CAPACITY: 581 KW, MAX. TEMP. 350° C, NITROGEN COVERED TOTAL LENGTH NEEDED: APPROX. 20,000mm TOTAL WIDTH OF MACHINE: 6,200mm TOTAL HEIGHT OF MACHINE: 3,100mm ENTRY COMBINATION GUIDING CHAIN FOR A-FRAMES CORRECT POSITIONING RUBBERIZED ROLLERS AS INFEED UNIT WECO IMPREGNATION UNIT, CONTROL AND TANK ROLLER WITH LOAD CELL MAHLO WEFT STRAIGHTENER, TYPE: RFMC-10A 6 MEASURING HEADS, WW 4200mm OPERATION PEDESTAL OPERATION PANEL, MONITOR 1 UPPER INFEED ROLLER + 1 BENDED ROLLER E+L FABRIC INFEED VERTICAL PIN CHAIN 3 SECTIONAL DRYER (6 M) COOLING UNIT AT EXIT 2 CAMERAS VIDEO CONTROL STRETCH WORK: 2 PRESSING ROLLERS 3 HEATED DRAG ROLLERS WITH SINGLE DRIVE TEMPERATURE 80° C TO 250° C ON-WINDING UNIT FOR A-FRAMES ELECTRICAL CABINET QUANTITY AVAILABLE: 1 Learn More