Search results for: 'double be'

- Related search terms

- double

- Double Twister

- DOUBLE BELT THERMOBONDING

- double needle

- doubler

-

TT-1606 VECOPLAN SHREDDER VAZ 1300-M – NEW, YEAR 2022TT-1606 VECOPLAN SHREDDER VAZ 1300-M – NEW, YEAR 2022 VECOPLAN SHREDDER VAZ 1300-M – NEW (IN PLANT - COMPANY DECIDED NOT TO USE IT - AVAILABLE IMMEDIATELY - STILL IN WRAPPER) QUANTITY: 1 Learn More

TT-1606 VECOPLAN SHREDDER VAZ 1300-M – NEW, YEAR 2022TT-1606 VECOPLAN SHREDDER VAZ 1300-M – NEW, YEAR 2022 VECOPLAN SHREDDER VAZ 1300-M – NEW (IN PLANT - COMPANY DECIDED NOT TO USE IT - AVAILABLE IMMEDIATELY - STILL IN WRAPPER) QUANTITY: 1 Learn More -

TT-1087 HERGETH/RAMISCH/EDELMANN THERMOBOND LINE, WIDTH 4000mm, YEAR 1990 TO 1995TT-1087 HERGETH/RAMISCH/EDELMANN THERMOBOND LINE, WIDTH 4000mm, YEAR 1990 TO 1995 HERGETH/RAMISCH/EDELMANN THERMOBOND LINE TYPE: COMPLETE THERMOBONDING LINE WIDTH: 4000mm YEAR: 1990 TO 1995 QUANTITY: 1 Learn More

TT-1087 HERGETH/RAMISCH/EDELMANN THERMOBOND LINE, WIDTH 4000mm, YEAR 1990 TO 1995TT-1087 HERGETH/RAMISCH/EDELMANN THERMOBOND LINE, WIDTH 4000mm, YEAR 1990 TO 1995 HERGETH/RAMISCH/EDELMANN THERMOBOND LINE TYPE: COMPLETE THERMOBONDING LINE WIDTH: 4000mm YEAR: 1990 TO 1995 QUANTITY: 1 Learn More -

P-2505 KARL MAYER ROTAL SIZING MACHINE YEAR 2001 WIDTH 4000mmREFERENCE NUMBER: P-2505 KARL MAYER ROTAL SIZING MACHINE YEAR 2001 WIDTH 4000mm KARL MAYER-ROTAL SIZING MACHINE YEAR: 2001 HEAD 4600mm QUANTITY AVAILABLE: 1 Learn More

P-2505 KARL MAYER ROTAL SIZING MACHINE YEAR 2001 WIDTH 4000mmREFERENCE NUMBER: P-2505 KARL MAYER ROTAL SIZING MACHINE YEAR 2001 WIDTH 4000mm KARL MAYER-ROTAL SIZING MACHINE YEAR: 2001 HEAD 4600mm QUANTITY AVAILABLE: 1 Learn More -

G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERSREFERENCE NUMBER: G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERS MODEL PM25 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 25 DISTANCE BETWEEN NEEDLES: 6.2mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST MODEL PM33 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 33 DISTANCE BETWEEN NEEDLES: 406mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST QUANTITY AVAILABLE: 2 Learn More

G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERSREFERENCE NUMBER: G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERS MODEL PM25 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 25 DISTANCE BETWEEN NEEDLES: 6.2mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST MODEL PM33 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 33 DISTANCE BETWEEN NEEDLES: 406mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST QUANTITY AVAILABLE: 2 Learn More -

K-9772 OSTHOFF-SENGE SINGEING MACHINE PK90 YEAR 1992 WIDTH 1800mmREFERENCE NUMBER: K-9772 OSTHOFF-SENGE SINGEING MACHINE PK90 YEAR 1992 WIDTH 1800mm SINGEING MACHINE OSTHOFF-SENGE 5600 MODEL PK90 YEAR OF CONSTRUCTION: 1992 ROLLERS WIDTH: 2000mm USEFUL WORKING WIDTH: 1800mm SPEED FROM 20 TO 120 METERS PER MINUTE QUANTITY AVAILABLE: 1 Learn More

K-9772 OSTHOFF-SENGE SINGEING MACHINE PK90 YEAR 1992 WIDTH 1800mmREFERENCE NUMBER: K-9772 OSTHOFF-SENGE SINGEING MACHINE PK90 YEAR 1992 WIDTH 1800mm SINGEING MACHINE OSTHOFF-SENGE 5600 MODEL PK90 YEAR OF CONSTRUCTION: 1992 ROLLERS WIDTH: 2000mm USEFUL WORKING WIDTH: 1800mm SPEED FROM 20 TO 120 METERS PER MINUTE QUANTITY AVAILABLE: 1 Learn More -

M-5157 ETON SYSTEMS YEAR 1988

M-5157 ETON SYSTEMS YEAR 1988REFERENCE NUMBER: M-5157 (1212PTKRXX11) L

ETON SYSTEMS YEAR 1988

ETON 2001

YEAR OF MANUFACUTRE: AROUND 1988

ABOUT 70 STATIONS, MAYBE MORE

TWO SEPARATE LINES, EACH AROUND 50 METERS LONG

TWO LINES ARE ASSEMBLED AND WORKING

LOTS OF SPARE PARTS FROM DISMANTLED ETONS SYSTEMS AND LOTS OF HANGERS

QUANTITY AVAILABLE: 2

Learn More -

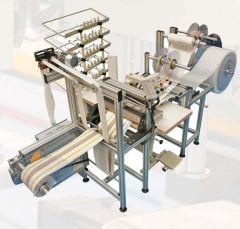

M-4608 VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mmREFERENCE NUMBER: M-4608 (11116SWJK10R) L VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mm LAMINATING LINE MANUFACTURER: VILLARS (CH) ACTUALLY SANTEX YEAR OF CONSTRUCTION: 1993 WORKING WIDTH: 2200mm (NOMINAL WIDTH 2100mm) OPERATING VOLTAGE: 3X380(400)V TOTAL POWER: 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION: INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997): 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS: 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED. ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM MANUFACTURER: MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR OF CONSTRUCTION: 1999 OPERATING VOLTAGE: 3X380V CAPACITY ACCUMULATOR: +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE MANUFACTURER: MENZEL YEAR OF CONSTRUCTION: 2000 OPERATING VOLTAGE: 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT. KNOWN PROBLEM: PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) MISCELLANEA SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS CAN BE INSPECTED BUT NOT IN PRODUCTION MACHINE WILL BE DISMANTLED AT END OF NOV 2014 QUANTITY AVAILABLE: 1 Learn More

M-4608 VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mmREFERENCE NUMBER: M-4608 (11116SWJK10R) L VILLARS-SANTEX HOTMELT POWDER SCATTERING AND LAMINATING MACHINE YEAR 1993 WIDTH 2100mm LAMINATING LINE MANUFACTURER: VILLARS (CH) ACTUALLY SANTEX YEAR OF CONSTRUCTION: 1993 WORKING WIDTH: 2200mm (NOMINAL WIDTH 2100mm) OPERATING VOLTAGE: 3X380(400)V TOTAL POWER: 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION: INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997): 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS: 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED. ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM MANUFACTURER: MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR OF CONSTRUCTION: 1999 OPERATING VOLTAGE: 3X380V CAPACITY ACCUMULATOR: +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE MANUFACTURER: MENZEL YEAR OF CONSTRUCTION: 2000 OPERATING VOLTAGE: 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT. KNOWN PROBLEM: PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) MISCELLANEA SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS CAN BE INSPECTED BUT NOT IN PRODUCTION MACHINE WILL BE DISMANTLED AT END OF NOV 2014 QUANTITY AVAILABLE: 1 Learn More -

M-3973 HOTMELT POWDER SCATTERING AND LAMINATING MACHINE-2200mmREFERENCE NUMBER: M-3973 (99016AVEZ8RX)-D HOTMELT POWDER SCATTERING AND LAMINATING MACHINE-2200mm 1.LAMINATING LINE : MAKE : VILLARS (CH) ACTUALLY SANTEX YEAR: 1993 WORKING WIDTH : 2200mm (NOMINAL WIDTH 2M10) VOLTAGE: 3X380(400)V TOTAL POWER : 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION : INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997) : 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS : 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED 2.ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM : MAKE : MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR: 1999 OPERATING VOLTAGE : 3X380V CAPACITY ACCUMULATOR : +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) 3. SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE : MAKE: MENZEL YEAR: 2000 OPERATING VOLTAGE : 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT KNOWN PROBLEM : PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) 4.MISCELLANEOUS : SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS Learn More

M-3973 HOTMELT POWDER SCATTERING AND LAMINATING MACHINE-2200mmREFERENCE NUMBER: M-3973 (99016AVEZ8RX)-D HOTMELT POWDER SCATTERING AND LAMINATING MACHINE-2200mm 1.LAMINATING LINE : MAKE : VILLARS (CH) ACTUALLY SANTEX YEAR: 1993 WORKING WIDTH : 2200mm (NOMINAL WIDTH 2M10) VOLTAGE: 3X380(400)V TOTAL POWER : 158KW RECOMMENDED MAX. SPEED 10M BUT 15M IS POSSIBLE ORIGINAL CONFIGURATION : INPUT UNIT (WITH POSSIBILITY TO HANG IN ROLLERS BY MEANS OF E.G. FLAT BEARINGS), POWDER SPREADER, INFRARED PREHEATING ZONE AND DOUBLE BAND LAMINATING PRESS (HEATING THROUGH IR) LATER EXTENSION (1997) : 2ND INFRARED ZONE WITH COLD WATER COOLED CALENDAR AT THE BACK EQUIPPED WITH SELVEDGE CUTTING SYSTEM WITH ADJUSTABLE INFRARED FOLLOW UP SYSTEM. STRENGTH OF INFRARED CAN BE ADJUSTED SO THAT E.G. THE UPPER SUBSTRATE CAN BE ‘NEGLECTED’. KNOWN PROBLEMS : 1)INFRARED PREHEATING ZONE : 2 IR STRIPS BROKEN 2)CERTAIN PARTS IR ZONES (MOSTLY EXTERIOR ZONES) OF THE DOUBLE BAND LAMINATING PRESS DO NOT LONGER FUNCTION, BUT SECOND PART OF THE MACHINE CAN STILL BE HEATED TILL 160 À 170°C AND EVEN MORE, BUT THEN AT VERY LOW SPEED 2.ACCUMULATOR WITH WINDER AND CONTROLLING SYSTEM : MAKE : MATTHIJS (ELECTRICAL PART BY ELECTRO VANDEVELDE) YEAR: 1999 OPERATING VOLTAGE : 3X380V CAPACITY ACCUMULATOR : +/- 50M UNIT FUNCTIONS INDEPENDENTLY FROM LAMINATING MACHINE AND SPEED VARIES FROM 0 TILL 50M (SPEED OF WINDING UP UNIT = SPEED LAMINATING MACHINE WHEN ACCUMULATOR IS EMPTY) 3. SUPERSTRUCTURE FOR SUPPLY SECOND SUBSTRATE : MAKE: MENZEL YEAR: 2000 OPERATING VOLTAGE : 3X380V FUNCTIONS INDEPENDENTLY FROM THE LAMINATING MACHINE. SPEED REGULATION BASED ON A 0-10V (=0-15M) EXIT SIGNAL OF THE LAMINATING MACHINE MANUAL RIGHT-LEFT GUIDANCE OF THE SUBSTRATE. A SECOND AUTOMATIC PRE-GUIDANCE IS FORESEEN, BUT THE MOTOR DOES NO LONGER FUNCTION AND IT IS IN PRACTICE NOT REQUIRED BECAUSE THE ROLLS ARE ALWAYS WINDED STRAIGHT. A MEASURING ROLLER IS INCLUDED TO MEASURE THE TENSION OF THE SUBSTRATE. THIS MEASURING ROLLER DIRECTS THE MOTOR SPEED SO THAT THE ADJUSTING OF THE TENSION STAYS STEADY. IT IS EVEN POSSIBLE TO GO TO A +/- TENSIONLESS SITUATION. THE LINE IS MOUNTED ON A SELF-MADE PLATFORM EQUIPPED WITH A SIMPLE UNWINDING UNIT KNOWN PROBLEM : PRESSURE ROLLER TO AVOID THAT THE SUBSTRATE “SLIDES” OVER THE BRAKE ROLLER IS WORN OUT, BUT IS IN PRAXIS NOT NEEDED. MOTOR OF THE PRE-GUIDANCE IS BROKEN (SEE ABOVE) 4.MISCELLANEOUS : SELF-BUILD ENTRY J-BOX WITH SIMPLE ROLL MEASUREMENT SEPARATE J-BOX FOR UNWINDING FROM DOCKS, SO THAT CAN BE LAMINATED IN THE POLE DIRECTION SEWING MACHINE MERROW TO MAKE FLAT SEAMS ON FINE/THIN FABRICS SELVEDGE CUTTERS ARE MOUNTED ON A SYSTEM SO THAT THE FABRIC CAN BE LEVELLED EASILY, EVENTUALLY CAN BE WINDED ON DOCKS. INCLUDING 2 DOCKS OF 2M30 OF WHICH 1 WITH FLAP BEARINGS Learn More -

BENNINGER ZELL SIZETEC HIGH PERFORMANCE SIZING MACHINE YEAR 1995 WIDTH 2200mmBENNINGER ZELL HIGH PERFORMANCE SIZING MACHINE, 1995 TYPE: BEN – SIZETEC SWA TKD 2T8 BB USABLE WIDTH: 2200mm MACHINE TYPE: BEAM TO BEAM SINGLE SIZE BOX CONSISTING OF DOUBLE DIP, DOUBLE NIP ROLLERS WET SPLITTING ZONE 8 DRYING CYLINDERS WAXING DEVICE SIZE KITCHEN WITH COOKER TYPE SHEARTRONIC 700, CAPACITY 700 LITRES, SIZE STORAGE TANK TYPE V10T, CAPACITY 1000 LITRES AUTOMATIC DELIVERY SYSTEM TO SIZE BOX UPGRADED WITH HMI SYSTEM TOUCH SCREEN IN 2011 Learn More

BENNINGER ZELL SIZETEC HIGH PERFORMANCE SIZING MACHINE YEAR 1995 WIDTH 2200mmBENNINGER ZELL HIGH PERFORMANCE SIZING MACHINE, 1995 TYPE: BEN – SIZETEC SWA TKD 2T8 BB USABLE WIDTH: 2200mm MACHINE TYPE: BEAM TO BEAM SINGLE SIZE BOX CONSISTING OF DOUBLE DIP, DOUBLE NIP ROLLERS WET SPLITTING ZONE 8 DRYING CYLINDERS WAXING DEVICE SIZE KITCHEN WITH COOKER TYPE SHEARTRONIC 700, CAPACITY 700 LITRES, SIZE STORAGE TANK TYPE V10T, CAPACITY 1000 LITRES AUTOMATIC DELIVERY SYSTEM TO SIZE BOX UPGRADED WITH HMI SYSTEM TOUCH SCREEN IN 2011 Learn More