Search results for: 'Control+pan'

- Related search terms

- control+pane

- control+panel

- control+panel'

- Control+pan'

- Control+pan''

-

V-2195 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 1850mmV-2195 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 1850mm APPLICATIONS: SUITABLE FOR VARIOUS TAPE SUCH AS PVC, MASKING, DOUBLE SIDE, OPP PACKAGING AND FOAM TAPES, ETC. QUANTITY: 1 MACHINE NOTE: BLADE SIZE IS PER CUSTOMER REQUIREMENTS Learn More

V-2195 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 1850mmV-2195 FULLY AUTOMATIC SINGLE SHAFT BALONEY SLITTER, WORKING WIDTH 1850mm APPLICATIONS: SUITABLE FOR VARIOUS TAPE SUCH AS PVC, MASKING, DOUBLE SIDE, OPP PACKAGING AND FOAM TAPES, ETC. QUANTITY: 1 MACHINE NOTE: BLADE SIZE IS PER CUSTOMER REQUIREMENTS Learn More -

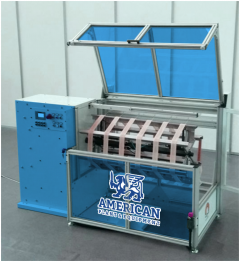

YY-2756 SKEIN WINDER FOR LABORATORIES AND SMALL FIBER MILLSYY-2756 SKEIN WINDER FOR LABORATORIES AND SMALL FIBER MILLS ELECTRIC SPECIFICATIONS: POWER CONSUMPTION: 1.0 KW SINGLE PHASE 230V 50/60Hz (CUSTOMIZABLE) SIZE OF THE MACHINE (LENGTH X WIDTH X HEIGHT): 3060 mm X 1580 mm X 2060 mm (120'' X 62'' X 81'') THE WOODEN CRATE SIZE IS 235 X 140 X 182 CM, WITH A GROSS WEIGHT OF 840 KG. THE MACHINE ITSELF WEIGHS 500 KG. QUANTITY: 1 Learn More

YY-2756 SKEIN WINDER FOR LABORATORIES AND SMALL FIBER MILLSYY-2756 SKEIN WINDER FOR LABORATORIES AND SMALL FIBER MILLS ELECTRIC SPECIFICATIONS: POWER CONSUMPTION: 1.0 KW SINGLE PHASE 230V 50/60Hz (CUSTOMIZABLE) SIZE OF THE MACHINE (LENGTH X WIDTH X HEIGHT): 3060 mm X 1580 mm X 2060 mm (120'' X 62'' X 81'') THE WOODEN CRATE SIZE IS 235 X 140 X 182 CM, WITH A GROSS WEIGHT OF 840 KG. THE MACHINE ITSELF WEIGHS 500 KG. QUANTITY: 1 Learn More -

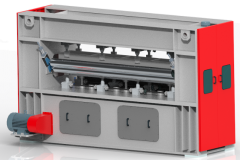

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More -

T-7125 CARDING WILLOW, WORKING WIDTH 1500mmT-7125 CARDING WILLOW, WORKING WIDTH 1500mm TYPE OF FIBRES: ALPACA OR WOOL WILLOW CARDING IS EQUIPPED WITH MECHANICAL AND ELECTRICAL DRIVES CAPACITY: UP TO 1500 KGS/HOUR WORKING WIDTH: 1500mm QUANTITY: 1 Learn More

T-7125 CARDING WILLOW, WORKING WIDTH 1500mmT-7125 CARDING WILLOW, WORKING WIDTH 1500mm TYPE OF FIBRES: ALPACA OR WOOL WILLOW CARDING IS EQUIPPED WITH MECHANICAL AND ELECTRICAL DRIVES CAPACITY: UP TO 1500 KGS/HOUR WORKING WIDTH: 1500mm QUANTITY: 1 Learn More -

L-5934 MONFORTS 6-F TWIN AIR STENTER YEAR 2003 – WORKING WIDTH 2400mm

L-5934 MONFORTS 6-F TWIN AIR STENTER YEAR 2003 – WORKING WIDTH 2400mmREFERENCE NUMBER: L-5934

MONFORTS 6-F TWIN AIR STENTER YEAR 2003 – WORKING WIDTH 2400mm

STENTER

RAMA MONFORTS

MAKE: MONFORTS

MODEL: 6-F TWIN

YEAR: 2003

440 VAC 60HZ

NATURAL GAS

AIR COMPRESSOR 7 BAR

QUANTITY: 1

Learn More -

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOSP-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

THIS ROASTER OFFERS EXACTLY WHAT CUSTOMERS NEED TO PRODUCE TOP-QUALITY COFFEE. AN INNOVATIVE AND EASY-TO-USE PLC CONTROL SYSTEM ENSURES CONSTANT QUALITY DURING PRODUCTION BUT ALSO RETAINS THE ABILITY TO INFLUENCE THE PROCESSING WHEN NECESSARY. OPTIMIZED PARAMETERS CAN BE SAVED IN THE MACHINE’S MEMORY AND RE-USED. THE MACHINE IS MADE OF STAINLESS STEEL AND OTHER HIGH-QUALITY MATERIALS WHICH PROVIDE SUPERIOR HYGIENE AND MAKE CLEANING COMFORTABLE. THIS ROASTER PROVES THAT DURABILITY AND A MODERN DESIGN CAN BE COMBINED.

THE ROASTER BECOMES A PLUG-AND-PLAY MACHINE BY THE COMBINATION OF SEPARATE COOLING AND HEATING FANS WHICH ALLOW TO ROAST AND COOL AT THE SAME TIME WITH THE INCLUDED CYCLONE. HOT AIR IS THE BEST CHOICE TO ENSURE A UNIFORM ROAST, BECAUSE OF THE HOMOGENOUS HEAT TRANSFER.

THE VARIABLE DRUM SPEED OF THE ROASTING CHAMBER AND THE TWO STEP BURNER ALWAYS DELIVER THE BEST CONDITIONS FOR THE PRODUCT – NO MATTER IF THE BEANS ARE HEAVY AND SMALL AT THE BEGINNING OF THE PROCESS OR IF THEY HAVE ALREADY BECOME LIGHTER TOWARDS TO THE END OF THE ROAST. THE HELICOIDAL BLADES POWERED BY A VARIABLE DRUM SPEED DRIVE OFFER A PERFECT BLENDING AND AN OPTIMAL HEAT EXCHANGE AT ANY TIME OF THE PROCESS. MOREOVER, THE ERGONOMICALLY DESIGNED ROASTER PROVIDES MAXIMUM SAFETY.

THIS ROASTER WAS DESIGNED TO PROVIDE SMALL AND MEDIUM-SIZED COMPANIES WITH A FLEXIBLE HIGH-QUALITY SOLUTION. THE SOPHISTICATED DESIGN OF THE ROASTING MACHINE PLUS MODERN PROCESS TECHNOLOGY ENSURES A HIGH-QUALITY COFFEE PRODUCT THAT IS UNIFORMLY ROASTED – FROM THE SURFACE TO THE CORE OF EVERY SINGLE COFFEE BEAN.

THE COFFEE AND THE HOT AIR TEMPERATURE AS WELL AS THE ROASTING TIME PER BATCH IS PERMANENTLY MONITORED VIA THE TOUCH SCREEN. THE MACHINE’S DESIGN FEATURES AND INSULATING MATERIALS REDUCE INERTIA AND HEAT LOSS TO A MINIMUM, WHICH IMPACTS POSITIVELY ON WORKING ENVIRONMENTS AND FUEL CONSUMPTION.

FEATURES:

AUTOMATIC AND EASY-TO-USE PLC CONTROL SYSTEM WITH INTEGRATED TOUCH PANEL, PARAMETER MEMORY, TEMPERATURE TREND AND SAFETY FEATURES.

GOOD VALUE FOR MONEY.

INDIRECT, CONVECTIVE HOT-AIR SYSTEM FOR UNIFORM ROASTING.

FULL RANGE HEAT CONTROL - BURNER MODULATES BETWEEN 130,000 BTU ALL THE WAY DOWN TO A MERE 20,000 BTU

VARIABLE DRUM SPEEDS OFFER OPTIMAL HEAT TRANSFER AND PRODUCT QUALITY.

FUNCTIONAL AND ATTRACTIVE MACHINE DESIGN MADE OF HIGH-QUALITY MATERIAL.

STATE-OF-THE-ART TECHNOLOGY AND A PLC CONTROL SYSTEM OFFER USER-FRIENDLY AND EFFICIENT COFFEE ROASTING.

A WIDE VARIETY OF GREEN COFFEE CHARACTERISTICS AND BLENDS CAN BE PROCESSED TO HIGH-CLASS COFFEE PRODUCTS.

A USER-FRIENDLY AUTOMATION-PANEL ALLOWS THE PERFECT CONTROL OVER VARIOUS PROCESS PARAMETERS.

UL LISTED AND MADE RIGHT HERE IN MINNEAPOLIS.

GAS CONSUMPTION: RATED AT MAXIMUM - UP TO 150,000BTU (44KW/HR) OPERATES BEST BETWEEN 75 - 80,000 BTUOPTIONAL FEATURES:

PNEUMATIC FEEDER

PNEUMATIC DESTONER/DISCHARGE UNIT

AFTERBURNERQUANTITY: 1

Learn More -

TT-8151 AUTO FOAM GENERATOR, YEAR 2023TT-8151 AUTO FOAM GENERATOR, YEAR 2023 1. AUTO FOAM GENERATOR 2. YEAR 2023 3. AUTO FOAM UNIT 200Mm DIAMETER MIXING HEAD SHAFT DRIVEN BY 4.0 KWATT, 960 RPM, 3 PHASE, AC MOTOR, 3½ TO 1 REDUCTION REQUIRED, BY PULLEY/BELT OR BY GEARBOX. QUANTITY: 1 Learn More

TT-8151 AUTO FOAM GENERATOR, YEAR 2023TT-8151 AUTO FOAM GENERATOR, YEAR 2023 1. AUTO FOAM GENERATOR 2. YEAR 2023 3. AUTO FOAM UNIT 200Mm DIAMETER MIXING HEAD SHAFT DRIVEN BY 4.0 KWATT, 960 RPM, 3 PHASE, AC MOTOR, 3½ TO 1 REDUCTION REQUIRED, BY PULLEY/BELT OR BY GEARBOX. QUANTITY: 1 Learn More -

TT-7787 WARTSILA POWER PLANT, 169 MW, 60Hz, YEAR 2010TT-7787 WARTSILA POWER PLANT, 169 MW, 60Hz, YEAR 2010 1. WARTSILA POWER PLANT 2. COMMERCIAL OPERATION START: JANUARY 2010 3. CONTRACT STATUS: OPERATED UNDER STANDBY MODE UNTIL DECEMBER 2024 4. 20 X WARTSILA 20V32 5. 8.45MW EACH, 60Hz 6. HFO, BUT CONVERTIBLE TO DIESEL OR BIODIESEL. GREEN. VERY GOOD CONDITION Learn More

TT-7787 WARTSILA POWER PLANT, 169 MW, 60Hz, YEAR 2010TT-7787 WARTSILA POWER PLANT, 169 MW, 60Hz, YEAR 2010 1. WARTSILA POWER PLANT 2. COMMERCIAL OPERATION START: JANUARY 2010 3. CONTRACT STATUS: OPERATED UNDER STANDBY MODE UNTIL DECEMBER 2024 4. 20 X WARTSILA 20V32 5. 8.45MW EACH, 60Hz 6. HFO, BUT CONVERTIBLE TO DIESEL OR BIODIESEL. GREEN. VERY GOOD CONDITION Learn More -

YY-3398 USED JENBACHER 320 WOOD GAS / SYNGAS, YEAR 2008YY-3398 USED JENBACHER 320 WOOD GAS / SYNGAS, YEAR 2008 DETAILS: 1. FUEL: WOODGAS 2. YEAR: 2008 3. WORK HOURS: 3.000 HR 4. CAPACITY: 588 KW 5. VOLTAGE: 400 V 6. FREQUENCY: 50 Hz QUANTITY: 2 Learn More

YY-3398 USED JENBACHER 320 WOOD GAS / SYNGAS, YEAR 2008YY-3398 USED JENBACHER 320 WOOD GAS / SYNGAS, YEAR 2008 DETAILS: 1. FUEL: WOODGAS 2. YEAR: 2008 3. WORK HOURS: 3.000 HR 4. CAPACITY: 588 KW 5. VOLTAGE: 400 V 6. FREQUENCY: 50 Hz QUANTITY: 2 Learn More -

YY-3397 USED JENBACHER 320 SYNGAS 588KW GENERATORS, YEAR 2008YY-3397 USED JENBACHER 320 SYNGAS 588KW GENERATORS, YEAR 2008 DETAILS: 1. FUEL: SYNGAS 2. YEAR: 2008 3. WORK HOURS: 5.000 HR 4. CAPACITY: 588 KW 5. VOLTAGE: 400 V 6. FREQUENCY: 50 Hz QUANTITY: 2 Learn More

YY-3397 USED JENBACHER 320 SYNGAS 588KW GENERATORS, YEAR 2008YY-3397 USED JENBACHER 320 SYNGAS 588KW GENERATORS, YEAR 2008 DETAILS: 1. FUEL: SYNGAS 2. YEAR: 2008 3. WORK HOURS: 5.000 HR 4. CAPACITY: 588 KW 5. VOLTAGE: 400 V 6. FREQUENCY: 50 Hz QUANTITY: 2 Learn More