Search results for: 'TANK'

- Related search terms

- tank 524

- tank heater jacket

- Tanks

-

YY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOURYY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOUR PURITY: ≥ 93%, FLOW RATE: 50M3 PER H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) Learn More

YY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOURYY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOUR PURITY: ≥ 93%, FLOW RATE: 50M3 PER H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) Learn More -

YY-1348 PSA OXYGEN GENERATION SYSTEM SCHEME, FLOW RATE 100 M3 PER HOURYY-1348 PSA OXYGEN GENERATION SYSTEM SCHEME, FLOW RATE 100 M3 PER HOUR DETAILS: PURITY: ≥ 93%, FLOW RATE: 100 M3 / H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) QUANTITY: 1 Learn More

YY-1348 PSA OXYGEN GENERATION SYSTEM SCHEME, FLOW RATE 100 M3 PER HOURYY-1348 PSA OXYGEN GENERATION SYSTEM SCHEME, FLOW RATE 100 M3 PER HOUR DETAILS: PURITY: ≥ 93%, FLOW RATE: 100 M3 / H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) QUANTITY: 1 Learn More -

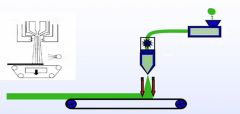

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More -

T-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mmT-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mm (1) EFFECTIVE WIDTH: 1600mm; (2) MAXIMUM COIL DIAMETER: 1200mm; (3) YIELD: 1.5 TO 2.0T /24 HOURS (20G/SQUARE); (4) FILAMENT SIZE: 2UM-5UM; (5) MAIN RAW MATERIALS: POLYPROPYLENE SLICING (MELTING AND SPRAYING SPECIAL MATERIALS) (6) PRODUCT WEIGHT: 15 TO 200G/M2. (7) MECHANICAL SPEED: 10 TO 80M/MIN; (8) INSTALLED CAPACITY: 450KW; (9) EQUIPMENT SIZE: 16000mm×6000mm×6000mm QUANTITY: 1 Learn More

T-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mmT-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mm (1) EFFECTIVE WIDTH: 1600mm; (2) MAXIMUM COIL DIAMETER: 1200mm; (3) YIELD: 1.5 TO 2.0T /24 HOURS (20G/SQUARE); (4) FILAMENT SIZE: 2UM-5UM; (5) MAIN RAW MATERIALS: POLYPROPYLENE SLICING (MELTING AND SPRAYING SPECIAL MATERIALS) (6) PRODUCT WEIGHT: 15 TO 200G/M2. (7) MECHANICAL SPEED: 10 TO 80M/MIN; (8) INSTALLED CAPACITY: 450KW; (9) EQUIPMENT SIZE: 16000mm×6000mm×6000mm QUANTITY: 1 Learn More -

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

L-5744 LPG GAS MANUFACTURING PLANT, YEAR 2010 – PROPANE, ISO BUTANE, BUTANE, PENTANE

L-5744 LPG GAS MANUFACTURING PLANT, YEAR 2010 – PROPANE, ISO BUTANE, BUTANE, PENTANEREFERENCE NUMBER: L-5744

LPG GAS MANUFACTURING PLANT, YEAR 2010 – PROPANE, ISO BUTANE, BUTANE, PENTANE

MANUFACTURING YEAR: 2010

CAPACITIES:

LIQUEFACTION EQUIPMENT: 80,000 SM³/DAY

DISTILLATION EQUIPMENT: 65,000 SM³/DAY(120TON/DAY)

PRODUCT : PROPANE, ISO BUTANE, BUTANE, PENTANE

QUANTITY: 1

Learn More -

R-8710 WIEGERS CREAM TEMPERING AND AERATION SYSTEM, YEAR 2012

R-8710 WIEGERS CREAM TEMPERING AND AERATION SYSTEM, YEAR 2012REFERENCE NUMBER: R-8710

MANUFACTURED: WIEGERS PROCESS INNOVATIONS (NETHERLANDS)

YEAR: 2012

QUANTITY: 1

Learn More -

R-6856 FUTURA K AUTOMATIC ROASTING MACHINES

R-6856 FUTURA K AUTOMATIC ROASTING MACHINESR-6856 FUTURA K AUTOMATIC ROASTING MACHINES

AUTOMATIC ROASTING MACHINES RESULT OF LONG STUDIES AND LIVED EXPERIENCE.

THE ROASTING MACHINES SERIES FUTURA K ARE THE RESULT OF LONG STUDIES AND LIVED EXPERIENCE ALONGSIDE OUR CLIENTS COFFEE ROASTERS, FOR THE REALIZATION OF THE MOST ADVANCED MACHINERIES IN THE FIELD OF INDUSTRIAL COFFEE ROASTING.

THE COMPACT DIMENSIONS, RELIABILITY OF THE MATERIALS AND COMPONENTS, THERMAL MANAGEMENT WITH IMMEDIATE RESPONSE, CALIBRATED AND PARTICULARLY FUEL EFFICIENT, HIGH THERMAL AND ACOUSTIC INSULATION AND OTHER POSITIVE FEATURES, MAKE THESE MACHINES REFERENCEGUIDE IN PROFESSIONAL ROASTING FIELD.MAIN COMPONENTS:

FEEDING HOPPER INSULATED WITH PNEUMATIC FILLER DEVICE, MOVABLE INLET, ELECTROPNEUMATIC UNLOADING CONTROL.

ROASTING DRUM MADE BY A FIXED HOUSING WITH DOUBLE INSULATING WALLS FOR THERMAL PROTECTION AND SUPPORTING THE ROTARY CYCLINDER THAT MOVES THE PRODUCT. THE WHOLE CYCLINDER IS MADE OF COMPOUND STEEL TO WITHSTAND THERMAL SHOCKS, ABSOLUTELY ODOURLESS, WITH PERFORATED SHEET FOR PRODUCT CONTAINEMENT, RIGHT AND LEFT BLENDERS SETTLED AT DIFFERENT LEVELS TO OBTAIN PERFECT MIXTURE.

WHEN THE ROASTING PROCESS IS FINISHED, THE COFFEE IS UNLOADED THROUGH A LARGE DOOR WITH ELECTROPNEUMATIC CONTROL OF OPENING AND CLOSING.

THE HEATING GENERATOR IS SPECIFICALLY DESIGNED FOR ROASTING LINE APPLICATIONS. THE PRINCIPLE OF HEATING IS BASED ON HOT AIR FLOWS BY CONVECTION. GAS OR GASOIL BURNER TYPE MODULATING OR MULTI LEVEL- FLAMES ACCORDING THE APPLICATION.

COOLING TANK WITH LARGE STAINLESS STEEL SURFACE, SELF CLEANING, WHERE THE PRODUCT IS MOVED BY MEANS OF 4 CROSSED ARMS. TWO DISCHARGES: ONE IS ELECTROPNEUMATICALLY DRIVEN AND THE OTHER IS MANUAL FOR EMERGENCY. DOOR OF INSPECTION AND EASY CLEANING OF THE LOWER SIDE.

PELLICLES SEPARATOR WITH EXTRACTION, BY WORM CONVEYOR OR INCINERATOR FOR CONSTANT EFFICIENCY OF THE AIR CHAFFS SEPARATION SYSTEM.

SUPPORTING FRAME IN TUBULAR PROFILES, STEEL MADE, TO CONTAIN AND SUPPORT THE OPERATING DEVICES, SO TO OBTAIN A COMPACT MACHINE-LIMITED ENCUMBRANCE, COMPLETE WITH PANELS FOR HEATING AND NOISE CONTAINMENT.

INDEPENDENT ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN AND ALL DEVICES FOR MACHINE CONTROL AND

MANAGEMENT, CAREFULLY WIRED AND EQUIPPED WITH ALL SIGNALS USEFULL FOR ROASTING PROCESS.STANDARD EQUIPMENT:

AUTOMATIC ROASTING SYSTEM MANAGED BY PLC + TOUCH SCREEN WITH RECORDING FOR ROASTING CURVES – PROFILES.

VISUALIZATION BY MONITOR OF TEMPERATURES AND ROASTING FUNTIONS.

FIRE PREVENTION EQUIPMENT ON THE ROASTING DRUM AND COOLING TANK; ON THE CYCLONE-CHAFFS SEPARATOR IF EQUIPPED WITH WORM CONVEYOR FOR CHAFFS EXTRACTION.

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP, UPON INTERVENTION OF THE OVERLOAD PROTECTION DEVICES ON THE ELECTRIC-MOTORS AND ON THE BURNER.

PROTECTING SAFETY SYSTEMS.

CYCLONE FOR COOLING TANK: STANDARD ON MOD. 240-300- 360-480.

OPTIONALS EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

Learn More

HEATING RECOVERY SYSTE

SMOKE BURNER TYPE THERMICAL AND/OR CATALYST

CLEAN AIR ROASTING SYSTEM

CHAFFS COMPACTOR. -

A-1910 COMPLETE PLANT FOR DYEING BOBBINS, HIGH TEMPERATURE, LORIS BELLINI

A-1910 COMPLETE PLANT FOR DYEING BOBBINS, HIGH TEMPERATURE, LORIS BELLINIA-1910 COMPLETE PLANT FOR DYEING BOBBINS, HIGH TEMPERATURE, LORIS BELLINI

(1) AUTOMATIC PREPARATION FOR CONES LORIS BELLINI, 2003 - PREPARATION OF CONES AND AUTOMATIC LOADING OF THE CONES ON THE EQUIPMENT LOOPS

(1) MINOX APPARATUS MODEL RPP/0-25, YEAR 1999 - LOAD 20KG - COMPLETE WITH TANK AND SAMPLER WITH 1 CONE

(2) HORIZONTAL APPARATUS LORIS BELLINI, YEAR 1988 - OPERATING AT PRESSURE OF 5 BAR AND AT TEMPERATURE 140°C - LOAD CAPACITY 500 BOBBINS APPROX KG.1000 EACH - PREPARATION TANK FOR WATER HEATING – POSSIBILITY TO WORK INDIVIDUALLY AND IN PARALLEL

(2) HORIZONTAL APPARATUS LORIS BELLINI, YEAR 1987 - OPERATING AT PRESSURE OF 5 BAR AND AT TEMPERATURE 140°C - LOAD CAPACITY 500 BOBBINS APPROX KG.1000 EACH - PREPARATION TANK FOR WATER HEATING - POSSIBILITY TO WORK INDIVIDUALLY AND IN PARALLEL

(1) DRYER CONDENSATION LORIS BELLINI

THE PLANT IS NOT SOLD SEPARATELY.QUANTITY: 1

Learn More -

L-1193 WARTSILA 1.48 MW MODEL 9L20 HFO GENERATOR

L-1193 WARTSILA 1.48 MW MODEL 9L20 HFO GENERATORL-1193 WARTSILA 1.48 MW MODEL 9L20 HFO GENERATOR

MODEL: W9L-20

YEAR: 05/2004

DATE OF COMMISSIONING: 08/09/2004

CAPACITY: 1548 KW

SPEED: 1000 RPM

NO. OF RUNNING HOURS: 41733HRS

INSTALLATION TYPE: STATIONARY ENGINE

FITTED WITH SINGLE BASE FRAME LOADED ON SPRING

ENGINE MOUNTED PHE & CHARGER AIR COOLER.ALTERNATOR DETAILS:

MAKE: AVK

TYPE: DIG 130K/6

CAPACITY :1852 KVA

SELF EXCITED WITH ROTATING BRIDGEDIODESBOOSTER AND FEEDER UNIT:

MAKE: WARTSILA INDIA LTDLUBE OIL SEPARATOR:

MAKE: ALFA LAVAL

MODEL: MMPX 403 SGP-11HFO SEPARATOR:

MAKE: ALFA LAVAL

MODEL: PA-6001) HFO STORAGE TANK

CAPACITY :100 KL2) HFO DAY TANK

CAPACITY :50 KL3) SLUDGE TANK

CAPACITY :10 KL

CHARGE AIR FILTER:

MAKE: AAFRADIATOR:

MAKE: COIL COMPANY

MODEL: FCW220

RETURN FUEL UNIT:

MAKE: WARTSILA INDIA LIMITEDENGINE CONTROL PANEL:

1) ENGINE CONTROL PANEL(CFC_011)

2) BATTERY CHARGER UNIT

MAKE: AMARARAJA

RATING :100AH

PCC PANELSTARTING AIR COMPRESSOR:

MAKE: INGERSOLL RAND

MODEL :7T2INCOMING & OUT GOING BREAKER:

MAKE: ABB

TYPE: SF6QUANTITY: 1

Learn More