Search results for: 'Filling li'

- Related search terms

- Filling mac

- FILLING MACHI

- Filling line fo

- filling c

- Filling lin'[0]

-

TT-6640 BOTTLING KRONES COMPLETE BOTTLING LINE PET, 12,000 BPH, YEAR 2008TT-6640 BOTTLING KRONES COMPLETE BOTTLING LINE PET, 12,000 BPH, YEAR 2008 1. MACHINE TYPE: BEVERAGE MAKING MACHINE 2. BRAND: BOTTLING KRONES 12,000 BPH 3. MODEL: COMPLETE BOTTLING LINE PET 4. YEAR OF CONSTRUCTION: 2008 5. CONDITION: EXCELLENT (USED) QUANTITY: 1 Learn More

TT-6640 BOTTLING KRONES COMPLETE BOTTLING LINE PET, 12,000 BPH, YEAR 2008TT-6640 BOTTLING KRONES COMPLETE BOTTLING LINE PET, 12,000 BPH, YEAR 2008 1. MACHINE TYPE: BEVERAGE MAKING MACHINE 2. BRAND: BOTTLING KRONES 12,000 BPH 3. MODEL: COMPLETE BOTTLING LINE PET 4. YEAR OF CONSTRUCTION: 2008 5. CONDITION: EXCELLENT (USED) QUANTITY: 1 Learn More -

J-5381 MACHINE TO PRODUCE PILLOW FILLING OF POE/EVAJ-5381 MACHINE TO PRODUCE PILLOW FILLING OF POE/EVA TO FILL PILLOWS WITH POE/EVA WITH DENSITY 20 TO 90 DENSITY (KGS/CUBIC METER) WITH THICKNESS BETWEEN 10mm AND 200mm QUANTITY: 1 Learn More

J-5381 MACHINE TO PRODUCE PILLOW FILLING OF POE/EVAJ-5381 MACHINE TO PRODUCE PILLOW FILLING OF POE/EVA TO FILL PILLOWS WITH POE/EVA WITH DENSITY 20 TO 90 DENSITY (KGS/CUBIC METER) WITH THICKNESS BETWEEN 10mm AND 200mm QUANTITY: 1 Learn More -

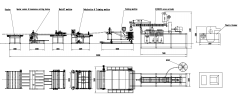

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

YY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOURYY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOUR PURITY: ≥ 93%, FLOW RATE: 50M3 PER H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) Learn More

YY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOURYY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOUR PURITY: ≥ 93%, FLOW RATE: 50M3 PER H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) Learn More -

YY-1348 PSA OXYGEN GENERATION SYSTEM SCHEME, FLOW RATE 100 M3 PER HOURYY-1348 PSA OXYGEN GENERATION SYSTEM SCHEME, FLOW RATE 100 M3 PER HOUR DETAILS: PURITY: ≥ 93%, FLOW RATE: 100 M3 / H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) QUANTITY: 1 Learn More

YY-1348 PSA OXYGEN GENERATION SYSTEM SCHEME, FLOW RATE 100 M3 PER HOURYY-1348 PSA OXYGEN GENERATION SYSTEM SCHEME, FLOW RATE 100 M3 PER HOUR DETAILS: PURITY: ≥ 93%, FLOW RATE: 100 M3 / H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) QUANTITY: 1 Learn More -

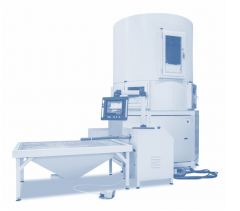

J-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHERJ-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHER SILO CAPACITY: 4.4m3 AUTOMATIC PRE-WEIGHING UNIT: 1, 300 LITER CAPACITY FILLING NOZZLES: 1 OUTPUT CAPACITY: UP TO 400 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (UP TO 2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 3 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 5.2 KW – 16 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db QUANTITY: 1 Learn More

J-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHERJ-2968 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT, FOR FEATHER SILO CAPACITY: 4.4m3 AUTOMATIC PRE-WEIGHING UNIT: 1, 300 LITER CAPACITY FILLING NOZZLES: 1 OUTPUT CAPACITY: UP TO 400 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (UP TO 2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 3 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 5.2 KW – 16 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db QUANTITY: 1 Learn More -

J-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHERJ-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHER SILO VOLUME: 6.0m3 AUTOMATIC PRE-WEIGHING UNITS: 2 UNITS WITH 210 LITER CAPACITY FILLING NOZZLE: 1 OUTPUT CAPACITY: UP TO 700 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 6 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 7.4 KW – 32 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db Learn More

J-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHERJ-2967 PILLOW FILLING MACHINE WITH AUTOMATIC PRE-WEIGHING UNIT FOR FEATHER SILO VOLUME: 6.0m3 AUTOMATIC PRE-WEIGHING UNITS: 2 UNITS WITH 210 LITER CAPACITY FILLING NOZZLE: 1 OUTPUT CAPACITY: UP TO 700 FILLINGS PER HOUR FILLING WEIGHT ACCURACY: UP TO 1 GRAM (2% OF THE TOTAL WEIGHT) EXPECTED OUTPUT: 6 PILLOWS PER MINUTE WITH 2 LBS FEATHER PILLOWS VOLTAGE: 480 VOLTS (+/- 10%) PHASE: 3-PHASE + N + PE FREQUENCY: 60 Hz (+/- 2%) VOLTAGE AUXILIARY CIRCUITS: 24 VDC / 24 VAC INSTALLED POWER: 7.4 KW – 32 AMPS OPERATING PRESSURE: 6 BAR AIR CONSUMPTION: 50 LITERS PER MINUTE NOISE: < 70 Db Learn More -

P-3307 VAMATEX DYNA TERRY RAPIER and PICANOL AIRJET TERRY LOOMS

P-3307 VAMATEX DYNA TERRY RAPIER and PICANOL AIRJET TERRY LOOMSREFERENCE NUMBER: P-3307

VAMATEX DYNA TERRY RAPIER and PICANOL AIRJET TERRY LOOMS

3 PICANOL

TYPE: TERRY PLUS

AIRJET TERRY LOOMS

YEAR: 2005 to 2006

CONDITION: ALMOST NEW

3 VAMATEX

TYPE: DYNA TERRY

RAPIER WEAVING MACHINES FOR TERRY FABRICS

YEAR: 2007

REED WIDTH: 2600mm

DOBBY FIMTESILE 7P, 20 SHHAFTS

8 COLORS

4 BEAMS 800+1000mm

2650 DROPPERS

6 PRE FEEDERS

2 CLOTH ROLLERS

16 HEALD FRAMES

3 PICANOL

TYPE: TERRY PLUS

AIRJET TERRY LOOMS

2 DOBBY and 1 JACQUARD

PICANOL

TYPE: TERRY PLUS 800-6-R

AIRJET LOOMS

YEAR: 2005

REED SPACE: 2600mm

6 COLORS

6 PICANOL 1131 CAN PLUS WEFT ACCUMULATORS

STAUBLI DOBBY TYPE 2861-16K FOR 16 SHAFTS

14 SHAFTS PROVIDED – DRC30 DRIVE HARNESS CONNECTION

ELSY ELECTRONIC SELVEDGE SYSTEM

PFT (PROGRAMMABLE FILLING TENSIONER) and PSO (PRE-WINDER SWITCH OFF)

GROUND WRAP BEAM 805mm DIAMETER

PILE WARP BEAM 1000mm DIAMETER

1 GROUND WARP BEAMS, TYPE 190

1 PILE WARP BEAM

2 ADAPTERS

1 CLOTH ROLLER

APPROXIMATELY 5000 DROPPERS, 5000 HEALD WIRES

380 VOLTS, 50 HERTZ

PICANOL

TYPE: TERRY PLUS 800-6-R

AIRJET TERRY LOOM

YEAR: 2006

REED SPACE: 2300mm

6 COLORS

6 WEFT ACCUMULATORS

STAUBLI DOBBY TYPE 2861-A6K FOR 16 SHAFTS

14 SHAFTS PROVIDED – DRC DRIVE HARNESS ONNECTION

ELSY ELECTRONIC SELVEDGE SYSTEM

PFT (PROGRAMMABLE FILLING TENSIONER) and PSO (PRE-WINDER SWITCH OFF)

GROUND WARP BEAM 805mm DIAMETER

PILE WARP BEAM 1000mm DIMAETER

1 GROUND WARP BEAM 805mm, TYPE 190

1 PILE WARP BEAM

2 ADAPTERS

1 CLOTH ROLLER

380 VOLTS, 50 HERTZ

PICANOL

TYPE: TERRY PLUS 800-8-J

AIRJET LOOMS

YEAR: 2006

REED SPACE: 2600mm

6 COLORS, 6 WEFT ACCUMULATORS

STAUBLI ELECTRONIC JACQUARD TYPE LX1602 FOR 3072 HOOKS AND HARNESS WITH SPRINGS AND 5756 ENDS

LIETTI STEEL JACQUARD GANTRY

ELSY ELECTRONIC SELVEDGE SYSTEM

PFT (PROGRAMMABLE FILLING TENSIONER) and PSO (PRE-WINDER SWITCH OFF)

GROUND WARP BEAM 805mm DIAMETER

PILE WARP BEAM 1000mm DIAMETER

1 GROUND WARP BEAM 805mm DIAMETER

1 PILE WARP BEAM 1000mm DIAMETER

2 ADAPTERS FOR WORKING FROM BEAMS, TYPE 190

1 CLOTH ROLLER

APPROXIMATELY 5000 DROPPERS

3 VAMATEX

TYPE: DYNA-TERRY

RAPIER WEAVING MACHINES FOR TERRY FABRICS

YEAR: 2007

REED WIDTH: 2600mm

DOBBY FIMTESILE 7P-20 SHAFTS

8 COLORS

4 BEAMS 800+1000mm

6250 DROPPERS

6 PRE FEEDERS and 2 CLOTH ROLLERS

16 HEALD FRAMES

QUANTITY: 15

Learn More -

K-3843 KAPOK FILLING MACHINEREFERENCE NUMBER: K-3843 KAPOK FILLING MACHINE STUFFING MACHINE AND BLOWER KAPOK FEEDING HOPPER AIR COMPRESSOR QUANTITY AVAILABLE: 1 Learn More

K-3843 KAPOK FILLING MACHINEREFERENCE NUMBER: K-3843 KAPOK FILLING MACHINE STUFFING MACHINE AND BLOWER KAPOK FEEDING HOPPER AIR COMPRESSOR QUANTITY AVAILABLE: 1 Learn More -

E-9988 AUTOMATIC PILLOW MACHINEREFERENC ENUMBER: E-9988 AUTOMATIC PILLOW MACHINE MODEL: CF INSTALLATION AREA: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) MIXING CHAMBER SIZE: AROUND 300KG (600 LBS) VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 11.8KW CAPACITY: 6 PILLOWS PER MINUTE WEIGHING: ACCORDING TO THE TIME OF FILLING DISCHARGE. WEIGHT: 1.8MT (4000 LBS) LABOR: 1 OPERATOR CONTROL SYSTEM: COMPUTERIZED CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More

E-9988 AUTOMATIC PILLOW MACHINEREFERENC ENUMBER: E-9988 AUTOMATIC PILLOW MACHINE MODEL: CF INSTALLATION AREA: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) MIXING CHAMBER SIZE: AROUND 300KG (600 LBS) VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 11.8KW CAPACITY: 6 PILLOWS PER MINUTE WEIGHING: ACCORDING TO THE TIME OF FILLING DISCHARGE. WEIGHT: 1.8MT (4000 LBS) LABOR: 1 OPERATOR CONTROL SYSTEM: COMPUTERIZED CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More