Search results for: 'pillow co'

- Related search terms

- pillow+filling+machine

- pillow bl

- pillow+bl

- pillow+co

- pillow f

-

ORMONT FIBER FILLING MACHINEREFERENCE NUMBER: T-6865 ORMONT FIBER FILLING MACHINE ORMONT FIBER FILLING MACHINE TYPE TP-02 SIZE 5 OPERATING ON 240/2 PHASE MOTOR SPEED 1800 RPM WITH 30” CONVEYOR FEED WIDTH USED FOR FILLING SMALL DECORATIVE PILLOWS QUANTITY: 1 Learn More

ORMONT FIBER FILLING MACHINEREFERENCE NUMBER: T-6865 ORMONT FIBER FILLING MACHINE ORMONT FIBER FILLING MACHINE TYPE TP-02 SIZE 5 OPERATING ON 240/2 PHASE MOTOR SPEED 1800 RPM WITH 30” CONVEYOR FEED WIDTH USED FOR FILLING SMALL DECORATIVE PILLOWS QUANTITY: 1 Learn More -

J-3800 AUTOMATIC ROLL PACKING MACHINE FOR PILLOWS – 960 PILLOWS PER 8 HOUR SHIFT

J-3800 AUTOMATIC ROLL PACKING MACHINE FOR PILLOWS – 960 PILLOWS PER 8 HOUR SHIFTPILLOW DIMENSIONS (MAXIMUM): 800 x 600 x 200mm (ONCE COMPRESSED, HEIGHT IS 30mm)

Learn More

CAPACITY: 2 PILLOWS PER MINUTE (960 PILLOWS PER 8 HOUR SHIFT)

EXIT DIAMETER: 80 TO 200mm (CUSTOMIZED PER CUSTOMER, PLEASE SPECIFY WHEN ORDERING)

PRESSURE: 1.2 TONS

POWER: 6.37 KW

WEIGHT: 400 KGS

DIMENSIONS: 1850 x 2940 x 2100mm -

R-8717 BUBBLE GUM LINE

R-8717 BUBBLE GUM LINEREFERENCE NUMBER: R-8717

BUBBLE GUM LINE

HEIGHT: 2 TO 15mm. WIDTH: 12 TO 30mm. LENGTH: 18 TO 120mm

QUANTITY: 1

Learn More -

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSION

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSIONREFERENCE NUMBER: L-1760

Learn More

FOR PUNCHING HOLES IN PU FOAM

WORKING WIDTH: 2100mm

QUANTITY: 1 -

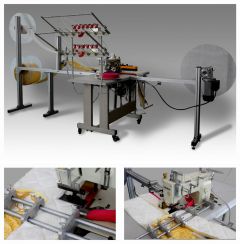

L-5049 FAUX PILLOW-TOP AUTO SEWING MACHINE

L-5049 FAUX PILLOW-TOP AUTO SEWING MACHINEREFERENCE NUMBER: L-5049

Learn More

AUTO SEWING MACHINE

MAX. STITCH LENGTH: 6mm

PRESSER FOOT HEIGHT: 10mm

QUANTITY: 1 -

C-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

C-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGEC-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

OFFER 001

Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

PRODUCTION TYPE: BABY WET TISSUE

PRODUCTION PROCESS: CONNECT TO Y-2700 FOLDING MACHINE (OR Y-12 FOLDING MACHINE) → FEEDING WIPE AUTOMATIC →CONVEYING TO PACKING MACHINE → SETTING PACKING FILM → SETTING WINDOW HOLE LABEL → CENTRAL SEALING →END SEALING AND RECIPROCATING CUT → OUTPUT FINISHED PRODUCTS.

MAINTECHNICAL PARAMETER: (SUITABLE TO PACK: 5 TO 120PCS/BAG)

PRODUCT SPEED: 55 TO 60 BAG/MIN

DIAMETER OF RAW FILM ROLL: ≤380mm

WIDTH OF RAW FILM ROLL: ≤420mm

WRAPPING MATERIAL: PP, OPP, PET, PE, AND ALL SUITABLE FILMS

SHAPES OF PACKING: PILLOW TYPE PACKAGING

PACKING LENGTH: 110 TO 300mm (TOUCH SCREEN SETABLE)

PACKING WIDTH: 80 TO 150mm (ADJUSTABLE)

HEIGHT OF PACKING: 10 TO 100mm (ADJUSTABLE)

HORIZONTAL SEALING PATTERN: RECIPROCATION HEAT SEALING

DRIVE MOTOR PATTERN: ALL SERVO DRIVE

CONTROL PATTERN: YASKAWA SIMOTION CONTROL SYSTEM

OPERATION INTERFACE: 7 INCH LCD

FILM SUPPLY SYSTEM: SERVO DRIVE

HORIZONTAL SYSTEM: SERVO DRIVE

FEEDING SYSTEM: SERVO DRIVE

LABELING SYSTEM: SERVO DRIVE

PUNCHING SYSTEM: SERVO DRIVE

HORIZONTAL PROTECTION: TORQUE OVERLOAD PROTECTION

AIR REQUIREMENTS: 0.5 TO 0.8 MPA 0.01 M3/MIN

ELECTRIC POWER REQUIREMENTS: 380VAC 50/60HZ

GENERAL POWER: 7.6KW

DIMENSION OF MACHINE: 3610 × 1150 × 1900mm

STANDARD EQUIPMENT: DATE PRINTING UNIT, PUNCHING UNIT, LABELLING UNIT, INSERTING CORNER UNIT, ELECTRICAL EYE TRACKING AUTOMATICALLY

(2) SYSTEM CHARACTER

1. THE PACKING FILM ADOPTS MECHNICAL TENSION CONTROL

2. TWO LABEL MACHINE, ONE SUB-LABELING, THE OTHER IS ANTI-COUNTERFEITING LABEL

3. PUNCHING AT THE PACKING FILM AUTOMATICALLY

4. HEATING PRINTING (DATE) DEVICE

5. FOUR BACK AND FORTH TRANSVERSE SEALING DEVICE WITHINSERT CORNER BY CYLINDER FORM

6. EIGHT SERVO MOTORS, CONTROLLING FEEDING PACKING FILM, TRANSVERSE SEALING, FEEDING TISSUE RESPECTIVELY

7. LENGTHWAYS SEALING DEVICE, CONTROL THEOPEN-CLOSEBY CYLINDER. THE SEALING WHEEL ARE APART AUTOMATICALLY WHEN THE MACHINE STOPS

8. PUNCHING, LABELING AND THE EYE MARK’S RELATIVED POSITION CAN BE SET IN THE TOUCH SCREEN.

9. AUTOMATIC FEEDING RAW MATERIAL DEVICE

10. COLOUR TOUCH SCREEN, MOTION SYSTEM CONTROL

11. MAIN MOTOR ADOPTS FAMOUS BRAND

12. MAIN MACHINE ADOPTS FRAMES FORMOFFER 002

Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

YASKAWA ELECTRICITY FROM JAPAN

ITEM NUMBER: 1

MOTION CONTROLLER

JEPMC-MP2300S-E

YASKAWA

QUANTITY: 1

ITEM NUMBER: 2

EXTENDED MODULE

R7K4FML-6-DCA32A

YASKAWA

QUANTITY: 1

ITEM NUMBER: 3

SERVO MOTOR/SERVO UNIT

SGMJV-08ADE6S /SGDV-5R5A11A

YASKAWA 750W

QUANTITY: 5

ITEM NUMBER: 4

SERVO MOTOR/SERVO UNIT

SGMGV-13ADC61 /SGDV-120A11A

YASKAWA 1.3KW

QUANTITY: 1

ITEM NUMBER: 5

SERVO MOTOR/SERVO UNIT

SGMGV-20ADA61/SGDV-180A11A

YASKAWA 1.8KW

QUANTITY: 1

ITEM NUMBER: 6

SERVO MOTOR/SERVO UNIT

SGMGV-09ADC61/SGDV-7R6A11A

YASKAWA 0.85 KW

QUANTITY: 1

ITEM NUMBER: 7

POWER CABLE + ENCODER CABLE

JZZP-CVM09/JZSP-CVP02-05

YASKAWA 850W

QUANTITY: 1

ITEM NUMBER: 8

POWER CABLE + ENCODER CABLE

JZSP-CMM00-05 JZSP-CMP00-05

YASKAWA 750W

QUANTITY: 7

ITEM NUMBER: 9

POWER CABLE + ENCODER CABLE

JZSP-CVM30-05 JZSP-CVP02-5

YASKAWA 1.3KW, 1.8KW

QUANTITY: 2

ITEM NUMBER: 10

COMMUNICATION CABLE

JEPMC-W6002-05

QUANTITY: 12

ITEM NUMBER: 11

TERMINAL RESISTANCE

JEPMC-W6022-E

QUANTITY: 2

ITEM NUMBER: 12

TOUCH PANEL

WEINVIEW

7 INCH

QUANTITY: 1

ITEM NUMBER: 13

AIR BREAK SWITCH

LG

QUANTITY: 12

ITEM NUMBER: 14

RESIDUAL CURRENT CIRCUIT BREAKER

CHINT

QUANTITY: 1

ITEM NUMBER: 15

CONTACTOR (SWITCH)

SCHNEIDER

QUANTITY: 1

ITEM NUMBER: 16

POWER SWITCH

M&W

350W

QUANTITY: 1

ITEM NUMBER: 17

SOLID STATE RELAY (SSR)

ANV

QUANTITY: 6

ITEM NUMBER: 18

TEMPERATURE CONTROLLER

DTE10P

QUANTITY: 1

ITEM NUMBER: 19

RELAY

OMRON

QUANTITY: 4OFFER 003

Y-12 BABY WIPES FOLDING MACHINE

PRODUCTION FLOW: UNROLLING - SLITTING FABRIC INTO LANES - FOLDING - WETTING - CUTTING – PILE & COUNTING - DELIVERING

MAIN TECHNICAL PARAMETER (SUITABLE TO WET TISSUE FOR LARGE SIZE PACKING)

PRODUCT TYPE: BABY WIPES (NON CROSS FOLDING)

PRODUCT SPEED: 200 TO 270 CUTS/MIN (SET ON PLC)

SUITABLE RAW MATERIAL: AIR LAID PAPER, SPUNLACE/HOT-ROLLING NONWOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40-80G/㎡

FOLDING WAY: “Z” SHAPE (POP UP AND NON-POP UP)

CUTTING UNITE:

A. DOUBLE PAPER SHELVES

B. 10 LANES OR 12 LANES, 2 ROLLS

C. RAW MATERIAL ROLL WIDTH: 900 TO 1200mm

LENGTH OF WET TISSUE: 140 TO 185mm (SET ON PLC)

FREQUENCY OF RECEIVING PAPER: 14 TO 20 TIMES/MIN (SET ON PLC)

SIZE OF RAW MATERIAL: (1000 TO 1250) × Ø1000 (mm, W×DIA)

WET TISSUE UNFOLDED SIZE: (140 TO 185) × (150 TO 200) (mm, L×W)

WET TISSUE FOLDED SIZE: (140 TO 185) × (80 TO 110) (mm, L×W)

MATERIAL SUPPLY SYSTEM: SERVO MOTOR

CUTTING SYSTEM: CONVERTER MOTOR

PILING SYSTEM: SERVO MOTOR

POWER SUPPLY: 380V 50HZOFFER 004

Learn More

Y-12 WET TISSUE FOLDING MACHINE

MAIN PARTS

ITEM NUMBER: 1

PLC

FX3U-32T

MITSUBISHI (JAPAN)

QUANTITY: 1

ITEM NUMBER: 2

SERVO MOTOR (CONTROL THE DISTANCE OF TISSUE

ASD-B2-2023-B, ECMA-E21320RS

3.0KW DELTA (TAIWAN)

QUANTITY: 1

ITEM NUMBER: 3

SERVO MOTOR (RECEIVING TISSUE)

ASD-B2-0721-B, ECMA-C20807RS

750W DELTA (TAIWAN)

QUANTITY: 1

ITEM NUMBER: 4

TURBINE WORM REDUCER MOTOR

WPDA120-1:10-Y100L2-4

3KW NANJING UTTON (CHINA)

QUANTITY: 1

ITEM NUMBER: 5

INVERTER

SB70G4

4KW SENLON

QUANTITY: 1

ITEM NUMBER: 6

TOUCH SCREEN

7INCH

WECON

QUANTITY: 1

ITEM NUMBER: 7

AIR SWITCH

LG

QUANTITY: 1

ITEM NUMBER: 8

SWITCHING POWER SUPPLY

S-100-24

SHANGHAI MINGWEI (CHINA)

QUANTITY: 1

ITEM NUMBER: 9

INDICATOR LIGHT

SCHNEIDER

SCHNEIDER (GERMAN)

QUANTITY: 1

ITEM NUMBER: 10

EMERGENCY STOP SWITCH

SCHNEIDER

SCHNEIDER (GERMAN)

QUANTITY: 1

ITEM NUMBER: 11

POTENTIOMETER

5KΩ

QUANTITY: 1

ITEM NUMBER: 12

ROTARY ENCODER

INCREMENTAL POLE OUTPUT

KOYO (JAPAN)

QUANTITY: 1

ITEM NUMBER: 13

RELAY

OMRON

OMRON (JAPAN)

QUANTITY: 5

ITEM NUMBER: 14

PROXIMITY SWITCH

AUTONICS

AUTONICS (KOREA)

QUANTITY: 2 -

F-1429 DOWN FILLING MACHINE MODEL SR-3

F-1429 DOWN FILLING MACHINE MODEL SR-3REFERENCE NUMBER: F-1429

down FILLING MACHINE MODEL SR-3

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• TYPE : SR-3

• DIMENSION: 3000 x 2500 x 2000MM

• VOLTAGE: 200/380/415V 50/60HZ 3PHASE

• POWER: 3.8 KW

• FILLING RANGE: 2-100 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±0.2G

• AIR PRESSURE: 0.5 TO 0.8MPA

• THE DEVELOPED COMPUTERIZED DOWN & FEATHER WEIGHING FILLING MACHINE IS MAINLY USED TO FILL JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS, COMFORTERS ETC THAT ARE MADE WITH DOWN & FEATHER AND CONTROLLED BY A COMPUTERIZED WEIGHING SYSTEM.

• THREE HOPPER-SYSTEM FOR CONSTANT SUPPLY

• THE VACUUM FILLING FUNCTION THAT DOES NOT HURT THE MATERIAL AND KEEPS THE ORIGINAL ELASTICITY AND SOFT-HAND FEELING.

• ACCURATE WEIGHING RESULTS; THE TOLERANCE IS WITHIN 0.2 GRAM. IT CAN BE ADJUSTED ACCORDING TO THE PRODUCTION REQUIREMENT BY CHOOSING GROUP ERROR OR SINGLE PIECE ERROR FROM THE CONTROL PANEL, SO THAT THE PRODUCTION QUALITY IS ASSURED AND MATERIAL WASTE IS CONTROLLED

• THE WHOLE LINE CAN BE HANDLED BY ONE OPERATOR WITH VERY SIMPLE

OPERATION

• ALL THE MATERIALS ARE INSIDE THE HOPPERS WITHOUT PRODUCING ANY DUST THAT AFFECTS THE WORKING AREA

• KEY ELECTRICAL COMPONENTS ARE IMPORTED

• THE WHOLE LINE OPERATION IS CONTROLLED BY PLC SYSTEM

• ACCORDING TO DIFFERENT QUANTITY AND QUALITY PRODUCTION REQUIREMENTS THE MACHINE CONTROL PANEL CAN BE SET UP FOR 100 GROUPS OF RECIPES AND EACH RECIPE CAN BE 50 SETS OF DIFFERENT WEIGHT VALUE FOR FILLING OPTIONS, WHICH IS ENOUGH TO FILL DIFFERENT PARTS OF THE SAME PRODUCTION.

• THE AVERAGE FILLING TIME CAN BE 4 TO 10 SECONDS (DEPENDING ON THE ACCURACY) AND THE FILLING TIME CAN BE ADJUSTED

• THE CUSTOMER’S DIFFERENT REQUIREMENTS ARE CONSIDERED BY OUR PROFESSIONAL ENGINEERS SO THAT THE MACHINES ARE SUITABLE FOR YOUR PARTICULAR NEEDS

• MATERIAL HOPPER: DIA.1200 x 2000MM 1PCS

• WEIGHING SYSTEM: 1200 x 1000 x 1000MM 1PCS(3SETS)

• FILLING TABLE :1200 x 550 x 1500 1PCS

• PLC CONTROL SYSTEM AND CONTROL PANEL: 1SETS

• BLOWER: 3PCS

• PIPE SYSTEM

Learn More -

F-1427 FEATHER FILLING MACHINE MODEL SR-1

F-1427 FEATHER FILLING MACHINE MODEL SR-1REFERENCE NUMBER: F-1427

FEATHER FILLING MACHINE MODEL SR-1

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• PRODUCT NAME: WEIGHING DOWN & FEATHER FILLING MACHINE

• TYPE: SR-1

• DIMENSION: 7500 x 2500 x 3500MM

• VOLTAGE: 200/380/415V 50/60HZ 3PHASE

• POWER: 11KW

• FILLING RANGE: 2 TO 100 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±0.5G,±1.0G,±1.5G,DEPENDING ON THE FILLING WEIGHT

• AIR SUPPLY: 0.5 TO 0.8MPA

• WEIGHT: APPROX. 800KG

• THE AUTOMATIC DOWN AND FEATHER FILLING MACHINE IS MAINLY USED TO PRODUCE JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS AND COMFORTERS THAT MADE WITH DOWN AND FEATHER MATERIAL BY COMPUTERIZED WEIGHING SYSTEM.

• THREE HOPPER-SYSTEM( FOR ONE FILLING PIPE) FOR CONSTANT SUPPLY

• THE SYSTEM IS THE VACUUM FILLING FUNCTION AND DOES NOT HURT THE MATERIAL; IT KEEPS THE ORIGINAL ELASTICITY AND SOFT HAND FEELING.

• ACCURATE WEIGHING RESULTS; THE TOLERANCE IS WITHIN 0.2 GRAM. IT CAN BE ADJUSTED ACCORDING TO THE PRODUCTION REQUIREMENT AND CHOOSE TOTAL ERROR OR SINGLE ERROR FROM THE CONTROL PANEL. THIS CONTROLS FOR THE PRODUCTION QUALITY AND MATERIAL WASTE

• ONE FILLING PIPE CAN BE HANDLED BY 1 OPERATOR BY VERY SIMPLE OPERATION WHICH SAVES YOU A BIG AMOUNT OF LABOR COSTS..

• THE KEY ELECTRICAL COMPONENTS ARE IMPORTED, SO THAT THE QUALITY IS RELIABLE AND STABLE.

• THE WHOLE LINE OPERATION IS CONTROLLED BY PLC SYSTEM

• ACCORDING TO DIFFERENT QUANTITY AND QUALITY REQUIREMENTS THE MACHINE CONTROL PANEL CAN BE SET UP FOR 100 DIFFERENT RECIPES AND EACH RECIPE CAN BE 80 SETS DIFFERENT WEIGHT VALUE FOR FILLING OPTIONS

• AVERAGE FILLING TIME CAN BE 2 TO 5 SECONDS (DEPENDING ON THE WEIGHT AND FABRIC) AND THE FILLING TIME CAN BE ADJUSTED

• DIFFERENT CUSTOMER REQUIREMENTS CAN BE CONSIDERED BY OUR PROFESSIONAL ENGINEERS TO WORK ON OUR MACHINES TO MATCH THE CUSTOMER’S NEED.

• MATERIAL HOPPER: DIA. 1700 x 2500MM 1PCS

• WEIGHING SYSTEM: 1200 x 1000 x 1000MM 3 PCS(6SETS)

• FILLING TABLE :1200 x 550 x 1500 2 PCS

• PLC CONTROL SYSTEM AND CONTROL PANEL: 2 SETS

• AIR OUTPUT BOX: 1200 x 1800 x 1700MM 1 PCS

• MATERIAL FEEDING BOX: 1200x1200x2500MM 1 PCS

• BLOWER: 6PCS

• PIPE SYSTEM: 1SET

Learn More -

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009REFERENCE NUMBER: V-1288

MERELLO ME-305PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

WRAPS PILLOWS AND CUSHIONS BETWEEN 35X35 AND 150X70cm IN POLYETHYLENE TUBE, WITHOUT LATERAL SEALS

HIGH QUALITY BAGS, MORE ESTHETICAL AND VERY WELL ADJUSTED. INCLUDES OPTIONAL PRINTER FOR LABELS DIRECTLY ON THE BAG, PUNCHES HANDLES AND DETECTS CENTERED LOGOS. MINIMUM WASTE, ENERGY SAVINGS.

AUTOMATIC CYCLE: IN-FEED, WRAPPING, COMPRESSION AND SEALING. EASY AND FAST CHANGE OF THE ROLL, MÁX. ROLL: 500 mm.. CYCLE CONTROLLED BY PLC WITH TOUCH SCREEN. SURFACE OCCUPATION: 4.5X2M (EXTRA BIG DIMENSIONS AVAILABLE AS OPTION).

HIGH PRODUCTIVITY: 10/12 UNITS PER MINUTE

WELL-ENGINEERED MACHINE FOR FLATTENING AND WRAPPING CUSHIONS FOR “FLAT PACK” OPERATIONS

THIS IS IDEAL FOR STORING AND SHIPPING PILLOWS AND CUSHIONS IN A MINIMAL AMOUNT OF SPACE

AUTOMATICALLY WRAPS EVERY TYPE OF PILLOW BETWEEN 40CM x 40CM (16”x16”) TO 110CM x 80CM (42”x32”)

CYCLES UP TO 8 PER MINUTE

AUTOMATICALLY ADJUSTS TO VARYING SIZES

PLASTIC ROLLS ARE EASILY CHANGES

THE MACHINE FORMS A TUBE STYLE BAG FROM A POLYETHYLENE ROLL, WITH PERFECT SIZE ADJUSTMENT AND REQUIRES NO LATERAL SEALING. CHANGING THE POLYETHYLENE ROLL IS FAST AND EASY, AND DIFFERENT SIZES CAN BE USED WITHOUT ADJUSTMENT

CUTS ARE MADE BY A MAINTENANCE-FREE, SMOKELESS COLD BLADE

A TOUCH SCREEN PLC CONTROL DISPLAYS INPUT PARAMETERS AND CYCLE INFORMATION

ELECTRONIC INVERTER ENABLES SMOOTH MOTORIZED MOVEMENTS

OPTIONAL VIDEO JET THERMAL PRINTER CAN PRINT PRODUCT DATA AND BAR CODES DIRECTLY ON FINISHED PACKAGE

MACHINE DIMENSIONS ARE: 4.5M x 2M (14.75’ x 6.5’)

SAVES SPACE AND MATERIAL EXPENSE BY EXTRACTING AIR FROM THE BAG DURING PACKAGING PROCESS

QUANTITY: 1

Learn More