Search results for: '130'

- Related search terms

- 130 sulzer loom

- 1300-10

- 130$

- 1300+1100+400

- 1300 1100 400

-

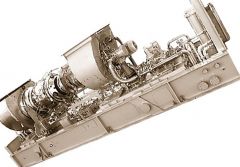

TT-3596 SOLAR MARS 90, YEAR 2004TT-3596 SOLAR MARS 90, YEAR 2004 MARS 90 ENGINES ONLY ITEM 001 ENGINE ONE: EM132S-S5G00M0P MARS 90S VERSION: T-13000 TESTED AS T-12000 REPORTED HOURS: 24,700 SINCE LAST OH ITEM 002 ENGINE TWO: EM132S-S5G00M0P MARS 90S VERSION: T-13000 Learn More

TT-3596 SOLAR MARS 90, YEAR 2004TT-3596 SOLAR MARS 90, YEAR 2004 MARS 90 ENGINES ONLY ITEM 001 ENGINE ONE: EM132S-S5G00M0P MARS 90S VERSION: T-13000 TESTED AS T-12000 REPORTED HOURS: 24,700 SINCE LAST OH ITEM 002 ENGINE TWO: EM132S-S5G00M0P MARS 90S VERSION: T-13000 Learn More -

TT-2778 NATIONAL 110 UE 1500 HP SCR OIL RIG, YEAR 2006TT-2778 NATIONAL 110 UE 1500 HP SCR OIL RIG, YEAR 2006 NATIONAL 110 UE 1500 HP SCR MAJOR REBUILD LIKE NEW (RIG BUILT NEW IN 2006) Learn More

TT-2778 NATIONAL 110 UE 1500 HP SCR OIL RIG, YEAR 2006TT-2778 NATIONAL 110 UE 1500 HP SCR OIL RIG, YEAR 2006 NATIONAL 110 UE 1500 HP SCR MAJOR REBUILD LIKE NEW (RIG BUILT NEW IN 2006) Learn More -

TT-3033 SOLAR GENERATOR SETS, 50 TO 60 Hz, YEAR 1976 TO 2015TT-3033 SOLAR GENERATOR SETS, 50 TO 60 Hz, YEAR 1976 TO 2015 Learn More

TT-3033 SOLAR GENERATOR SETS, 50 TO 60 Hz, YEAR 1976 TO 2015TT-3033 SOLAR GENERATOR SETS, 50 TO 60 Hz, YEAR 1976 TO 2015 Learn More -

V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”)V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”) THIS LINE INCLUDES PREFOLDING MACHINE, BANDAGE DRYING MACHINE, FOLDING MACHINE, AND WINDING MACHINE. FINAL PRODUCT IS 6 PLY USES 4 OUTPUT LINES, OUTPUT IS APPROXIMATELY 48 PIECES PER MINUTE FINAL WIDTH OF FABRIC: USUALLY CUSTOMERS USE 780mm WIDTH, MACHINE CAN BE MADE ACCORDING TO DIFFERENT REQUESTS MACHINE TOTAL LENGTH: 19 METERS (62.3 FEET) TOTAL QUANTITY: 1 COMPLETE PRODUCTION LINE Learn More

V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”)V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”) THIS LINE INCLUDES PREFOLDING MACHINE, BANDAGE DRYING MACHINE, FOLDING MACHINE, AND WINDING MACHINE. FINAL PRODUCT IS 6 PLY USES 4 OUTPUT LINES, OUTPUT IS APPROXIMATELY 48 PIECES PER MINUTE FINAL WIDTH OF FABRIC: USUALLY CUSTOMERS USE 780mm WIDTH, MACHINE CAN BE MADE ACCORDING TO DIFFERENT REQUESTS MACHINE TOTAL LENGTH: 19 METERS (62.3 FEET) TOTAL QUANTITY: 1 COMPLETE PRODUCTION LINE Learn More -

TT-1712 UNTHA SHREDDER, WORKING WIDTH 1988mm, 150KWTT-1712 UNTHA SHREDDER, WORKING WIDTH 1988mm, 150KW BRAND: UNTHA 150KW WORKING WIDTH 1988mm 400AMP 150KW VOLTAGE: 3X 400V CONTROL VOLTAGE 230V 2-SHAFT MACHINE Learn More

TT-1712 UNTHA SHREDDER, WORKING WIDTH 1988mm, 150KWTT-1712 UNTHA SHREDDER, WORKING WIDTH 1988mm, 150KW BRAND: UNTHA 150KW WORKING WIDTH 1988mm 400AMP 150KW VOLTAGE: 3X 400V CONTROL VOLTAGE 230V 2-SHAFT MACHINE Learn More -

TT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KNTT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KN COMPUTERIZED TENSILE TESTING MACHINE KEY SPECIFICATION: CAPACITY: KGF 3000, 5000, 10000, 15000 KN 30, 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 560 (800 OPTIONAL) CROSSHEAD TRAVEL (mm): 980 (1480 OPTIONAL) TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200, 0.2~200 OR 0.5~500 MAXIMUM FORCE AT FULL SPEED (KGF): 1000, 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100, 50 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION: 0.001 DRIVING METHOD: AC SERVO MOTOR POWER SPECIFICATIONS: 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CONSUMPTION: 3000 KGF 30 KN 5000 KGF 50 KN 10000 KGF 100 KN 15000 KGF 150 KN 2 KVA, 3 KVA, 5 KVA, 10 KVA DIMENSIONS FRAME (mm): 1300 X 600 X 2130 1540 X 600 X 2130 1300 X 600 X 2630 1540 X 600 X 2630 CONTROL BOX (mm) COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG) FRAME 800, CONTROL BOX 100 FRAME 1200, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY Learn More

TT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KNTT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KN COMPUTERIZED TENSILE TESTING MACHINE KEY SPECIFICATION: CAPACITY: KGF 3000, 5000, 10000, 15000 KN 30, 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 560 (800 OPTIONAL) CROSSHEAD TRAVEL (mm): 980 (1480 OPTIONAL) TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200, 0.2~200 OR 0.5~500 MAXIMUM FORCE AT FULL SPEED (KGF): 1000, 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100, 50 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION: 0.001 DRIVING METHOD: AC SERVO MOTOR POWER SPECIFICATIONS: 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CONSUMPTION: 3000 KGF 30 KN 5000 KGF 50 KN 10000 KGF 100 KN 15000 KGF 150 KN 2 KVA, 3 KVA, 5 KVA, 10 KVA DIMENSIONS FRAME (mm): 1300 X 600 X 2130 1540 X 600 X 2130 1300 X 600 X 2630 1540 X 600 X 2630 CONTROL BOX (mm) COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG) FRAME 800, CONTROL BOX 100 FRAME 1200, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY Learn More -

J-4138 BAUMER BSR TABLE SLITTER, WORKING WIDTH 1600mm, YEAR 1988 - CUTTING SPEED: 50 METERS PER MINUTEJ-4138 BAUMER BSR TABLE SLITTER, WORKING WIDTH 1600mm, YEAR 1988 - CUTTING SPEED: 50 METERS PER MINUTE IN PERFECT CONDITION STATUS: UNDER POWER QUANTITY: 1 Learn More

J-4138 BAUMER BSR TABLE SLITTER, WORKING WIDTH 1600mm, YEAR 1988 - CUTTING SPEED: 50 METERS PER MINUTEJ-4138 BAUMER BSR TABLE SLITTER, WORKING WIDTH 1600mm, YEAR 1988 - CUTTING SPEED: 50 METERS PER MINUTE IN PERFECT CONDITION STATUS: UNDER POWER QUANTITY: 1 Learn More -

V-1996 MICROFIBER OPENER WITH 4 FILLING FANS FOR PILLOWS AND CUSHIONSV-1996 MICROFIBER OPENER WITH 4 FILLING FANS FOR PILLOWS AND CUSHIONS A. MICROFIBER OPENER B. OPENING DRUM 900mm WORKING WIDTH C. FEED SUCTION FAN D. RECEIVING BOX – METAL FABRICATION E. FILLING FANS AT EXIT (FAN-1112) QUANTITY: 1 SET Learn More

V-1996 MICROFIBER OPENER WITH 4 FILLING FANS FOR PILLOWS AND CUSHIONSV-1996 MICROFIBER OPENER WITH 4 FILLING FANS FOR PILLOWS AND CUSHIONS A. MICROFIBER OPENER B. OPENING DRUM 900mm WORKING WIDTH C. FEED SUCTION FAN D. RECEIVING BOX – METAL FABRICATION E. FILLING FANS AT EXIT (FAN-1112) QUANTITY: 1 SET Learn More -

SUGAR REFINERY COMPLETE LINE 70 TONS PER HOURREFERENCE NUMBER: AJ-2088 SUGAR REFINERY COMPLETE LINE 70 TONS PER HOUR PROCESSING 70 TON PER HOUR OF UNREFINED BROWN SUGAR INTO WHITE CRYSTALLINE. 2007 PUTSCH 1300 X 1300 FILTER PRESSES 2008 AND 2012 BROADBENT CONTINUOUS AND BATCH CENTRIFUGALS BMA AND 1 WIEDMANN VACUUM PAN CRYSTALLIZER SYSTEM 2016 ALFA LAVAL HEAT EXCHANGER OR EVAPORATION SETS 3X ALFA-LAVAL PLATE HEAT EXCHANGERS M10-MFM 105 ℃ STEAM SYRUP 90 T/H 333KW WIDMANN, SHELL AND TUBE HEAT EXCHANGER, MDL. CALANDRIA DN2000 SEPARATOR DN 2400 BMA ROTARY DRYER WITH FLUIDIZED BED COOLER 60 ASSORTED SIZE STAINLESS TANKS AND VESSELS FULL INVENTORY OF NEW SPARE PARTS FOR ALL ABOVE POWER STATION FEATURING 12.5 MW SIEMENS TURBINES VOLUND HIGH-PRESSURE STEAM BOILER (63 TONS AT 60 BAR) 24 JORD AIR COOLING CONDENSER 2014 ATLAS COPCO COMPRESSED AIR SYSTEM AND DRYERS WIDE ASSORTMENT OF ABB SIEMENS SWITCHGEAR 24 UNIT FREE STANDING AIR COOLED CONDENSER SYSTEM PLUSS 100 PROCESS AND VACUUM PUMP INCLUDING NASH, WARMAN, DURCO, PUTSCH, SANDPIPER AND OTHER QUANTITY: 1 Learn More

SUGAR REFINERY COMPLETE LINE 70 TONS PER HOURREFERENCE NUMBER: AJ-2088 SUGAR REFINERY COMPLETE LINE 70 TONS PER HOUR PROCESSING 70 TON PER HOUR OF UNREFINED BROWN SUGAR INTO WHITE CRYSTALLINE. 2007 PUTSCH 1300 X 1300 FILTER PRESSES 2008 AND 2012 BROADBENT CONTINUOUS AND BATCH CENTRIFUGALS BMA AND 1 WIEDMANN VACUUM PAN CRYSTALLIZER SYSTEM 2016 ALFA LAVAL HEAT EXCHANGER OR EVAPORATION SETS 3X ALFA-LAVAL PLATE HEAT EXCHANGERS M10-MFM 105 ℃ STEAM SYRUP 90 T/H 333KW WIDMANN, SHELL AND TUBE HEAT EXCHANGER, MDL. CALANDRIA DN2000 SEPARATOR DN 2400 BMA ROTARY DRYER WITH FLUIDIZED BED COOLER 60 ASSORTED SIZE STAINLESS TANKS AND VESSELS FULL INVENTORY OF NEW SPARE PARTS FOR ALL ABOVE POWER STATION FEATURING 12.5 MW SIEMENS TURBINES VOLUND HIGH-PRESSURE STEAM BOILER (63 TONS AT 60 BAR) 24 JORD AIR COOLING CONDENSER 2014 ATLAS COPCO COMPRESSED AIR SYSTEM AND DRYERS WIDE ASSORTMENT OF ABB SIEMENS SWITCHGEAR 24 UNIT FREE STANDING AIR COOLED CONDENSER SYSTEM PLUSS 100 PROCESS AND VACUUM PUMP INCLUDING NASH, WARMAN, DURCO, PUTSCH, SANDPIPER AND OTHER QUANTITY: 1 Learn More -

ADVANCED LEVEL MULTI NOZZLE ELECTROSPINNING UNIT - 8 NOZZLESREFERENCE NUMBER: A-2476 ADVANCED LEVEL MULTI NOZZLE ELECTROSPINNING UNIT - 8 NOZZLES FULLY AUTOMATED ELECTROSPINNING MACHINE IS DESIGNED TO CARRY ELECTROSPINNING RESEARCH TO A MORE ADVANCED LEVEL. MACHINE IS A HYBRID ELECTROSPINNING SYSTEM OF EIGHT NEEDLES. IT HAS A 314 X 220 mm NANOFIBER COATING AREA VIA A ROTATING DRUM COLLECTOR, ALSO A FLAT COLLECTOR OF 130 X 370 mm COMES WITH THE STANDARD CONFIGURATION. THE NE 300 HAS AN ELECTRICALLY INSULATED CABINET WITH HIGH DENSITY PE PARTS INERT TO CHEMICAL SOLUTIONS, WHICH ENABLES WORKING WITH MANY DIFFERENT SOLVENTS AND POLYMERS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATICALLY PAINTED STEEL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: 7000 SERIES ALUMINUM ALLOY, STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX.150 KGS DIMENSIONS: 770 X 675 X 1040 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 4 PCS NUMBER OF FEEDING PIPE SETS: UP TO 2 SETS NUMBER OF NOZZLES: UP TO 8 NOZZLES SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm COMPATIBLE WITH STANDARD SYRNIGE NOZZLES MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 1 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 8.5 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 16 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 33.5 TO 233.5 mm DISTANCE ADJUSTMENT PRECISION: 1 mm ROTATING COLLECTOR DRUM COLLECTOR MATERIAL: ALUMINUM DIMENSIONS OF DRUM: 100 X 220 mm FIBER DEPOSITION AREA: 314 X 220 mm DRUM ROTATING SPEED: 100 TO 500 RPM SURFACE SPEED: 52.3 CM/S TO 261.6 CM/S COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 30 TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm /SEC STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 370 X 130 mm UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION FULLY SEALED CABINET TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 1000 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 150 KGS. Learn More

ADVANCED LEVEL MULTI NOZZLE ELECTROSPINNING UNIT - 8 NOZZLESREFERENCE NUMBER: A-2476 ADVANCED LEVEL MULTI NOZZLE ELECTROSPINNING UNIT - 8 NOZZLES FULLY AUTOMATED ELECTROSPINNING MACHINE IS DESIGNED TO CARRY ELECTROSPINNING RESEARCH TO A MORE ADVANCED LEVEL. MACHINE IS A HYBRID ELECTROSPINNING SYSTEM OF EIGHT NEEDLES. IT HAS A 314 X 220 mm NANOFIBER COATING AREA VIA A ROTATING DRUM COLLECTOR, ALSO A FLAT COLLECTOR OF 130 X 370 mm COMES WITH THE STANDARD CONFIGURATION. THE NE 300 HAS AN ELECTRICALLY INSULATED CABINET WITH HIGH DENSITY PE PARTS INERT TO CHEMICAL SOLUTIONS, WHICH ENABLES WORKING WITH MANY DIFFERENT SOLVENTS AND POLYMERS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATICALLY PAINTED STEEL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: 7000 SERIES ALUMINUM ALLOY, STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX.150 KGS DIMENSIONS: 770 X 675 X 1040 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 4 PCS NUMBER OF FEEDING PIPE SETS: UP TO 2 SETS NUMBER OF NOZZLES: UP TO 8 NOZZLES SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm COMPATIBLE WITH STANDARD SYRNIGE NOZZLES MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 1 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 8.5 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 16 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 33.5 TO 233.5 mm DISTANCE ADJUSTMENT PRECISION: 1 mm ROTATING COLLECTOR DRUM COLLECTOR MATERIAL: ALUMINUM DIMENSIONS OF DRUM: 100 X 220 mm FIBER DEPOSITION AREA: 314 X 220 mm DRUM ROTATING SPEED: 100 TO 500 RPM SURFACE SPEED: 52.3 CM/S TO 261.6 CM/S COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 30 TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm /SEC STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 370 X 130 mm UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION FULLY SEALED CABINET TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 1000 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 150 KGS. Learn More