Search results for: 'Machine fl'

- Related search terms

- machine''

- Machine we

- Machine+we

- Machine fe

- Machine+c''

-

COMPLETE WEAVING PLANT YEAR 2005-2006WEAVING MACHINES BENNINGER BEN DIRECT WARPER YEAR 2006 BEAM DIAMETER 1000mm, WIDTH 2200mm V-CREEL – 1024 ENDS, AUTOMATIC CUTTING AT CREEL CHANGE ELECTRICAL STOP MOTION, MECHANICAL TENSIONER MICROPROCESSOR CONTROL SUCKER MOENUS SIZING MACHINE YEAR 2006 SIZING MACHINE SUCKER MOENUS Z 14, WIDTH 3400mm 1000mm FLANG DIAMETER, 14 DRYING CYLINDERS 2 SOW BOXES, 2 DIP AND 2 NIP, 24 WARP BEAMS CREEL, FULLY AUTOMATIC PLC CONTROL SIZE MIXING COOLER, 1200 LITERS SIZE STORAGE VESSEL, 1200 LITERS STAUBLI DELTA AUTO DRAWING IN MACHINE YEAR 2006 AUTO DRAWING IN MACHINE, STAUBLI DELTA 110 3400mm, YARN MODULE (HM5), HEALD MODULE (HM2) REED MODULE (HM6), DROP WIRE MODULE (HM3) AND CONTROL MODULE JAYTEX WARP TYING MACHINE YEAR 2005 WARP TYEING MACHINE JAYTEX TROLLEY WITH TRANSFORMER WITH 2 NOS. TYING FRAMES SETIA KIJJI REED CLEANING MACHINE YEAR 2006 SETIA KIJJI – ULTRA SONIC CLEANING MACHINE REED CLEANER CONSISTS OF RINSING UNIT ULTRASONIC UNIT DRYING UNIT, SEMI AUTOMATIC PROCESS USING PLC. (18 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 3E+06 EACH – 16 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI ELECTRONIC DOBBY 16 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (48 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 3E+06 – 10 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI CAM MOTION 10 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (24 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 2E+06 – 6 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI CAM MOTION 6 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (2 UNITS) GREY INSPECTION MACHINE YEAR 2006 INSPECTION TABLE IS LAMINATED, PUSH BUTTON CONTROLS ARE GIVEN ON THE DRIVE BOX ON THE RIGHT HAND SIDE, CLOTH CAN RUN IN FORWARD AS WELL AS IN REVERSE DIRECTION FABRIC RUNS FACE IN/FACE OUT SPECIAL JOGGING OR INCHING DEVICE FABRIC FOLDING MACHINE YEAR 2006 SWINGING MOTION IS MINIMIZED TO ENSURE HIGH MACHINE CAPACITY AND INCREASE OUTPUT FOLDING BLADES ARE MOUNTED ON A CARRIAGE WHICH HAS A TO AND FRO MOVEMENT ACHIEVED BY SPECIAL STEEL ROLLER CHAIRS BALE PRESS YEAR 2001 BATH BEI HYDRAULIC BALE PRESS MACHINE FABRIC PROCESSING SINGEING MACHINE YAMUNA SINGEING MACHINE WIDER WIDTH – YEAR 2006 (2 UNITS) HYDRAULIC JIGGER KUSTER CALICO YEAR 2006 3E+06 VERTICAL DRYING RANGE YEAR 2006 CONTINUOUS DYEING RANGE – KUSTER CALICO KUSTER CALICO COLD PAD BATCH YEAR 2006 HARISH STENTER – SUPRA 5 DLXI ALMAC FINISH INSPECTION MACHINE YEAR 2006 SHRI NARAYAN COTEX FINISH PLAITING MACHINE YEAR 2006 Learn More

COMPLETE WEAVING PLANT YEAR 2005-2006WEAVING MACHINES BENNINGER BEN DIRECT WARPER YEAR 2006 BEAM DIAMETER 1000mm, WIDTH 2200mm V-CREEL – 1024 ENDS, AUTOMATIC CUTTING AT CREEL CHANGE ELECTRICAL STOP MOTION, MECHANICAL TENSIONER MICROPROCESSOR CONTROL SUCKER MOENUS SIZING MACHINE YEAR 2006 SIZING MACHINE SUCKER MOENUS Z 14, WIDTH 3400mm 1000mm FLANG DIAMETER, 14 DRYING CYLINDERS 2 SOW BOXES, 2 DIP AND 2 NIP, 24 WARP BEAMS CREEL, FULLY AUTOMATIC PLC CONTROL SIZE MIXING COOLER, 1200 LITERS SIZE STORAGE VESSEL, 1200 LITERS STAUBLI DELTA AUTO DRAWING IN MACHINE YEAR 2006 AUTO DRAWING IN MACHINE, STAUBLI DELTA 110 3400mm, YARN MODULE (HM5), HEALD MODULE (HM2) REED MODULE (HM6), DROP WIRE MODULE (HM3) AND CONTROL MODULE JAYTEX WARP TYING MACHINE YEAR 2005 WARP TYEING MACHINE JAYTEX TROLLEY WITH TRANSFORMER WITH 2 NOS. TYING FRAMES SETIA KIJJI REED CLEANING MACHINE YEAR 2006 SETIA KIJJI – ULTRA SONIC CLEANING MACHINE REED CLEANER CONSISTS OF RINSING UNIT ULTRASONIC UNIT DRYING UNIT, SEMI AUTOMATIC PROCESS USING PLC. (18 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 3E+06 EACH – 16 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI ELECTRONIC DOBBY 16 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (48 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 3E+06 – 10 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI CAM MOTION 10 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (24 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 2E+06 – 6 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI CAM MOTION 6 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (2 UNITS) GREY INSPECTION MACHINE YEAR 2006 INSPECTION TABLE IS LAMINATED, PUSH BUTTON CONTROLS ARE GIVEN ON THE DRIVE BOX ON THE RIGHT HAND SIDE, CLOTH CAN RUN IN FORWARD AS WELL AS IN REVERSE DIRECTION FABRIC RUNS FACE IN/FACE OUT SPECIAL JOGGING OR INCHING DEVICE FABRIC FOLDING MACHINE YEAR 2006 SWINGING MOTION IS MINIMIZED TO ENSURE HIGH MACHINE CAPACITY AND INCREASE OUTPUT FOLDING BLADES ARE MOUNTED ON A CARRIAGE WHICH HAS A TO AND FRO MOVEMENT ACHIEVED BY SPECIAL STEEL ROLLER CHAIRS BALE PRESS YEAR 2001 BATH BEI HYDRAULIC BALE PRESS MACHINE FABRIC PROCESSING SINGEING MACHINE YAMUNA SINGEING MACHINE WIDER WIDTH – YEAR 2006 (2 UNITS) HYDRAULIC JIGGER KUSTER CALICO YEAR 2006 3E+06 VERTICAL DRYING RANGE YEAR 2006 CONTINUOUS DYEING RANGE – KUSTER CALICO KUSTER CALICO COLD PAD BATCH YEAR 2006 HARISH STENTER – SUPRA 5 DLXI ALMAC FINISH INSPECTION MACHINE YEAR 2006 SHRI NARAYAN COTEX FINISH PLAITING MACHINE YEAR 2006 Learn More -

K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/HREFERENCE NUMBER: K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/H ASSEMBLED WITH A BALL FIBER MACHINE AND A TRANSPORT BLOWER WHICH TRANSPORTS FINISHED BALL FIBER TO NEXT PROCESS FOR USE. SUITABLE RAW MATERIAL IS CONJUGATED HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm, SUCH AS 3D, 7D, 15D, 32mm, 51mm, 64mm ETC. BALL FIBER MACHINE INNER ASSEMBLY WITH AN OPENING ROLLER AND BALLING ROLLER. THIS MAKES THE PRODUCED BALL FIBER ELASTIC AND FLEXIBLE MACHINE WITH PLC CONTROL SYSTEM THAT KEY PARTS ARE FROM THE FAMOUS WORLD BRANDS SUCH LIKE SIEMENS, OMRON AND SCHNEIDER ETC. STABLE QUALITY AND WITH LOCAL SERVICE TO SUPPORT YOU. BALL FIBER SIZE ADJUSTABLE FAN MADE FROM ALUMINUM MATERIAL, SO CAN RUN FAST AND QUIET SIMPLE OPERATOR SKILL REQUIRED DIFFERENT POWER VOLTAGE AND SAFETY STANDARD CAN BE ORDERED ACCORDING TO THE CUSTOMER’S LOCAL REQUIREMENT CE CERTIFICATION DIMENSIONS: 4860 X 1630 X 1250mm QUANTITY AVAILABLE: 1 Learn More

K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/HREFERENCE NUMBER: K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/H ASSEMBLED WITH A BALL FIBER MACHINE AND A TRANSPORT BLOWER WHICH TRANSPORTS FINISHED BALL FIBER TO NEXT PROCESS FOR USE. SUITABLE RAW MATERIAL IS CONJUGATED HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm, SUCH AS 3D, 7D, 15D, 32mm, 51mm, 64mm ETC. BALL FIBER MACHINE INNER ASSEMBLY WITH AN OPENING ROLLER AND BALLING ROLLER. THIS MAKES THE PRODUCED BALL FIBER ELASTIC AND FLEXIBLE MACHINE WITH PLC CONTROL SYSTEM THAT KEY PARTS ARE FROM THE FAMOUS WORLD BRANDS SUCH LIKE SIEMENS, OMRON AND SCHNEIDER ETC. STABLE QUALITY AND WITH LOCAL SERVICE TO SUPPORT YOU. BALL FIBER SIZE ADJUSTABLE FAN MADE FROM ALUMINUM MATERIAL, SO CAN RUN FAST AND QUIET SIMPLE OPERATOR SKILL REQUIRED DIFFERENT POWER VOLTAGE AND SAFETY STANDARD CAN BE ORDERED ACCORDING TO THE CUSTOMER’S LOCAL REQUIREMENT CE CERTIFICATION DIMENSIONS: 4860 X 1630 X 1250mm QUANTITY AVAILABLE: 1 Learn More -

TT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KNTT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.5mm TEST SPEED: 0.001-500mm/MIN OR 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARD ACCESSORIES: 1 SET OF GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC LOAD CELL OPTION ACCESSORIES: DESKTOP COMPUTER UNIVERSAL COMPRESSION TESTING MACHINE SOFTWARE FUNCTION: TEST & CONTROL SYSTEM IS DESIGNED FOR PC ELECTRONIC UNIVERSAL TESTING MACHINES, PC HYDRAULIC UNIVERSAL TESTING MACHINES AND PC COMPRESSION TESTERS. CAN CONDUCT TENSILE, COMPRESSION, BENDING, SHEARING, TEARING AND PEELING TEST; USE PC AND INTERFACE BOARD FOR DATA COLLECTION, PRESERVATION, PROCESSING AND PRINTING TEST RESULT; CAN CALCULATE MAX FORCE, YIELD STRENGTH, AVERAGE PEELING FORCE, MAX DEFORMATION, YIELD POINT, ELASTIC MODULUS AND OTHER PARAMETERS. CAN CONDUCT CURVE GRAPHICS PROCESSING, MULTI-SENSOR SUPPORT, VIDEO AND IMAGE INTERFACE, FLEXIBLE DATA PROCESSING, MS-ACCESS DATABASE SUPPORT, MAKING MORE POWERFUL FUNCTION OF SYSTEM. QUANTITY: 1 Learn More

TT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KNTT-1044 SERVO CONTROL UNIVERSAL TESTING MACHINE, 20KN KEY SPECIFICATIONS: MAX. CAPACITY: 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN,10KN,20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.5mm TEST SPEED: 0.001-500mm/MIN OR 0.001-1000mm/MIN (OPTION), CAN SET BY COMPUTER, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 400W DIMENSIONS: 720 X 620 X 1400mm (W X D X H) WEIGHT: 150KG POWER SUPPLY: 220V 50/60Hz 10A STANDARD ACCESSORIES: 1 SET OF GRIPS ENGLISH OPERATION SOFTWARE CABLE CONNECT WITH PC LOAD CELL OPTION ACCESSORIES: DESKTOP COMPUTER UNIVERSAL COMPRESSION TESTING MACHINE SOFTWARE FUNCTION: TEST & CONTROL SYSTEM IS DESIGNED FOR PC ELECTRONIC UNIVERSAL TESTING MACHINES, PC HYDRAULIC UNIVERSAL TESTING MACHINES AND PC COMPRESSION TESTERS. CAN CONDUCT TENSILE, COMPRESSION, BENDING, SHEARING, TEARING AND PEELING TEST; USE PC AND INTERFACE BOARD FOR DATA COLLECTION, PRESERVATION, PROCESSING AND PRINTING TEST RESULT; CAN CALCULATE MAX FORCE, YIELD STRENGTH, AVERAGE PEELING FORCE, MAX DEFORMATION, YIELD POINT, ELASTIC MODULUS AND OTHER PARAMETERS. CAN CONDUCT CURVE GRAPHICS PROCESSING, MULTI-SENSOR SUPPORT, VIDEO AND IMAGE INTERFACE, FLEXIBLE DATA PROCESSING, MS-ACCESS DATABASE SUPPORT, MAKING MORE POWERFUL FUNCTION OF SYSTEM. QUANTITY: 1 Learn More -

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More -

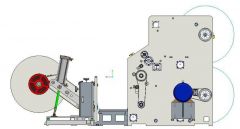

J-1563 COFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENT

J-1563 COFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENTCOFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENT

Learn More -

TT-6699 COMPLETE BOTTLING LINE, YEAR 2013TT-6699 COMPLETE BOTTLING LINE, YEAR 2013 1. COMPOSED OF FILLING MONOBLOCK + LABELING MACHINE 2. SPEED: 700 BPH 3. CONTAINERS: GLASS 4. FORMATS: 0.33 L 5. PRODUCT: BEER 6. FILL TYPE: ISOBARIC QUANTITY: 1 Learn More

TT-6699 COMPLETE BOTTLING LINE, YEAR 2013TT-6699 COMPLETE BOTTLING LINE, YEAR 2013 1. COMPOSED OF FILLING MONOBLOCK + LABELING MACHINE 2. SPEED: 700 BPH 3. CONTAINERS: GLASS 4. FORMATS: 0.33 L 5. PRODUCT: BEER 6. FILL TYPE: ISOBARIC QUANTITY: 1 Learn More -

Y-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mmYY-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mm WLS ROLLING & SCORING THE RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS: 2000 TO 3800 KG/HR. FEATURES: - CONDITION: REFURBISHED - MANUFACTURER: WLS - USAGE: CHEWING GUM FORMING LINE - CAPACITY: 2.000 KG/HR. - WORKING WIDTH: 460mm - PIECES’ DIMENSIONS: ACCORDING TO THE CUSTOMERS NEED Learn More

Y-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mmYY-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mm WLS ROLLING & SCORING THE RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS: 2000 TO 3800 KG/HR. FEATURES: - CONDITION: REFURBISHED - MANUFACTURER: WLS - USAGE: CHEWING GUM FORMING LINE - CAPACITY: 2.000 KG/HR. - WORKING WIDTH: 460mm - PIECES’ DIMENSIONS: ACCORDING TO THE CUSTOMERS NEED Learn More -

TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021 AVAILABILITY SHORT DELIVERY TIMES UPON AGREEMENT. Learn More

TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021 AVAILABILITY SHORT DELIVERY TIMES UPON AGREEMENT. Learn More -

YY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mmYY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400 METERS PER MINUTE SLITTING WIDTH: 30 TO 1800mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø1000mm; MACHINE WEIGHT: 5000 KG; TOTAL MOTOR POWER: 31KW; DIMENSIONS: W 3500 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3 " (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 11KW X 2; TRACTION MOTOR: 11KW; MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More

YY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mmYY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400 METERS PER MINUTE SLITTING WIDTH: 30 TO 1800mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø1000mm; MACHINE WEIGHT: 5000 KG; TOTAL MOTOR POWER: 31KW; DIMENSIONS: W 3500 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3 " (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 11KW X 2; TRACTION MOTOR: 11KW; MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More -

H-1261 GOOSE FEATHER CLEANING MACHINE

H-1261 GOOSE FEATHER CLEANING MACHINEH-1261 GOOSE FEATHER CLEANING MACHINE

LIST OF COMPONENTS FOR THE GOOSE FEATHER CLEANING MACHINE:

1) RINSING MACHINE OF THE TYPE 2000 (STAINLESS STEEL USED FOR IT)

EXTERIOR DIMENSION: 4000×2000×2600×Ф1800MM

QUANTITY: 12) GOOSE FEATHER ADDING MACHINE

EXTERIOR DIMENSION: 4000×1800×3300MM

QUANTITY: 13) WATER TANK

EXTERIOR DIMENSION: Ф1930MM×2440MM

QUANTITY: 14) DEWATERING MACHINE FLAT PLATE TYPE (BEING EQUIPPED WITH VARIABLE FREQUENCY CONTROL) - 2 SETS

QUANTITY: 25)DRYER OF THE TYPE 2000 (BEING EQUIPPED WITH ELECTRONIC WEIGHING)

EXTERIOR DIMENSION: 4500×2100×2900MM

QUANTITY: 16)GOOSE FEATHER ADDING MACHINE FOR DRYER(STAINLESS STEEL USED FOR IT AND ELECTRONIC WEIGHING INCLUDED)

EXTERIOR DIMENSION: 1500×1200×3600MM

QUANTITY: 17)THE COOLER OF THE TYPE 4700(STEEL & WOOD STRUCTURE, OPTIMIZED MOISTURE PROOF PANEL)

EXTERIOR DIMENSION: 4700×2350×2600×Ф2000MM

QUANTITY: 18) SORTING EQUIPMENT

QUANTITY: 29) POWER DISTRIBUTION CABINET

QUANTITY: 2RINSING MACHINE: TYPE 2000

1. EXTERIOR DIMENSION: 4000×2000×2600×Ф1800MM DIAMETER

2.THE MATERIAL OF 14MM IN THICKNESS STAINLESS STEEL IS USED FOR THE WALL FOR WASHING MACHINE AND 5MM IN THICKNESS FOR BARREL

3. THE MATERIAL OF AISI 1045 IS USED FOR THE SPINDLE OF THE SQUARE SHAPE(SPECIFICATION =108MMX108MM). WRAPPED WITH 2MM STAINLESS STEEL IN THE OUTER.

10MM IN THICKNESS STAINLESS STEEL IS FOR HOOP OF VANE.

4MM IN THICKNESS STAINLESS STEEL WHICH IS FOLDED IS FOR VANE.

HOOP SCREW OF M14 X 70 (HIGH STRENGTH GRADE) ARE USED.

THE BEARING HOUSING &BEARING OF UKP318 IS USED FOR THE SPINDLE.4.THE SIEVE OF 1.5MM IN THICKNESS STAINLESS STEEL IS USED FOR WACHING MACHINE.THE HOLE IS 1.8MM IN DIAMETER. HOLE SPACING 3.8MM .THE STAINLESS STEEL OF 2MM IS USED FOR THE OBLIQUE OF OUTPUTTING THE GOOSE FEATHER.THE OUTLET NEAR DEWATERING MACHINE FOR GOOSE FEATHER CAN BE TURNED UPWARD. FOR GOOSE FEATHER.

5.THE PIPE FOR WATER INLET IS 114MM IN DIAMETER

6.THE POWER OF FAN: 7.5KW AND SPEED: 2900R/M

7.THE PIPE FOR FEEDING GOOSE FEATHER IS 250MM IN DIAMETER.

8.THE REDUCER FOR THE SPINDLE: JZQ-400. THE POWER OF MOTOR IS 15KW AND OUTPUT SPEED IS 42 R/M

9.EXTERIOR DIMENSION OF THE BOTTOM FOR WASHING MACHINE: WIDTH=1600MM;LENGTH=3500MM.ONE SIEVE OF 1MM IN THICKNESS FOR IT.

WATER TANK

1. THE DIMENSION OF TANK: Ф1930MM×2440MM

2.THE STAINLESS STEELOF 2MM IN THICKNESS FOR ITS BARREL AND 3MM FOR THE BOTTOM.THE COVER IS CONSTUCTED WITH ANGLE IRON OF STAINLESS STEEL AND INNER COVER 2MM STAINLESS STEEL PLATE.

DEWATERING MACHINE OF TYPE 1600

1. ONE SETS OF RINSING MACHING OF THE TYPE 2000 IS EQUIPPED WITH TWO SETS DEWATERING MACHINE OF THE TYPE 1600

2.THE POWER OF MOTOR=11KW-17KW.DOUBLE SPEED MOTOR WITH VARIABLE FREQUENCY CONTROL.

DRYER OF TYPE 2000

1. EXTERIOR DIMENSION: 4500×2100×2900×Ф1800MM(DIAMETER)

2. THE MATERIAL OF 14MM IN THICKNESS STAINLESS STEEL(Q345R) IS USED FOR THE WALL FOR WASHING MACHINE. 10MM STAINLESS STEEL(Q345R) IS USED FOR INNER COVER OF THE BARREL AND 10MM STAINLESS STEEL (Q345R) PLATE FOR OUTER COVER OF THE BARREL.

3. THE INNER WALL OF WIND PLATE IS 0.5MM IN THICKNESS AND THE HOLE 1.5MM IN DIAMETER STAINLESS STEEL. 3MM COLD ROLLED PLATE IS USED FOR THE OUTER GATE.

4. THE SEAMLESS PIPE OF Ф108MM×10MM IS FOR THE MAIN SPINDLE.THE STEEL PLATE OF 10MM IN THICKNESS IS FOR THE VANE.THE WIDTH OF THE VANE IS 80MM. HOOP SCREW IS M12X70

6. THERE ARE FOUR INLET OF 1.5INCH IN DIAMETER FOR STEAM.

RELIEF VALVE FROM 3 KILO TO 7 (1 SETS)

THE PRESSURE GAGE (0-16 KILO) (2 SETS)

THE THERMOMETER (0-150 DEGREE) (1 SETS)

THERE ARE THREE DRAIN HOLE OF 1.5 INCH IN DIAMETER AT THE BOTTOM6. THERE ARE TWO LAYERS FOR GOOSE FEATHER ADDING FOR DRYER: 1.5×1.2×3.6M.THEY ARE MADE WITH STAINLESS STEEL.THE SPECIFICATION OF CHARGING SPOUT ON THE TOP OF DRYER IS 1.55 X 0.55M.

7. THE OUTLET FOR GOOSE FEATHER OF DRYER CAN BE TURNED UPWARD.THE PIPE FOR OUTPUTTING GOOSE FEATHER IS 300MM IN DIAMETER.

8. TWO FANS ARE EQUIPPED FOR PRECISE WASHING LINE.THE POWER OF FAN FOR ADDING GOOSE FEATHER IS 7.5KW,SPEED: 2900R/M.WHICH IS USED TOGETHER WITH GOOSE ADDING MACHINE OF WASHING MACHINE.THE POWER OF FAN FOR DRYER IS 5.5KW,SPEED IS 2900 R/M.

9. MAIN SHAFT SPEED REDUCER FOR BELT BRIDGE MOTOR 7.5KW.OUTPUT SPEED IS 52 R/M

THE COOLER IS OF TYPE 47001. EXTERIOR DIMENSION: 4700×2350×2600×Ф2000MM DIAMETER

2. THE EXTERIOR IS CONSTRUCTED WITH THE WHOLE WOOD STRUCTURE.THE MATERIAL OF STEEL WITH 4# ANGLE STEEL AND 30X30 SQUARE TUBE IS FOR THE INNER SKELETON.

3. THE SEAMLESS PIPE OF Ф108MM×10MM IS FOR THE MAIN SPINDLE.THE STEEL PLATE OF 14MM IN THICKNESS IS FOR THE VANE.THE WIDTH OF THE VANE IS 80MM. HOOP SCREW IS M16X70

4. THE DIAMETER OF WIND PIPE: MAIN PIPE IS 300MM IN DIAMETER AND BRANCH IS 250MM IN DIAMETER.THERE ARE FOUR AIR OUTLET OF 300MM IN DIAMETER EQUIPPED EQUALLY SPACE.

5. ONE SIEVE IS EQUIPPED FOR THE COOLER.THE SIEVE IS MADE WITH 0.6MM IN THICKNESS GALVANIZED STEEL SHEET.THE HEIGHT OF HOLE IS 1.1MM.THE SCREEN FRAME IS MADE WITH 3# ANGLE STEEL.

6.THERE ARE TWO SORTING BOX WHICH IS CONSTRUCTED WITH STEEL FRAME AND WOODEN STRUCTURE. SIEVE 14 MESH GALVANIZED MESH BOLD

7. ONE FAN IS FOR THE COOLER.THE POWER OF THE FAN IS 11KW AND OUTPUT SPEED IS 2900 R/M

8. THE MOTOR FOR THE MAIN SPINDLE IS 15KW (6 POLE).THE SPEED OF 140 R/M IS FOR THE COOLER.

QUANTITY: 1

Learn More