Search results for: 'Cutting foam m'

- Related search terms

- cutting 0

- CUTTING+S

- cutting 0'

- Cutting ma'

- CUTTING+S'

-

J-3403 ALBRECHT BAUMER BSA HORIZONTAL FOAM SPLITTING MACHINE (SKIVER)J-3403 ALBRECHT BAUMER BSA HORIZONTAL FOAM SPLITTING MACHINE (SKIVER) HORIZONTAL SPLITTING MACHINE WITH INTEGRATED DESTACKING SYSTEM PRESSURE ROLLER ADJUSTABLE IN HEIGHT BY MOTOR RETAINER ADJUSTMENT UNLOADING CONVEYOR DOWNSTREAM OF THE CUTTING UNIT 600 VOLTS, 3-PHASE, 60 Hz QUANTITY: 1 Learn More

J-3403 ALBRECHT BAUMER BSA HORIZONTAL FOAM SPLITTING MACHINE (SKIVER)J-3403 ALBRECHT BAUMER BSA HORIZONTAL FOAM SPLITTING MACHINE (SKIVER) HORIZONTAL SPLITTING MACHINE WITH INTEGRATED DESTACKING SYSTEM PRESSURE ROLLER ADJUSTABLE IN HEIGHT BY MOTOR RETAINER ADJUSTMENT UNLOADING CONVEYOR DOWNSTREAM OF THE CUTTING UNIT 600 VOLTS, 3-PHASE, 60 Hz QUANTITY: 1 Learn More -

M-1998 BAUMER ISL YEAR 2003REFERENCE NUMBER: M-1998-A BAUMER ISL YEAR 2003 80" BAUMER ISL SAW YEAR 2003 DIMENSIONS OF THE TABLE: 87.5” LONG AND 92” ON EACH SIDE OF THE FENCE MANUAL VERTICAL CUTTING MACHINE FOR THE CUTTING AND TRIMMING, RESPECTIVELY, OF BLOCK OR SHEET WARE FROM FLEXIBLE FOAMS THE TABLE IS MANUALLY MOVED, THE LATERAL STOP IS ADJUSTED BY MEANS OF A HAND WHEEL. QUANTITY AVAILABLE: 1 Learn More

M-1998 BAUMER ISL YEAR 2003REFERENCE NUMBER: M-1998-A BAUMER ISL YEAR 2003 80" BAUMER ISL SAW YEAR 2003 DIMENSIONS OF THE TABLE: 87.5” LONG AND 92” ON EACH SIDE OF THE FENCE MANUAL VERTICAL CUTTING MACHINE FOR THE CUTTING AND TRIMMING, RESPECTIVELY, OF BLOCK OR SHEET WARE FROM FLEXIBLE FOAMS THE TABLE IS MANUALLY MOVED, THE LATERAL STOP IS ADJUSTED BY MEANS OF A HAND WHEEL. QUANTITY AVAILABLE: 1 Learn More -

YY-3176 ROLLER AUTO FEEDING DIE CUTTING MACHINESYY-3176 ROLLER AUTO FEEDING DIE CUTTING MACHINES APPLICATION: SOFT MATERIAL FORMING DIE CUTTING, LIKE EPE, EVA, FOAM, PET, LEATHER, BAGS, HANDBAGS, TEXTILES, RUBBER, CLOTH AND SO ON. Learn More

YY-3176 ROLLER AUTO FEEDING DIE CUTTING MACHINESYY-3176 ROLLER AUTO FEEDING DIE CUTTING MACHINES APPLICATION: SOFT MATERIAL FORMING DIE CUTTING, LIKE EPE, EVA, FOAM, PET, LEATHER, BAGS, HANDBAGS, TEXTILES, RUBBER, CLOTH AND SO ON. Learn More -

YY-1829 FOAM BUN, BLOCK RACK STORAGE SYSTEMYY-1829 FOAM BUN, BLOCK RACK STORAGE SYSTEM THE FOAM BLOCK RACK STORAGE SYSTEM IS FOR THE STORAGE OF THE UNCURED FOAM BLOCK AFTER FOAMING AND CUTTING OFF, AND THE SUPER SOFT FOAM WHICH CAN NOT BE LIFTED BY CRANE. EQUIPPED WITH THE AUTOMATIC MOVABLE CONVEYOR LINE, WHICH CAN MOVE WITH LEFT & RIGHT, UP & DOWN DIRECTION TO CONNECT TO EACH CONVEYOR RACK OF THE SYSTEM. WITH THE TOUCH SCREEN AND PLC AUTO CONTROL, THE FOAM BLOCKS IN THE STORAGE SYSTEM WILL BE MOVED IN AND OUT OF THE STORAGE SYSTEM AUTOMATICALLY. THIS STORAGE SYSTEM WILL HELP THE FOAM CURING PROCESS, AND UTILIZE MORE STORAGE SPACE EFFECTIVELY UNDER LIMITED WORKSHOP, AND SAVE A LOT OF TIME AND LABOR COST. Learn More

YY-1829 FOAM BUN, BLOCK RACK STORAGE SYSTEMYY-1829 FOAM BUN, BLOCK RACK STORAGE SYSTEM THE FOAM BLOCK RACK STORAGE SYSTEM IS FOR THE STORAGE OF THE UNCURED FOAM BLOCK AFTER FOAMING AND CUTTING OFF, AND THE SUPER SOFT FOAM WHICH CAN NOT BE LIFTED BY CRANE. EQUIPPED WITH THE AUTOMATIC MOVABLE CONVEYOR LINE, WHICH CAN MOVE WITH LEFT & RIGHT, UP & DOWN DIRECTION TO CONNECT TO EACH CONVEYOR RACK OF THE SYSTEM. WITH THE TOUCH SCREEN AND PLC AUTO CONTROL, THE FOAM BLOCKS IN THE STORAGE SYSTEM WILL BE MOVED IN AND OUT OF THE STORAGE SYSTEM AUTOMATICALLY. THIS STORAGE SYSTEM WILL HELP THE FOAM CURING PROCESS, AND UTILIZE MORE STORAGE SPACE EFFECTIVELY UNDER LIMITED WORKSHOP, AND SAVE A LOT OF TIME AND LABOR COST. Learn More -

M-5032 FORM PROFILE CUTTING MACHINE WIDTH 1900mmREFERENCE NUMBER: M-5032 (1212126KTY11R) L FORM PROFILE CUTTING MACHINE WIDTH 1900mm MAXIMUM CUTTING HEIGHT: 250mm TABLE WIDTH: 1980mm TABLE LENGTH: 2200mm MAXIMUM MATTRESS DIMENSION: 2100mm X 1900mm FLOOR SPACE: 5185 X 6010 X H 2200 TABLE SPEED: 5 TO 25 M/MIN POWER: 15 KW CURRENT: 30A MASS: 4876 KG PRESSURE: 6 BAR QUANTITY AVAILABLE: 1 Learn More

M-5032 FORM PROFILE CUTTING MACHINE WIDTH 1900mmREFERENCE NUMBER: M-5032 (1212126KTY11R) L FORM PROFILE CUTTING MACHINE WIDTH 1900mm MAXIMUM CUTTING HEIGHT: 250mm TABLE WIDTH: 1980mm TABLE LENGTH: 2200mm MAXIMUM MATTRESS DIMENSION: 2100mm X 1900mm FLOOR SPACE: 5185 X 6010 X H 2200 TABLE SPEED: 5 TO 25 M/MIN POWER: 15 KW CURRENT: 30A MASS: 4876 KG PRESSURE: 6 BAR QUANTITY AVAILABLE: 1 Learn More -

M-0324 PROFILING MACHINE F2200 FOR FOAM MATTRESSES, MATTRESSES, MAXIMUM WIDTH 2200mmREFERENCE NUMBER: M-0324 PROFILING MACHINE F2200 FOR FOAM MATTRESSES, MATTRESSES, MAXIMUM WIDTH 2200mm WORKING CUTTING WIDTH 2200mm WORKING CUTTING HEIGHT 20/200mm QUANTITY AVAILABLE: 1 Learn More

M-0324 PROFILING MACHINE F2200 FOR FOAM MATTRESSES, MATTRESSES, MAXIMUM WIDTH 2200mmREFERENCE NUMBER: M-0324 PROFILING MACHINE F2200 FOR FOAM MATTRESSES, MATTRESSES, MAXIMUM WIDTH 2200mm WORKING CUTTING WIDTH 2200mm WORKING CUTTING HEIGHT 20/200mm QUANTITY AVAILABLE: 1 Learn More -

M-0323 PROFILING MACHINE F2000 FOR FOAM MATTRESSES,MATTRESSES,MAXIMUM WIDTH 2200mm

M-0323 PROFILING MACHINE F2000 FOR FOAM MATTRESSES,MATTRESSES,MAXIMUM WIDTH 2200mmREFERENCE NUMBER: M-0323 PROFILING MACHINE F2000 FOR FOAM MATTRESSES,MATTRESSES,MAXIMUM WIDTH 2200mm WORKING CUTTING WIDTH: 2000mm WORKING CUTTING HEIGHT: 20 / 180mm QUANTITY AVAILABLE: 1

Learn More -

T-8385 AUTOMATIC DIE CUTTING MACHINE, DOUBLE SIDE, CUTTING FORCE 100 TONS, CUTTING AREA 810 X 1600mmT-8385 AUTOMATIC DIE CUTTING MACHINE, DOUBLE SIDE, CUTTING FORCE 100 TONS, CUTTING AREA 810 X 1600mm WEIGHT: 5200KG DIMENSION: 2300 X 3250 X 1680mm QUANTITY: 1 Learn More

T-8385 AUTOMATIC DIE CUTTING MACHINE, DOUBLE SIDE, CUTTING FORCE 100 TONS, CUTTING AREA 810 X 1600mmT-8385 AUTOMATIC DIE CUTTING MACHINE, DOUBLE SIDE, CUTTING FORCE 100 TONS, CUTTING AREA 810 X 1600mm WEIGHT: 5200KG DIMENSION: 2300 X 3250 X 1680mm QUANTITY: 1 Learn More -

TT-3371 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE, YEAR 1986TT-3371 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE, YEAR 1986 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE YEAR OF CONSTRUCTION 1986 CONDITION USED QUANTITY: 1 Learn More

TT-3371 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE, YEAR 1986TT-3371 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE, YEAR 1986 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE YEAR OF CONSTRUCTION 1986 CONDITION USED QUANTITY: 1 Learn More -

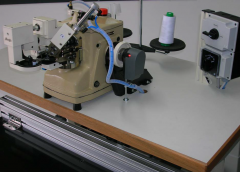

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More