Search results for: 'MACHINE+SHO'

-

J-4925 SCHMIDT BALER AND UNBALERJ-4925 SCHMIDT BALER AND UNBALER MAKE: SCHMIDT, CO. INC. MODEL: FSB MANUFACTURING DATE: 9-30-09 QUANTITY: 1 Learn More

J-4925 SCHMIDT BALER AND UNBALERJ-4925 SCHMIDT BALER AND UNBALER MAKE: SCHMIDT, CO. INC. MODEL: FSB MANUFACTURING DATE: 9-30-09 QUANTITY: 1 Learn More -

TT-2767 MELCO AMAYA EMBROIDERY MACHINE, 16 NEEDLES/COLORSTT-2767 MELCO AMAYA EMBROIDERY MACHINE, 16 NEEDLES/COLORS MELCO AMAYA EMBROIDERY MACHINE SINGLE HEAD EMBROIDERY MACHINES 16 NEEDLES/COLORS COMPUTERIZED Learn More

TT-2767 MELCO AMAYA EMBROIDERY MACHINE, 16 NEEDLES/COLORSTT-2767 MELCO AMAYA EMBROIDERY MACHINE, 16 NEEDLES/COLORS MELCO AMAYA EMBROIDERY MACHINE SINGLE HEAD EMBROIDERY MACHINES 16 NEEDLES/COLORS COMPUTERIZED Learn More -

TT-1821 NISSEI ASB PF8-4B INJECTION STRETCH BLOW MOULDING MACHINE, YEAR 2008TT-1821 NISSEI ASB PF8-4B INJECTION STRETCH BLOW MOULDING MACHINE, YEAR 2008 AVAILABILITY: IMMEDIATE QUANTITY: 1 Learn More

TT-1821 NISSEI ASB PF8-4B INJECTION STRETCH BLOW MOULDING MACHINE, YEAR 2008TT-1821 NISSEI ASB PF8-4B INJECTION STRETCH BLOW MOULDING MACHINE, YEAR 2008 AVAILABILITY: IMMEDIATE QUANTITY: 1 Learn More -

TT-1524 TUFTING ROBOT, YEAR 2019, MAXIMUM CARPET SIZE 4 METERS x 3 METERSTT-1524 TUFTING ROBOT, YEAR 2019, MAXIMUM CARPET SIZE 4 METERS x 3 METERS INCLUDING 2 SOFTWARE LICENSES AND ARTIFICIAL GRASS YARN FULL WORKING CONDITION YEAR: 2019 MADE BY GERMAN COMPANY EFAB STATUS: CURRENTLY RUNNING Learn More

TT-1524 TUFTING ROBOT, YEAR 2019, MAXIMUM CARPET SIZE 4 METERS x 3 METERSTT-1524 TUFTING ROBOT, YEAR 2019, MAXIMUM CARPET SIZE 4 METERS x 3 METERS INCLUDING 2 SOFTWARE LICENSES AND ARTIFICIAL GRASS YARN FULL WORKING CONDITION YEAR: 2019 MADE BY GERMAN COMPANY EFAB STATUS: CURRENTLY RUNNING Learn More -

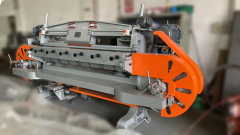

J-4504 RUBBER EVA SPLITTING MACHINE (SKIVING MACHINE), WORKING WIDTH 1780mmJ-4504 RUBBER EVA SPLITTING MACHINE (SKIVING MACHINE), WORKING WIDTH 1780mm WEIGHT: ABOUT 3.5 TONS REQUIRES 1 20 FOOT CONTAINER QUANTITY: 1 Learn More

J-4504 RUBBER EVA SPLITTING MACHINE (SKIVING MACHINE), WORKING WIDTH 1780mmJ-4504 RUBBER EVA SPLITTING MACHINE (SKIVING MACHINE), WORKING WIDTH 1780mm WEIGHT: ABOUT 3.5 TONS REQUIRES 1 20 FOOT CONTAINER QUANTITY: 1 Learn More -

TT-1037 SINGLE COLUMN TENSILE STRENGTH TESTERTT-1037 SINGLE COLUMN TENSILE STRENGTH TESTER KEY SPECIFICATIONS CAPACITY: 50N, 100N, 200N, 500N, 1KN, 2KN, 2.5KN, 5KN DISPLAY: COMPUTER DISPLAY FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RANGE: 1000mm STROKE RESOLUTION: 0.001mm TEST SPEED: 0.001-1000mm/MIN CAN SET ON DISPLAY, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON. SPECIMEN DAMAGE AUTOMATIC STOP MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 120W POWER SUPPLY: AC 220V 50-60Hz 10A DIMENSIONS: APPROX 500 X 400 X 1450mm WEIGHT: 60KG ACCESSORIES: STANDARDS ACCESSORIES: 1 SET MANUAL GRIPS, 1 PC LOAD CELL, 1 PC ENGLISH OPERATION SOFTWARE, 1 PC CABLE CONNECT WITH PC OPTION ACCESSORIES: OPTIONAL DESKTOP COMPUTER OPTIONAL OTHER GRIPS QUANTITY: 1 Learn More

TT-1037 SINGLE COLUMN TENSILE STRENGTH TESTERTT-1037 SINGLE COLUMN TENSILE STRENGTH TESTER KEY SPECIFICATIONS CAPACITY: 50N, 100N, 200N, 500N, 1KN, 2KN, 2.5KN, 5KN DISPLAY: COMPUTER DISPLAY FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RANGE: 1000mm STROKE RESOLUTION: 0.001mm TEST SPEED: 0.001-1000mm/MIN CAN SET ON DISPLAY, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON. SPECIMEN DAMAGE AUTOMATIC STOP MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 120W POWER SUPPLY: AC 220V 50-60Hz 10A DIMENSIONS: APPROX 500 X 400 X 1450mm WEIGHT: 60KG ACCESSORIES: STANDARDS ACCESSORIES: 1 SET MANUAL GRIPS, 1 PC LOAD CELL, 1 PC ENGLISH OPERATION SOFTWARE, 1 PC CABLE CONNECT WITH PC OPTION ACCESSORIES: OPTIONAL DESKTOP COMPUTER OPTIONAL OTHER GRIPS QUANTITY: 1 Learn More -

V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETERV-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE WARP DENSITY: 0.3 TO 0.65 G/cm3; BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER; BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE); LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS; LENGTH MEASURING ACCURACY: ±0.1%; PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE; EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT; REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE; REED TRAVERSE ADJUSTMENT: MANUALLY; REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE; EXPANSION REED STRETCH METHOD: ELECTRICAL; REED CENTERING METHOD: ELECTRICAL; BEAM CLAMP: PNEUMATIC; PRESS ROLLER CENTERING: ELECTRICAL; WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR. QUANTITY: 1 SET SHIPPING NOTICE: 1 40FT CONTAINER FOR WARPER AND CREEL 1 40FT CONTAINER FOR 48 BEAMS TIME TO BUILD THE MACHINE: 100 DAYS Learn More

V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETERV-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE WARP DENSITY: 0.3 TO 0.65 G/cm3; BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER; BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE); LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS; LENGTH MEASURING ACCURACY: ±0.1%; PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE; EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT; REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE; REED TRAVERSE ADJUSTMENT: MANUALLY; REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE; EXPANSION REED STRETCH METHOD: ELECTRICAL; REED CENTERING METHOD: ELECTRICAL; BEAM CLAMP: PNEUMATIC; PRESS ROLLER CENTERING: ELECTRICAL; WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR. QUANTITY: 1 SET SHIPPING NOTICE: 1 40FT CONTAINER FOR WARPER AND CREEL 1 40FT CONTAINER FOR 48 BEAMS TIME TO BUILD THE MACHINE: 100 DAYS Learn More -

YY-1834 AUTOMATIC ANGLE FOAM CUTTING MACHINE WITH CONVEYOR, CUTTING ANGLE 16 TO 60°YY-1834 AUTOMATIC ANGLE FOAM CUTTING MACHINE WITH CONVEYOR, CUTTING ANGLE 16 TO 60° THE MACHINE IS WITH TOUCH SCREEN & PLC AUTO CONTROL, THE CUTTING BLADE CAN MOVE UP & DOWN AUTOMATICALLY, WITH AUTOMATIC CONVEYOR AND POSITIONING BAR TO LOAD THE FOAM SHEET. WITH MOTOR TO ADJUST THE ANGLE, WITH A METER TO SHOW THE ANGLE WITH TOUCH SCREEN AND MOTOR TO CONTROL THE BELT AND BLADE FRAME UP AND DOWN, AND VACUUM MOTOR TO SUCK THE FOAM SHEET DOWN. HOT NEW FEATURE: CONVEYOR HAS PERFORATIONS AND MATERIAL BEING CUT STAYS STABLE IN ITS POSITION DUE TO THE SUCTION MOTOR PROVIDING SUCTION THROUGH CONVEYOR PERFORATIONS, ALLOWS MACHINE TO GIVE CLEAN CUTS EVERY TIME. QUANTITY: 1 Learn More

YY-1834 AUTOMATIC ANGLE FOAM CUTTING MACHINE WITH CONVEYOR, CUTTING ANGLE 16 TO 60°YY-1834 AUTOMATIC ANGLE FOAM CUTTING MACHINE WITH CONVEYOR, CUTTING ANGLE 16 TO 60° THE MACHINE IS WITH TOUCH SCREEN & PLC AUTO CONTROL, THE CUTTING BLADE CAN MOVE UP & DOWN AUTOMATICALLY, WITH AUTOMATIC CONVEYOR AND POSITIONING BAR TO LOAD THE FOAM SHEET. WITH MOTOR TO ADJUST THE ANGLE, WITH A METER TO SHOW THE ANGLE WITH TOUCH SCREEN AND MOTOR TO CONTROL THE BELT AND BLADE FRAME UP AND DOWN, AND VACUUM MOTOR TO SUCK THE FOAM SHEET DOWN. HOT NEW FEATURE: CONVEYOR HAS PERFORATIONS AND MATERIAL BEING CUT STAYS STABLE IN ITS POSITION DUE TO THE SUCTION MOTOR PROVIDING SUCTION THROUGH CONVEYOR PERFORATIONS, ALLOWS MACHINE TO GIVE CLEAN CUTS EVERY TIME. QUANTITY: 1 Learn More -

J-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPESJ-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPES LABEL SHEARING AND FOLDING MACHINE AUTOMATIC SLIDING PATH OF LABEL ABLE TO SHEAR AND FOLD 5 TYPES OF LABELS BY ONLY REPLACING THE MOLD ADJUSTABLE LABEL LENGTH WITHOUT ANY TOOLS AND CAN BE SEPARATELY FITTED WITH ELECTRONIC EYE SYSTEM IF NEEDED USED FOR PRINTING LABELS AND CUTTING AND FOLDING WITHOUT PUSH-LINE SHEARING AND FOLDING TYPES: END FOLD, CENTER FOLD, TRIANGLE FOLD, LENGTHFOLD CUTTING LENGTH: 15 TO 16mm CUTTING WIDTH: 10 TO 75mm CUTTER TYPE: COOLED SHEARING, HOT SHEARING CUTTING SPEED: 30 TO 200 METERS PER MINUTE POWER: 220 VOLTS, SINGLE PHASE, 60 OR 50 Hz TOTAL POWER: 1.8 KW HORSEPOWER: ½ HP WEIGHT: 295 KG PACKED DIMENSIONS: 1100 x 950 x 1620mm QUANTITY: 1 Learn More

J-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPESJ-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPES LABEL SHEARING AND FOLDING MACHINE AUTOMATIC SLIDING PATH OF LABEL ABLE TO SHEAR AND FOLD 5 TYPES OF LABELS BY ONLY REPLACING THE MOLD ADJUSTABLE LABEL LENGTH WITHOUT ANY TOOLS AND CAN BE SEPARATELY FITTED WITH ELECTRONIC EYE SYSTEM IF NEEDED USED FOR PRINTING LABELS AND CUTTING AND FOLDING WITHOUT PUSH-LINE SHEARING AND FOLDING TYPES: END FOLD, CENTER FOLD, TRIANGLE FOLD, LENGTHFOLD CUTTING LENGTH: 15 TO 16mm CUTTING WIDTH: 10 TO 75mm CUTTER TYPE: COOLED SHEARING, HOT SHEARING CUTTING SPEED: 30 TO 200 METERS PER MINUTE POWER: 220 VOLTS, SINGLE PHASE, 60 OR 50 Hz TOTAL POWER: 1.8 KW HORSEPOWER: ½ HP WEIGHT: 295 KG PACKED DIMENSIONS: 1100 x 950 x 1620mm QUANTITY: 1 Learn More -

U-1369 RING TWISTER MACHINE RT-723 WITH NYLON BOBBINS, 10 INCH DIAMETER RING, 18 SPINDLESU-1369 RING TWISTER MACHINE RT-723 WITH NYLON BOBBINS, 10 INCH DIAMETER RING, 18 SPINDLES PRODUCTION CAPACITY: ABOUT 1.3 KG PER SPINDLE PER HOUR, AT 100 TWISTS PER METER AND 3800 RPM QUANTITY: 1 Learn More

U-1369 RING TWISTER MACHINE RT-723 WITH NYLON BOBBINS, 10 INCH DIAMETER RING, 18 SPINDLESU-1369 RING TWISTER MACHINE RT-723 WITH NYLON BOBBINS, 10 INCH DIAMETER RING, 18 SPINDLES PRODUCTION CAPACITY: ABOUT 1.3 KG PER SPINDLE PER HOUR, AT 100 TWISTS PER METER AND 3800 RPM QUANTITY: 1 Learn More