V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER

V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER

MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE

WARP DENSITY: 0.3 TO 0.65 G/cm3;

BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER;

BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE);

LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH

MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS;

LENGTH MEASURING ACCURACY: ±0.1%;

PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE;

EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT;

REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE;

REED TRAVERSE ADJUSTMENT: MANUALLY;

REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE;

EXPANSION REED STRETCH METHOD: ELECTRICAL;

REED CENTERING METHOD: ELECTRICAL;

BEAM CLAMP: PNEUMATIC;

PRESS ROLLER CENTERING: ELECTRICAL;

WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR.

QUANTITY: 1 SET

SHIPPING NOTICE:

1 40FT CONTAINER FOR WARPER AND CREEL

1 40FT CONTAINER FOR 48 BEAMS

TIME TO BUILD THE MACHINE: 100 DAYS

In stock

SKU

V-2005

REFERENCE NUMBER: V-2005

WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER

MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE

WARP DENSITY: 0.3 TO 0.65 G/cm3;

BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER;

BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE);

LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH

MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS;

LENGTH MEASURING ACCURACY: ±0.1%;

PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE;

EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT;

REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE;

REED TRAVERSE ADJUSTMENT: MANUALLY;

REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE;

EXPANSION REED STRETCH METHOD: ELECTRICAL;

REED CENTERING METHOD: ELECTRICAL;

BEAM CLAMP: PNEUMATIC;

PRESS ROLLER CENTERING: ELECTRICAL;

WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR;

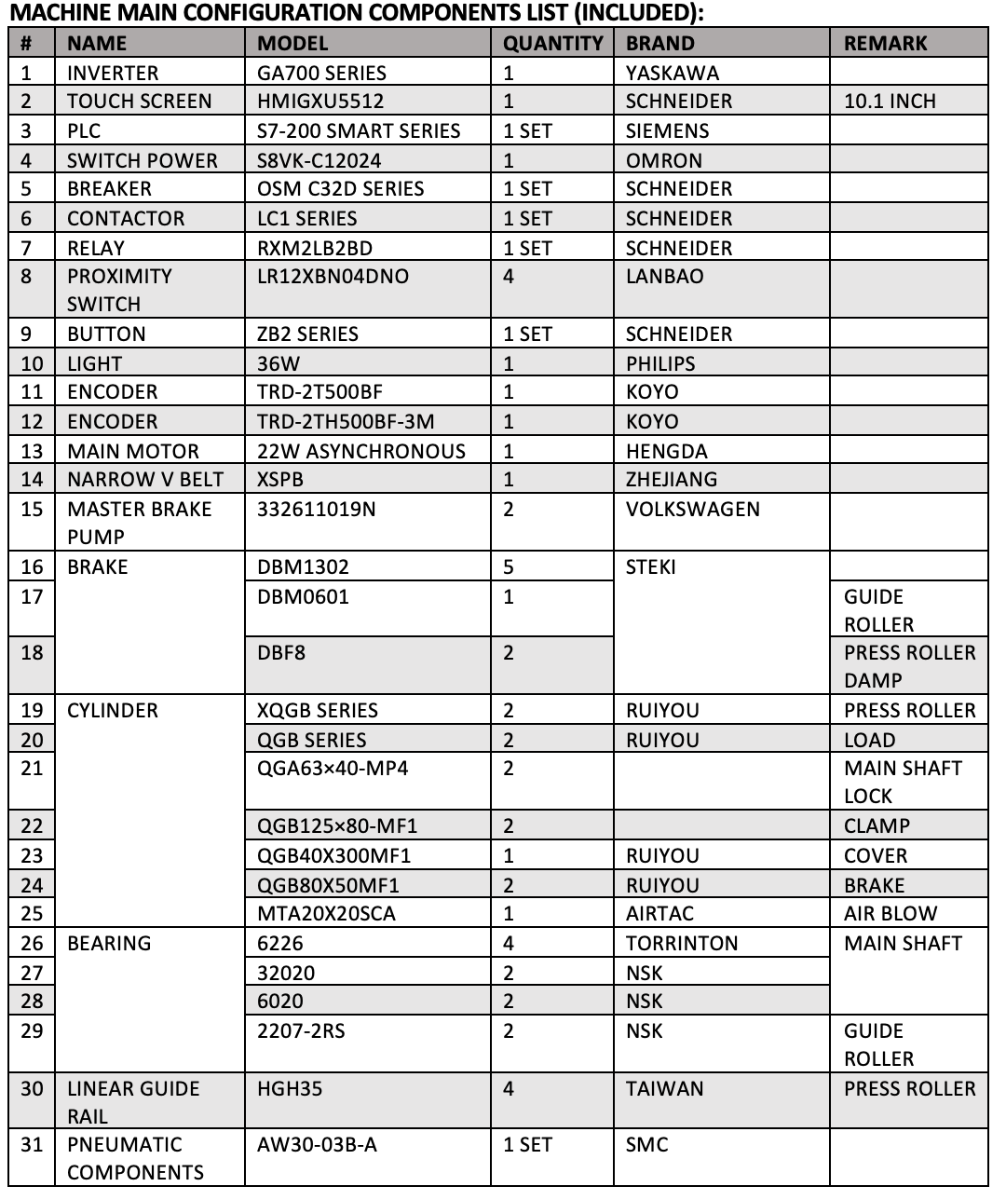

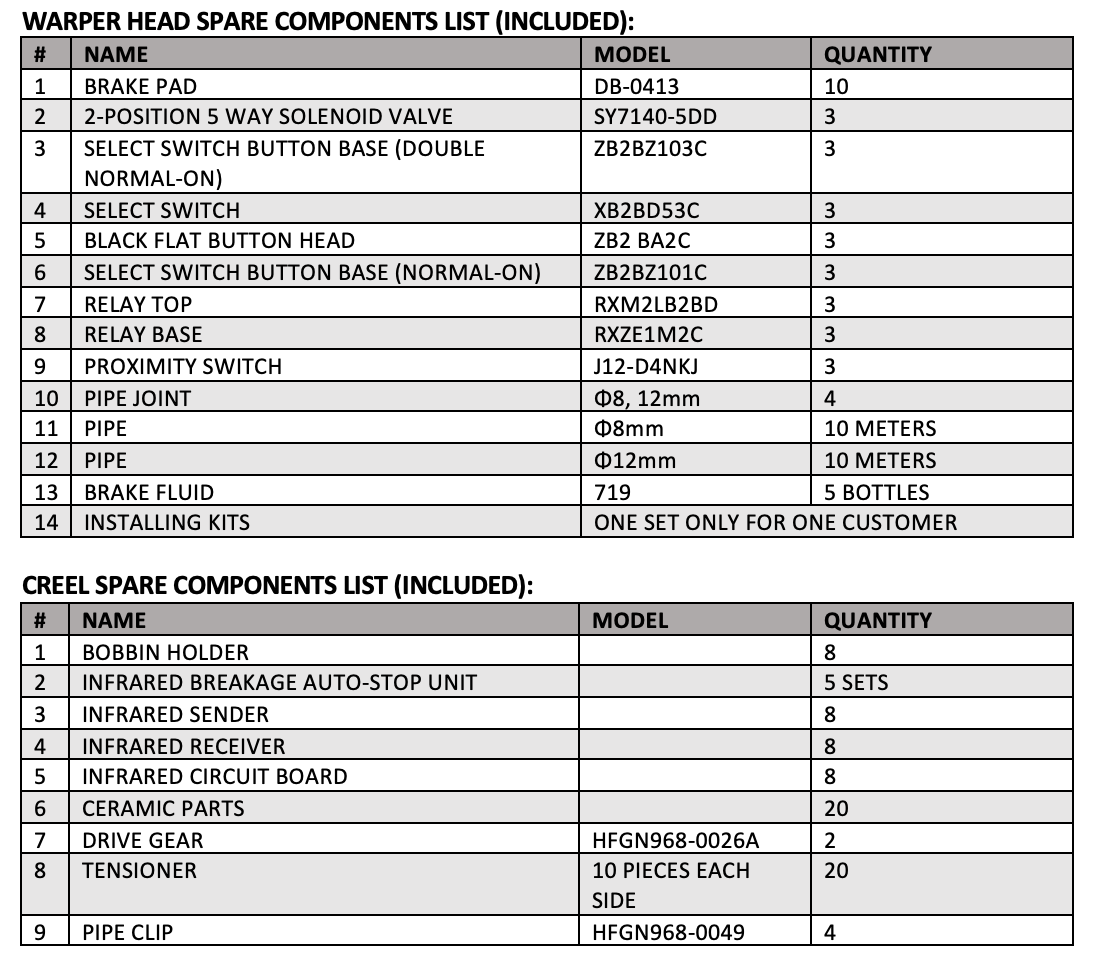

FRAME STRUCTURE:

40mm THICKNESS STEEL PLATE WALL, THE FRAME STRUCTURE IS COMPOSED OF BOTTOM BORDER, WALL AND THREE BEAMS. GOOD RIGIDITY, HIGH POSITIONING ACCURACY BETWEEN BEAM AND HOLES, NO DISTORTION, SOLID FOUNDATION FOR HIGH-SPEED RUNNING.

MAIN DRIVE:

THE MOTOR ROTATING SPEED REDUCES PROGRESSIVELY WHEN WARPING BEAM DIAMETER INCREASES GRADUALLY. SO AS TO MAKE YARN WINDING IN CONSTANT LINE SPEED AND MAINTAIN THE SAME YARN TENSION, ENSURES THE BEST WARPING BEAM SHAPE. 22KW.

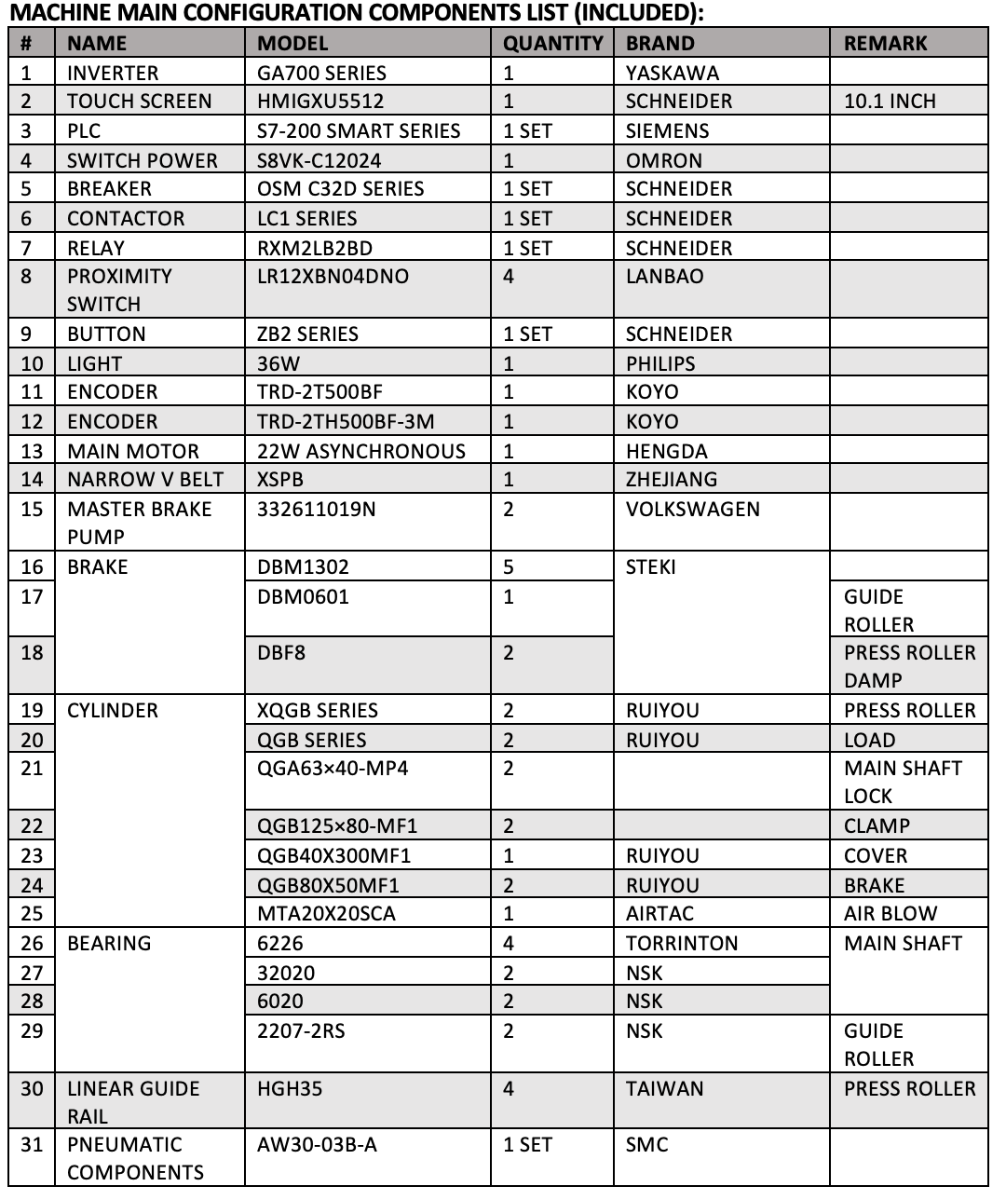

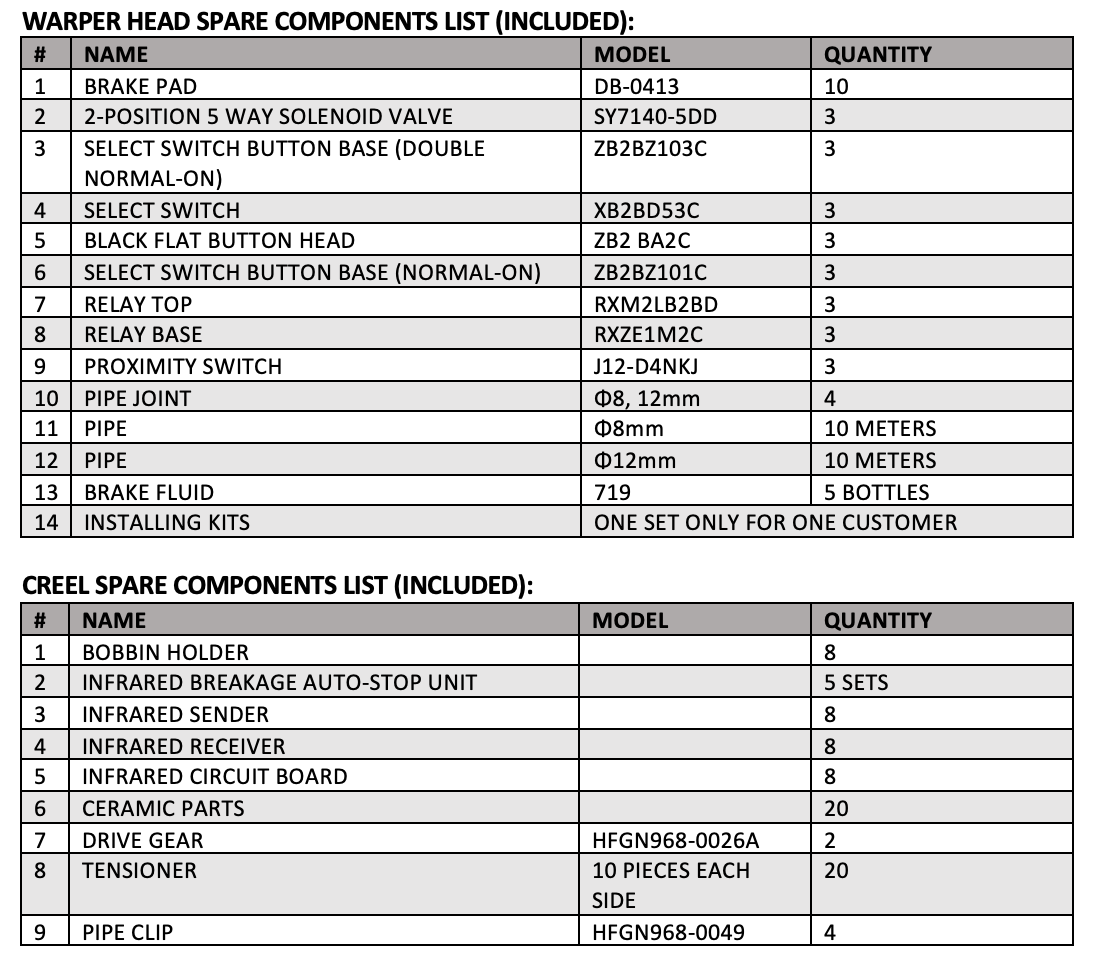

BRAKE SYSTEM:

WARPING BEAM BRAKE DISCS ARE CONNECTED TOGETHER WITH BELL WHEEL BY HIGH-STRENGTH BOLT, WHEN BRAKING, THE INERTIA FORCE DIRECTLY EFFECTS THE BRAKE DISCS, SMOOTHLY AND WITH POWER. WITH DIFFERENT WARPING SPEED, THE BRAKING PRESSURE CAN BE ADJUSTED BY REGULATING VALVE. KEEPING SAME BRAKING EFFECT BY REDUCING THE BRAKING PRESSURE, MAXIMUM PROTECTION OF THE BRAKING SYSTEM, REDUCES LOSSES. HYDRAULIC BRAKE DISCS ARE INCORPORATED ON WARPING BEAM AND PRESSER ROLLER. PERFORMANCE AND QUALITY ARE HIGHLY GUARANTEED. GUIDE ROLLER ALSO USES HYDRAULIC BRAKE DISCS, IN CASE OF FRICTION BETWEEN GUIDE ROLLER AND YARN.

WARPING BEAM CLAMP:

PUSH OUT AND CLAMP THE WARPING BEAM BY TWO CYLINDERS. LOCKING CYLINDERS ON BOTH SIDES TO PREVENT BEAM LOOSENING WHEN HIGH SPEED RUNNING, THUS GUARANTEEING THE SAFETY OF OPERATION.

PRESS ROLLER:

1. PRESS ROLLER IS MADE BY FRP, ALSO ASSEMBLED WITH LIGHTWEIGHT HIGH STRENGTH ALUMINUM WHEEL ARM. PNEUMATIC CYLINDER PULLS PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINE GUIDE, AIR PRESSURE CAN BE ADJUSTED BY PRECISE REGULATING VALVE, DIFFERENT PRESSURE LEAD DIFFERENT DENSITY OF BEAMS. TO MAKE PRESSURE STEADIER, TWO DAMPING DISCS ARE USED ON THE SYSTEM, ALSO ENSURE THE ROUNDNESS OF THE BEAM.

2. IN CASE OF RELATIVE ROTATION FOR PRESS ROLLER AND BEAM WHEN BRAKING, WHICH CAN CAUSE YARN DAMAGE, IT IS DESIGNED TO RAPIDLY RUN BACKWARDS FOR THE PRESS ROLLER. WHEN BRAKING, PRESS ROLLER STOPS ROTATING AND MOVES BACKWARD RAPIDLY FROM YARN SURFACE, THEN PRESSES AGAIN ON THE YARN.

3. TO ENSURE PRESSER ROLLER AND WARPING BEAM COOPERATE PERFECTLY, A WORM GEAR REDUCER IS DESIGNED ON THE PRESSER ROLLER TO MAKE PRESSER ROLLER TO MOVE LEFT AND RIGHT ON LINEAR GUIDE RAIL, ENSURING THE SAME DISTANCE BETWEEN PRESS ROLLER EDGE AND BOTH SIDES OF THE BEAM DISCS.

EXPANSION REED:

W SHAPE EXPANSION REED, INDIVIDUAL MOTOR CONTROLS THE SCREW AND NUTS TO ADJUST THE REED ELONGATION AND SHORTENING, REED DENSITY AND WORKING WIDTH. EXPANSION REED MOVES IN X AND Y AXIS WHICH CAN PREVENT YARN BREAKAGE AND INCREASE THE LIFE OF THE REED. IT CAN ALSO ARRANGE FOR YARN CROSS WINDING, UNIFORMLY WINDING ON THE WARPING BEAM. THE REED MOVING LEFT AND RIGHT, THE CENTERING OF THE EXPANSION CENTER WITH THE WARPING BEAM CENTER ARE BOTH CONVENIENTLY CONTROLLED BY BUTTONS ON THE SAFETY BAR. THE AIR BLOWING PERFORATIONS IN FRONT THE EXPANSION REED, ENSURES THE EXPANSION REED IS CLEAN, THE BLOWING TIME AND INTERVAL TIME IS SET ON THE TOUCH SCREEN AS REQUIRED. THE AIR BLOWING PIPE CAN BE ROTATED THROUGH THE AIR CYLINDER, PREVENTS ENTANGLING WITH THE YARN WHEN WORKING.

SAFETY BAR:

THERE ARE VARIOUS BUTTONS ON SAFETY BAR, INCHING, RUNNING, REED DENSITY, CENTERING, PRESSER ROLLER CENTERING ETC. THE MACHINE WILL WORK ONLY AFTER THE SAFETY BAR IS PULLED DOWN. DURING WORKING, IF AN EMERGENCY HAPPENS, PRESS STRONGLY ON THE BAR OR LIFT IT UP, THE MACHINE WILL STOP IMMEDIATELY.

WARPER AND CREEL:

WARPER:

528 LIVE ENDS

528 RESERVE POSITIONS (MAGAZINE)

WARPER HEAD 2370mm FRONT TO BACK BY 3320mm TOTAL WIDTH

CREEL (SWIVEL):

LENGTH: 16900mm BY 5290mm WIDE

GAUGE: 350mm VERTICAL X 350mm HORIZONTAL (CREEL PITCH)

5 METER DISTANCE BETWEEN CREEL AND WARPER HEAD

2 TRAVELING CLEANERS

INFRARED STOP MOTIONS

STOP MOTIONS DISK TYPE 3 PILLAR TYPE YARN TENSIONERS

TOTAL HEIGHT TO TOP OF TRAVELING CLEANER IS: 3315mm

HEIGHT OF CREEL BY ITSELF IS: 2450mm

NUMBER OF LAYERS (TIERS): 6

CONES: ARE LOADED FROM THE CREEL CENTER (INSIDE), AND YARNS ARE GUIDED FROM CREEL OUTSIDE.

TENSIONERS

BEAMS:

1800mm WIDTH X 1400mm DIAMETER FLANGE

PIPES (CORES): ARE SEAMLESS STEEL PIPES

CORE: 9mm WALL THICKNESS

CORE: 454mm DIAMETER

BRAKE DISCS: ARE CASTINGS

DISCS: ARE MADE OF ALUMINUM ALLOY.

CAST BEAM FLANGE

MOTOR LIST AND DESCRIPTION:

1. MAIN MOTOR 22KW

2. EXPANSION REED HAS 2 MOTORS.

UP DOWN MOTOR 180W WITH GEAR REDUCER 1:60 AND LEFT RIGHT MOTOR 90W WITH GEAR REDUCER 1:15

3. PRESS ROLLER LEFT AND RIGHT MOTOR

180W. WITH GEAR REDUCER 1:100

QUANTITY: 1 SET

SHIPPING NOTICE:

1 40FT CONTAINER FOR WARPER AND CREEL

1 40FT CONTAINER FOR 48 BEAMS

TIME TO BUILD THE MACHINE: 100 DAYS

QUANTITY: 1 SET

SHIPPING NOTICE:

1 40FT CONTAINER FOR WARPER AND CREEL

1 40FT CONTAINER FOR 48 BEAMS

TIME TO BUILD THE MACHINE: 100 DAYS

QUANTITY: 1 SET

SHIPPING NOTICE:

1 40FT CONTAINER FOR WARPER AND CREEL

1 40FT CONTAINER FOR 48 BEAMS

TIME TO BUILD THE MACHINE: 100 DAYS

QUANTITY: 1 SET

SHIPPING NOTICE:

1 40FT CONTAINER FOR WARPER AND CREEL

1 40FT CONTAINER FOR 48 BEAMS

TIME TO BUILD THE MACHINE: 100 DAYS

| Video | https://youtu.be/bMTTSRh_Ss0, https://youtu.be/pzQAXFSWHys, https://youtu.be/ZGVp4CKYIZ8 |

|---|

Write Your Own Review