Search results for: 'control panel''

- Related search terms

- control pane

- Control pa

- Control+pan

- control+pane

- control+pro'

-

TT-5991 CATERPILLAR 3516B HD PRIME DIESEL GENERATOR – NEW, 1820 KW, YEAR 2022 AND 2023TT-5991 CATERPILLAR 3516B HD PRIME DIESEL GENERATOR – NEW, 1820 KW, YEAR 2022 AND 2023 CATERPILLAR 3516B HD – NEW YEAR: 2022 AND 2023 HOURS: ZERO 1820 KW FUEL: DIESEL OIL IMMEDIATE DELIVERY QUANTITY: 5 Learn More

TT-5991 CATERPILLAR 3516B HD PRIME DIESEL GENERATOR – NEW, 1820 KW, YEAR 2022 AND 2023TT-5991 CATERPILLAR 3516B HD PRIME DIESEL GENERATOR – NEW, 1820 KW, YEAR 2022 AND 2023 CATERPILLAR 3516B HD – NEW YEAR: 2022 AND 2023 HOURS: ZERO 1820 KW FUEL: DIESEL OIL IMMEDIATE DELIVERY QUANTITY: 5 Learn More -

TT-3156 SITOLA SVC-A AUTOMATIC VERTICAL FOAM CUTTING MACHINE, YEAR 2021TT-3156 SITOLA SVC-A AUTOMATIC VERTICAL FOAM CUTTING MACHINE, YEAR 2021 CONDITION: NEW MACHINE MACHINE TYPE: AUTOMATIC VERTICAL FOAM CUTTING MACHINE MANUFACTURER: SITOLA MODEL: SVC-A YEAR OF CONSTRUCTION: 2021 CONDITION: NEW UPDATE: 23.08.2023 THE AUTOMATIC VERTICAL CUTTING MACHINE TYPE SITOLA SVC IS USED TO CUT SHEETS OR TRIM BLOCKS OF PU AND PE FOAMS, REBONDED FOAMS AND SIMILAR MATERIALS IN THE INDUSTRIES OF FURNITURE, MATTRESSES AND PACKING. Learn More

TT-3156 SITOLA SVC-A AUTOMATIC VERTICAL FOAM CUTTING MACHINE, YEAR 2021TT-3156 SITOLA SVC-A AUTOMATIC VERTICAL FOAM CUTTING MACHINE, YEAR 2021 CONDITION: NEW MACHINE MACHINE TYPE: AUTOMATIC VERTICAL FOAM CUTTING MACHINE MANUFACTURER: SITOLA MODEL: SVC-A YEAR OF CONSTRUCTION: 2021 CONDITION: NEW UPDATE: 23.08.2023 THE AUTOMATIC VERTICAL CUTTING MACHINE TYPE SITOLA SVC IS USED TO CUT SHEETS OR TRIM BLOCKS OF PU AND PE FOAMS, REBONDED FOAMS AND SIMILAR MATERIALS IN THE INDUSTRIES OF FURNITURE, MATTRESSES AND PACKING. Learn More -

J-4901 GRIBETZ RELIANCE M 4 QUILTER WITH PANEL CUTTER, QUILTING WIDTH 90 INCHES, YEAR 2008-CHAINSTITCH, 3 BAR, 1 X 3 X 6J-4901 GRIBETZ RELIANCE M 4 QUILTER WITH PANEL CUTTER, QUILTING WIDTH 90 INCHES, YEAR 2008-CHAINSTITCH, 3 BAR, 1 X 3 X 6 QUANTITY: 1 Learn More

J-4901 GRIBETZ RELIANCE M 4 QUILTER WITH PANEL CUTTER, QUILTING WIDTH 90 INCHES, YEAR 2008-CHAINSTITCH, 3 BAR, 1 X 3 X 6J-4901 GRIBETZ RELIANCE M 4 QUILTER WITH PANEL CUTTER, QUILTING WIDTH 90 INCHES, YEAR 2008-CHAINSTITCH, 3 BAR, 1 X 3 X 6 QUANTITY: 1 Learn More -

YY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINEYY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: 1. BAG SIZE: BASED ON CUSTOMER'S REQUEST; 2. SPEED: 120 TO 180 BAGS/MIN; 3. PACKING MATERIALS: PAPER + PAPER, PAPER + PLASTIC, 4. PACKAGE MATERIAL DIAMETER Φ≤350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; 5. VOLTAGE: 3 PHASE 380V 50Hz OR 220V 50/60Hz; 6. MOTORS: a. SERVO MOTOR 1.5KW b. SERVO MOTOR: 1KW c. STEPPING MOTOR 110 d. STEPPING MOTOR VARIABLE FREQUENCY MOTOR 0.37KW 7. TOTAL OF 5 MOTORS IS 4KW 8. USES 28 VOLT FOR THE HEAT CIRCUIT, 2 HEATING PANELS, EACH PANEL WITH 8 HEATING TUBES, EACH TUBE IS 300 W, TOTAL 4.8 KW; 9. MACHINE WEIGHT: 800 KG; 10. MACHINE SIZE: LENGTH 5000 × WIDTH 1300 × HEIGHT 1600mm; 11. CRATE SHIPPING DATA: LENGTH 2600 × WIDTH 1900 × HEIGHT 1800mm. 12. TOTAL OF 5 MOTORS IS: 4KW QUANTITY: 1 Learn More

YY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINEYY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: 1. BAG SIZE: BASED ON CUSTOMER'S REQUEST; 2. SPEED: 120 TO 180 BAGS/MIN; 3. PACKING MATERIALS: PAPER + PAPER, PAPER + PLASTIC, 4. PACKAGE MATERIAL DIAMETER Φ≤350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; 5. VOLTAGE: 3 PHASE 380V 50Hz OR 220V 50/60Hz; 6. MOTORS: a. SERVO MOTOR 1.5KW b. SERVO MOTOR: 1KW c. STEPPING MOTOR 110 d. STEPPING MOTOR VARIABLE FREQUENCY MOTOR 0.37KW 7. TOTAL OF 5 MOTORS IS 4KW 8. USES 28 VOLT FOR THE HEAT CIRCUIT, 2 HEATING PANELS, EACH PANEL WITH 8 HEATING TUBES, EACH TUBE IS 300 W, TOTAL 4.8 KW; 9. MACHINE WEIGHT: 800 KG; 10. MACHINE SIZE: LENGTH 5000 × WIDTH 1300 × HEIGHT 1600mm; 11. CRATE SHIPPING DATA: LENGTH 2600 × WIDTH 1900 × HEIGHT 1800mm. 12. TOTAL OF 5 MOTORS IS: 4KW QUANTITY: 1 Learn More -

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

SIEMENS S5 AND S7 CONTROLLERS AND COMPONENTSREFERENCE NUMBER: T-6948 SIEMENS S5 AND S7 CONTROLLERS AND COMPONENTS SIEMENS SIMODRIVE POSITIONIERMOTOR SIMODRIVE A 300 SIEMENS KEY PANEL OP270 KEY 6-CSTN KEY-6 CSTN SIEMENS TOUCH PANEL OP270 TOUCH 6-CSTN SIEMENS OPERATOR PANEL OP17-DP 6AV3 SIEMENS COMMUNICATION PROCESSOR 6GK7 SIEMENS LOGIC MODULE 6ED1 SIEMENS FAN MODULE 6ES5 SIEMENS MICROMASTER VECTOR 420 SIEMENS POWER SUPPLY PS 407 6ES7 AND MORE AVAILABLE Learn More

SIEMENS S5 AND S7 CONTROLLERS AND COMPONENTSREFERENCE NUMBER: T-6948 SIEMENS S5 AND S7 CONTROLLERS AND COMPONENTS SIEMENS SIMODRIVE POSITIONIERMOTOR SIMODRIVE A 300 SIEMENS KEY PANEL OP270 KEY 6-CSTN KEY-6 CSTN SIEMENS TOUCH PANEL OP270 TOUCH 6-CSTN SIEMENS OPERATOR PANEL OP17-DP 6AV3 SIEMENS COMMUNICATION PROCESSOR 6GK7 SIEMENS LOGIC MODULE 6ED1 SIEMENS FAN MODULE 6ES5 SIEMENS MICROMASTER VECTOR 420 SIEMENS POWER SUPPLY PS 407 6ES7 AND MORE AVAILABLE Learn More -

A-1243 MACHINERY AND EXTRUSION RELATED MACHINESREFERENCE NUMBER: A-1243 (0101GHBXX12) A MACHINERY AND EXTRUSION RELATED MACHINES REFERENCE #102: 1 BARMAG EXTRUDER DIA. 90 WITH CONTROL PANEL REFERENCE #103: 4 BARMAG EXTRUDERS 28 MM REFERENCE #104: 1 PLASTICIZERS EXTRUDER 40 MM REFERENCE #105: 1 PLASTICISERS EXTRUDER 20 MM REFERENCE #108: 1 NYLON POLYMER DRYER REFERENCE #110: 50 SAHM WINDERS TRAVERSE 200 MM X CORE 35 MM REFERENCE #111: 32 SAHM WINDERS – TRAVERSE 200MM X CORE 35 MM REFERENCE #113: 31 LEESONA WINDERS – TYPE 969 – TRAVERSE 300 MM REFERENCE #114: 9 SAHM WINDERS TYPE 280 – TRAVERSE 300 MM + PANEL REFERENCE #119: 1 OVEN - BARMAG LONG 3000 MM X ENTRANCE 1400 MM REFERENCE #127: 1 SETS OF GODETS 7 ROLLERS – 1150 MM X 200 MM DIA – 2 HEATED ROLLERS AND 1 CHILLED ROLLER + OIL HEATER - BARMAG REFERENCE #129: 1 SET OF GODETS 3 ROLLERS – 1150 X 200 MM DIA - BARMAG REFERENCE #131: NEW PARTS OF A RECYCLING LINE – DIA 120 MM – NEW SCREW – WITH SPAGHETTI DIE – + DAVID BROWN GEARBOX FOR A 150 HP MOTOR REFERENCE #132: 1 LABORATORIUM LDPE “PLASTICIZERS” – EXTRUDER 20MM REFERENCE #134: 1 SEMI-AUTOMATIC BALING-PRESS, PRESSURE 60 TONS, AUTEFA REFERENCE #134B: 1 HORIZONTAL PRESS REFERENCE #137: 1 NEUMAG STAPLE FIBRE CRIMPER – ENTRANCE 80 MM REFERENCE #139: 1 NEUMAG WITRAS 6008R FOR 8 ENDS – ALMOST NEW, ONLY USED FOR A FEW MONTHS YEAR 2000 REFERENCE #142: OIL HEATERS REFERENCE #143: INOX WATERBATH – WIDTH 1200 MM REFERENCE #144: INOX WATERBATH – WIDTH 750 MM REFERENCE #146: SEVERAL SAHM WINDERS FOR CF YARN REFERENCE #147: SEVERAL BARMAG SPINNZWIRN LFW 25 WINDERS REFERENCE #148: STAPLE FIBER CUTTER – TYPE LUMMUS –WITH 2 CUTTER REELS WITH KNIVES REFERENCE #152: 1 SCREENCHANGER – AUTOSCREEN - WAS FITTED ON A 45 MM EXTRUDER REFERENCE #153: SEVERAL FLAT TAPE DIES – 800 MM WIDTH – REFERENCE #164: 2 FANS WITH MOTORS OF ABOUT 12 KW REFERENCE #165: 1 SPAGHETTI DIE REFERENCE #167: 36 SAHM FLANGE WINDERS – TYPE 211 + PANEL QUANTITY AVAILABLE: 35 Learn More

A-1243 MACHINERY AND EXTRUSION RELATED MACHINESREFERENCE NUMBER: A-1243 (0101GHBXX12) A MACHINERY AND EXTRUSION RELATED MACHINES REFERENCE #102: 1 BARMAG EXTRUDER DIA. 90 WITH CONTROL PANEL REFERENCE #103: 4 BARMAG EXTRUDERS 28 MM REFERENCE #104: 1 PLASTICIZERS EXTRUDER 40 MM REFERENCE #105: 1 PLASTICISERS EXTRUDER 20 MM REFERENCE #108: 1 NYLON POLYMER DRYER REFERENCE #110: 50 SAHM WINDERS TRAVERSE 200 MM X CORE 35 MM REFERENCE #111: 32 SAHM WINDERS – TRAVERSE 200MM X CORE 35 MM REFERENCE #113: 31 LEESONA WINDERS – TYPE 969 – TRAVERSE 300 MM REFERENCE #114: 9 SAHM WINDERS TYPE 280 – TRAVERSE 300 MM + PANEL REFERENCE #119: 1 OVEN - BARMAG LONG 3000 MM X ENTRANCE 1400 MM REFERENCE #127: 1 SETS OF GODETS 7 ROLLERS – 1150 MM X 200 MM DIA – 2 HEATED ROLLERS AND 1 CHILLED ROLLER + OIL HEATER - BARMAG REFERENCE #129: 1 SET OF GODETS 3 ROLLERS – 1150 X 200 MM DIA - BARMAG REFERENCE #131: NEW PARTS OF A RECYCLING LINE – DIA 120 MM – NEW SCREW – WITH SPAGHETTI DIE – + DAVID BROWN GEARBOX FOR A 150 HP MOTOR REFERENCE #132: 1 LABORATORIUM LDPE “PLASTICIZERS” – EXTRUDER 20MM REFERENCE #134: 1 SEMI-AUTOMATIC BALING-PRESS, PRESSURE 60 TONS, AUTEFA REFERENCE #134B: 1 HORIZONTAL PRESS REFERENCE #137: 1 NEUMAG STAPLE FIBRE CRIMPER – ENTRANCE 80 MM REFERENCE #139: 1 NEUMAG WITRAS 6008R FOR 8 ENDS – ALMOST NEW, ONLY USED FOR A FEW MONTHS YEAR 2000 REFERENCE #142: OIL HEATERS REFERENCE #143: INOX WATERBATH – WIDTH 1200 MM REFERENCE #144: INOX WATERBATH – WIDTH 750 MM REFERENCE #146: SEVERAL SAHM WINDERS FOR CF YARN REFERENCE #147: SEVERAL BARMAG SPINNZWIRN LFW 25 WINDERS REFERENCE #148: STAPLE FIBER CUTTER – TYPE LUMMUS –WITH 2 CUTTER REELS WITH KNIVES REFERENCE #152: 1 SCREENCHANGER – AUTOSCREEN - WAS FITTED ON A 45 MM EXTRUDER REFERENCE #153: SEVERAL FLAT TAPE DIES – 800 MM WIDTH – REFERENCE #164: 2 FANS WITH MOTORS OF ABOUT 12 KW REFERENCE #165: 1 SPAGHETTI DIE REFERENCE #167: 36 SAHM FLANGE WINDERS – TYPE 211 + PANEL QUANTITY AVAILABLE: 35 Learn More -

G-8386 BAUMER CNC MACHINE YEAR 1988REFERENCE NUMBER: G-6856 56' BAUMER FOAM SKIVER SMALL LOOP (HEAD, PANEL, CONVEYOR NBELT, ROLLERS) BAUMER BSV-R, YEAR: 1983 QUANTITY AVAILABLE: 1 Learn More

G-8386 BAUMER CNC MACHINE YEAR 1988REFERENCE NUMBER: G-6856 56' BAUMER FOAM SKIVER SMALL LOOP (HEAD, PANEL, CONVEYOR NBELT, ROLLERS) BAUMER BSV-R, YEAR: 1983 QUANTITY AVAILABLE: 1 Learn More -

K-8728 BAUMER FOAM CUTTER BSV-R YEAR 1983REFERENCE NUMBER: K-8728 BAUMER FOAM CUTTER BSV-R YEAR 1983 SMALL LOOP (HEAD, PANEL, CONVEYORBELT, ROLLERS) BAUMER BSV-R, 1983, FAB # 4150 IT IS ALL DISMANTLED AND WE DON'T HAVE ANY FRAME WORK FOR THE LOOP BUT WE HAVE ROLLERS THAT CAME OUT OF IT. QUANTITY AVAILABLE: 1 Learn More

K-8728 BAUMER FOAM CUTTER BSV-R YEAR 1983REFERENCE NUMBER: K-8728 BAUMER FOAM CUTTER BSV-R YEAR 1983 SMALL LOOP (HEAD, PANEL, CONVEYORBELT, ROLLERS) BAUMER BSV-R, 1983, FAB # 4150 IT IS ALL DISMANTLED AND WE DON'T HAVE ANY FRAME WORK FOR THE LOOP BUT WE HAVE ROLLERS THAT CAME OUT OF IT. QUANTITY AVAILABLE: 1 Learn More -

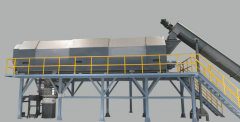

TT-3878 POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSIONTT-3878 POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSION POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSION PELLETIZING SYSTEM W/MOST UPGRADE OPTIONS INCLUDING DUAL CONTROL PANELS, NIP ROLL FEEDER, CUTTER/COMPACTOR INVERTER, SIDEFEEDER, PE AND PP DIES, UPGRADED HORIZONTAL WATER RING PELLETIZER, SCREENER, CYCLONE SCALE. QUANTITY: 1 Learn More

TT-3878 POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSIONTT-3878 POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSION POLYSTAR REPRO-FLEX PLUS 165VS (6.5”) TWO-STAGE EXTRUSION PELLETIZING SYSTEM W/MOST UPGRADE OPTIONS INCLUDING DUAL CONTROL PANELS, NIP ROLL FEEDER, CUTTER/COMPACTOR INVERTER, SIDEFEEDER, PE AND PP DIES, UPGRADED HORIZONTAL WATER RING PELLETIZER, SCREENER, CYCLONE SCALE. QUANTITY: 1 Learn More