Search results for: 'Pillow r'

- Related search terms

- pillow+b

- pillow co

- pillow machine

- pillow+machine

- Pillow fill

-

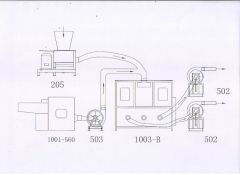

L-2926 COMBINATION PILLOW AND CUSHION FILLING MACHINE FIBER OPENER AND FOAM SHREDDER LINE

L-2926 COMBINATION PILLOW AND CUSHION FILLING MACHINE FIBER OPENER AND FOAM SHREDDER LINEREFERENCE NUMBER: L-2926

Learn More

1 X FIBER CARDING MACHINE

MODEL: 1001-560

1 X FIBER FEEDING MACHINE

MODEL: 503

1 X MIXING MACHINE

MODEL: 1003-B

2 X FILLING MACHINES

MODEL: 502

QUANTITY: 1 SET

FOAM SHREDDER

MODEL: 205

QUANTITY: 1 -

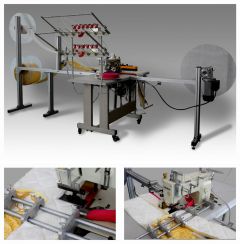

L-5049 FAUX PILLOW-TOP AUTO SEWING MACHINE

L-5049 FAUX PILLOW-TOP AUTO SEWING MACHINEREFERENCE NUMBER: L-5049

Learn More

AUTO SEWING MACHINE

MAX. STITCH LENGTH: 6mm

PRESSER FOOT HEIGHT: 10mm

QUANTITY: 1 -

F-1429 DOWN FILLING MACHINE MODEL SR-3

F-1429 DOWN FILLING MACHINE MODEL SR-3REFERENCE NUMBER: F-1429

down FILLING MACHINE MODEL SR-3

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• TYPE : SR-3

• DIMENSION: 3000 x 2500 x 2000MM

• VOLTAGE: 200/380/415V 50/60HZ 3PHASE

• POWER: 3.8 KW

• FILLING RANGE: 2-100 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±0.2G

• AIR PRESSURE: 0.5 TO 0.8MPA

• THE DEVELOPED COMPUTERIZED DOWN & FEATHER WEIGHING FILLING MACHINE IS MAINLY USED TO FILL JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS, COMFORTERS ETC THAT ARE MADE WITH DOWN & FEATHER AND CONTROLLED BY A COMPUTERIZED WEIGHING SYSTEM.

• THREE HOPPER-SYSTEM FOR CONSTANT SUPPLY

• THE VACUUM FILLING FUNCTION THAT DOES NOT HURT THE MATERIAL AND KEEPS THE ORIGINAL ELASTICITY AND SOFT-HAND FEELING.

• ACCURATE WEIGHING RESULTS; THE TOLERANCE IS WITHIN 0.2 GRAM. IT CAN BE ADJUSTED ACCORDING TO THE PRODUCTION REQUIREMENT BY CHOOSING GROUP ERROR OR SINGLE PIECE ERROR FROM THE CONTROL PANEL, SO THAT THE PRODUCTION QUALITY IS ASSURED AND MATERIAL WASTE IS CONTROLLED

• THE WHOLE LINE CAN BE HANDLED BY ONE OPERATOR WITH VERY SIMPLE

OPERATION

• ALL THE MATERIALS ARE INSIDE THE HOPPERS WITHOUT PRODUCING ANY DUST THAT AFFECTS THE WORKING AREA

• KEY ELECTRICAL COMPONENTS ARE IMPORTED

• THE WHOLE LINE OPERATION IS CONTROLLED BY PLC SYSTEM

• ACCORDING TO DIFFERENT QUANTITY AND QUALITY PRODUCTION REQUIREMENTS THE MACHINE CONTROL PANEL CAN BE SET UP FOR 100 GROUPS OF RECIPES AND EACH RECIPE CAN BE 50 SETS OF DIFFERENT WEIGHT VALUE FOR FILLING OPTIONS, WHICH IS ENOUGH TO FILL DIFFERENT PARTS OF THE SAME PRODUCTION.

• THE AVERAGE FILLING TIME CAN BE 4 TO 10 SECONDS (DEPENDING ON THE ACCURACY) AND THE FILLING TIME CAN BE ADJUSTED

• THE CUSTOMER’S DIFFERENT REQUIREMENTS ARE CONSIDERED BY OUR PROFESSIONAL ENGINEERS SO THAT THE MACHINES ARE SUITABLE FOR YOUR PARTICULAR NEEDS

• MATERIAL HOPPER: DIA.1200 x 2000MM 1PCS

• WEIGHING SYSTEM: 1200 x 1000 x 1000MM 1PCS(3SETS)

• FILLING TABLE :1200 x 550 x 1500 1PCS

• PLC CONTROL SYSTEM AND CONTROL PANEL: 1SETS

• BLOWER: 3PCS

• PIPE SYSTEM

Learn More -

F-1427 FEATHER FILLING MACHINE MODEL SR-1

F-1427 FEATHER FILLING MACHINE MODEL SR-1REFERENCE NUMBER: F-1427

FEATHER FILLING MACHINE MODEL SR-1

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• PRODUCT NAME: WEIGHING DOWN & FEATHER FILLING MACHINE

• TYPE: SR-1

• DIMENSION: 7500 x 2500 x 3500MM

• VOLTAGE: 200/380/415V 50/60HZ 3PHASE

• POWER: 11KW

• FILLING RANGE: 2 TO 100 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±0.5G,±1.0G,±1.5G,DEPENDING ON THE FILLING WEIGHT

• AIR SUPPLY: 0.5 TO 0.8MPA

• WEIGHT: APPROX. 800KG

• THE AUTOMATIC DOWN AND FEATHER FILLING MACHINE IS MAINLY USED TO PRODUCE JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS AND COMFORTERS THAT MADE WITH DOWN AND FEATHER MATERIAL BY COMPUTERIZED WEIGHING SYSTEM.

• THREE HOPPER-SYSTEM( FOR ONE FILLING PIPE) FOR CONSTANT SUPPLY

• THE SYSTEM IS THE VACUUM FILLING FUNCTION AND DOES NOT HURT THE MATERIAL; IT KEEPS THE ORIGINAL ELASTICITY AND SOFT HAND FEELING.

• ACCURATE WEIGHING RESULTS; THE TOLERANCE IS WITHIN 0.2 GRAM. IT CAN BE ADJUSTED ACCORDING TO THE PRODUCTION REQUIREMENT AND CHOOSE TOTAL ERROR OR SINGLE ERROR FROM THE CONTROL PANEL. THIS CONTROLS FOR THE PRODUCTION QUALITY AND MATERIAL WASTE

• ONE FILLING PIPE CAN BE HANDLED BY 1 OPERATOR BY VERY SIMPLE OPERATION WHICH SAVES YOU A BIG AMOUNT OF LABOR COSTS..

• THE KEY ELECTRICAL COMPONENTS ARE IMPORTED, SO THAT THE QUALITY IS RELIABLE AND STABLE.

• THE WHOLE LINE OPERATION IS CONTROLLED BY PLC SYSTEM

• ACCORDING TO DIFFERENT QUANTITY AND QUALITY REQUIREMENTS THE MACHINE CONTROL PANEL CAN BE SET UP FOR 100 DIFFERENT RECIPES AND EACH RECIPE CAN BE 80 SETS DIFFERENT WEIGHT VALUE FOR FILLING OPTIONS

• AVERAGE FILLING TIME CAN BE 2 TO 5 SECONDS (DEPENDING ON THE WEIGHT AND FABRIC) AND THE FILLING TIME CAN BE ADJUSTED

• DIFFERENT CUSTOMER REQUIREMENTS CAN BE CONSIDERED BY OUR PROFESSIONAL ENGINEERS TO WORK ON OUR MACHINES TO MATCH THE CUSTOMER’S NEED.

• MATERIAL HOPPER: DIA. 1700 x 2500MM 1PCS

• WEIGHING SYSTEM: 1200 x 1000 x 1000MM 3 PCS(6SETS)

• FILLING TABLE :1200 x 550 x 1500 2 PCS

• PLC CONTROL SYSTEM AND CONTROL PANEL: 2 SETS

• AIR OUTPUT BOX: 1200 x 1800 x 1700MM 1 PCS

• MATERIAL FEEDING BOX: 1200x1200x2500MM 1 PCS

• BLOWER: 6PCS

• PIPE SYSTEM: 1SET

Learn More -

F-1433 FEATHER FILLING MACHINE MODEL SR-4-A

F-1433 FEATHER FILLING MACHINE MODEL SR-4-AREFERENCE NUMBER: F-1433

FEATHER FILLING MACHINE MODEL SR-4-A

MACHINE MODEL: SR-4-A

• MAINLY USED TO FILL SLEEPING BAGS, CUSHIONS, PILLOWS, PADS, QUILTS, COMFORTERS ETC

• DIMENSION: 700 x 600 x 1400MM

• POWER: 1.6 KW

• FILLING RANGE: 1 TO 100 G, DEPENDING ON THE MATERIAL

• ACCURACY: 0 TO 8 G, +/-, DEPENDING ON THE OPERATION

• WEIGHING AND FILLING WITH ONLY ONE MACHINE, IN ONLY ONE OPERATION,

RELIABLY AND PRECISELY

• LOW NOISE BY USE OF A SPECIAL FAN FOR GENTLE FEATHER TRANSPORTATION AT EXTREMELY HIGH PERFORMANCE.

• VARIABLE FILLING SPEED, QUICK-START AND QUICK-BRAKE OF THE FAN BY USE OF A

FREQUENCY INVERTER.

• NICE DESIGN, ERGONOMIC AND SOPHISTICATED

• EASY AND FAULTLESS OPERATION - LIGHT, BIG DISPLAY - BASED ON THE LATEST TECHNOLOGY.

• START BY FOOT-SWITCH ON AND STOP BY FOOT-SWITCH OFF

Learn More -

F-1434 FEATHER FILLING MACHINE MODEL SR-4-B

F-1434 FEATHER FILLING MACHINE MODEL SR-4-BREFERENCE NUMBER: F-1434

FEATHER FILLING MACHINE MODEL SR-4-B

MACHINE MODEL: SR-4-B

MAINLY USED TO FILL JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS, QUILTS, COMFORTERS, ETC.

• DIMENSION: 700 x 600 x 1400MM

• POWER: 0.1 KW

• FILLING RANGE: 1 TO 100 GRAMS, DEPENDING ON THE MATERIAL

• ACCURACY: 0 TO 8 GRAMS, +/-, DEPENDING ON THE OPERATION

• WEIGHING AND FILLING WITH ONLY ONE MACHINE, IN ONLY ONE OPERATION, RELIABLE AND PRECISE.

• THE VACUUM FILLING FUNCTION THAT PREVENTS DAMAGE TO THE MATERIAL AND KEEPS THE ORIGINAL ELASTICITY AND SOFT HAND FEELING

• NICE DESIGN, ERGONOMIC AND SOPHISTICATED

• EASY AND FAULTLESS OPERATION – LARGE, LIT DISPLAY - BASED ON UP-TO-DATE TECHNOLOGY.

• START BY FOOT-SWITCH ON AND STOP BY FOOT-SWITCH OFF

Learn More -

F-1435 FEATHER FILLING MACHINE MODEL SR-4-C

F-1435 FEATHER FILLING MACHINE MODEL SR-4-CREFERENCE NUMBER: F-1435

FEATHER FILLING MACHINE MODEL SR-4-C

MACHINE MODEL: SR-4-C

• MAINLY USED TO FILL JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS, QUILTS, COMFORTERS ETC

• DIMENSION: 700 x 600 x 1400MM

• FILLING RANGE: 1 TO 100 GRAMS, DEPENDING ON MATERIAL

• THE VACUUM FILLING FUNCTION PREVENTS DAMAGE TO MATERIAL AND KEEPS THE ORIGINAL ELASTICITY AND SOFT HAND FEELING

• NICE DESIGN, ERGONOMIC AND SOPHISTICATED

• START BY FOOT-SWITCH ON AND STOP BY FOOT-SWITCH OFF

Learn More -

F-1436 FEATHER FILLING MACHINE MODEL SR-4-D

F-1436 FEATHER FILLING MACHINE MODEL SR-4-DREFERENCE NUMBER: F-1436

FEATHER FILLING MACHINE MODEL SR-4-D

MACHINE MODEL: SR-4-D

• MAINLY USED TO FILL JACKETS, CUSHIONS, PILLOWS, PADS, QUILTS, COMFORTERS ETC,

• DIMENSION: 700 x 600 x 1100MM

• POWER: 0.8KW

• FILLING RANGE: 1 TO 100 GRAMS, DEPENDING ON THE MATERIAL

• ACCURACY: 0.5 GRAMS, +/-, DEPENDING ON THE OPERATION

• WEIGHING AND FILLING WITH ONLY ONE MACHINE; RELIABLE AND PRECISE

• EASY AND FAULTLESS OPERATION BY PROGRAMMING, YOU CAN SET FILLING WEIGHT AND SAVE 20 RECIPES

• LOW NOISE BY USE OF A SPECIAL FAN FOR GENTLE FEATHER TRANSPORTATION AT

EXTREMELY HIGH PERFORMANCE

• VARIABLE FILLING SPEED; QUICK-START AND QUICK-BRAKE OF THE FAN BY USE OF A FREQUENCY INVERTER

• NICE DESIGN, ERGONOMIC AND SOPHISTICATED

• START BY FOOT-SWITCH, AUTOMATIC FINISH OF THE FILLING CYCLE

Learn More -

M-3674-A WISE PILLOW MACHINE FILLING MACHINE

M-3674-A WISE PILLOW MACHINE FILLING MACHINEREFERENCE NUMBER: M-3674-A

WISE PILLOW MACHINE FILLING MACHINEPLATE INFO FOR THE HOPPER:

DATE: JUNE/00

MOD. NO.: WK 4×36

PLATE INFO FOR THE FIRST BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE SECOND BLOWER:

DATE: JUNE/00

MOD. NO.: 4C 113PLATE INFO FOR THE CONTROL PANEL:

DATE: JUNE/2000

MOD. NO.: SYSTEM 1NOTE: THE HOPPER APRON WIDTH: 35 ½” INCHES

AFTER THE HOPPER THERE IS ANOTHER MACHINE WHICH MIGHT BE A FINE OPENER WITH (2) BLOWERS, (2) NOZZLES AND (1) CONTROL PANEL

QUANTITY: 1

Learn More -

A-1602 FIBER OPENING MACHINES – 300 Kg/Hz

A-1602 FIBER OPENING MACHINES – 300 Kg/HzA-1602 FIBER OPENING MACHINES – 300 Kg/Hz

MODEL: 3F-2

CAPACITY: 260 TO 300 KG/H

VOLTAGE: 380V / 50HZQUANTITY: 1

Learn More