Search results for: 'Production capa'

- Related search terms

- Production capacity

- Production+capacity

- Production+ca

- production line

- Production+capacity'

-

P-5044 STA IMPIANTI ROASTER 5 KILOS

P-5044 STA IMPIANTI ROASTER 5 KILOSP-5044 STA IMPIANTI ROASTER 5 KILOS

STA

MODEL: IMPIANTI

ROASTER

5 KILOS

STA IS A MANUFACTURING GROUP IN ITALY - THAT IS MADE UP OF SEASONED ENGINEERS FROM MOST OF THE BIG OLD ITALIAN ROASTING MACHINE MAKERS - SO THEIR SCOPE OF KNOWLEDGE AND HISTORY IS FANTASTIC. BASICALLY - THEIR CLAIM TO FAME IS HOT AIR INTRODUCED INTO THE TOP OF THE ROASTING CHAMBER . . . BEING PULLED THROUGH THE TURBULATING COFFEE AND EXITING THROUGH DRUM PERFORATIONS INTO THE BOTTOM. FIRST, THAT MAKES IT REALLY FRIENDLY TO BLENDING FORMULAS AND SECOND IT MAKES FOR SMALLER CHAFF - AS THE TURNING COFFEE BEATS IT UP A LITTLE AND THUS THE ROAST COMES OUT MORE CLEAN THAN THE OLD DAYS OF SOME SOLID DRUMS . . . SO IT IS DIFFERENT - WHICH DOES NOT MAKE IT BETTER - BUT IF YOU HAVE A BACKGROUND ON JABEZ BURNS . . THEN YOU WILL REALLY LOVE THIS PRODUCTION. BIG NATURALLY DEVELOPED BEANS - VERY EVEN ROAST. FOLLOWING IS THE MANUFACTURERS SPECS AND WE WILL BE GLAD TO DISCUSS MORE IN-DEPTH AS YOU HAVE QUESTIONS.ROASTING MACHINES LINE, PARTICULARLY SUITABLE FOR LITTLE PRODUCTION ACTIVITIES OF HIGH QUALITY ROASTED COFFEE, SUCH AS SHOPS, PASTRIES OR ARTISAN LABORATORIES. SMALL SIZE, TECHNOLOGICALLY ADVANCED, CONFIRM THEM ELVES AS IDEAL TOOL FOR THE PRODUCTION OF SELECTED COFFEES IN LITTLE QUANTITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS BURNER (AVAILABLE ALSO BY ELECTRIC RESISTANCES) AND AUTOMATIC CONTROL SYSTEM WITH SEMIAUTOMATIC MANAGEMENT.

TECHNICAL DATA:

ROASTER CAPACITY: 5 KG. - MAX. 7 KG. CYCLE

ROASTING CYCLE: 9 MINUTES ÷ 20

RAW COFFEE PROCESSING PER HOUR: 20 KG. ÷ 30

INSTALLED ELECTRIC POWER: 0.9 KW | SINGLEPHASE 220 VOLTS 50 HZ

THERMAL POWER (NATURAL GAS OR LPG): 8000 KCAL/H

MAIN COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM

HEATING GENERATOR OF NEW GENERATION, PATENTED AND COMPLETE OF BURNER

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL

COOLING TANK IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TANK

SUPPORTING FRAME FOR THE OVER INDICATED COMPONENTS

ELECTRIC CONTROL BOARD MADE ACCORDING CE RULES, INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN DEVICE FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TANK

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TANK

CYCLONE FOR CHAFFS COLLECTING

DETAILS OF COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL WITH MANUAL IN-LET OF COFFEE WITH DOORUNLOADING SYSTEM.

ROASTING DRUM: MADE BY A FIXED ELEMENT WITH DOUBLE WALLS INSULATED FOR THERMAL PROTECTION AND SUPPORT OF THE ROTATING CYLINDER MOVING THE PRODUCT. SUCH CYLINDER, COMPLETELY MADE IN COMPOUND STEEL TO OVERCOME THE THERMAL CHANGES, IS DEVELOPED WITH A PERFORATED PLATE FOR THE CONTAINMENT AND SPECIAL BLENDERS ON THE RIGHT AND LEFT SIDE PLACED ON DIFFERENT LEVELS TO GET A PERFECT BLENDING OF COFFEE. AT THE END OF THE ROASTING CYCLE, THE PRODUCT UNLOADING IS ALLOWED BY A WIDE DOOR WITH MANUAL OPENING/CLOSING SYSTEM.

HEATING GAS GENERATOR OF NEW CONCEPT, PATENTED, COMPLETE OF BURNER, RAMP VALVES FOR GAS SAFETY AND ELECTRONIC EQUIPMENTS FOR FLAME CONTROL RATIFIED AND COMPLETE OF SIGNALLING ALARM.

COOLING TANK IN STAINLESS STEEL: WIDE SURFACE PERFORATED WITH TWO ARMS AND CROSSED FLOWS. UNLOADING MOUTH WITH HAND DRIVE.

SUPPORTING FRAME: MONO-BLOCK, PLATE PRESS-BENDED, STEEL MADE, SUPPORTING THE COMPONENTS PREVIOUSLY DESCRIBED.

SAFETY PROTECTION FOR COOLING TANK

ELECTRIC CONTROL BOARD FOR MACHINE MANAGEMENT ACCORDING CE RULES INTEGRATED. COMPLETE OF PLC + TOUCH SCREEN FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

POSSIBLE RECORDING OF ROASTING PARAMETERS

CYCLONE FOR CHAFFS COLLECTING.

INDEPENDENT MOTORIZATION FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT ELECTRIC-FAN FOR ROASTING DRUM AND ELECTRIC –FAN FOR COOLING TANK.QUANTITY: 1

Learn More -

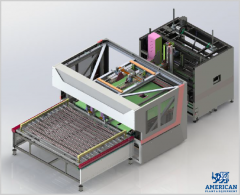

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mm

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmREFERENCE NUMBER: A-1876

END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmPRODUCT TO BE PROCESSED: NEEDLEPUNCHED NONWOVENS

PRODUCT WIDTH: 4.000 MMWORKING SPEED: 1 – 20 M/MIN

QUANTITY: 1

Learn More -

C-1163 AIRJET MÜLLER LABEL WEAVING MACHINES w/JACQUARD, YEAR 2001, REED WIDTH 1150REFERENCE NUMBER: C-1163 AIRJET MÜLLER LABEL WEAVING MACHINES w/JACQUARD, YEAR 2001, REED WIDTH 1150 SPECIFICATIONS: Make Jakob Muller (Switzerland) YEAR CONSTRUCTIONS: 2001 Type M JET MBJL 1/1150 QUANTITY AVAILABLE: 2 Learn More

C-1163 AIRJET MÜLLER LABEL WEAVING MACHINES w/JACQUARD, YEAR 2001, REED WIDTH 1150REFERENCE NUMBER: C-1163 AIRJET MÜLLER LABEL WEAVING MACHINES w/JACQUARD, YEAR 2001, REED WIDTH 1150 SPECIFICATIONS: Make Jakob Muller (Switzerland) YEAR CONSTRUCTIONS: 2001 Type M JET MBJL 1/1150 QUANTITY AVAILABLE: 2 Learn More -

TT-7796 MUNCHY 100 RECYCLING MACHINE, YEAR 2008TT-7796 MUNCHY 100 RECYCLING MACHINE, YEAR 2008 1. BRAND: MUNCHY 2. MODEL: 100 3. YEAR: 2008 4. CATEGORY: RECYCLING MACHINES 5. CAPACITY: 110 KG/H 6. RECYCLED MATERIAL: LDPE, HDPE, PP QUANTITY: 1 Learn More

TT-7796 MUNCHY 100 RECYCLING MACHINE, YEAR 2008TT-7796 MUNCHY 100 RECYCLING MACHINE, YEAR 2008 1. BRAND: MUNCHY 2. MODEL: 100 3. YEAR: 2008 4. CATEGORY: RECYCLING MACHINES 5. CAPACITY: 110 KG/H 6. RECYCLED MATERIAL: LDPE, HDPE, PP QUANTITY: 1 Learn More -

TT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50HzTT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50Hz CONDITION: NEW FIBERS CARDING MACHINE/BLENDING MACHINE VOLTAGE: 380V/50Hz 3 PHASE CAN BE CUSTOMIZED QUANTITY: 1 Learn More

TT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50HzTT-5050 FIBERS CARDING MACHINE/INDUSTRIAL BLENDING MACHINE/NONWOVEN CARDING MACHINERY SHEEP WOOL MACHINE CASHMERE CARDING MACHINE FOR NONWOVEN, 50Hz CONDITION: NEW FIBERS CARDING MACHINE/BLENDING MACHINE VOLTAGE: 380V/50Hz 3 PHASE CAN BE CUSTOMIZED QUANTITY: 1 Learn More -

YY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINEYY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINE THE PLANT WAS USED IN FULLY CONTINUOUS OPERATION WHICH MEANS 24 / 7 FOR 350 DAYS PER YEAR. BULK MATERIALS OF ALL TYPES (PET BOTTLE FLAKES, RESINS / GRANULE CHIPS, REGRINDS OF VARIOUS TYPES OF MATERIALS AND AGGLOMERATES) WERE USED AS INPUT MATERIAL FROM THE EUROPEAN MARKET, BUT ALSO FROM ALL OVER THE WORLD. THE REGENERATED FIBERS PRODUCED WERE BETWEEN 3 DEN AND 25 DEN AND COULD BE USED FOR MANY DIFFERENT APPLICATIONS, SUCH AS AUTOMOTIVE, GEOTEXTILES, TECHNICAL TEXTILES AND ALL GENERAL TEXTILE SECTORS – ALWAYS IN 100% RECYCLED FIBERS. PREDOMINANTLY THE LINE WAS PRODUCING A HIGH QUALITY BLACK STAPLE FIBER! Learn More

YY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINEYY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINE THE PLANT WAS USED IN FULLY CONTINUOUS OPERATION WHICH MEANS 24 / 7 FOR 350 DAYS PER YEAR. BULK MATERIALS OF ALL TYPES (PET BOTTLE FLAKES, RESINS / GRANULE CHIPS, REGRINDS OF VARIOUS TYPES OF MATERIALS AND AGGLOMERATES) WERE USED AS INPUT MATERIAL FROM THE EUROPEAN MARKET, BUT ALSO FROM ALL OVER THE WORLD. THE REGENERATED FIBERS PRODUCED WERE BETWEEN 3 DEN AND 25 DEN AND COULD BE USED FOR MANY DIFFERENT APPLICATIONS, SUCH AS AUTOMOTIVE, GEOTEXTILES, TECHNICAL TEXTILES AND ALL GENERAL TEXTILE SECTORS – ALWAYS IN 100% RECYCLED FIBERS. PREDOMINANTLY THE LINE WAS PRODUCING A HIGH QUALITY BLACK STAPLE FIBER! Learn More -

TT-4198 SUGAR AND ALCOHOL MILL, CAPACITY OF 1,500,000 TONS PER HARVESTTT-4198 SUGAR AND ALCOHOL MILL, CAPACITY OF 1,500,000 TONS PER HARVEST SUGAR AND ALCOHOL MILL QUANTITY: 1 Learn More

TT-4198 SUGAR AND ALCOHOL MILL, CAPACITY OF 1,500,000 TONS PER HARVESTTT-4198 SUGAR AND ALCOHOL MILL, CAPACITY OF 1,500,000 TONS PER HARVEST SUGAR AND ALCOHOL MILL QUANTITY: 1 Learn More -

TT-3618 LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING, YEAR 1996TT-3618 LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING, YEAR 1996 LAROCHE BRAND: LAROCHE YEAR: 1996 STATE: USED FULLY OPERATIVE LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING. QUANTITY: 1 Learn More

TT-3618 LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING, YEAR 1996TT-3618 LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING, YEAR 1996 LAROCHE BRAND: LAROCHE YEAR: 1996 STATE: USED FULLY OPERATIVE LAROCHE TEXTILE RECYCLING LINE FOR MECHANICAL TEARING. QUANTITY: 1 Learn More -

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More -

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More