Search results for: 'Yarn c'

- Related search terms

- Yarn cond

- yarn winder

- Yarn con

- Yarn condi

- Yarn Condition

-

K-3940 LABORATORY MULTI-FUNCTIONAL SPINNING MACHINE

K-3940 LABORATORY MULTI-FUNCTIONAL SPINNING MACHINEREFERENCE NUMBER: K-3940

LABORATORY MULTI-FUNCTIONAL SPINNING MACHINE

HAS COMPACT SPINNING DEVICE TO SPIN PLIED YARN INTO FINE YARN, THROUGH DRAFTING AND RING SPINNING

CONTROL:TOUCH SCREEN + PLC

COMPACT SPINNING DEVICE

NO OF SPINDLES:4/6

TWISTING DEGREE:ABOUT 200-2000 TIMES/METER

DRAFTING RANGE:ABOUT 2-50

FIBER LENGTH:22mm TO 42mm

OUTPUT:ABOUT 0.25KG-1KG

SPINDLE SPEED 12000 RPM

ROLLER SIZE:Φ25/25/25mm

RING SIZE:Φ38-45 mm

TOTAL POWER 550W

VOLTAGE:220/3×380V AC 50/60Hz

MACHINE DIMENSIONS 1000mm×800mm×1600mm

QUANTITY: 1

Learn More -

G-8230 HIGH-TEMPERATURE AND HIGH-PRESSURE YARN DYEING MACHINE 40KG

G-8230 HIGH-TEMPERATURE AND HIGH-PRESSURE YARN DYEING MACHINE 40KGREFERENCE NUMBER: G-8230

HIGH-TEMPERETURE AND HIGH-PRESSURE YARN DYEING MACHINE 40KG

DESIGNED FOR DYEING, BOILING OFF, BLEACHING, AND WATER WASHING, ETC. SUITABLE FOR HANK YARN, BOBBIN OR RAW STOCK FIBER

MACHINE TYPE: VERTICAL CYLINDER

VAT DIAMETER: Ф600mm

CONE QUANTITY: 7 X 7 = 49 CONES

WORKING TEMPERATURE: 130C

MAX WORKING PRESSURE: 0.4MPA

BOTH RATIO: 1:7 TO 9

WITH COMPUTERIZED CONTROL SYSTEM

HEAT EXCHANGING: COIL TYPE HEAT EXCHANGER, WHICH CAN BE USED FOR EITHER HEATING OR COOLING.

HEAT EXCHANGING SPEED: WHEN THE HEATED STEAM PRESSURE IS 0.4MPA, 40MINUTES WILL BE REQUIRED FOR THE LIQUID INSIDE THE DYEING BARREL RAISING FROM 20OC TO 130OC. WHEN THE COOLING WATER PRESSURE IS 0. 3MPA AND THE WATER TEMPERATURE IS 20 OC, 40 MINUTES WILL BE REQUIRED FOR THE LIQUID INSIDE THE DYEING BECK TO LOWER FROM 130OC TO 80OC.

RECYCLING OF DYEING LIQUID: THE POSITIVE AND NEGATIVE RECYCLING OF DYEING LIQUID WILL BE ADJUSTED BY THE CYLINDER THROUGH THE SWITCHING DEVICE INSIDE THE CENTRIFUGAL PUMP.

SEALING OF BOILER: RUBBER ADHESIVE

THE WORKING PRESSURE INSIDE THE TANK WILL MAKE THE RUBBER SEAL CLOSELY TO ATTACH THE FLANGE. THE CONICAL SURFACE OF THE TANK MOUTH IS TO ENHANCE THE SEALING.

OPENING OF TANK COVER: FIRST OPEN THE AIR VALVE TO RELEASE THE PRESSURE INSIDE THE BOILER. WAIT UNTIL NO EXHAUSTED AIR GOING THRU THE EXHAUST VALVE AND THE READING OF PRESSURE GAUGE IS ZERO, WITHDRAW THE WRENCH HANDLE, OPEN THE CLAMPING HOOP TO REMOVE THE FLANGE; AND THEN OPEN THE COVER WITH DRAG WEIGHT. THE COVER WILL BE CLOSED.

CONFIGURATION:

1. ELECTRICAL CABINET: STAINLESS STEEL CABINET, PLASTIC COATING

2. ELECTRICAL COMPONENTS: SIEMENS, OMRON

3. COMPUTER: HG COMPUTER (MADE IN CHINA)

4. ELECTROMAGNETIC VALVE: TAIWAN YADEKE

5. PUMP: CENTRIFUGAL PUMP

6. MOTOR: WANNAN MOTOR

7. TEMPERATURE CONTROL: COMPUTER CONTROL, WITH HEATING, COOLING, KEEPING WARM, ETC. FUNCTION.

8. HEAT EXCHANGER: INTERNAL COIL HEATING

9. VALVE: STAINLESS ANGLE VALVES, PNEUMATIC BUTTERFLY VALVES

10. ONE CARRIER BASKET

11. MACHINE BODY MATERIAL: STAINLESS STEEL, 316 LITERS

12. ACCESSORIES: SEAL RING FOR DYE VAT, SEAL FOR MAIN PUMP, SEAL FOR REVERSING SHAFT

QUANTITY: 1

Learn More -

P-1471 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1978 to 1979 WIDTH 2500mmREFERENCE NUMBER: P-1471 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1978 to 1979 WIDTH 2500mm HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR: 1978 to 1979 WIDTH: 2500mm TYPE: AA.201 QUANTITY AVAILABLE: 1 Learn More

P-1471 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1978 to 1979 WIDTH 2500mmREFERENCE NUMBER: P-1471 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1978 to 1979 WIDTH 2500mm HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR: 1978 to 1979 WIDTH: 2500mm TYPE: AA.201 QUANTITY AVAILABLE: 1 Learn More -

P-1470 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1982 WIDTH 2500mmREFERENCE NUMBER: P-1470 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1982 WIDTH 2500mm HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR: 1982 WIDTH: 2500mm TYPE: GALAXY AS.202 QUANTITY AVAILABLE: 1 Learn More

P-1470 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1982 WIDTH 2500mmREFERENCE NUMBER: P-1470 HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR 1982 WIDTH 2500mm HOUGET DUESBERG BOSSON AUTOMATIC CARDING YEAR: 1982 WIDTH: 2500mm TYPE: GALAXY AS.202 QUANTITY AVAILABLE: 1 Learn More -

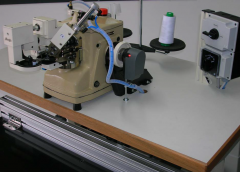

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More -

A-1204 KARL MAYER DOUBLE RASCHEL MACHINEREFERENCE NUMBER: A-1204 (1212GHBXX11) A KARL MAYER DOUBLE RASCHEL MACHINE RD 6 / 3-15 EL RD 6 / 3-15 EL RASCHEL MACHINE FOR THE PRODUCTION OF WARP-KNITTED SPACER FABRIC MAX. WORKING WIDTH: 3505 MM (138 INCHES) KAMCOS (KARL MAYER COMMAND SYSTEM) QUANTITY AVAILABLE: 1 Learn More

A-1204 KARL MAYER DOUBLE RASCHEL MACHINEREFERENCE NUMBER: A-1204 (1212GHBXX11) A KARL MAYER DOUBLE RASCHEL MACHINE RD 6 / 3-15 EL RD 6 / 3-15 EL RASCHEL MACHINE FOR THE PRODUCTION OF WARP-KNITTED SPACER FABRIC MAX. WORKING WIDTH: 3505 MM (138 INCHES) KAMCOS (KARL MAYER COMMAND SYSTEM) QUANTITY AVAILABLE: 1 Learn More -

M-4432 SCHLAFHORST 338 WINDER YEAR 2001-2002 – 60 POSITIONS / 50 POSITIONSREFERENCE NUMBER: M-4432 (1010MNJWHH9) K SCHLAFHORST 338 WINDER YEAR 2001-2002 – 60 POSITIONS / 50 POSITIONS 2 SETS OF SCHALFHORST’S 338 WINDER A. 1 SET X 60 DRUMS MODEL : 338 (R SIDE) YEAR : 2001 NO. OF SPINDLE : 60 FEEDING : MAGAZINE MAGAZINE POCKET : 6 DRUM : STEEL MADE, 2.0 TURN, 6” TRAVERSE TAKE-UP SHAPE : 5°57 YARN CLEARER : USTER QUANTUM 1 (NO FOREIGN FIBER DETECTOR) SPLICER : PRISM DZ3 SUCTION TAIL END WITH OVERHEAD CLEANER WITHOUT WAXING DEVICE INDIVIDUAL SUCTION BLOWER (UPWARD) WITHOUT AUTO-DOFFER WITHOUT PACKAGE CONVEYOR POWER “ 380V50HZ B. 1 SET X 50 DRUMS MODEL : 338 (L SIDE) YEAR 2002 NO. OF SPINDLE : 50 FEEDING : MAGAZINE MAGAZINE POCKET : 6 DRUM : STEEL MADE, 2.5 TURN, 6” TRAVERSE TAKE-UP SHAPE : 5°57 YARN CLEARER : USTER QUANTUM 2 (NO FOREIGN FIBER DETECTOR) SPLICER : PRISM DZ3 SUCTION TAIL END WITH OVERHEAD CLEANER WITH WAXING DEVICE INDIVIDUAL SUCTION BLOWER (UPWARD) WITHOUT AUTO-DOFFER WITHOUT PACKAGE CONVEYOR POWER “ 380V50HZ QUANTITY AVAILABLE: 2 Learn More

M-4432 SCHLAFHORST 338 WINDER YEAR 2001-2002 – 60 POSITIONS / 50 POSITIONSREFERENCE NUMBER: M-4432 (1010MNJWHH9) K SCHLAFHORST 338 WINDER YEAR 2001-2002 – 60 POSITIONS / 50 POSITIONS 2 SETS OF SCHALFHORST’S 338 WINDER A. 1 SET X 60 DRUMS MODEL : 338 (R SIDE) YEAR : 2001 NO. OF SPINDLE : 60 FEEDING : MAGAZINE MAGAZINE POCKET : 6 DRUM : STEEL MADE, 2.0 TURN, 6” TRAVERSE TAKE-UP SHAPE : 5°57 YARN CLEARER : USTER QUANTUM 1 (NO FOREIGN FIBER DETECTOR) SPLICER : PRISM DZ3 SUCTION TAIL END WITH OVERHEAD CLEANER WITHOUT WAXING DEVICE INDIVIDUAL SUCTION BLOWER (UPWARD) WITHOUT AUTO-DOFFER WITHOUT PACKAGE CONVEYOR POWER “ 380V50HZ B. 1 SET X 50 DRUMS MODEL : 338 (L SIDE) YEAR 2002 NO. OF SPINDLE : 50 FEEDING : MAGAZINE MAGAZINE POCKET : 6 DRUM : STEEL MADE, 2.5 TURN, 6” TRAVERSE TAKE-UP SHAPE : 5°57 YARN CLEARER : USTER QUANTUM 2 (NO FOREIGN FIBER DETECTOR) SPLICER : PRISM DZ3 SUCTION TAIL END WITH OVERHEAD CLEANER WITH WAXING DEVICE INDIVIDUAL SUCTION BLOWER (UPWARD) WITHOUT AUTO-DOFFER WITHOUT PACKAGE CONVEYOR POWER “ 380V50HZ QUANTITY AVAILABLE: 2 Learn More -

M-4427 SIMA RING TWISTERS YEAR 2000-2001 - 48 POSITIONS EACHREFERENCE NUMBER: M-4427 SIMA RING TWISTERS YEAR 2000-2001 - 48 POSITIONS EACH RING TWISTER MODEL HRT-6 SIMA ITALY 48 SPINDLES YEAR 2001 SPINDLE GAUGE 250mm RING 160 x 25.4mm YARN RANGE 1000 TO 12000 DENIER MAX SPEED 6500 T PER MIN TWIST RANGE 22 TO 258 T PER MIN SPOOLS 140 x 55 x 450mm (VOL CM3, 3481) WEIGHT 2.7 KGS POWER 93KW QUANTITY: 1 RING TWISTER MODEL HRT-9 SIMA ITALY 48 SPINDLES YEAR 2000 SPINDLE GAUGE 350mm RING 228.6 x 38.1 mm YARN RANGE 2000 TO 23000 DENIER MAX SPEED 4600 T PER MIN TWIST RANGE 20 TO 228 T PER MIN SPOOLS 200 x 70 x 500mm (VOL CM3, 12695) WEIGHT 6 KGS POWER 93KW QUANTITY: 1 QUANTITY AVAILABLE: 2 Learn More

M-4427 SIMA RING TWISTERS YEAR 2000-2001 - 48 POSITIONS EACHREFERENCE NUMBER: M-4427 SIMA RING TWISTERS YEAR 2000-2001 - 48 POSITIONS EACH RING TWISTER MODEL HRT-6 SIMA ITALY 48 SPINDLES YEAR 2001 SPINDLE GAUGE 250mm RING 160 x 25.4mm YARN RANGE 1000 TO 12000 DENIER MAX SPEED 6500 T PER MIN TWIST RANGE 22 TO 258 T PER MIN SPOOLS 140 x 55 x 450mm (VOL CM3, 3481) WEIGHT 2.7 KGS POWER 93KW QUANTITY: 1 RING TWISTER MODEL HRT-9 SIMA ITALY 48 SPINDLES YEAR 2000 SPINDLE GAUGE 350mm RING 228.6 x 38.1 mm YARN RANGE 2000 TO 23000 DENIER MAX SPEED 4600 T PER MIN TWIST RANGE 20 TO 228 T PER MIN SPOOLS 200 x 70 x 500mm (VOL CM3, 12695) WEIGHT 6 KGS POWER 93KW QUANTITY: 1 QUANTITY AVAILABLE: 2 Learn More -

SCHLAFHORST 238D AUTOMATIC WINDERS YEAR 1994(3 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER POLYMATIC YARN CLEARER TYPE: MK-C15-AC WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (3 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER QUANTUM-2 CLEARERS WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (1 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER PEYER YARN CLEARER TYPE: MK-C15-AC WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (1 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER QUANTUM-1 CLEARERS WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER 380V, 50HZ SUPERB CONDITION. HIGHLY MAINTAINED MACHINES. Learn More

SCHLAFHORST 238D AUTOMATIC WINDERS YEAR 1994(3 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER POLYMATIC YARN CLEARER TYPE: MK-C15-AC WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (3 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER QUANTUM-2 CLEARERS WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (1 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER PEYER YARN CLEARER TYPE: MK-C15-AC WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER (1 SET) SCHALFHORST AUTOMATIC WINDER YEAR: 1994 TYPE: 238D VERSION 147 60 SPINDLES STEEL DRUMS 2.5 TURNS YOKE CRADLE CONE ANGLE 4' 20 USTER QUANTUM-1 CLEARERS WAXING DEVICE AUTO DOFFING INFORMATOR OHTC MAKE SOHLER 380V, 50HZ SUPERB CONDITION. HIGHLY MAINTAINED MACHINES. Learn More -

USTER TENSORAPID 3USTER TENSORAPID 3 IT HAS 500 NEWTON LOAD CELL WORKING CONDITION FITTED WITH YARN CLAMPS CAN BE USED FOR CHECKING SINGLE YARN STRENGTH TENACITY TENSILE PROPERTIES ALSO CAN BE USED FOR CHECKING SPLICE STRENGTH AUTOMATIC TESTING AT 5000 MM / MINUTE IS THE HIGHEST SPEED. TEST LENGTH MAXIMUM 500 MM HAVING SEPARATE CREEL 24 PACKAGES TESTED AUTOMATICALLY Learn More

USTER TENSORAPID 3USTER TENSORAPID 3 IT HAS 500 NEWTON LOAD CELL WORKING CONDITION FITTED WITH YARN CLAMPS CAN BE USED FOR CHECKING SINGLE YARN STRENGTH TENACITY TENSILE PROPERTIES ALSO CAN BE USED FOR CHECKING SPLICE STRENGTH AUTOMATIC TESTING AT 5000 MM / MINUTE IS THE HIGHEST SPEED. TEST LENGTH MAXIMUM 500 MM HAVING SEPARATE CREEL 24 PACKAGES TESTED AUTOMATICALLY Learn More