Search results for: 'automatic tension c'

- Related search terms

- automatic te

- automatic+cutting+ma

- tension

- Automatic d

- Automatic+4+s

-

TT-3205 NEWLONG BAG MACHINE 136T + 508T FLAT HANDLE UNIT, YEAR 2015TT-3205 NEWLONG BAG MACHINE 136T + 508T FLAT HANDLE UNIT, YEAR 2015 WITH INLINE PRINTER 412FK +19R PAPER ROLL UNWIND STAND AVAILABILITY: IMMEDIATELY Learn More

TT-3205 NEWLONG BAG MACHINE 136T + 508T FLAT HANDLE UNIT, YEAR 2015TT-3205 NEWLONG BAG MACHINE 136T + 508T FLAT HANDLE UNIT, YEAR 2015 WITH INLINE PRINTER 412FK +19R PAPER ROLL UNWIND STAND AVAILABILITY: IMMEDIATELY Learn More -

TT-2675 WINDMOLLER & HOLSCHER FILM EXTRUSION LINE, CAST FILM, WIDTH 2100mm, 5 LAYERS, YEAR 2008TT-2675 WINDMOLLER & HOLSCHER FILM EXTRUSION LINE, CAST FILM, WIDTH 2100mm, 5 LAYERS, YEAR 2008 BRAND: WINDMOLLER & HOLSCHER MODEL: FILMEX YEAR: 2008 QUANTITY: 1 Learn More

TT-2675 WINDMOLLER & HOLSCHER FILM EXTRUSION LINE, CAST FILM, WIDTH 2100mm, 5 LAYERS, YEAR 2008TT-2675 WINDMOLLER & HOLSCHER FILM EXTRUSION LINE, CAST FILM, WIDTH 2100mm, 5 LAYERS, YEAR 2008 BRAND: WINDMOLLER & HOLSCHER MODEL: FILMEX YEAR: 2008 QUANTITY: 1 Learn More -

TT-2231 DUSENBERY MODEL 635 BL, WIDTH 62”TT-2231 DUSENBERY MODEL 635 BL, WIDTH 62” QUANTITY: 1 Learn More

TT-2231 DUSENBERY MODEL 635 BL, WIDTH 62”TT-2231 DUSENBERY MODEL 635 BL, WIDTH 62” QUANTITY: 1 Learn More -

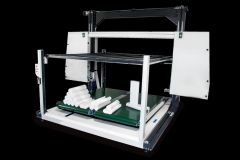

TT-2004 INFOTEC 2424 C FOAM CONTOUR CUTTING MACHINE CNC, YEAR 2022TT-2004 INFOTEC 2424 C FOAM CONTOUR CUTTING MACHINE CNC, YEAR 2022 MACHINE TYPE: CONTOUR CUTTING MACHINE CNC, FOR FOAM BRAND: INFOTEC MODEL: INFOTEC 2424 C FOAM YEAR OF CONSTRUCTION: 2022 CONDITION: NEW THE CONTOUR CUTTING MACHINE CUTS A VARIETY OF SHAPES FROM FLEXIBLE POLYURETHANE FOAM BLOCKS. USED IN THE MANY INDUSTRIES, ESPECIALLY IN THE PRODUCTION OF UPHOLSTERED FURNITURE AND MATTRESSES. FOR CUTTING FOAM BLOCKS WITH A MAXIMUM SIZE OF: 2400 X 2400 X 1300mm. THE MACHINE IS EQUIPPED WITH A ROTARY TABLE, WHICH MAKES IT POSSIBLE TO CUT OUT ANY COMPLEX SPATIAL SHAPES. IT CAN ALSO SLICE BLOCKS OF FOAM AS A VERTICAL OR AS HORIZONTAL MACHINE DOES. Learn More

TT-2004 INFOTEC 2424 C FOAM CONTOUR CUTTING MACHINE CNC, YEAR 2022TT-2004 INFOTEC 2424 C FOAM CONTOUR CUTTING MACHINE CNC, YEAR 2022 MACHINE TYPE: CONTOUR CUTTING MACHINE CNC, FOR FOAM BRAND: INFOTEC MODEL: INFOTEC 2424 C FOAM YEAR OF CONSTRUCTION: 2022 CONDITION: NEW THE CONTOUR CUTTING MACHINE CUTS A VARIETY OF SHAPES FROM FLEXIBLE POLYURETHANE FOAM BLOCKS. USED IN THE MANY INDUSTRIES, ESPECIALLY IN THE PRODUCTION OF UPHOLSTERED FURNITURE AND MATTRESSES. FOR CUTTING FOAM BLOCKS WITH A MAXIMUM SIZE OF: 2400 X 2400 X 1300mm. THE MACHINE IS EQUIPPED WITH A ROTARY TABLE, WHICH MAKES IT POSSIBLE TO CUT OUT ANY COMPLEX SPATIAL SHAPES. IT CAN ALSO SLICE BLOCKS OF FOAM AS A VERTICAL OR AS HORIZONTAL MACHINE DOES. Learn More -

TT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mmTT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mm MACHINE STRUCTURE FEATURES: 1. SPLICING TYPE STRUCTURE, IT IS MADE BY HIGH QUALITY Q235 STEEL PLATE WELDING, THEN FINE TEMPERING QUALITATIVELY WITH SUFFICIENT COMPLETENESS AND STABILITY. UPPER AND DOWN MACHINE GIRDERS BOTH PRECISELY PROCESSING MACHINED. 2. ECCENTRIC BEARINGS ADOPT TORRINGTON FAMOUS BRAND 3. MAIN SHAFT IS USING 42CROMO MATERIAL. AFTER CONDITIONING TREATMENT FINE FINISHING AND GRINDING. 4. NEEDLE GIRDER HIGH SPEED TURBINE ELECTRIC LIFTING, STRIPPER PLATE TURBINE ELECTRIC LIFTING, NEEDLE GIRDER ROLLER SCALE DISPLAY. AIR LOCKED THE NEEDLE PLATE TIGHTLY. 5. NEEDLE PLATE LUOYANG MADE BY MAGNESIUM ALLOY DIE CASTING PLATE COMPOSITE PU, RADON ARRANGE NEEDLES HOLE φ1.82mm 6. INPUT PVC LATTICE, OUTPUT ROLLER ADOPTS φ155mm, HIGH QUALITY SEAMLESS STEEL PIPE, AFTER FINISHING GRINDING, THE SURFACE IS PLATED WITH HARD CHROME, UPPER ROLLER ADJUSTABLE HEIGHT AIR CYLINDER. 7. MAIN MOTOR, OUTPUT ROLLER ALL FREQUENCY CONTROL. 8. INSTALLED POWER: AROUND 15.5KW, MAIN MOTOR 11 KW. QUANTITY: 1 SET Learn More

TT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mmTT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mm MACHINE STRUCTURE FEATURES: 1. SPLICING TYPE STRUCTURE, IT IS MADE BY HIGH QUALITY Q235 STEEL PLATE WELDING, THEN FINE TEMPERING QUALITATIVELY WITH SUFFICIENT COMPLETENESS AND STABILITY. UPPER AND DOWN MACHINE GIRDERS BOTH PRECISELY PROCESSING MACHINED. 2. ECCENTRIC BEARINGS ADOPT TORRINGTON FAMOUS BRAND 3. MAIN SHAFT IS USING 42CROMO MATERIAL. AFTER CONDITIONING TREATMENT FINE FINISHING AND GRINDING. 4. NEEDLE GIRDER HIGH SPEED TURBINE ELECTRIC LIFTING, STRIPPER PLATE TURBINE ELECTRIC LIFTING, NEEDLE GIRDER ROLLER SCALE DISPLAY. AIR LOCKED THE NEEDLE PLATE TIGHTLY. 5. NEEDLE PLATE LUOYANG MADE BY MAGNESIUM ALLOY DIE CASTING PLATE COMPOSITE PU, RADON ARRANGE NEEDLES HOLE φ1.82mm 6. INPUT PVC LATTICE, OUTPUT ROLLER ADOPTS φ155mm, HIGH QUALITY SEAMLESS STEEL PIPE, AFTER FINISHING GRINDING, THE SURFACE IS PLATED WITH HARD CHROME, UPPER ROLLER ADJUSTABLE HEIGHT AIR CYLINDER. 7. MAIN MOTOR, OUTPUT ROLLER ALL FREQUENCY CONTROL. 8. INSTALLED POWER: AROUND 15.5KW, MAIN MOTOR 11 KW. QUANTITY: 1 SET Learn More -

TT-1047 MICRO COMPUTER TENSILE STRENGTH TESTING MACHINETT-1047 MICRO COMPUTER TENSILE STRENGTH TESTING MACHINE TENSILE COMPRESSION TESTING MACHINE KEY SPECIFICATIONS CAPACITY: 50N, 100N, 200N, 500N, 1KN, 2KN,2.5KN DISPLAY: LCD DISPLAY FORCE RESOLUTION: 1/50,000 FORCE ACCURACY: ≤+/-0.5% STROKE RANGE: 1100mm (EXCLUDE THE GRIPS) STROKE RESOLUTION: 0.001mm TEST SPEED: 0.001-500mm/MIN CAN BE SET, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON. SPECIMEN DAMAGE AUTOMATIC STOP MACHINE DRIVE: AC INVERTER MOTOR DRIVE POWER SUPPLY: AC 220V 50-60Hz 5A DIMENSIONS: 470 X 380 X 1860mm WEIGHT: 60KG QUANTITY: 1 Learn More

TT-1047 MICRO COMPUTER TENSILE STRENGTH TESTING MACHINETT-1047 MICRO COMPUTER TENSILE STRENGTH TESTING MACHINE TENSILE COMPRESSION TESTING MACHINE KEY SPECIFICATIONS CAPACITY: 50N, 100N, 200N, 500N, 1KN, 2KN,2.5KN DISPLAY: LCD DISPLAY FORCE RESOLUTION: 1/50,000 FORCE ACCURACY: ≤+/-0.5% STROKE RANGE: 1100mm (EXCLUDE THE GRIPS) STROKE RESOLUTION: 0.001mm TEST SPEED: 0.001-500mm/MIN CAN BE SET, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON. SPECIMEN DAMAGE AUTOMATIC STOP MACHINE DRIVE: AC INVERTER MOTOR DRIVE POWER SUPPLY: AC 220V 50-60Hz 5A DIMENSIONS: 470 X 380 X 1860mm WEIGHT: 60KG QUANTITY: 1 Learn More -

INDUSTRIAL ELECTROSPINNING MACHINEREFERENCE NUMBER: A-2471 INDUSTRIAL ELECTROSPINNING MACHINE A MASS PRODUCTION MACHINE OF ELECTROSPINNING. ALUMINUM FRAME STRUCTURE MAKES IT POSSIBLE FOR EXTENDING DIFFERENT FUNCTIONS. THE SPINNERET USED IS MULTI-NEEDLE ARRAYS, FROM 64 TO 384 NEEDLES ARE EQUIPPED. THE LENGTH AND WIDTH CAN BE MADE ACCORDING TO CUSTOMER'S REQUIREMENT. ROLL TO ROLL COLLECTOR AND CONTINUOUS COLLECTOR CAN BE USED BASED ON THE THICKNESS OF REQUIRED FIBER SHEET. FOR SOLUTIONS, A MULTI-CHANNEL PUMP WILL BE SUPPLIED FOR LONG TIME PRODUCTION OR NONE-STOP PRODUCTION. FEATURES: - EQUIPPED WITH BOTH POSITIVE & NEGATIVE HIGH VOLTAGE SUPPLY DEVICES - EQUIPPED WITH UNWINDING & WINDING MACHINES - CONTINUOUS ELECTROSPINNING & WINDING - ALUMINUM ALLOY FRAME STRUCTURE, MULTI-FUNCTIONS EXPANSIBLE - MULTI-NEEDLES IN ARRAYS. 16 NEEDLES X N ROWS, UP TO 384 NEEDLES - SPINNERET MOVING MACHINERY ENSURES EVEN FIBER SHEET - ONLINE AUTO-CLEAN DEVICE FOR NEEDLES - THICKNESS OF THE FIBER SHEET IS CONTROLLABLE - CE & FCC CERTIFICATE SPINNERET STANDARD:16 NEEDLES X 8 GROUPS =128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ADJUSTED FREELY ACCORDING TO THE REQUIREMENTS OF USE) X-Y-Z MOTION SYSTEM - THE NOZZLE CAN BE MOVED UP AND DOWN IN THE Z DIRECTION THROUGH THE TOUCH SCREEN CONTROL TO DETERMINE THE APPROPRIATE SPINNING DISTANCE. - THE NOZZLE CAN MOVE BACK AND FORTH ALONG THE YAXIS DIRECTION OF THE TANGENT DIRECTION OF THE RECEIVING FILM TO PREPARE A UNIFORM FIBER FILM. - THE NOZZLE AUTOMATIC ONLINE CLEANING DEVICE SCANS ALONG THE X-AXIS DIRECTION. COLLECTOR - STAINLESS STEEL PLATE / MESH SERVES AS A CARRIER FOR THE FIBER MEMBRANE SUBSTRATE. - CONNECTED WITH NEGATIVE HIGH VOLTAGE. - RECEIVER BOARD WIDTH: 500 mm - SPINNING DISTANCE: 80 TO 300 mm ADJUSTABLE WINDER AND UNWINDER - AUTOMATICALLY CALCULATE THE ROLL DIAMETER OF THE LOADED MATERIAL AND CONTROL THE TENSION BETWEEN THE UNWINDING AND SPINNING SECTIONS. - CONSTANT FEEDING SPEED. THE FEEDING SPEED RANGE IS 0 TO 5000 mm / min. - ONLINE HOT PRESSING FUNCTION MODULE. AFTER THE SPINNING IS COMPLETED, BEFORE THE WINDING, A TEMPERATURE-CONTROLLED HOT PRESSING DEVICE (ROOM TEMPERATURE TO 60 ° C) IS USED FOR HOT PRESSING. (OPTIONAL THIRD LAYER MATERIAL STICKING AND REWINDING DEVICE). - CAN BE OPERATED BY TOUCH SCREEN. - DO NOT USE METAL FILM AS THE RECEIVING CARRIER. SYRINGE PUMP - 200ML X 4N CHANNEL - FLOW RATE: 0.1ML / H TO 1280 ML / H - SPECIALLY DESIGNED FOR ELECTRO-SPINNING AND RESISTANT TO HIGH VOLTAGE. HIGH VOLTAGE DEVICE -0 TO 50KV, DIGITAL DISPLAY --50KV ~ 0 KV, DIGITAL DISPLAY -OUTPUT CURRENT: <1 MA -CONTINUOUSLY ADJUSTABLE CONTROL SYSTEM -PLC CONTROL SYSTEM, 7-INCH TOUCH SCREEN. -CONTROL THE MOVEMENT OF THE NOZZLE. -CONTROL THE NOZZLE TO MOVE UP AND DOWN. -YOU CAN SET THE MOVEMENT TIME, STROKE AND SPEED OF THE NOZZLE. -CONTROL THE FREQUENCY OF NOZZLE CLEANING. -SPINNING PROCESS PARAMETER RECORDS. ENVIRONMENTAL CONTROL SYSTEM -PROVIDE INTERFACE TO LET IN DRY AMBIENT HUMIDITY AIR. -AN EXTERNAL DEHUMIDIFIER CAN BE USED TO CONTROL THE AMBIENT HUMIDITY. THE EXTERNAL DEHUMIDIFIER NEEDS TO BE SELECTED ACCORDING TO THE SIZE OF THE WORKSHOP. THIS EQUIPMENT DOES NOT INCLUDE THIS DEHUMIDIFIER. EXHAUST SYSTEM -BOTTOM UP, AND FOUR FANS ARE PUMPED AT THE SAME TIME. -THE DISCHARGE VOLUME OF A SINGLE UNIT IS 5 TO 150 M3 / H, AND THE RATE IS ADJUSTABLE. THE COMBINED DISCHARGE VOLUME OF THE TWO EXHAUST FANS IS 10 TO 300M3 / H. THE EXTRACTOR IS DRAWN FROM THE MIDDLE. IN THIS WAY, THE HIGH-SPEED AIR VENTILATION MINIMIZES THE RELATIVE DISTURBANCE TO THE SPINNING. THE EXHAUST FAN IS A SILENT EXHAUST FAN. SAFETY -AUTOMATIC POWER-OFF DEVICE FOR OPENING THE DOOR. -RESIDUAL STATIC ELECTRICITY REMOVAL DEVICE. -EMERGENCY STOP SWITCH. -GROUND AT MULTIPLE POINTS. -ALARM DEVICE AFTER THE CONTROL PARAMETERS EXCEED THE LIMIT. CHAMBER -THE CHAMBER IS MADE OF ALUMINUM ALLOY FRAME. -THE FRONT AND SIDE WINDOWS OF THE CABINET ARE MADE OF TEMPERED GLASS. -MULTI-POINT TEMPERATURE AND HUMIDITY COLLECTION AND DISPLAY. -THE PROCESS CAN BE OBSERVED WITH THE NAKED EYE. -AIR INLET: HOT AND DRY AIR CAN BE INTRODUCED TO QUICKLY ADJUST THE HUMIDITY INSIDE THE CHAMBER. POWER SOURCE -220 VOLTS AND 50/60 Hz -TOTAL POWER: 10KW NUMBER OF NEEDLES: 128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ARBITRARILY REDUCED ACCORDING TO THE SOLVENT USAGE) FLOW RATE OF EACH NEEDLE: (~ 3ML ± 50%) / HOUR TOTAL FLOW OF THE WHOLE MACHINE: ABOUT (400ML ± 50%) / HOUR SOLUTION CONCENTRATION: 10 TO 20% 8 HOURS SOLUTION PROCESSING CAPACITY: ABOUT (3L ± 50%) / 8 HOURS SOLID CONTENT (WEIGHT OF FIBER PRODUCED): (300G ± 50%) / 8 HOURS ACCORDING TO THE APPROXIMATE PRODUCTION OF FIBER MATERIAL WITH A GRAM WEIGHT OF 2GSM. WINDING AND UNWINDING SPEED: 50M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 25 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 200 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: 600 SQUARE METERS BASED ON THE PRODUCTION OF FIBER MATERIAL WITH A GRAMMAGE OF 0.02G / ㎡, APPROXIMATELY: WINDING AND UNWINDING SPEED: 5000M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 2500 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 20,000 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: ABOUT 60,000 SQUARE METERS Learn More

INDUSTRIAL ELECTROSPINNING MACHINEREFERENCE NUMBER: A-2471 INDUSTRIAL ELECTROSPINNING MACHINE A MASS PRODUCTION MACHINE OF ELECTROSPINNING. ALUMINUM FRAME STRUCTURE MAKES IT POSSIBLE FOR EXTENDING DIFFERENT FUNCTIONS. THE SPINNERET USED IS MULTI-NEEDLE ARRAYS, FROM 64 TO 384 NEEDLES ARE EQUIPPED. THE LENGTH AND WIDTH CAN BE MADE ACCORDING TO CUSTOMER'S REQUIREMENT. ROLL TO ROLL COLLECTOR AND CONTINUOUS COLLECTOR CAN BE USED BASED ON THE THICKNESS OF REQUIRED FIBER SHEET. FOR SOLUTIONS, A MULTI-CHANNEL PUMP WILL BE SUPPLIED FOR LONG TIME PRODUCTION OR NONE-STOP PRODUCTION. FEATURES: - EQUIPPED WITH BOTH POSITIVE & NEGATIVE HIGH VOLTAGE SUPPLY DEVICES - EQUIPPED WITH UNWINDING & WINDING MACHINES - CONTINUOUS ELECTROSPINNING & WINDING - ALUMINUM ALLOY FRAME STRUCTURE, MULTI-FUNCTIONS EXPANSIBLE - MULTI-NEEDLES IN ARRAYS. 16 NEEDLES X N ROWS, UP TO 384 NEEDLES - SPINNERET MOVING MACHINERY ENSURES EVEN FIBER SHEET - ONLINE AUTO-CLEAN DEVICE FOR NEEDLES - THICKNESS OF THE FIBER SHEET IS CONTROLLABLE - CE & FCC CERTIFICATE SPINNERET STANDARD:16 NEEDLES X 8 GROUPS =128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ADJUSTED FREELY ACCORDING TO THE REQUIREMENTS OF USE) X-Y-Z MOTION SYSTEM - THE NOZZLE CAN BE MOVED UP AND DOWN IN THE Z DIRECTION THROUGH THE TOUCH SCREEN CONTROL TO DETERMINE THE APPROPRIATE SPINNING DISTANCE. - THE NOZZLE CAN MOVE BACK AND FORTH ALONG THE YAXIS DIRECTION OF THE TANGENT DIRECTION OF THE RECEIVING FILM TO PREPARE A UNIFORM FIBER FILM. - THE NOZZLE AUTOMATIC ONLINE CLEANING DEVICE SCANS ALONG THE X-AXIS DIRECTION. COLLECTOR - STAINLESS STEEL PLATE / MESH SERVES AS A CARRIER FOR THE FIBER MEMBRANE SUBSTRATE. - CONNECTED WITH NEGATIVE HIGH VOLTAGE. - RECEIVER BOARD WIDTH: 500 mm - SPINNING DISTANCE: 80 TO 300 mm ADJUSTABLE WINDER AND UNWINDER - AUTOMATICALLY CALCULATE THE ROLL DIAMETER OF THE LOADED MATERIAL AND CONTROL THE TENSION BETWEEN THE UNWINDING AND SPINNING SECTIONS. - CONSTANT FEEDING SPEED. THE FEEDING SPEED RANGE IS 0 TO 5000 mm / min. - ONLINE HOT PRESSING FUNCTION MODULE. AFTER THE SPINNING IS COMPLETED, BEFORE THE WINDING, A TEMPERATURE-CONTROLLED HOT PRESSING DEVICE (ROOM TEMPERATURE TO 60 ° C) IS USED FOR HOT PRESSING. (OPTIONAL THIRD LAYER MATERIAL STICKING AND REWINDING DEVICE). - CAN BE OPERATED BY TOUCH SCREEN. - DO NOT USE METAL FILM AS THE RECEIVING CARRIER. SYRINGE PUMP - 200ML X 4N CHANNEL - FLOW RATE: 0.1ML / H TO 1280 ML / H - SPECIALLY DESIGNED FOR ELECTRO-SPINNING AND RESISTANT TO HIGH VOLTAGE. HIGH VOLTAGE DEVICE -0 TO 50KV, DIGITAL DISPLAY --50KV ~ 0 KV, DIGITAL DISPLAY -OUTPUT CURRENT: <1 MA -CONTINUOUSLY ADJUSTABLE CONTROL SYSTEM -PLC CONTROL SYSTEM, 7-INCH TOUCH SCREEN. -CONTROL THE MOVEMENT OF THE NOZZLE. -CONTROL THE NOZZLE TO MOVE UP AND DOWN. -YOU CAN SET THE MOVEMENT TIME, STROKE AND SPEED OF THE NOZZLE. -CONTROL THE FREQUENCY OF NOZZLE CLEANING. -SPINNING PROCESS PARAMETER RECORDS. ENVIRONMENTAL CONTROL SYSTEM -PROVIDE INTERFACE TO LET IN DRY AMBIENT HUMIDITY AIR. -AN EXTERNAL DEHUMIDIFIER CAN BE USED TO CONTROL THE AMBIENT HUMIDITY. THE EXTERNAL DEHUMIDIFIER NEEDS TO BE SELECTED ACCORDING TO THE SIZE OF THE WORKSHOP. THIS EQUIPMENT DOES NOT INCLUDE THIS DEHUMIDIFIER. EXHAUST SYSTEM -BOTTOM UP, AND FOUR FANS ARE PUMPED AT THE SAME TIME. -THE DISCHARGE VOLUME OF A SINGLE UNIT IS 5 TO 150 M3 / H, AND THE RATE IS ADJUSTABLE. THE COMBINED DISCHARGE VOLUME OF THE TWO EXHAUST FANS IS 10 TO 300M3 / H. THE EXTRACTOR IS DRAWN FROM THE MIDDLE. IN THIS WAY, THE HIGH-SPEED AIR VENTILATION MINIMIZES THE RELATIVE DISTURBANCE TO THE SPINNING. THE EXHAUST FAN IS A SILENT EXHAUST FAN. SAFETY -AUTOMATIC POWER-OFF DEVICE FOR OPENING THE DOOR. -RESIDUAL STATIC ELECTRICITY REMOVAL DEVICE. -EMERGENCY STOP SWITCH. -GROUND AT MULTIPLE POINTS. -ALARM DEVICE AFTER THE CONTROL PARAMETERS EXCEED THE LIMIT. CHAMBER -THE CHAMBER IS MADE OF ALUMINUM ALLOY FRAME. -THE FRONT AND SIDE WINDOWS OF THE CABINET ARE MADE OF TEMPERED GLASS. -MULTI-POINT TEMPERATURE AND HUMIDITY COLLECTION AND DISPLAY. -THE PROCESS CAN BE OBSERVED WITH THE NAKED EYE. -AIR INLET: HOT AND DRY AIR CAN BE INTRODUCED TO QUICKLY ADJUST THE HUMIDITY INSIDE THE CHAMBER. POWER SOURCE -220 VOLTS AND 50/60 Hz -TOTAL POWER: 10KW NUMBER OF NEEDLES: 128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ARBITRARILY REDUCED ACCORDING TO THE SOLVENT USAGE) FLOW RATE OF EACH NEEDLE: (~ 3ML ± 50%) / HOUR TOTAL FLOW OF THE WHOLE MACHINE: ABOUT (400ML ± 50%) / HOUR SOLUTION CONCENTRATION: 10 TO 20% 8 HOURS SOLUTION PROCESSING CAPACITY: ABOUT (3L ± 50%) / 8 HOURS SOLID CONTENT (WEIGHT OF FIBER PRODUCED): (300G ± 50%) / 8 HOURS ACCORDING TO THE APPROXIMATE PRODUCTION OF FIBER MATERIAL WITH A GRAM WEIGHT OF 2GSM. WINDING AND UNWINDING SPEED: 50M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 25 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 200 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: 600 SQUARE METERS BASED ON THE PRODUCTION OF FIBER MATERIAL WITH A GRAMMAGE OF 0.02G / ㎡, APPROXIMATELY: WINDING AND UNWINDING SPEED: 5000M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 2500 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 20,000 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: ABOUT 60,000 SQUARE METERS Learn More -

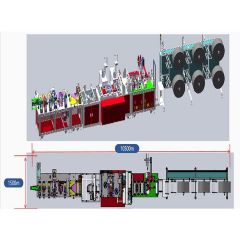

Y-2003 FULLY AUTOMATIC N95 FACE MASK MACHINE, 35 MASKS PER MINUTE

Y-2003 FULLY AUTOMATIC N95 FACE MASK MACHINE, 35 MASKS PER MINUTECAPACITY: 30-35 MASKS PER MINUTE

HIGH STABILITY, LOW FAILURE RATE

COMPUTER CONTROLLED OPERATIONS DRIVEN BY PLC

WITH AUTOMATIC TENSION CONTROL

VOLTAGE: 380 VOLTS, +5%, 50 Hz (OR AS PER CUSTOMER)

TOTAL POWER: ABOUT 15 KW

DIMENSIONS: L 10500 x W 1500 x H 2200mmQUANTITY: 1

Learn More -

R-2243 SULZER P7300HP LOOMS, WIDTH 3600mm, YEAR 2008, CAM

R-2243 SULZER P7300HP LOOMS, WIDTH 3600mm, YEAR 2008, CAMR-2243 SULZER P7300HP LOOMS, WIDTH 3600mm, YEAR 2008, CAM

SULZER P7300HP

WIDTH: 3600mm

MODEL: P7300HP

TYPE V8 B360 N 2 EP D12 R

YEAR: 2008

WITH IRON PROJECTILE FEEDER - LAST GENERATION (NO CARBON)

AUTOMATIC LUBRICATION

WITH LED LIGHT AND WITH A WEFT TENSIONER SYSTEM CALLED “COBRA”

10 HEALD FRAMES

8 CAMS (2 LOOMS 3/1 - 2 LOOMS 2/2)

10000 HEDDLES

10000 DROPPERS

THERE ARE TWO DIFFERENT TAKE UP ROLLERS: THE ONES WHICH ARE “UNDERGROUND” WITH INSPECTING MACHINE (THESE ARE IN 3600mm)

AND “NORMAL” ONES WHICH ARE 3900mm – CAN CHOOSE ANY ONE

WEFT FEEDERS NOT INCLUDED

LOOMS ALREADY STOPPED AT WAREHOUSE

INSPECTION POSSIBLE

TOP CONDITIONQUANTITY: 4

Learn More -

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSES

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSESREFERENCE NUMBER: V-1468

SURGICAL GAUZE COMPRESSING, FOLDING, AND BAGGING MACHINE

COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTONG GAUZE, COMPRESSES, AND THEN PACKS THEM INDIVIDUALLY OR IN GROUPS INTO SACHETS.

FEATURES

USEFUL WIDTH: 45 CM

NUMBER OF TRACKS: MAXIMUM 2 (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

SIZE:

MINIMUM DIMENSIONS OF COMPRESSES: 5 CM X 5 CM

MAXIMUM DIMENSIONS OF COMPRESSES: 10 CM X 20 CM (16 PLIES)

ALL THE USUAL OR INTERMEDIATE SIZES CAN BE PRODUCED ON THE MACHINE BY SIMPLE ADJUSTMENTS.

NUMBER OF PLIES 8 / 12 / 16 / 20 / 24 / 28 / 32 PLIES (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

FOLDING: THE CONVENTIONAL FOLDING IS THE 5-FOLD "SURGICAL" OR "AMERICAN" TYPE, WITH EDGES AND CORNERS TUCKED-IN, HOWEVER BY OFFSETTING FOLDS OTHER COMBINATIONS ARE POSSIBLE.

STACKING: STACKING IS CARRIED OUT IN THE CHANNELS WHERE THE COMPRESSES ARE COUNTED AND READY TO BE MANUALLY INSERTED INTO PAPER BAGS.

PRODUCTION :

EXAMPLES OF THEORETICAL PRODUCTIONS:

5 CM X5 CM 8 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

7.5 CM X 7.5 CM 12 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

10 CM X 10 CM 12 PLIES (2 TRACKS) 12000 COMPRESSES PER HOUR

OPTIONS:

BARIUM FIXING TRACK BY TRACK

GAUZE ROLL LOADING BY PNEUMATIC CYLINDERS"

FEATURES LIST:

MATERIAL SUPPORT ADJUSTABLE IN WIDTH,

POSITIVE UNWINDING WITH TENSION CHECK ADJUSTABLE TRACK BY TRACK,

MULTIPLE LENGTH FOLDING DEVICE ADJUSTABLE TRACK BY TRACK,

SPRAY HUMIDIFYING SYSTEM,

SUCTION SYSTEM,

ANTI-STATIC BARS,

ADJUSTABLE FLY CUT MODULE MOTORISED WITH BRUSHLESS MOTOR,

THREE CROSS FOLDING MECHANISMS WITH INDEPENDENT ADJUSTMENT OF EACH FOLD,

TRANSFER BELTS FOR THE COMPRESSES,

MOTORISED LATERAL UNWINDING OF THE PAPER ROLL MODULE,

DEVICE FOR INDIVIDUAL, IN MULTIPLES OR IN SHINGLED FORM PACKAGING - WITH A CHANGEABLE

NUMBER OF COMPRESSES BY SACHET,

CHECK OF FOLLOWING OPERATIONS TRACK BY TRACK:

. END OF FABRIC,

. PRESENCE OF SEAM,

. PRESENCE OF CROSS-FOLDED COMPRESS,

. JAM PREVENTION BEFORE PACKAGING.

COLD SEALING BY PRESSURE AND CUTTING OF SACHETS IN PRINTED AND ZONED PAPER,

POWER SYSTEM OF PACKAGING BY BRUSHLESS MOTOR ALLOWING FOR FLY ADJUSTMENT OF:

. THE COMPRESS POSITION IN THE SACHET,

. THE CROSSWISE KNURLING POSITION,

. THE CROSSWISE CUTTING OF SACHETS.

ACCELERATION RAMP BY FREQUENCY VARIATION,

MACHINE OPERATION BY TOUCH-SENSITIVE SCREEN:

. STORABLE CONFIGURATIONS,

. CLEAR LANGUAGE FAULT DISPLAY,

. COUNTERS : TOTALIZER, PRE-SELECTION, ETC.,

. SOUND AND VISUAL ALARMS,

. "INCIDENT" STATISTICS.

STARTING, STOPPING, STEP BY STEP - BY REMOTE CONTROL.

* CONTINUOUS, TRACK BY TRACK INTEGRATION OF ULTRASONIC BARIUM FIXING.

* PAPER ROLL LOADING BY PNEUMATIC CYLINDERS.

* INK JET MARKING UP TILL 8 LINES.

* SACHETS QUALITY CONTROL DEVICE: EITHER A CHECK BY PHOTO CELLS, OR BY CAMERAS,

* FAULTY SACHET EJECTION DEVICE.

* TABLE WITH CONVERGING BELTS.

Learn More