Search results for: 'Air sep'

-

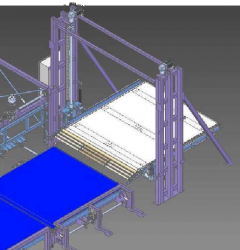

YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) AUTOMATIC UNLOADER FOR FOAM LAYERS MODEL: G220PRO QUANTITY: 1 Learn More

YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2748 AUTOMATIC UNSTACKER FOR FOAM LAYERS MOTORIZED 2 WAY, INTEGRATED BELT FOR FAST ALIGNMENT, MACHINE N. 1, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) AUTOMATIC UNLOADER FOR FOAM LAYERS MODEL: G220PRO QUANTITY: 1 Learn More -

YY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOURYY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOUR THE MACHINE IS COMPOSED OF MOTOR, HYDRAULIC SYSTEM, DRAG HOOK, PULL MOUTH, BODY, ETC. THE BASIC PRINCIPLE IS: THE MOTOR DRIVES THE HYDRAULIC SYSTEM AND HYDRAULIC CYLINDER, AND THE DRAG HOOK IS CONNECTED TO THE PULL ROD OF THE OIL CYLINDER. THE ACTION OF THE OIL PUMP AND OIL CYLINDER MAKES THE DRAG HOOK RECIPROCATE. QUANTITY: 1 Learn More

YY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOURYY-2696 HYDRAULIC TIRE WIRE DRAWING MACHINE (SINGLE HOOK), OUTPUT ABOUT 20 TO 50 PIECES PER HOUR THE MACHINE IS COMPOSED OF MOTOR, HYDRAULIC SYSTEM, DRAG HOOK, PULL MOUTH, BODY, ETC. THE BASIC PRINCIPLE IS: THE MOTOR DRIVES THE HYDRAULIC SYSTEM AND HYDRAULIC CYLINDER, AND THE DRAG HOOK IS CONNECTED TO THE PULL ROD OF THE OIL CYLINDER. THE ACTION OF THE OIL PUMP AND OIL CYLINDER MAKES THE DRAG HOOK RECIPROCATE. QUANTITY: 1 Learn More -

TT-2138 LAROCHE / THIBEAU / ASSELIN / ICBT / FLEISSNER/ SPUNLACE / JETLACE / HYDROENTANGLEMENT LINES, YEAR 2000TT-2138 LAROCHE / THIBEAU / ASSELIN / ICBT / FLEISSNER/ SPUNLACE / JETLACE / HYDROENTANGLEMENT LINES, YEAR 2000 Learn More

TT-2138 LAROCHE / THIBEAU / ASSELIN / ICBT / FLEISSNER/ SPUNLACE / JETLACE / HYDROENTANGLEMENT LINES, YEAR 2000TT-2138 LAROCHE / THIBEAU / ASSELIN / ICBT / FLEISSNER/ SPUNLACE / JETLACE / HYDROENTANGLEMENT LINES, YEAR 2000 Learn More -

TT-1750 HEIDELBERG SPEEDMASTER CD 74 5P2LX2-C, YEAR 2005TT-1750 HEIDELBERG SPEEDMASTER CD 74 5P2LX2-C, YEAR 2005 HEIDELBERG CD 74-5P2+L X2-C YEAR 2005 AVAILABLE: IMMEDIATELY QUANTITY: 1 Learn More

TT-1750 HEIDELBERG SPEEDMASTER CD 74 5P2LX2-C, YEAR 2005TT-1750 HEIDELBERG SPEEDMASTER CD 74 5P2LX2-C, YEAR 2005 HEIDELBERG CD 74-5P2+L X2-C YEAR 2005 AVAILABLE: IMMEDIATELY QUANTITY: 1 Learn More -

YY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINEYY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINE TECHNICAL DATA: 1. INCORPORATED PEGASUS OVERLOCK SEWING MACHINE, WITH HIGH SPEED AND STABLE PERFORMANCE. 2. DUAL MACHINE HEAD SYNCHRONOUS OPERATION, FREELY SWITCHABLE, INDEPENDENT OPERATION, OR RUN SYNCHRO - NOUSLY. 3. ELASTIC TENSION CONTROL STRUCTURE, AUTOMATIC GUIDE STRUCTURE, TO ENSURE ELASTIC SEWING AUTOMATION IS COMPLETED. 4. AUTOMATIC CORRECTION OF ALIGNMENT TO ENSURE THE SEWING PROCESS OF RUBBER BAND PERFECTLY & CONTINUOUS STITCHING. 5. PEDAL CONTROL SEWING SPEED, CUT AND STITCH TOGETHER, EXCESS EDGE MATERIAL CUT AND COLLECTED VIA ABSORPTION BIN. 6. SKIRT WIDTH SUPPORTS: 200 TO 500mm. 7. THREAD BREAKAGE DETECTION AND ALERT WITH ALARM. 8. THE MACHINE OCCUPIES SMALL SPACE, LOW POWER, AND SAVE ENERGY. 9. LARGE THREAD SPOOL HOLDER RACK IS OPTIONAL TO REDUCE FREQUENCY OF THREAT CHANGES. 10. CONSTANT TENSION CONTROL ENSURES THE STITCHING QUALITY OF ELASTIC SKIRT. APPLICATION: FOR MATTRESS PROTECTOR PRODUCTION, AUTOMATIC RUBBER BANDS SEWING, AUTO EDGE-ALIGNMENT, AUTO-FEEDING, DETECT MATERIAL, ETC. QUANTITY: 1 Learn More

YY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINEYY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINE TECHNICAL DATA: 1. INCORPORATED PEGASUS OVERLOCK SEWING MACHINE, WITH HIGH SPEED AND STABLE PERFORMANCE. 2. DUAL MACHINE HEAD SYNCHRONOUS OPERATION, FREELY SWITCHABLE, INDEPENDENT OPERATION, OR RUN SYNCHRO - NOUSLY. 3. ELASTIC TENSION CONTROL STRUCTURE, AUTOMATIC GUIDE STRUCTURE, TO ENSURE ELASTIC SEWING AUTOMATION IS COMPLETED. 4. AUTOMATIC CORRECTION OF ALIGNMENT TO ENSURE THE SEWING PROCESS OF RUBBER BAND PERFECTLY & CONTINUOUS STITCHING. 5. PEDAL CONTROL SEWING SPEED, CUT AND STITCH TOGETHER, EXCESS EDGE MATERIAL CUT AND COLLECTED VIA ABSORPTION BIN. 6. SKIRT WIDTH SUPPORTS: 200 TO 500mm. 7. THREAD BREAKAGE DETECTION AND ALERT WITH ALARM. 8. THE MACHINE OCCUPIES SMALL SPACE, LOW POWER, AND SAVE ENERGY. 9. LARGE THREAD SPOOL HOLDER RACK IS OPTIONAL TO REDUCE FREQUENCY OF THREAT CHANGES. 10. CONSTANT TENSION CONTROL ENSURES THE STITCHING QUALITY OF ELASTIC SKIRT. APPLICATION: FOR MATTRESS PROTECTOR PRODUCTION, AUTOMATIC RUBBER BANDS SEWING, AUTO EDGE-ALIGNMENT, AUTO-FEEDING, DETECT MATERIAL, ETC. QUANTITY: 1 Learn More -

TT-1176 PICANOL SUMMUM AIRJET, WIDTH 2200mm, YEAR 2014 TO 2016, DOBBYTT-1176 PICANOL SUMMUM AIRJET, WIDTH 2200mm, YEAR 2014 TO 2016, DOBBY OMNIPLUSSUMMUM-F-4-R WIDTH 2200mm YEAR 2014 TO 2016 WEIGHT 3100KG 4 COLORS WITH 4 PICANOL 1131 X2 WEFT FEEDERS 4 COLORS, PATTERN MONITORED BY MICROPROCESSOR QUANTITY: 2 Learn More

TT-1176 PICANOL SUMMUM AIRJET, WIDTH 2200mm, YEAR 2014 TO 2016, DOBBYTT-1176 PICANOL SUMMUM AIRJET, WIDTH 2200mm, YEAR 2014 TO 2016, DOBBY OMNIPLUSSUMMUM-F-4-R WIDTH 2200mm YEAR 2014 TO 2016 WEIGHT 3100KG 4 COLORS WITH 4 PICANOL 1131 X2 WEFT FEEDERS 4 COLORS, PATTERN MONITORED BY MICROPROCESSOR QUANTITY: 2 Learn More -

J-4109 HIGH-SPEED ELECTRONIC BAR TACKING SEWING MACHINE, LIFT HEIGHT 117mm, THROAT 280mmJ-4109 HIGH-SPEED ELECTRONIC BAR TACKING SEWING MACHINE, LIFT HEIGHT 117mm, THROAT 280mm HIGH QUALITY DIE STEEL GUARANTEES RIGIDITY, REDUCES DEFORMATION AND MAKES THE HEAD SEPARATION SMOOTH QUANTITY: 1 Learn More

J-4109 HIGH-SPEED ELECTRONIC BAR TACKING SEWING MACHINE, LIFT HEIGHT 117mm, THROAT 280mmJ-4109 HIGH-SPEED ELECTRONIC BAR TACKING SEWING MACHINE, LIFT HEIGHT 117mm, THROAT 280mm HIGH QUALITY DIE STEEL GUARANTEES RIGIDITY, REDUCES DEFORMATION AND MAKES THE HEAD SEPARATION SMOOTH QUANTITY: 1 Learn More -

T-9183 BARMAG FDY LINE 2, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 END, 920mm CHUCK = 102 THREAD LINEST-9183 BARMAG FDY LINE 2, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 END, 920mm CHUCK = 102 THREAD LINES 50-70 DENIER MACHINE IS CAPACITY 3,250 TO 4,600 KG/DAY YEAR 1998 Learn More

T-9183 BARMAG FDY LINE 2, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 END, 920mm CHUCK = 102 THREAD LINEST-9183 BARMAG FDY LINE 2, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 END, 920mm CHUCK = 102 THREAD LINES 50-70 DENIER MACHINE IS CAPACITY 3,250 TO 4,600 KG/DAY YEAR 1998 Learn More -

T-8028 HIGH SPEED SOFT WINDING MACHINET-8028 HIGH SPEED SOFT WINDING MACHINE SIZE: 2050 X 750 X 1500mm SINGLE-SIDE CONFIGURATION: 6 SPINDLES/SET WEIGHT: 150KG QUANTITY: 1 SET (6 SPINDLES) Learn More

T-8028 HIGH SPEED SOFT WINDING MACHINET-8028 HIGH SPEED SOFT WINDING MACHINE SIZE: 2050 X 750 X 1500mm SINGLE-SIDE CONFIGURATION: 6 SPINDLES/SET WEIGHT: 150KG QUANTITY: 1 SET (6 SPINDLES) Learn More -

YY-1136 ULTRAVIOLET STERILIZERYY-1136 ULTRAVIOLET STERILIZER MAINTENANCE OF UV STERILIZER: 1 CHECK REGULARLY TO ENSURE THE NORMAL OPERATION OF THE UV LAMP. 2. AFTER 9000 HOURS OR ONE YEAR OF CONTINUOUS USE, THE ULTRAVIOLET LAMP SHOULD BE REPLACED. WHEN REPLACING A NEW LAMP, FIRST UNPLUG THE POWER SOCKET OF THE LAMP AND TAKE OUT THE ULTRAVIOLET LAMP. PAY ATTENTION NOT TO TOUCH THE QUARTZ GLASS OF THE NEW LAMP WITH YOUR FINGERS, BECAUSE THE STAIN WILL AFFECT THE INTENSITY OF THE LIGHT, AND CAREFULLY PUT THE LAMP INTO THE CHAMBER OF THE STERILIZER. Learn More

YY-1136 ULTRAVIOLET STERILIZERYY-1136 ULTRAVIOLET STERILIZER MAINTENANCE OF UV STERILIZER: 1 CHECK REGULARLY TO ENSURE THE NORMAL OPERATION OF THE UV LAMP. 2. AFTER 9000 HOURS OR ONE YEAR OF CONTINUOUS USE, THE ULTRAVIOLET LAMP SHOULD BE REPLACED. WHEN REPLACING A NEW LAMP, FIRST UNPLUG THE POWER SOCKET OF THE LAMP AND TAKE OUT THE ULTRAVIOLET LAMP. PAY ATTENTION NOT TO TOUCH THE QUARTZ GLASS OF THE NEW LAMP WITH YOUR FINGERS, BECAUSE THE STAIN WILL AFFECT THE INTENSITY OF THE LIGHT, AND CAREFULLY PUT THE LAMP INTO THE CHAMBER OF THE STERILIZER. Learn More