Search results for: 'Foam+machine+s'

-

YY-1834 AUTOMATIC ANGLE FOAM CUTTING MACHINE WITH CONVEYOR, CUTTING ANGLE 16 TO 60°YY-1834 AUTOMATIC ANGLE FOAM CUTTING MACHINE WITH CONVEYOR, CUTTING ANGLE 16 TO 60° THE MACHINE IS WITH TOUCH SCREEN & PLC AUTO CONTROL, THE CUTTING BLADE CAN MOVE UP & DOWN AUTOMATICALLY, WITH AUTOMATIC CONVEYOR AND POSITIONING BAR TO LOAD THE FOAM SHEET. WITH MOTOR TO ADJUST THE ANGLE, WITH A METER TO SHOW THE ANGLE WITH TOUCH SCREEN AND MOTOR TO CONTROL THE BELT AND BLADE FRAME UP AND DOWN, AND VACUUM MOTOR TO SUCK THE FOAM SHEET DOWN. HOT NEW FEATURE: CONVEYOR HAS PERFORATIONS AND MATERIAL BEING CUT STAYS STABLE IN ITS POSITION DUE TO THE SUCTION MOTOR PROVIDING SUCTION THROUGH CONVEYOR PERFORATIONS, ALLOWS MACHINE TO GIVE CLEAN CUTS EVERY TIME. QUANTITY: 1 Learn More

YY-1834 AUTOMATIC ANGLE FOAM CUTTING MACHINE WITH CONVEYOR, CUTTING ANGLE 16 TO 60°YY-1834 AUTOMATIC ANGLE FOAM CUTTING MACHINE WITH CONVEYOR, CUTTING ANGLE 16 TO 60° THE MACHINE IS WITH TOUCH SCREEN & PLC AUTO CONTROL, THE CUTTING BLADE CAN MOVE UP & DOWN AUTOMATICALLY, WITH AUTOMATIC CONVEYOR AND POSITIONING BAR TO LOAD THE FOAM SHEET. WITH MOTOR TO ADJUST THE ANGLE, WITH A METER TO SHOW THE ANGLE WITH TOUCH SCREEN AND MOTOR TO CONTROL THE BELT AND BLADE FRAME UP AND DOWN, AND VACUUM MOTOR TO SUCK THE FOAM SHEET DOWN. HOT NEW FEATURE: CONVEYOR HAS PERFORATIONS AND MATERIAL BEING CUT STAYS STABLE IN ITS POSITION DUE TO THE SUCTION MOTOR PROVIDING SUCTION THROUGH CONVEYOR PERFORATIONS, ALLOWS MACHINE TO GIVE CLEAN CUTS EVERY TIME. QUANTITY: 1 Learn More -

M-2077 ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLEREFERENCE NUMBER: M-2077 (77082KHU6UX) ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLE COMPLETELY MODERNISED VERTICAL FOAM CUTTING MACHINE TYPE IS-M WITH TURNTABLE THAT IS NOW AVAILABLE. QUANTITY AVAILABLE: 1 Learn More

M-2077 ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLEREFERENCE NUMBER: M-2077 (77082KHU6UX) ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLE COMPLETELY MODERNISED VERTICAL FOAM CUTTING MACHINE TYPE IS-M WITH TURNTABLE THAT IS NOW AVAILABLE. QUANTITY AVAILABLE: 1 Learn More -

V-1947 BLOCK FOAM COMPRESSION ROLLING SYSTEM, 120 TON CAPACITY, OUTPUT DIAMETER 500 TO 800mmV-1947 BLOCK FOAM COMPRESSION ROLLING SYSTEM, 120 TON CAPACITY, OUTPUT DIAMETER 500 TO 800mm WORKING TABLE SIZE: 2600 x 2300mm MAXIMUM FOAM SIZE: 2300 x 2600 x 1300mm PRESSURE: 120 TONS WEIGHT: 25,000 KG EXTERNAL DIMENSIONS: 11720 x 3610 x 4000mm TOTAL POWER: 56.5 KW VOLTAGE: 3-PHASE, 380 VOLTS, 50 OR 60 Hz CE CERTIFICATE SPARE PARTS ARE SIEMENS BRAND REQUIRES 2 40 FOOT HQ CONTAINERS TO SHIP QUANTITY: 1 Learn More

V-1947 BLOCK FOAM COMPRESSION ROLLING SYSTEM, 120 TON CAPACITY, OUTPUT DIAMETER 500 TO 800mmV-1947 BLOCK FOAM COMPRESSION ROLLING SYSTEM, 120 TON CAPACITY, OUTPUT DIAMETER 500 TO 800mm WORKING TABLE SIZE: 2600 x 2300mm MAXIMUM FOAM SIZE: 2300 x 2600 x 1300mm PRESSURE: 120 TONS WEIGHT: 25,000 KG EXTERNAL DIMENSIONS: 11720 x 3610 x 4000mm TOTAL POWER: 56.5 KW VOLTAGE: 3-PHASE, 380 VOLTS, 50 OR 60 Hz CE CERTIFICATE SPARE PARTS ARE SIEMENS BRAND REQUIRES 2 40 FOOT HQ CONTAINERS TO SHIP QUANTITY: 1 Learn More -

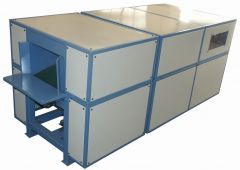

M-5305 QUILTED FABRIC WASTE & FOAM CUTTING MACHINE

M-5305 QUILTED FABRIC WASTE & FOAM CUTTING MACHINEREFERENCE NUMBER: M-5305

QUILTED FABRIC WASTE & FOAM CUTTING MACHINE

QUILTED FABRIC WASTE & FOAM CUTTING MACHINE

ADDITIONAL FAN FEEDING MACHINE MODEL 503

WITH 3 SERIES CUTTERS

WORKING WIDTH: 500mm

DIMENSIONS (LxWxH): 2850mm x 1240mm x 1270mm

CUTTING SIZE (WIDTH): 8mm

POSSIBLE THICKNESS: ≤ 60mm

CAPACITY: 250 TO 300 KG PER HOUR (CUTTING FOAM WASTE)

125 TO 160 KG PER HOUR (CUTTING QUILTED FABRIC WASTE)

POWER: 14.2 KW

WEIGHT: 1,300 KG

QUANTITY: 1 SET

Learn More -

TT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KNTT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KN COMPUTERIZED TENSILE TESTING MACHINE KEY SPECIFICATION: CAPACITY: KGF 3000, 5000, 10000, 15000 KN 30, 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 560 (800 OPTIONAL) CROSSHEAD TRAVEL (mm): 980 (1480 OPTIONAL) TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200, 0.2~200 OR 0.5~500 MAXIMUM FORCE AT FULL SPEED (KGF): 1000, 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100, 50 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION: 0.001 DRIVING METHOD: AC SERVO MOTOR POWER SPECIFICATIONS: 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CONSUMPTION: 3000 KGF 30 KN 5000 KGF 50 KN 10000 KGF 100 KN 15000 KGF 150 KN 2 KVA, 3 KVA, 5 KVA, 10 KVA DIMENSIONS FRAME (mm): 1300 X 600 X 2130 1540 X 600 X 2130 1300 X 600 X 2630 1540 X 600 X 2630 CONTROL BOX (mm) COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG) FRAME 800, CONTROL BOX 100 FRAME 1200, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY Learn More

TT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KNTT-1040 COMPUTERIZED TENSILE TESTING MACHINE, 150KN COMPUTERIZED TENSILE TESTING MACHINE KEY SPECIFICATION: CAPACITY: KGF 3000, 5000, 10000, 15000 KN 30, 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 560 (800 OPTIONAL) CROSSHEAD TRAVEL (mm): 980 (1480 OPTIONAL) TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200, 0.2~200 OR 0.5~500 MAXIMUM FORCE AT FULL SPEED (KGF): 1000, 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100, 50 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION: 0.001 DRIVING METHOD: AC SERVO MOTOR POWER SPECIFICATIONS: 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CONSUMPTION: 3000 KGF 30 KN 5000 KGF 50 KN 10000 KGF 100 KN 15000 KGF 150 KN 2 KVA, 3 KVA, 5 KVA, 10 KVA DIMENSIONS FRAME (mm): 1300 X 600 X 2130 1540 X 600 X 2130 1300 X 600 X 2630 1540 X 600 X 2630 CONTROL BOX (mm) COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG) FRAME 800, CONTROL BOX 100 FRAME 1200, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY Learn More -

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More -

TT-2463 BAUMER OFS-HE3 HORIZONTAL CONTOUR CNC FOAM CUTTING MACHINE, YEAR 2008TT-2463 BAUMER OFS-HE3 HORIZONTAL CONTOUR CNC FOAM CUTTING MACHINE, YEAR 2008 BAUMER OFS-HE3 HORIZONTAL CONTOUR CNC FOAM CUTTING MACHINE YEAR 2008 WITH MATERIAL FEED QUANTITY: 1 Learn More

TT-2463 BAUMER OFS-HE3 HORIZONTAL CONTOUR CNC FOAM CUTTING MACHINE, YEAR 2008TT-2463 BAUMER OFS-HE3 HORIZONTAL CONTOUR CNC FOAM CUTTING MACHINE, YEAR 2008 BAUMER OFS-HE3 HORIZONTAL CONTOUR CNC FOAM CUTTING MACHINE YEAR 2008 WITH MATERIAL FEED QUANTITY: 1 Learn More -

J-4857 FECKEN-KIRFEL D5 FOAM COMPRESSION CUTTING MACHINE, YEAR 1998J-4857 FECKEN-KIRFEL D5 FOAM COMPRESSION CUTTING MACHINE, YEAR 1998 MAKE: FECKEN-KIRFEL MODEL: D5 YEAR: 1998 CONDITION: USED, EXCELLENT QUANTITY: 1 Learn More

J-4857 FECKEN-KIRFEL D5 FOAM COMPRESSION CUTTING MACHINE, YEAR 1998J-4857 FECKEN-KIRFEL D5 FOAM COMPRESSION CUTTING MACHINE, YEAR 1998 MAKE: FECKEN-KIRFEL MODEL: D5 YEAR: 1998 CONDITION: USED, EXCELLENT QUANTITY: 1 Learn More -

YY-1832 AUTOMATIC CARROUSEL SPLITTING MACHINE, DIAMETER 7800mm, CUT HEIGHT 1200mmYY-1832 AUTOMATIC CARROUSEL SPLITTING MACHINE, DIAMETER 7800mm, CUT HEIGHT 1200mm THE MACHINE IS TOUCH SCREEN & PLC AUTO CONTROL, TO CUT SEVERAL FOAM BLOCKS AT THE SAME TIME, IT IS WITH AUTOMATIC FOAM BLOCK LOADING WORKTABLE, AND AUTOMATIC FOAM SHEET DELIVERY SYSTEM. THE HEIGHT OF THE BLADE AND DELIVERY WORKTABLE IS SYNCHRONIZED, WITH SERVO SYSTEM CONTROL. QUANTITY: 1 Learn More

YY-1832 AUTOMATIC CARROUSEL SPLITTING MACHINE, DIAMETER 7800mm, CUT HEIGHT 1200mmYY-1832 AUTOMATIC CARROUSEL SPLITTING MACHINE, DIAMETER 7800mm, CUT HEIGHT 1200mm THE MACHINE IS TOUCH SCREEN & PLC AUTO CONTROL, TO CUT SEVERAL FOAM BLOCKS AT THE SAME TIME, IT IS WITH AUTOMATIC FOAM BLOCK LOADING WORKTABLE, AND AUTOMATIC FOAM SHEET DELIVERY SYSTEM. THE HEIGHT OF THE BLADE AND DELIVERY WORKTABLE IS SYNCHRONIZED, WITH SERVO SYSTEM CONTROL. QUANTITY: 1 Learn More -

J-5462 HOT AIR LAMINATING MACHINE, MAXIMUM LAMINATING THICKNESS 260mm -WORKING AREA 1100 x 700mmJ-5462 HOT AIR LAMINATING MACHINE, MAXIMUM LAMINATING THICKNESS 260mm -WORKING AREA 1100 x 700mm TO LAMINATE EPE, XPE, EPP, EPS, PLASTAZOTE, ETHAFOAM, STRATOCELL FOAM, ETC. YOU CAN LAMINATE DIFFERENT MATERIALS ON ONE MACHINE. QUANTITY: 1 Learn More

J-5462 HOT AIR LAMINATING MACHINE, MAXIMUM LAMINATING THICKNESS 260mm -WORKING AREA 1100 x 700mmJ-5462 HOT AIR LAMINATING MACHINE, MAXIMUM LAMINATING THICKNESS 260mm -WORKING AREA 1100 x 700mm TO LAMINATE EPE, XPE, EPP, EPS, PLASTAZOTE, ETHAFOAM, STRATOCELL FOAM, ETC. YOU CAN LAMINATE DIFFERENT MATERIALS ON ONE MACHINE. QUANTITY: 1 Learn More