Search results for: 'Waste'

- Related search terms

- waste opener

-

YY-2095 POLYURETHANE FOAM CUTTING MACHINEYY-2095 POLYURETHANE FOAM CUTTING MACHINE POWER: 13KW WEIGHT: 1000 KG QUANTITY: 1 Learn More

YY-2095 POLYURETHANE FOAM CUTTING MACHINEYY-2095 POLYURETHANE FOAM CUTTING MACHINE POWER: 13KW WEIGHT: 1000 KG QUANTITY: 1 Learn More -

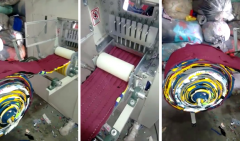

YY-2091 EDGE TRIM OPENERS, WORKING WIDTH 250 OR 500mmYY-2091 EDGE TRIM OPENERS, WORKING WIDTH 250 OR 500mm THE SPEED OF THE FEEDING UNIT AND WORKING ROLLERS IS CONTROLLED BY FREQUENCY INVERTER TO SYNCHRONIZE THE SPEED OF THE MACHINE TO THE LINE OR TO ADAPT TO THE PROCESSED RAW MATERIAL. THE MAIN ADAVANTAGES OF OUR EDGE TRIM OPENERS ARE A SOLID COMPACT DESIGN AND THE SAVINGS OF POST-PRODUCTION WASTES THAT CAN BE RECYCLED AND RE-USED. QUANTITY: 1 Learn More

YY-2091 EDGE TRIM OPENERS, WORKING WIDTH 250 OR 500mmYY-2091 EDGE TRIM OPENERS, WORKING WIDTH 250 OR 500mm THE SPEED OF THE FEEDING UNIT AND WORKING ROLLERS IS CONTROLLED BY FREQUENCY INVERTER TO SYNCHRONIZE THE SPEED OF THE MACHINE TO THE LINE OR TO ADAPT TO THE PROCESSED RAW MATERIAL. THE MAIN ADAVANTAGES OF OUR EDGE TRIM OPENERS ARE A SOLID COMPACT DESIGN AND THE SAVINGS OF POST-PRODUCTION WASTES THAT CAN BE RECYCLED AND RE-USED. QUANTITY: 1 Learn More -

T-9997 CEMENT AND MUD PLANTST-9997 CEMENT AND MUD PLANTS ITEM 001 CEMENT PLANT FULLY FUNCTIONAL CEMENT PLANT READY TO BE REASSEMBLED ITEM 002 MUD PLANT FUNCTIONAL LIQUID MUD PLANT (LMP) 31,500BBL CAPACITY Learn More

T-9997 CEMENT AND MUD PLANTST-9997 CEMENT AND MUD PLANTS ITEM 001 CEMENT PLANT FULLY FUNCTIONAL CEMENT PLANT READY TO BE REASSEMBLED ITEM 002 MUD PLANT FUNCTIONAL LIQUID MUD PLANT (LMP) 31,500BBL CAPACITY Learn More -

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More -

J-2210 DRILLING MACHINE, 2100mm MAX DRILLING WIDTH, 6 TO 28mm HOLE DIAMETERJ-2210 DRILLING MACHINE, 2100mm MAX DRILLING WIDTH, 6 TO 28mm HOLE DIAMETER DRILLING MACHINE VERTICAL DRILLING OF MATTRESSES AND PILLOWS BY MEANS OF SPECIAL INTERCHANGEABLE DRILLS WITH DIFFERENT DIAMETERS MATERIALS: EXPANDED PU FOAM, PE FOAM, VISCO, BONDED FOAM AND SIMILAR, LATEX EXCLUDED VERTICAL AND LATERAL MOVEMENTS OF THE THRUST YOKE ALLOW STRAIGHT AND CROSSED DRILLING, POSSIBLE TO OBTAIN 9 TYPES OF DRAWINGS FOR EACH MATTRESS COMPRESSED AIR JET TAKES FOAM SCRAPS OUT LEAVING HOLES FREE, WASTE EVACUATED WITH SMALL CONVEYOR AND SUCKED AND CONVEYED TO PROPER COLLECTOR STATION FOR RECYCLING CONTROLLED LUBRICATION DEVICE FOR DRILLS PNEUMATIC COMPRESSED DEVICE KEEPS MATTRESS FIRM DURING PERFORATION AND GUARANTEES BETTER PERFORMANCE EASY AND FAST REMOVING AND REPLACING OF DRILLS FEEDING AND UNLOADING CONVEYORS ARE CONTROLLED BY INVERTERS CONTROL CONSOLE COMPLETE WITH MULTIFUNCTION DEVICE (NEXUS) DRILLING SIMULATION AND PRODUCTION TIME AND COST COMPUTATION SOFTWARE INTERCONNECTION (INDUSTRY 4.0) QUANTITY: 1 Learn More

J-2210 DRILLING MACHINE, 2100mm MAX DRILLING WIDTH, 6 TO 28mm HOLE DIAMETERJ-2210 DRILLING MACHINE, 2100mm MAX DRILLING WIDTH, 6 TO 28mm HOLE DIAMETER DRILLING MACHINE VERTICAL DRILLING OF MATTRESSES AND PILLOWS BY MEANS OF SPECIAL INTERCHANGEABLE DRILLS WITH DIFFERENT DIAMETERS MATERIALS: EXPANDED PU FOAM, PE FOAM, VISCO, BONDED FOAM AND SIMILAR, LATEX EXCLUDED VERTICAL AND LATERAL MOVEMENTS OF THE THRUST YOKE ALLOW STRAIGHT AND CROSSED DRILLING, POSSIBLE TO OBTAIN 9 TYPES OF DRAWINGS FOR EACH MATTRESS COMPRESSED AIR JET TAKES FOAM SCRAPS OUT LEAVING HOLES FREE, WASTE EVACUATED WITH SMALL CONVEYOR AND SUCKED AND CONVEYED TO PROPER COLLECTOR STATION FOR RECYCLING CONTROLLED LUBRICATION DEVICE FOR DRILLS PNEUMATIC COMPRESSED DEVICE KEEPS MATTRESS FIRM DURING PERFORATION AND GUARANTEES BETTER PERFORMANCE EASY AND FAST REMOVING AND REPLACING OF DRILLS FEEDING AND UNLOADING CONVEYORS ARE CONTROLLED BY INVERTERS CONTROL CONSOLE COMPLETE WITH MULTIFUNCTION DEVICE (NEXUS) DRILLING SIMULATION AND PRODUCTION TIME AND COST COMPUTATION SOFTWARE INTERCONNECTION (INDUSTRY 4.0) QUANTITY: 1 Learn More -

T-8176 A8 OPEN END MACHINE, 552 ROTORS, YEAR 2015T-8176 A8 OPEN END MACHINE, 552 ROTORS, YEAR 2015 A8 OPEN END MACHINE YEAR 2015 552 ROTORS PER SET SAME TIME CAN PRODUCE 3 TYPE YARN 4 PCS ROBOTS COROLAB CLEANER T633BD ROTOR CUP BD174 COMBING ROLLER MOMENT SPINNING 20S COTTON YARN MACHINE WIDTH: 1547mm QUANTITY: 2 Learn More

T-8176 A8 OPEN END MACHINE, 552 ROTORS, YEAR 2015T-8176 A8 OPEN END MACHINE, 552 ROTORS, YEAR 2015 A8 OPEN END MACHINE YEAR 2015 552 ROTORS PER SET SAME TIME CAN PRODUCE 3 TYPE YARN 4 PCS ROBOTS COROLAB CLEANER T633BD ROTOR CUP BD174 COMBING ROLLER MOMENT SPINNING 20S COTTON YARN MACHINE WIDTH: 1547mm QUANTITY: 2 Learn More -

JJ-1113 POCKET COIL MACHINE FOR POCKET COILS 100mm TALL -FOR BOTH CYLINDRICAL AND BARREL SHAPED POCKET SPRINGS -VIDEOS AVAILABLEJJ-1113 POCKET COIL MACHINE FOR POCKET COILS 100mm TALL -FOR BOTH CYLINDRICAL AND BARREL SHAPED POCKET SPRINGS -VIDEOS AVAILABLE ITEM 001 HIGH SPEED AUTOMATIC DIGITAL POCKET SPRING MACHINE QUANTITY: 1 ITEM 002 POCKET SPRING CUTTING MACHINE QUANTITY: 1 ITEM 003 AUTOMATIC POCKET SPRING ASSEMBLER QUANTITY: 1 WITH 2 YEAR WARRANTY, WEAR-PARTS EXCLUDED Learn More

JJ-1113 POCKET COIL MACHINE FOR POCKET COILS 100mm TALL -FOR BOTH CYLINDRICAL AND BARREL SHAPED POCKET SPRINGS -VIDEOS AVAILABLEJJ-1113 POCKET COIL MACHINE FOR POCKET COILS 100mm TALL -FOR BOTH CYLINDRICAL AND BARREL SHAPED POCKET SPRINGS -VIDEOS AVAILABLE ITEM 001 HIGH SPEED AUTOMATIC DIGITAL POCKET SPRING MACHINE QUANTITY: 1 ITEM 002 POCKET SPRING CUTTING MACHINE QUANTITY: 1 ITEM 003 AUTOMATIC POCKET SPRING ASSEMBLER QUANTITY: 1 WITH 2 YEAR WARRANTY, WEAR-PARTS EXCLUDED Learn More -

J-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mmJ-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mm WORKING WIDTH: 2200mm ROLLER WIDTH: 2400mm LAMINATES FABRIC TO FABRIC AND FABRIC TO FILM GLUE TYPE: HOT MELT PUR GLUE WORKING SPEED: 0 TO 40M/MIN HEATING METHOD: ELECTRICITY, THERMAL OIL INSTALLED CAPACITY: ABOUT 80KVA COMPRESSED AIR: 4-8BAR HEATED PIPE LENGTH: 5M MAIN CONFIGURATION PART ONE BASE FABRIC UNWINDING DEVICE UNWINDING RACK - 4 SET φ74 PNEUMATIC SHAFT - 4 PC DAMPING DEVICE - 4 SET UNWINDING UNIT - 4 EA EPC POSITION ADJUST DEVICE - 1 SET φ75 ALUMINUM ALLOY ROLLER - 5 PC MACHINE RACK - 1 SET FOOTBOARD - 1 EA Learn More

J-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mmJ-3163 PUR HOT MELT GLUE LAMINATING MACHINE, WORKING WIDTH 2200mm WORKING WIDTH: 2200mm ROLLER WIDTH: 2400mm LAMINATES FABRIC TO FABRIC AND FABRIC TO FILM GLUE TYPE: HOT MELT PUR GLUE WORKING SPEED: 0 TO 40M/MIN HEATING METHOD: ELECTRICITY, THERMAL OIL INSTALLED CAPACITY: ABOUT 80KVA COMPRESSED AIR: 4-8BAR HEATED PIPE LENGTH: 5M MAIN CONFIGURATION PART ONE BASE FABRIC UNWINDING DEVICE UNWINDING RACK - 4 SET φ74 PNEUMATIC SHAFT - 4 PC DAMPING DEVICE - 4 SET UNWINDING UNIT - 4 EA EPC POSITION ADJUST DEVICE - 1 SET φ75 ALUMINUM ALLOY ROLLER - 5 PC MACHINE RACK - 1 SET FOOTBOARD - 1 EA Learn More -

DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE, WIDTH 1900mm, YEAR 2016REFERENCE NUMBER: T-6980 DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE, WIDTH 1900mm, YEAR 2016 DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE WIDTH 1900mm FLAT CARBON FIBER YARN YEAR 2016 (INCORPORATING ISUMI WEFT FEEDER AND TEXKIMP COMPOSITE 960 END CREEL) BRIEF TECHNICAL INFORMATION: MAKE AND TYPE: DORNIER PTS 4/S WEFT INSERTION: RAPIER RAPIER: FIXED / POSITIVE WEFT COLORS: 4 (ONLY 1 BEING USED) ECS SELECTORS: 4 WEFT FEED: ISUMI NO TWIST SINGLE FLAT YARN FEEDER MODEL WF-510 WARP FEED: 960 END TEXKIMP COMPOSITE CREEL TYPE CF-F SELVEDGE TYPE: CATCH SELVEDGE CUTTER LHS AND RHS PREINSTALLED SELVEDGE WASTE BIN: 1 DOBBY MODEL & TYPE: STAUBLI S3020 E3 INSTALLED LEVERS: 12 INSTALLED UNDERMOTIONS: 12 FRAMES SUPPLIED: 12 LOOM TAKE-UP: ELECTRICAL LOOM LET-OFF: ELECTRICAL CLOTH ROLLERS: 2 X AIR BARS FOR WINDING ONTO CARDBOARD TUBE HEALD WIRES: AS ON LOOMS CONTROL PANEL: 15 INCHES TOUCHSCREEN PANEL ERGOWEAVE SPARE PARTS & MANUALS: ALL RELATED SPARE PARTS AVAILABLE IN THE FACTORY ELECTRICAL SUPPLY: 3 PHASE 380-415V, 50Hz QUANTITY: 1 Learn More

DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE, WIDTH 1900mm, YEAR 2016REFERENCE NUMBER: T-6980 DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE, WIDTH 1900mm, YEAR 2016 DORNIER PTS4/S RAPIER LOOM SETUP TO WEAVE WIDTH 1900mm FLAT CARBON FIBER YARN YEAR 2016 (INCORPORATING ISUMI WEFT FEEDER AND TEXKIMP COMPOSITE 960 END CREEL) BRIEF TECHNICAL INFORMATION: MAKE AND TYPE: DORNIER PTS 4/S WEFT INSERTION: RAPIER RAPIER: FIXED / POSITIVE WEFT COLORS: 4 (ONLY 1 BEING USED) ECS SELECTORS: 4 WEFT FEED: ISUMI NO TWIST SINGLE FLAT YARN FEEDER MODEL WF-510 WARP FEED: 960 END TEXKIMP COMPOSITE CREEL TYPE CF-F SELVEDGE TYPE: CATCH SELVEDGE CUTTER LHS AND RHS PREINSTALLED SELVEDGE WASTE BIN: 1 DOBBY MODEL & TYPE: STAUBLI S3020 E3 INSTALLED LEVERS: 12 INSTALLED UNDERMOTIONS: 12 FRAMES SUPPLIED: 12 LOOM TAKE-UP: ELECTRICAL LOOM LET-OFF: ELECTRICAL CLOTH ROLLERS: 2 X AIR BARS FOR WINDING ONTO CARDBOARD TUBE HEALD WIRES: AS ON LOOMS CONTROL PANEL: 15 INCHES TOUCHSCREEN PANEL ERGOWEAVE SPARE PARTS & MANUALS: ALL RELATED SPARE PARTS AVAILABLE IN THE FACTORY ELECTRICAL SUPPLY: 3 PHASE 380-415V, 50Hz QUANTITY: 1 Learn More -

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTER

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERREFERENCE NUMBER: J-2326

QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERQUILTING MACHINE FOR RAGS

SEWS RAGS CONTINUOUSLY

SEW HEAD: 7 NEEDLES AND 7 LOOPERS

MAKES A CHAIN STITCH ON THE CONVEYED RAGS

USES OVERLOCK THREAD

DISTANCE BETWEEN NEEDLES: 250mm (ENSURES THAT EVEN SMALL RAGS ARE SEWN)

1 HP MOTOR, 3-PHASE, 220 VOLT

WITH FREQUENCY INVERTER TO ADJUST THE ROTATION SPEED OF THE MOTOR AS NEEDED

HEIGHT: 1800mm

WIDTH: 960mm

DEPTH; 370mm

CONVEYOR WIDTH: 200mm

CONVEYOR LENGTH: 1560mm

MACHINE TOTAL LENGTH WITH CONVEYOR: 2800mmAFTER SEWING, THE QUILT IS TRANSPORTED OUT INTO ROLLS WHICH CAN BE CUT ACCORDING TO CUSTOMER NEEDS

Learn More

OPERATION: PLACE A LARGER RAG AS THE BOTTOM LAYER, SMALLER RAGS AS FILLING, AND ANOTHER LARGER RAG AS THE TOP LAYER. OPERATION REQUIRES 2 TO 3 OPERATORS.

TO REDUCE THE NUMBER OF OPERATORS REQUIRED, A FIBER ROLL AS CAN BE USED AS THE LOWER LAYER. THIS ALSO INCREASES THE PRODUCTION RATE.

DAILY PRODUCTION: VARIES BETWEEN 300 TO 500 KG PER 8 HOURS OF OPERATION

FOR KNIT FABRICS SUCH AS COTTON, VISCOSE, SWEATSHIRT FLEECE, NYLON STRETCH-FABRIC, PIQUET AND POPELINE

THERE IS NO MATERIAL WASTE AS THE MACHINE USES 100% OF THE RAGS

WORKING WIDTH: 12 INCHES

NEEDLE SPACING: 1 INCH

WITH LOOPER STRUCTURE SIMILAR TO THE DIAGRAM BELOW (REDUCES BOTTOM THREAD BREAKAGE)

MACHINE IS NEW, MADE TO ORDER

LEAD TIME: 10 DAYS