Search results for: 'war'

-

E-2239 BENNINGER WARPERS & LEMAIRE TRANSFER PRINT MACHINES FOR SALEINVENTORY NUMBER: E-2239 BENNINGER WARPERS & LEMAIRE TRANSFER PRINT MACHINES FOR SALE 1 BENNINGER "BENTRONIC" SECTIONAL WARPER, WW 3800 MM, YOC 1999 1 BENNINGER SUPERTRONIC ELECTRONIC SECTIONAL WARPER, YOC 1994, WW 2600 MM 1 LEMAIRE ROLLING STATIC SGZ 791 TRANSFER PRINTING MACHINE, YOC 1992 WW 3200 MM 1 LEMAIRE ROLLINGSTATIC SMV - 178 TRANSFER PRINTING MACHINE, YOC 1993, WW 1800 MM QUANTITY AVAILABLE: 4 Learn More

E-2239 BENNINGER WARPERS & LEMAIRE TRANSFER PRINT MACHINES FOR SALEINVENTORY NUMBER: E-2239 BENNINGER WARPERS & LEMAIRE TRANSFER PRINT MACHINES FOR SALE 1 BENNINGER "BENTRONIC" SECTIONAL WARPER, WW 3800 MM, YOC 1999 1 BENNINGER SUPERTRONIC ELECTRONIC SECTIONAL WARPER, YOC 1994, WW 2600 MM 1 LEMAIRE ROLLING STATIC SGZ 791 TRANSFER PRINTING MACHINE, YOC 1992 WW 3200 MM 1 LEMAIRE ROLLINGSTATIC SMV - 178 TRANSFER PRINTING MACHINE, YOC 1993, WW 1800 MM QUANTITY AVAILABLE: 4 Learn More -

M-5080 BENNINGER WARPING CREELS YEAR 1996 – 320 POSITIONSREFERENCE NUMBER: M-5080 (1212AMKGXX11) L BENNINGER WARPING CREELS YEAR 1996 – 320 POSITIONS WARPING CREELS BRAND: BENNINGER 320 POSITIONS YEAR 1996 ENERGY 380V – 50HZ PERFECT CONDITION RUNNING Learn More

M-5080 BENNINGER WARPING CREELS YEAR 1996 – 320 POSITIONSREFERENCE NUMBER: M-5080 (1212AMKGXX11) L BENNINGER WARPING CREELS YEAR 1996 – 320 POSITIONS WARPING CREELS BRAND: BENNINGER 320 POSITIONS YEAR 1996 ENERGY 380V – 50HZ PERFECT CONDITION RUNNING Learn More -

M-5241 SUZUKI NAS 130 WARPER YEAR 2001 WIDTH 2250mmREFERENCE NUMBER: M-5241 (1313DTKPXX12) L SUZUKI NAS 130 WARPER YEAR 2001 WIDTH 2250mm WARPER SUZUKI NAS 130 YEAR 2001 QUANTITY AVAILABLE: 1 Learn More

M-5241 SUZUKI NAS 130 WARPER YEAR 2001 WIDTH 2250mmREFERENCE NUMBER: M-5241 (1313DTKPXX12) L SUZUKI NAS 130 WARPER YEAR 2001 WIDTH 2250mm WARPER SUZUKI NAS 130 YEAR 2001 QUANTITY AVAILABLE: 1 Learn More -

M-5185 COMEZ WARPER YEAR 1998 BEAMS 21X21 PERFECT FOR ELASTAM YARNREFERENCE NUMBER: M-5185 (13135CDT12R) L COMEZ WARPER YEAR 1998 BEAMS 21X21 PERFECT FOR ELASTAM YARN WARPER BRAND: COMEZ YEAR: 1998 QUANTITY AVAILABLE: 1 Learn More

M-5185 COMEZ WARPER YEAR 1998 BEAMS 21X21 PERFECT FOR ELASTAM YARNREFERENCE NUMBER: M-5185 (13135CDT12R) L COMEZ WARPER YEAR 1998 BEAMS 21X21 PERFECT FOR ELASTAM YARN WARPER BRAND: COMEZ YEAR: 1998 QUANTITY AVAILABLE: 1 Learn More -

A-1202 KARL MAYER WARP SAMPLING MACHINE YEAR 1999REFERENCE NUMBER: A-1202 (1212GHBXX11) A KARL MAYER WARP SAMPLING MACHINE YEAR 1999 YEAR: 1999 MODEL: ROM-99-01-102-0 1. 12 POSITION ROTATING CREEL 14 POSITION STATIC CREEL 2200 MM X 1100 MM WARP BEAM CAPACITY QUANTITY AVAILABLE: 1 Learn More

A-1202 KARL MAYER WARP SAMPLING MACHINE YEAR 1999REFERENCE NUMBER: A-1202 (1212GHBXX11) A KARL MAYER WARP SAMPLING MACHINE YEAR 1999 YEAR: 1999 MODEL: ROM-99-01-102-0 1. 12 POSITION ROTATING CREEL 14 POSITION STATIC CREEL 2200 MM X 1100 MM WARP BEAM CAPACITY QUANTITY AVAILABLE: 1 Learn More -

SUZUKI SAMPLE WARPER YEAR 1994 WIDTH 2250mmREFERENCE NUMBER: M-4526 (1111APDSXX10) L SUZUKI SAMPLE WARPER YEAR 1994 WIDTH 2250mm SUZUKI SAMPLE WARPER TYPE: NAS-10S WORKING WIDTH 2250mm YEAR OF CREATION: JULY 1994 QUANTITY AVAILABLE: 1 Learn More

SUZUKI SAMPLE WARPER YEAR 1994 WIDTH 2250mmREFERENCE NUMBER: M-4526 (1111APDSXX10) L SUZUKI SAMPLE WARPER YEAR 1994 WIDTH 2250mm SUZUKI SAMPLE WARPER TYPE: NAS-10S WORKING WIDTH 2250mm YEAR OF CREATION: JULY 1994 QUANTITY AVAILABLE: 1 Learn More -

SUZUKI K5 SECTIONAL WARPER YEAR 1998SUZUKI K5 SECTIONAL WARPER BENNINGER STANDARD CREEL MAXIMUM WARPER 1200 MTS YEAR 1998 Learn More

SUZUKI K5 SECTIONAL WARPER YEAR 1998SUZUKI K5 SECTIONAL WARPER BENNINGER STANDARD CREEL MAXIMUM WARPER 1200 MTS YEAR 1998 Learn More -

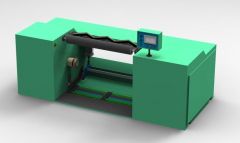

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More -

DIESEL POWER PLANT 81.3MW WARTSILA 18V46 HFODELIVERED IN YEAR 2001 AND OPERATED UNDER WARTSILA O&M TILL END OF 2012 TOTAL OPERATING HOURS APPROXIMATELY 40,000 / ENGINES AND ALL IN GOOD CONDITION GENERATOR DRIVER 5 X WARTSILA 18 CYLINDER / 500 RPM HFO ENGINES TYPE 18V46 COMPLETE PLANT, ELECTRICAL OUTPUT 81.3MW 11KV / 50HZ FROM ALTERNATORS THE ENGINES HAVE COOLING TOWER COOLING SYSTEM AND COMPLETE SET OF AXILLARIES EQUIPMENT IS STILL INSTALLED AND IN A GOOD CONDITION Learn More

DIESEL POWER PLANT 81.3MW WARTSILA 18V46 HFODELIVERED IN YEAR 2001 AND OPERATED UNDER WARTSILA O&M TILL END OF 2012 TOTAL OPERATING HOURS APPROXIMATELY 40,000 / ENGINES AND ALL IN GOOD CONDITION GENERATOR DRIVER 5 X WARTSILA 18 CYLINDER / 500 RPM HFO ENGINES TYPE 18V46 COMPLETE PLANT, ELECTRICAL OUTPUT 81.3MW 11KV / 50HZ FROM ALTERNATORS THE ENGINES HAVE COOLING TOWER COOLING SYSTEM AND COMPLETE SET OF AXILLARIES EQUIPMENT IS STILL INSTALLED AND IN A GOOD CONDITION Learn More -

M-4143 KARL MAYER SECTIONAL WARPER YEAR 2006 WIDTH 2200mmREFERENCE NUMBER: M-4143 (1010AVEXX9)-A KARL MAYER SECTIONAL WARPER YEAR 2006 WIDTH 2200MM Learn More

M-4143 KARL MAYER SECTIONAL WARPER YEAR 2006 WIDTH 2200mmREFERENCE NUMBER: M-4143 (1010AVEXX9)-A KARL MAYER SECTIONAL WARPER YEAR 2006 WIDTH 2200MM Learn More