Search results for: 'Fiber machi'

- Related search terms

- machine'

- machine''

- Machin'

- machine'''''

- Machin''

-

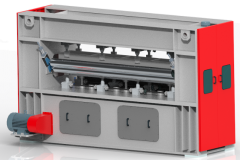

E-4400 QUILTED FOAM WASTE REPROCESSING MACHINEINVENTORY NUMBER: E-4400 QUILTED FOAM WASTE REPROCESSING MACHINE THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING QUANTITY AVAILABLE: 1 Learn More

E-4400 QUILTED FOAM WASTE REPROCESSING MACHINEINVENTORY NUMBER: E-4400 QUILTED FOAM WASTE REPROCESSING MACHINE THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING QUANTITY AVAILABLE: 1 Learn More -

K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW)REFERENCE NUMBER: K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW) THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING. THE MACHINE'S CUTTING TOOLS ARE IMPORTED FROM GERMANY. THE MACHINE CAN CUT THE FOAM INTO REGULAR PIECES AND WITHOUT PRODUCING WASTE POWDER AND CAN ALSO CUT QUILTED FOAM FABRIC WASTE; FOR EXAMPLE MATTRESS TICKING WITH FIBERFILL AND NONWOVEN-BACKING. ORDINARILY QUILTED FABRIC WASTE CANNOT BE REUSED BUT WITH OUR QUILTED FABRIC WASTE AND FOAM CUTTING MACHINE, THE MANUFACTURER CAN RECLAIM THIS WASTE. BY CUTTING THE QUILTED FABRIC WASTE IT IS TRANSFORMED INTO LITTLE PIECES, AND IT CAN BE USED AS FILLING MATERIAL FOR PILLOWS, CUSHIONS, ETC. QUANTITY AVAILABLE: 1 Learn More

K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW)REFERENCE NUMBER: K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW) THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING. THE MACHINE'S CUTTING TOOLS ARE IMPORTED FROM GERMANY. THE MACHINE CAN CUT THE FOAM INTO REGULAR PIECES AND WITHOUT PRODUCING WASTE POWDER AND CAN ALSO CUT QUILTED FOAM FABRIC WASTE; FOR EXAMPLE MATTRESS TICKING WITH FIBERFILL AND NONWOVEN-BACKING. ORDINARILY QUILTED FABRIC WASTE CANNOT BE REUSED BUT WITH OUR QUILTED FABRIC WASTE AND FOAM CUTTING MACHINE, THE MANUFACTURER CAN RECLAIM THIS WASTE. BY CUTTING THE QUILTED FABRIC WASTE IT IS TRANSFORMED INTO LITTLE PIECES, AND IT CAN BE USED AS FILLING MATERIAL FOR PILLOWS, CUSHIONS, ETC. QUANTITY AVAILABLE: 1 Learn More -

TT-7614 COMPLETE NONWOVEN NEEDLEPUNCH LINE, WIDTH 2400mm, YEAR 2017TT-7614 COMPLETE NONWOVEN NEEDLEPUNCH LINE, WIDTH 2400mm, YEAR 2017 1) COMPLETE NONWOVEN NEEDLEPUNCH LINE 2) YEAR 2017 3) CONDITION: USED 4) WORKING WIDTH 2400mm QUANTITY: 1 Learn More

TT-7614 COMPLETE NONWOVEN NEEDLEPUNCH LINE, WIDTH 2400mm, YEAR 2017TT-7614 COMPLETE NONWOVEN NEEDLEPUNCH LINE, WIDTH 2400mm, YEAR 2017 1) COMPLETE NONWOVEN NEEDLEPUNCH LINE 2) YEAR 2017 3) CONDITION: USED 4) WORKING WIDTH 2400mm QUANTITY: 1 Learn More -

TT-7540 LAEM-IMS-GOEBEL SLITTER-REWINDER, 1400mm, YEAR 2007TT-7540 LAEM-IMS-GOEBEL SLITTER-REWINDER, 1400mm, YEAR 2007 1. BRAND: LAEM/IMS/GOEBEL 2. SLITTER REWINDER FOR CONVERTERS 3. DUAL SHAFT CENTRE WINDER WITH SEPARATE SHAFTLESS UNWINDER 4. TR 115-1400 Learn More

TT-7540 LAEM-IMS-GOEBEL SLITTER-REWINDER, 1400mm, YEAR 2007TT-7540 LAEM-IMS-GOEBEL SLITTER-REWINDER, 1400mm, YEAR 2007 1. BRAND: LAEM/IMS/GOEBEL 2. SLITTER REWINDER FOR CONVERTERS 3. DUAL SHAFT CENTRE WINDER WITH SEPARATE SHAFTLESS UNWINDER 4. TR 115-1400 Learn More -

TT-6478 SSI MODEL M85-H DUAL SHAFT SHREDDER WITH CLEATED REM CONVEYOR - TRUCK TIRES, 100 HPTT-6478 SSI MODEL M85-H DUAL SHAFT SHREDDER WITH CLEATED REM CONVEYOR - TRUCK TIRES, 100 HP 1. SSI MODEL M85-H DUAL SHEAR SHREDDER 2. LOW SPEED, HIGH TORQUE, TWO SHAFT, ROTARY SHEAR SHREDDER DESIGNED TO EFFICIENTLY PROCESS A VARIETY OF DIFFICULT MATERIALS. QUANTITY: 1 Learn More

TT-6478 SSI MODEL M85-H DUAL SHAFT SHREDDER WITH CLEATED REM CONVEYOR - TRUCK TIRES, 100 HPTT-6478 SSI MODEL M85-H DUAL SHAFT SHREDDER WITH CLEATED REM CONVEYOR - TRUCK TIRES, 100 HP 1. SSI MODEL M85-H DUAL SHEAR SHREDDER 2. LOW SPEED, HIGH TORQUE, TWO SHAFT, ROTARY SHEAR SHREDDER DESIGNED TO EFFICIENTLY PROCESS A VARIETY OF DIFFICULT MATERIALS. QUANTITY: 1 Learn More -

TT-1644 PLASTIC AGGLOMERATOR, WITH CONVEYOR FEEDTT-1644 PLASTIC AGGLOMERATOR, WITH CONVEYOR FEED MACHINE TECHNICAL SPECIFICATIONS 1. FEEDING METHOD: BY CONVEYOR BELT 2. BELT WIDTH: 600mm 3. BELT LENGTH: 4500mm 4. MOTOR POWER: 2.2KW 380V 50Hz 3-P (OR 440 VOLTS AVAILABLE) 5. MACHINE TYPE: X800 6. CHAMBER VOLUME: 800LITER 7. CHAMBER MATERIAL: 12mm STAINLESS STEEL 8. CAPACITY: 500KG PER HOUR 9. ROTATING KNIFE: 4 PCS, CAN BE ADJUSTABLE 10. FIXED BLADES: 9 PCS 11. KNIFE LIFE TIME: MORE THAN 1000 TONS AT THE FIRST TIME THEN IT CAN BE RE-SHARPENED TO USE AGAIN. 12. BLADE & KNIFE MATERIAL: 9CRSI 13. ROTARY SPEED: 680 RPM 14. MOTOR POWER: 132KW (OR 440 VOLTS AVAILABLE) 380V-50Hz-3P 15. MOTOR MANUFACTURE: WNF FAMOUS 16. DISCHARGE METHOD: PNEUMATIC 17. ELECTRIC CONTROL CASE: SOLID METAL SHEET. 18. CONTACTORS AND SWITCHES: SIEMENS Learn More

TT-1644 PLASTIC AGGLOMERATOR, WITH CONVEYOR FEEDTT-1644 PLASTIC AGGLOMERATOR, WITH CONVEYOR FEED MACHINE TECHNICAL SPECIFICATIONS 1. FEEDING METHOD: BY CONVEYOR BELT 2. BELT WIDTH: 600mm 3. BELT LENGTH: 4500mm 4. MOTOR POWER: 2.2KW 380V 50Hz 3-P (OR 440 VOLTS AVAILABLE) 5. MACHINE TYPE: X800 6. CHAMBER VOLUME: 800LITER 7. CHAMBER MATERIAL: 12mm STAINLESS STEEL 8. CAPACITY: 500KG PER HOUR 9. ROTATING KNIFE: 4 PCS, CAN BE ADJUSTABLE 10. FIXED BLADES: 9 PCS 11. KNIFE LIFE TIME: MORE THAN 1000 TONS AT THE FIRST TIME THEN IT CAN BE RE-SHARPENED TO USE AGAIN. 12. BLADE & KNIFE MATERIAL: 9CRSI 13. ROTARY SPEED: 680 RPM 14. MOTOR POWER: 132KW (OR 440 VOLTS AVAILABLE) 380V-50Hz-3P 15. MOTOR MANUFACTURE: WNF FAMOUS 16. DISCHARGE METHOD: PNEUMATIC 17. ELECTRIC CONTROL CASE: SOLID METAL SHEET. 18. CONTACTORS AND SWITCHES: SIEMENS Learn More -

T-9838 HIGH SPEED BOBBIN WINDING MACHINE, TRAVERSE 250mmT-9838 HIGH SPEED BOBBIN WINDING MACHINE, TRAVERSE 250mm HIGH SPEED BOBBIN WINDING MACHINE SIZE: 1920 X 850 X 1500mm 1 SIDE 1920 X 1200 X 1500mm 2 SIDES CONFIGURATION: 4 SPINDLES/ SET 1 SIDE; 8 SPINDLES/ SET 2 SIDE BOBBIN SPEC: 10″ (280mm TO 300mm) TRANVERSE: 250mm TAKE-UP PACKAGE: CYLINDRICAL (0°); CONE, CAN WINDING 8KG YARN POWER SUPPLY: THREE-PHASE 380V 50/60Hz (ORDERED SEPARATELY) ZINC ALLOY DRUM YARN SENSOR: ELECTRONIC YARN BREAK STOP PACKAGING: WOODEN BOX QUANTITY: 2 SETS (8 SPINDLES) LCL Learn More

T-9838 HIGH SPEED BOBBIN WINDING MACHINE, TRAVERSE 250mmT-9838 HIGH SPEED BOBBIN WINDING MACHINE, TRAVERSE 250mm HIGH SPEED BOBBIN WINDING MACHINE SIZE: 1920 X 850 X 1500mm 1 SIDE 1920 X 1200 X 1500mm 2 SIDES CONFIGURATION: 4 SPINDLES/ SET 1 SIDE; 8 SPINDLES/ SET 2 SIDE BOBBIN SPEC: 10″ (280mm TO 300mm) TRANVERSE: 250mm TAKE-UP PACKAGE: CYLINDRICAL (0°); CONE, CAN WINDING 8KG YARN POWER SUPPLY: THREE-PHASE 380V 50/60Hz (ORDERED SEPARATELY) ZINC ALLOY DRUM YARN SENSOR: ELECTRONIC YARN BREAK STOP PACKAGING: WOODEN BOX QUANTITY: 2 SETS (8 SPINDLES) LCL Learn More -

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More -

T-7740 FOR CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1980T-7740 FOR CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1980 THE MACHINE IS COMPLETE STILL RUNNING RIGID CLOTHING IN GOOD CONDITION MACHINE NICELY MAINTAINED QUANTITY: 1 Learn More

T-7740 FOR CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1980T-7740 FOR CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1980 THE MACHINE IS COMPLETE STILL RUNNING RIGID CLOTHING IN GOOD CONDITION MACHINE NICELY MAINTAINED QUANTITY: 1 Learn More -

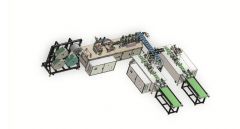

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTE

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTEITEM 001 - MASK PRODUCTION MACHINE WITH (2) ULTRASONIC EAR STRAP WELDING DEVICES

FOR THE PRODUCTION OF SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% (N95)

CAPACITY: 50 FOLDED N95 MASKS PER MINUTE

MASK DIMENSIONS: 175mm x 95mm

MATERIAL TYPE: 3 LAYERS OF POLYPROPYLENE NONWOVEN COMPOSITE FIBER

OPERATION CONTROLLED BY LCD TOUCH SCREEN

AUTOMATICALLY ALIGNS 3 ROLLS OF MATERIAL TO FEED IN (OUTER, FILTER AND INNER LAYERS)

PRESSES BOTH SIDES TOGETHER SYMMETRICALLY WHILE WELDING WITH ULTRASONIC HEAD

SPLITS TO 2 SERPATE WELDING DEVICES FOR EARLOOPS AND SENDS TO DIGITAL COUNTER

EARLOOPS ARE FINISHED WITH ULTRASONIC CUTTING AND WELDING

NOSE BRIDGE CAN BE PRODUCED WITH AUTOMATIC FEEDING, CUTTING AND ULTRASONIC WELDING

ULTRASONIC HEADS

VOLTAGE: 220 VOLTS

WATTS CAPACITY: 1500 WATT

FREQUENCY (KHZ): 20 KHZ

WARRANTY PERIOD FOR HEADS: 1 YEAR

COMPONENT MANUFACTURERS

SERVO MOTOR: PANASONIC / SCHNEIDER

CONTROL SYSTEM: PROPRIETARY

ULTRASONIC GENERATOR: PROPRIETARY, 220 VOLTS, 1.5 KW, 20 KHZ

SENSOR: OMRON / SICK

PNEUMATIC COMPONENT: SMC / FESTO

BELT: SAMSUNG / BANDO

MAIN BODY: PRE-MADE MATERIAL, WELDED ASSEMBLY

BEARINGS: NSK

BALL SCREWS: HIWIN

SECURITY DEVICE: SICK (SAFETY DEVICES TO PROTECT WORKERS)

TOTAL POWER: 4 KW

MACHINE MUST BE STOPPED TO FEED NEW ROLL OF MATERIAL

END OF ROLL DETECTOR INCLUDED: WHEN FABRIC IS FINISHED THE MACHINE WILL ALARM AND STOP

AIR PRESSURE: 0.6 MPa

VOLTAGE: 220 VOLTS, 60 Hz

DIMENSIONS: 6400mm x 4700mm x 1700mm

INCLUDES ELECTRONIC MANUAL BOOK (STORED ON USB MEMORY) AND WARRANTY CARD

OPTIONS (INQUIRE FOR PRICING): EAR STRAP FOLDER

ITEM 001 QUANTITY: 1 MASK PRODUCTION MACHINE AND 2 ULTRASONIC WELDING DEVICES FOR EAR STRAPS

ITEM 002 AUTOMATIC BAGGING MACHINE

SUITABLE FOR AUTOMATIC BAGGING OPERATIONS FOR VARIOUS MASK TYPES

MOTOR CONTROL SYSTEM: SERVO (3), AUTOMATICALLY SETS BAG LENGTH (UP TO 400mm) FOR SPECIFIED BAGGING LENGTH, WITH ANTI-AIR BAG , AUTOMATICALLY DETECTS PRODUCT BASE POINT AND MATERIAL POSITION, AUTOMATIC STOP WHEN OUT OF MATERIAL & STARTS WHEN MATERIAL IS PRESENT

FAST & CONVENIENT SETTING OF PARAMETERS, STORES SETS OF PARAMETERS FOR MULTIPLE PRODUCTS, OPERATOR CAN CHOOSE PARAMETERS ACCORDING TO PRODUCT SIZES

DIAGNOSTICS SYSTEM CLEARS ERROR & RESETS IN SINGLE STEP

HIGHLY SENSITIVE PHOTOELECTRIC EYE COLOR MARK TRACKER, DIGITAL INPUT SEAL/CUT POSITION MAKES SEAL & CUT POSITIONS MORE ACCURATE

TEMPERATURE CONTROLLED WITH INDEPENDENT PID, ALLOWS FOR VARIOUS MATERIALS IN PACKAGING

SIMPLE TRANSMISSION SYSTEM ALLOWS FOR EASY MAINTENANCE AND RELIABILITY

ALL CONTROLS SET BY SOFTWARE ALLOWING FOR ADJUSTING OF FUNCTIONS AND UPGRADES

MATERIALS

PVC FILM (HEAT SEALING), BOPP, OPP, CPP, ALUMINIZED PET FILM, ALUMINUM-PLASTIC FILM, PAPER FILM, PAPER GLUE, OTHER SINGLE- OR MULTIPLE-LAYERED HEAT-SEALED DIALYZABLE MATERIALS, ETC.

LENGTH OF PACKAGE BAGS: ≤400mm

WIDTH OF PACKAGE BAGS: 100 TO 165mm

HEIGHT OF PRODUCT: 55mm MAXIMUM

LENGTH OF FILM: 360mm MAXIMUM

DIAMETER OF FILM ROLL: 320mm MAXIMUM

CAPACITY/SPEED OF PACKAGING: 40 TO 230 BAGS PER MINUTE (1 TO 20 PIECES PER BAG)

POWER: 220 VOLTS, 50 OR 60 Hz, 2.4 KW

DIMENSIONS: 4050mm x 750mm x 1450mm

WEIGHT: APPROXIMATELY 300 KGS

COMPONENT MANUFACTURERS

TOUCH SCREEN: WEINVIEW

SERVO MOTOR: DORNA / WEIDE

SERVO CONTROLLER: DORNA / WEIDE

PROXIMITY SWITCH: OMRON

PHOTOELECTRIC SWITCH: OETAI

TEMPERATURE CONTROLLER: YATAI

SOLID STATE RELAY: SCHNEIDER

INTERMEDIATE RELAY: WEIDMUELLER

OPTIONS, INQUIRE FOR PRICING: STRAIGHT GRAIN SEALING, STAINLESS STEEL FRAME, CODE STAMPER (PRODUCTION DATE), EXHAUST (PINHOLE EXHAUST FEATURE)

ITEM 002 QUANTITY: 1 BAGGING MACHINE

ENTIRE LINE COMPOSED OF ITEM 001 AND ITEM 002

Learn More