Search results for: 'Manual press'

- Related search terms

- manual

- Manual de par

- press t

- press tab

- manual pre

-

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More -

YY-3532 FOAM AIR PERMEABILITY TESTER, 2 OPTIONSYY-3532 FOAM AIR PERMEABILITY TESTER, 2 OPTIONS 2 OPTIONS FOR FOAM AIR PERMEABILITY TESTER THIS INSTRUMENT IS COMPLETELY BASED ON THE NATIONAL STANDARD TEST REQUIREMENTS, RESEARCH AND DEVELOPMENT OF CUSTOM DEVELOPMENT, A COMPLETE REPLACEMENT FOR THE STANDARD RECOMMENDED RXQ-1 TYPE OF FOAM AIR PERMEABILITY TESTER, THE INSTRUMENT HAS A HIGH DEGREE OF INTEGRATION, THE USE OF THE LATEST MEASUREMENT AND CONTROL TECHNOLOGY, TO ACHIEVE THE AUTOMATION OF THE TEST PROCESS, INTELLIGENT, AND IMPROVE THE TESTING ACCURACY. THROUGH THE 7-INCH TOUCH SCREEN, THE ENTIRE TESTING PROCESS OF ONE-KEY OPERATION, SIMPLE OPERATION, INTELLIGENT AND CONVENIENT, IS A MAJOR RESEARCH INSTITUTIONS, SCIENTIFIC RESEARCH INSTITUTES, QUALITY INSPECTION UNITS FOR THE DETERMINATION OF SPONGE AIR PERMEABILITY OF THE NECESSARY INSTRUMENTS. QUANTITY: 1 Learn More

YY-3532 FOAM AIR PERMEABILITY TESTER, 2 OPTIONSYY-3532 FOAM AIR PERMEABILITY TESTER, 2 OPTIONS 2 OPTIONS FOR FOAM AIR PERMEABILITY TESTER THIS INSTRUMENT IS COMPLETELY BASED ON THE NATIONAL STANDARD TEST REQUIREMENTS, RESEARCH AND DEVELOPMENT OF CUSTOM DEVELOPMENT, A COMPLETE REPLACEMENT FOR THE STANDARD RECOMMENDED RXQ-1 TYPE OF FOAM AIR PERMEABILITY TESTER, THE INSTRUMENT HAS A HIGH DEGREE OF INTEGRATION, THE USE OF THE LATEST MEASUREMENT AND CONTROL TECHNOLOGY, TO ACHIEVE THE AUTOMATION OF THE TEST PROCESS, INTELLIGENT, AND IMPROVE THE TESTING ACCURACY. THROUGH THE 7-INCH TOUCH SCREEN, THE ENTIRE TESTING PROCESS OF ONE-KEY OPERATION, SIMPLE OPERATION, INTELLIGENT AND CONVENIENT, IS A MAJOR RESEARCH INSTITUTIONS, SCIENTIFIC RESEARCH INSTITUTES, QUALITY INSPECTION UNITS FOR THE DETERMINATION OF SPONGE AIR PERMEABILITY OF THE NECESSARY INSTRUMENTS. QUANTITY: 1 Learn More -

T-6575 NON-INVASIVE VENTILATOR

T-6575 NON-INVASIVE VENTILATORNON-INVASIVE VENTILATOR

Learn More

CERTIFICATE: CE

MEDICAL VENTILATOR

TECHNICAL PARAMETERS OF DOUBLE LEVEL VENTILATOR

VENTILATOR TYPE: ELECTRIC CONTROL

SCOPE OF APPLICATION: TREATMENT AND TITRATION OF SLEEP APNEA HYPOPNEA SYNDROME, SEVERE SNORING, AND RESPIRATORY INSUFFICIENCY.

DISPLAY INTERFACE: 3.5-INCH LED SCREEN, CHINESE OPERATING SYSTEM

*VENTILATION MODE: CPAP, S, S/T, T

PRESSURE RANGE:

PRESSURE RANGE: 4-30CMH2O (±0.5CMH2O)

PRESSURE ACCURACY: + 0.5CMH2O

PARAMETER SETTING:

DELAYED BOOST: 0-60MIN, SET THE DIVISION INTERVAL 5MIN

INITIAL PRESSURE: 4CMH2O TREATMENT PRESSURE / RESPIRATORY PRESSURE SETTING

THERAPEUTIC PRESSURE: 4-20CMH2O (IN CPAP MODE)

TARGET TIDAL VOLUME: 150ML - 1500ML, ON/ OFF

MAXIMUM SUCTION PRESSURE: 4-30CMH2O, (CAN BE SET WHEN THE TARGET TIDAL VOLUME FUNCTION IS ON)

MINIMUM SUCTION PRESSURE: 4-30CMH2O (NOT HIGHER THAN THE SUCTION PRESSURE), (CAN BE SET WHEN THE TARGET TIDAL VOLUME FUNCTION IS ON)

INSPIRATORY PHASE PRESSURE: 4-30CMH2O

EXPIRATORY PRESSURE: 4-30CMH2O

EXPIRATORY DECOMPRESSION: PATIENT, OFF, 1-3, THREE ADJUSTABLE

MANUAL VOLTAGE REGULATION: 0-2 GEAR, 0-2CMH2O (ONLY AVAILABLE IN CPAP MODE)

INSPIRATORY SENSITIVITY: 1-8 STALLS

EXPIRATORY SENSITIVITY: 1-8 STALLS

RESPIRATORY FREQUENCY: 3-40 TIMES / MIN

INSPIRATORY TIME: 0.3-3.0S

BACKUP RATE: ON / OFF, DEFAULT 10

PRESSURE RISE TIME: 1-4 STALLS

HUMIDIFIER: 1-5 ADJUSTABLE IN 5 GEARS

*TITRATION FUNCTION: SUPPORT MANUAL AND AUTOMATIC PRESSURE TITRATION, BUILT-IN REMOTE WIRELESS COMMUNICATION MODULE, COMPLETE THE RANDOM SWITCHING OF SINGLE AND DOUBLE LEVEL MODES IN THE TITRATION PROCESS, AND CONTROL MORE THAN 11 VENTILATOR PARAMETERS AT THE SAME TIME.

AUXILIARY FUNCTION: AUTOMATIC AIR LEAKAGE COMPENSATION, AUTOMATIC STARTUP, AUTOMATIC SHUTDOWN, DELAYED SHUTDOWN, SCREEN BACKLIGHT ADJUSTMENT

MONITORING PARAMETERS: PRESSURE, TIDAL VOLUME, RESPIRATORY RATE, MINUTE VENTILATION VOLUME, AIR LEAKAGE VOLUME, INSPIRATORY TIME, BLOOD OXYGEN SATURATION

WAVY CURVE: PRESSURE TIME WAVEFORM, FLOW RATE TIME WAVEFORM

ALARM PROMPT: PIPELINE AND MASK FALLING OFF, AIR LEAKAGE PROMPT, POWER INTERRUPTION, TREATMENT MACHINE FAILURE, HUMIDIFIER FAILURE, LOW VOLTAGE, HIGH RESPIRATORY RATE, LOW RESPIRATORY RATE, LOW MINUTE VENTILATION VOLUME, LOW BLOOD OXYGEN, REPLACEMENT OF FILTER COTTON, FULL SD CARD, RE INSERTION OF SD CARD

*DATA MANAGEMENT:

NETWORK DATA: BMC + RESPIRATORY HEALTH MANAGEMENT CLOUD PLATFORM

SD CARD DATA: RESART NPAP DATA ANALYSIS SOFTWARE

PARTS:

SD CARD: STANDARD

SD CARD SLOT: STANDARD

PIPING: 9 22MM, 1.8M LONG

FACE SHIELD: F2 NOSE MASK AS STANDARD

NOISE: LESS THAN 30DB

ENVIRONMENT CONDITION:

TEMPERATURE:

(WHEN USED) 5 -35 C

(DURING TRANSPORTATION AND STORAGE) -20 C -55 C

ATMOSPHERIC PRESSURE:

(WHEN USED) 760-1060HPA

(DURING TRANSPORTATION AND STORAGE) 760-1060HPA

WORKING HOURS: MORE THAN 8 HOURS

POWER SUPPLY REQUIREMENTS:

AC VOLTAGE: 100-240V

FREQUENCY: 50HZ/60HZ

INPUT POWER: LESS THAN 2A

WATERPROOF LEVEL: IP22 - DRIP PROOF EQUIPMENT

INSTRUMENT SIZE: 290mm X 180mm X 134mm

WEIGHT: 1.5KG (EXCLUDING HUMIDIFIER) 2.5KG (INCLUDING HUMIDIFIER)

ITEM 001

QUANTITY: 10 SETS-999 SETS

ITEM 002

QUANTITY: 1,000 SETS-9,999SETS

ITEM 003

QUANTITY: ≥10,000 SETS -

T-1652 SGT 400 GAS TURBINE, 50Hz, YEAR 2017, 11 KV, 12.9 MWT-1652 SGT 400 GAS TURBINE, 50Hz, YEAR 2017, 11 KV, 12.9 MW SGT 400 GAS TURBINE TYPE: STANDARD BRAND: SIEMENS CATEGORY: ENGINES/GENERATORS/MOTORS/TRANSMISSIONS SUBCATEGORY: TURBINE IN STOCK: YES CONDITION: EXCELLENT TYPE: UNUSED SGT-400 GAS TURBINE GENERATOR SET, WITH INTEGRAL LOCAL EQUIPMENT ROOM: UNIT(S) TO BE SUPPLIED ARE UNUSED, WITH ZERO RUNNING HOURS, NEVER INSTALLED THESE UNITS HAVE BEEN STORED INDOORS SINCE MANUFACTURE. QUANTITY: 2 Learn More

T-1652 SGT 400 GAS TURBINE, 50Hz, YEAR 2017, 11 KV, 12.9 MWT-1652 SGT 400 GAS TURBINE, 50Hz, YEAR 2017, 11 KV, 12.9 MW SGT 400 GAS TURBINE TYPE: STANDARD BRAND: SIEMENS CATEGORY: ENGINES/GENERATORS/MOTORS/TRANSMISSIONS SUBCATEGORY: TURBINE IN STOCK: YES CONDITION: EXCELLENT TYPE: UNUSED SGT-400 GAS TURBINE GENERATOR SET, WITH INTEGRAL LOCAL EQUIPMENT ROOM: UNIT(S) TO BE SUPPLIED ARE UNUSED, WITH ZERO RUNNING HOURS, NEVER INSTALLED THESE UNITS HAVE BEEN STORED INDOORS SINCE MANUFACTURE. QUANTITY: 2 Learn More -

TT-5191 CATERPILLAR 3616 MARINE GENSET, 4600KW, 10 HOURS, YEAR 2010, 60Hz, DIESEL OILTT-5191 CATERPILLAR 3616 MARINE GENSET, 4600KW, 10 HOURS, YEAR 2010, 60Hz, DIESEL OIL CATERPILLAR 3616 YEAR: 2010 HOURS: 10 POWER: 4600KW VOLT: 11200V FREQUENCY: 60Hz FUEL: DIESEL OIL MARINE GENSET WITH RADIATOR WITH SPECIFCATION BOOK/MANUAL BOOK DELIVERY TIME: TWO WEEKS QUANTITY: 8 Learn More

TT-5191 CATERPILLAR 3616 MARINE GENSET, 4600KW, 10 HOURS, YEAR 2010, 60Hz, DIESEL OILTT-5191 CATERPILLAR 3616 MARINE GENSET, 4600KW, 10 HOURS, YEAR 2010, 60Hz, DIESEL OIL CATERPILLAR 3616 YEAR: 2010 HOURS: 10 POWER: 4600KW VOLT: 11200V FREQUENCY: 60Hz FUEL: DIESEL OIL MARINE GENSET WITH RADIATOR WITH SPECIFCATION BOOK/MANUAL BOOK DELIVERY TIME: TWO WEEKS QUANTITY: 8 Learn More -

YY-3279 SGT – 600 GAS TURBINE GENERATOR SET, WITH INTEGRAL LOCAL EQUIPMENT ROOMYY-3279 SGT – 600 GAS TURBINE GENERATOR SET, WITH INTEGRAL LOCAL EQUIPMENT ROOM UNIT(S) TO BE SUPPLIED ARE UNUSED, WITH ZERO RUNNING HOURS, NEVER INSTALLED. Learn More

YY-3279 SGT – 600 GAS TURBINE GENERATOR SET, WITH INTEGRAL LOCAL EQUIPMENT ROOMYY-3279 SGT – 600 GAS TURBINE GENERATOR SET, WITH INTEGRAL LOCAL EQUIPMENT ROOM UNIT(S) TO BE SUPPLIED ARE UNUSED, WITH ZERO RUNNING HOURS, NEVER INSTALLED. Learn More -

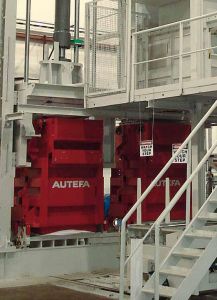

V-2151 AUTEFA, FULLY AUTOMATIC BALING PRESS MODEL LIFT BOX 1500 ADW (DOUBLE ROTATING LIFT BOXES) WITH FULLY AUTOMATIC STRAPPING AND FILM WRAPPING, YEAR 2011 – 45 BALES PER HOUR, BALE WEIGHT: 250KGS – VIDEOS AVAILABLE – NOW FULLY OPERATIONALV-2151 AUTEFA, FULLY AUTOMATIC BALING PRESS MODEL LIFT BOX 1500 ADW (DOUBLE ROTATING LIFT BOXES) WITH FULLY AUTOMATIC STRAPPING AND FILM WRAPPING, YEAR 2011 – 45 BALES PER HOUR, BALE WEIGHT: 250KGS – VIDEOS AVAILABLE – NOW FULLY OPERATIONAL – PERFECT CONDITION SHIPPING: • 3 TO 4 (40FT) CONTAINERS • OVERALL SHIPPING WEIGHT: 25 TONS (APPROXIMATELY) Learn More

V-2151 AUTEFA, FULLY AUTOMATIC BALING PRESS MODEL LIFT BOX 1500 ADW (DOUBLE ROTATING LIFT BOXES) WITH FULLY AUTOMATIC STRAPPING AND FILM WRAPPING, YEAR 2011 – 45 BALES PER HOUR, BALE WEIGHT: 250KGS – VIDEOS AVAILABLE – NOW FULLY OPERATIONALV-2151 AUTEFA, FULLY AUTOMATIC BALING PRESS MODEL LIFT BOX 1500 ADW (DOUBLE ROTATING LIFT BOXES) WITH FULLY AUTOMATIC STRAPPING AND FILM WRAPPING, YEAR 2011 – 45 BALES PER HOUR, BALE WEIGHT: 250KGS – VIDEOS AVAILABLE – NOW FULLY OPERATIONAL – PERFECT CONDITION SHIPPING: • 3 TO 4 (40FT) CONTAINERS • OVERALL SHIPPING WEIGHT: 25 TONS (APPROXIMATELY) Learn More -

TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024 COATING LINE FROM BATH MAT PLANT LENGTH 97000mm WIDTH 7000mm ARTOS LATEX FOR BATHMATSB YEAR OF CONSTRUCTION: 2024 WORKING WIDTH: 1000mm TO 2600mm MAXIMUM SETTING WIDTH: 2750mm SPEED: 1.7 METERS TO 35 METERS PER MINUTE Learn More

TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024 COATING LINE FROM BATH MAT PLANT LENGTH 97000mm WIDTH 7000mm ARTOS LATEX FOR BATHMATSB YEAR OF CONSTRUCTION: 2024 WORKING WIDTH: 1000mm TO 2600mm MAXIMUM SETTING WIDTH: 2750mm SPEED: 1.7 METERS TO 35 METERS PER MINUTE Learn More -

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mm

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmREFERENCE NUMBER: A-1876

END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmPRODUCT TO BE PROCESSED: NEEDLEPUNCHED NONWOVENS

PRODUCT WIDTH: 4.000 MMWORKING SPEED: 1 – 20 M/MIN

QUANTITY: 1

Learn More -

M-4747 INDUSTRIAL BREWERY WITH BREWHOUSE 20 HLREFERENCE NUMBER: M-4747 (1111NBRTHH10) L INDUSTRIAL BREWERY WITH BREWHOUSE 20 HL INDUSTRIAL BREWERY WITH CAPACITY OF 20 HL PER BREW YEAR PRODUCTIVITY OF 6,000 TO 7,000 HL, 3 SORTS OF BEER BREWERY IS NOT LOCATED AT A SEISMIC AREA EQUIPMENT DESIGNED ACCORDING TO EUROPEAN STANDARD STEAM HEATED 2-VESSEL BREW HOUSE OF 20 HECTOLITRES IN STAINLESS STEEL SCOPE OF SUPPLY: MALT MILL 1 X 2-ROLL MILL WITH CAPACITY OF 400 TO 800 KG/H WITH INLET FROM THE TOP FOR MALT SACKS BREW HOUSE 20HL STEAM HEATED STAINLESS STEEL 1.1 MASH/WORTH – KETTLE DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 LLC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL 2 STEAM HEATING ZONES (BOTTOM AND CYLINDRICAL PART) AGITATOR AND SHAFT IN STAINLESS STEEL, MATERIAL 1.4301. INSTALLATION OF BOTTOM CENTER. DRIVE VIA GEAR MOTOR, SPEED CONTROLLABLE BY FREQUENCY CONVERTER 1 SPRAY BALL 1 MAN HOLE WITH GLASS 1 PRESSURE RELIEF VALVE – SAFETY VALVE 1 LEVELMEASUREMENT DESIGNED FOR NON PRESSURE OPERATION 1.2 LAUTER TUN DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL ISOLATION OF THE CYLINDRICAL PART AND THE BOTTOM - 100 MM HALOGEN-FREE MINERAL WOOL. BOTTOM OF THE LAUTER TUN WITH OUTLET VALVES, BACK WASH VALVES AND A DRAIN VALVE MULTIPART SIEVE PLATE 1.4301 REMOVABLE THROUGH MANHOLE. HOEING 1.4301 TWO-ARMED WITH KNIVES AND TREBERN SWORD. INSTALLATION OF BOTTOM CENTER. 1 LAUTER STATION WITH CIP SPRAY BALL 1 MANHOLE WITH GLASS 1 SPRAY BALL 1 TREBERN FLAP AT THE CYLINDRICAL PART DESIGNED FOR NON PRESSURE OPERATION THE PACKAGE INCLUDES ALL VALVES, CHECK VALVES, BUTTERFLY VALVES, 2 PUMPS AND TEMPERATURE PROBES LANDING AND STAIRS MADE OF STAINLESS STEEL SQUARE ROOF BARS, COVERED WITH CORRUGATED SHEET METAL, HEIGHT ADJUSTABLE FEET WITH DOMES. THE PAN DUST WILL BE COLD DOWN WITH COLD WATER AND THE CONDENSATE WILL BE TRANSFERRED TO THE DRAIN WHIRLPOOL 20HL VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION WORTHCOOLING + WORTH AERATION VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION 1. SECTION: 20 HL WORTH IS COOLED WITH COLD WATER FROM 98°C TO 17°C IN 60 MINUTES (COLD WATER FROM CLIENT SIDE MUST BE MAX. 15°C OR LOWER) 2. SECTION: WITH ICE WATER OR GLYCOL THE WORTH IS COOLED TO 5°C CONTROL SYSTEM EACH PNEUMATIC CONTROLLED VALVE WILL HAVE A SWITCH BUTTON ON A CONTROL PANEL IN THE MIDDLE OF THE BREW HOUSE. ALSO THE TEMPERATURE CONTROL OF THE MASH KEETEL AND WORTH KETTLE WILL BE IMPLEMENTED AT THE CONTROL PANEL WITH A HARD WARE CONTROLLER. HOT WATER TANK 30 HL VERTICAL DESIGN, MATERIAL 1.4301 DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF MATERIAL 1.4301 WITH GRAIN 220 1 HOT WATER PUMP 1 CIRCULATION PUMP 1 PT 100 AN CONTROLLER 1 STEAM VALVE AND CONDENSATE VALVE 1 LEVEL INDICATION 10 X CYLINDER CONICAL TANKS 40/48 HL VERTICAL DESIGN WITH DISHED BOTTOM AND 60° CONE. CONE AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 4.050MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) AND CONE COOLING (2 ZONE), BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. SEPARATE CONNECTIONS FOR COOLING FOR CASING AND CONE : NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 2 OUTLET DN 32 INSTALLED IN A DN 125 - THREAD , PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 50, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 2 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 2 SOLENOID VALVE FOR THE COOLING DUCT 4 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. FILTRATION 20 HL/H KISELGUR- FILTER WITH HORIZONTAL SLICES AND CAPACITY OF 20HL / HOUR 3 X PRESSURE DISPENDING TANKS 40/46 HL VERTICAL DESIGN WITH DISHED BOTTOM LOWER + UPPER BOTTOM AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 3.350MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. CONNECTION FOR COOLING: NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 1OUTLET DN 32 PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN 25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32 FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 32, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 1 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 1 SOLENOID VALVE FOR THE COOLING DUCT 2 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. COOLING UNIT COOLING UNIT FOR THE OFFERT TANKS AND FOR THE WORTH COOLING. DESIGNED FOR OPERATION WITH GLYCOL COMPRESSOR OIL FREE FULLY AUTOMATIC, OIL-FREE AIR COMPRESSOR STATION WITH STAGE, MOUNTED ON A PRESSURE VESSEL, EQUIPPED WITH PRESSURE SWITCH, OUTLET VALVE, SAFETY VALVE, PRESSURE GAUGE AND MICRO FILTER. STEAM GENERATOR OIL OPERATED OIL OPERATED STEAM GENERATOR WITH A CAPACITY OF 200 KG/H INCLUDING FEED WATER TREATMENT AND FEED WATER CONTROL MOBILE BEER PUMP BEER PUMP WITH FREQUENCY CONVERTER, SINGLE MECHANICAL SEAL, ON STAINLESS STEEL FRAME (WITH CEE PLUG, MOTOR PROTECTION AND 10 M CABLE) FOR PUMPING FROM THE FERMENTATION TANKS TO THE PRESSURIZED TANK 4 PCS. BEER HOSES SET KEG-CLEANER WITH KEG-HANDFILLER CLEANER: CAPACITY: 10 – 15 KEGS / HOUR SEMI AUTOMATICALLY CLEANING PROCESS FOR ALL STANDARD KEGS KEG-HAND FILLER: COMPLETE MADE OF STAINLESS STEEL TUBES 2M LONG FOR ALL STANDARD KEGS PACKAGING WOODEN BOX AND FOILING FOR TRANSPORT IN A CONTAINER (SEA WAY), THE WOODEN BOX ALONE IS NOT ENOUGH FOR THE SEA WAY DOCUMENTATION IN ENGLISH (DEVICE DOCUMENTATION) IN ELECTRONIC FORM MOUNTING MATERIAL FOR MECHANICAL AND ELECTRICAL WORK UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING MOUNTING AND COMMISSIONING FOR MECHANIC WORK AND ELECTRIC WORK (LIFTING DEVICES- CRANE, ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET, LABOURER FOR MOUNTING SUPPORT) UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING 4 TEST BREWS (ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET) AND TRAINING OF THE OPERATOR STAFF UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING LABORATORY CIVIL WORK CO2 – SUPPLY PERMITS AND LICENSES FROM LOCAL AUTHORITIES TRANSPORT WATER TREATMENT AND COLD WATER TANK (IF REQUIRED) YEAST MANIPULATION (IF REQUIRED) Attached 3 photos from similar equipment. F1: brewhouse F2: CCT (cylindroconicalk tanks) and BBT (bright beer tanks = dispensing tanks) F3: PHE(plate heat exchanger = wort cooling, whirlpool, hot water tank) QUANTITY AVAILABLE: 1 Learn More

M-4747 INDUSTRIAL BREWERY WITH BREWHOUSE 20 HLREFERENCE NUMBER: M-4747 (1111NBRTHH10) L INDUSTRIAL BREWERY WITH BREWHOUSE 20 HL INDUSTRIAL BREWERY WITH CAPACITY OF 20 HL PER BREW YEAR PRODUCTIVITY OF 6,000 TO 7,000 HL, 3 SORTS OF BEER BREWERY IS NOT LOCATED AT A SEISMIC AREA EQUIPMENT DESIGNED ACCORDING TO EUROPEAN STANDARD STEAM HEATED 2-VESSEL BREW HOUSE OF 20 HECTOLITRES IN STAINLESS STEEL SCOPE OF SUPPLY: MALT MILL 1 X 2-ROLL MILL WITH CAPACITY OF 400 TO 800 KG/H WITH INLET FROM THE TOP FOR MALT SACKS BREW HOUSE 20HL STEAM HEATED STAINLESS STEEL 1.1 MASH/WORTH – KETTLE DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 LLC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL 2 STEAM HEATING ZONES (BOTTOM AND CYLINDRICAL PART) AGITATOR AND SHAFT IN STAINLESS STEEL, MATERIAL 1.4301. INSTALLATION OF BOTTOM CENTER. DRIVE VIA GEAR MOTOR, SPEED CONTROLLABLE BY FREQUENCY CONVERTER 1 SPRAY BALL 1 MAN HOLE WITH GLASS 1 PRESSURE RELIEF VALVE – SAFETY VALVE 1 LEVELMEASUREMENT DESIGNED FOR NON PRESSURE OPERATION 1.2 LAUTER TUN DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL ISOLATION OF THE CYLINDRICAL PART AND THE BOTTOM - 100 MM HALOGEN-FREE MINERAL WOOL. BOTTOM OF THE LAUTER TUN WITH OUTLET VALVES, BACK WASH VALVES AND A DRAIN VALVE MULTIPART SIEVE PLATE 1.4301 REMOVABLE THROUGH MANHOLE. HOEING 1.4301 TWO-ARMED WITH KNIVES AND TREBERN SWORD. INSTALLATION OF BOTTOM CENTER. 1 LAUTER STATION WITH CIP SPRAY BALL 1 MANHOLE WITH GLASS 1 SPRAY BALL 1 TREBERN FLAP AT THE CYLINDRICAL PART DESIGNED FOR NON PRESSURE OPERATION THE PACKAGE INCLUDES ALL VALVES, CHECK VALVES, BUTTERFLY VALVES, 2 PUMPS AND TEMPERATURE PROBES LANDING AND STAIRS MADE OF STAINLESS STEEL SQUARE ROOF BARS, COVERED WITH CORRUGATED SHEET METAL, HEIGHT ADJUSTABLE FEET WITH DOMES. THE PAN DUST WILL BE COLD DOWN WITH COLD WATER AND THE CONDENSATE WILL BE TRANSFERRED TO THE DRAIN WHIRLPOOL 20HL VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION WORTHCOOLING + WORTH AERATION VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION 1. SECTION: 20 HL WORTH IS COOLED WITH COLD WATER FROM 98°C TO 17°C IN 60 MINUTES (COLD WATER FROM CLIENT SIDE MUST BE MAX. 15°C OR LOWER) 2. SECTION: WITH ICE WATER OR GLYCOL THE WORTH IS COOLED TO 5°C CONTROL SYSTEM EACH PNEUMATIC CONTROLLED VALVE WILL HAVE A SWITCH BUTTON ON A CONTROL PANEL IN THE MIDDLE OF THE BREW HOUSE. ALSO THE TEMPERATURE CONTROL OF THE MASH KEETEL AND WORTH KETTLE WILL BE IMPLEMENTED AT THE CONTROL PANEL WITH A HARD WARE CONTROLLER. HOT WATER TANK 30 HL VERTICAL DESIGN, MATERIAL 1.4301 DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF MATERIAL 1.4301 WITH GRAIN 220 1 HOT WATER PUMP 1 CIRCULATION PUMP 1 PT 100 AN CONTROLLER 1 STEAM VALVE AND CONDENSATE VALVE 1 LEVEL INDICATION 10 X CYLINDER CONICAL TANKS 40/48 HL VERTICAL DESIGN WITH DISHED BOTTOM AND 60° CONE. CONE AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 4.050MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) AND CONE COOLING (2 ZONE), BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. SEPARATE CONNECTIONS FOR COOLING FOR CASING AND CONE : NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 2 OUTLET DN 32 INSTALLED IN A DN 125 - THREAD , PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 50, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 2 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 2 SOLENOID VALVE FOR THE COOLING DUCT 4 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. FILTRATION 20 HL/H KISELGUR- FILTER WITH HORIZONTAL SLICES AND CAPACITY OF 20HL / HOUR 3 X PRESSURE DISPENDING TANKS 40/46 HL VERTICAL DESIGN WITH DISHED BOTTOM LOWER + UPPER BOTTOM AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 3.350MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. CONNECTION FOR COOLING: NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 1OUTLET DN 32 PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN 25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32 FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 32, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 1 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 1 SOLENOID VALVE FOR THE COOLING DUCT 2 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. COOLING UNIT COOLING UNIT FOR THE OFFERT TANKS AND FOR THE WORTH COOLING. DESIGNED FOR OPERATION WITH GLYCOL COMPRESSOR OIL FREE FULLY AUTOMATIC, OIL-FREE AIR COMPRESSOR STATION WITH STAGE, MOUNTED ON A PRESSURE VESSEL, EQUIPPED WITH PRESSURE SWITCH, OUTLET VALVE, SAFETY VALVE, PRESSURE GAUGE AND MICRO FILTER. STEAM GENERATOR OIL OPERATED OIL OPERATED STEAM GENERATOR WITH A CAPACITY OF 200 KG/H INCLUDING FEED WATER TREATMENT AND FEED WATER CONTROL MOBILE BEER PUMP BEER PUMP WITH FREQUENCY CONVERTER, SINGLE MECHANICAL SEAL, ON STAINLESS STEEL FRAME (WITH CEE PLUG, MOTOR PROTECTION AND 10 M CABLE) FOR PUMPING FROM THE FERMENTATION TANKS TO THE PRESSURIZED TANK 4 PCS. BEER HOSES SET KEG-CLEANER WITH KEG-HANDFILLER CLEANER: CAPACITY: 10 – 15 KEGS / HOUR SEMI AUTOMATICALLY CLEANING PROCESS FOR ALL STANDARD KEGS KEG-HAND FILLER: COMPLETE MADE OF STAINLESS STEEL TUBES 2M LONG FOR ALL STANDARD KEGS PACKAGING WOODEN BOX AND FOILING FOR TRANSPORT IN A CONTAINER (SEA WAY), THE WOODEN BOX ALONE IS NOT ENOUGH FOR THE SEA WAY DOCUMENTATION IN ENGLISH (DEVICE DOCUMENTATION) IN ELECTRONIC FORM MOUNTING MATERIAL FOR MECHANICAL AND ELECTRICAL WORK UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING MOUNTING AND COMMISSIONING FOR MECHANIC WORK AND ELECTRIC WORK (LIFTING DEVICES- CRANE, ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET, LABOURER FOR MOUNTING SUPPORT) UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING 4 TEST BREWS (ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET) AND TRAINING OF THE OPERATOR STAFF UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING LABORATORY CIVIL WORK CO2 – SUPPLY PERMITS AND LICENSES FROM LOCAL AUTHORITIES TRANSPORT WATER TREATMENT AND COLD WATER TANK (IF REQUIRED) YEAST MANIPULATION (IF REQUIRED) Attached 3 photos from similar equipment. F1: brewhouse F2: CCT (cylindroconicalk tanks) and BBT (bright beer tanks = dispensing tanks) F3: PHE(plate heat exchanger = wort cooling, whirlpool, hot water tank) QUANTITY AVAILABLE: 1 Learn More