Search results for: 'electronic can'

- Related search terms

- Electronic t

- electronic'[0]

- electronic'[0]'[0]

- can

- can line

-

COMPLETE WEAVING PLANT YEAR 2005-2006WEAVING MACHINES BENNINGER BEN DIRECT WARPER YEAR 2006 BEAM DIAMETER 1000mm, WIDTH 2200mm V-CREEL – 1024 ENDS, AUTOMATIC CUTTING AT CREEL CHANGE ELECTRICAL STOP MOTION, MECHANICAL TENSIONER MICROPROCESSOR CONTROL SUCKER MOENUS SIZING MACHINE YEAR 2006 SIZING MACHINE SUCKER MOENUS Z 14, WIDTH 3400mm 1000mm FLANG DIAMETER, 14 DRYING CYLINDERS 2 SOW BOXES, 2 DIP AND 2 NIP, 24 WARP BEAMS CREEL, FULLY AUTOMATIC PLC CONTROL SIZE MIXING COOLER, 1200 LITERS SIZE STORAGE VESSEL, 1200 LITERS STAUBLI DELTA AUTO DRAWING IN MACHINE YEAR 2006 AUTO DRAWING IN MACHINE, STAUBLI DELTA 110 3400mm, YARN MODULE (HM5), HEALD MODULE (HM2) REED MODULE (HM6), DROP WIRE MODULE (HM3) AND CONTROL MODULE JAYTEX WARP TYING MACHINE YEAR 2005 WARP TYEING MACHINE JAYTEX TROLLEY WITH TRANSFORMER WITH 2 NOS. TYING FRAMES SETIA KIJJI REED CLEANING MACHINE YEAR 2006 SETIA KIJJI – ULTRA SONIC CLEANING MACHINE REED CLEANER CONSISTS OF RINSING UNIT ULTRASONIC UNIT DRYING UNIT, SEMI AUTOMATIC PROCESS USING PLC. (18 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 3E+06 EACH – 16 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI ELECTRONIC DOBBY 16 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (48 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 3E+06 – 10 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI CAM MOTION 10 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (24 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 2E+06 – 6 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI CAM MOTION 6 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (2 UNITS) GREY INSPECTION MACHINE YEAR 2006 INSPECTION TABLE IS LAMINATED, PUSH BUTTON CONTROLS ARE GIVEN ON THE DRIVE BOX ON THE RIGHT HAND SIDE, CLOTH CAN RUN IN FORWARD AS WELL AS IN REVERSE DIRECTION FABRIC RUNS FACE IN/FACE OUT SPECIAL JOGGING OR INCHING DEVICE FABRIC FOLDING MACHINE YEAR 2006 SWINGING MOTION IS MINIMIZED TO ENSURE HIGH MACHINE CAPACITY AND INCREASE OUTPUT FOLDING BLADES ARE MOUNTED ON A CARRIAGE WHICH HAS A TO AND FRO MOVEMENT ACHIEVED BY SPECIAL STEEL ROLLER CHAIRS BALE PRESS YEAR 2001 BATH BEI HYDRAULIC BALE PRESS MACHINE FABRIC PROCESSING SINGEING MACHINE YAMUNA SINGEING MACHINE WIDER WIDTH – YEAR 2006 (2 UNITS) HYDRAULIC JIGGER KUSTER CALICO YEAR 2006 3E+06 VERTICAL DRYING RANGE YEAR 2006 CONTINUOUS DYEING RANGE – KUSTER CALICO KUSTER CALICO COLD PAD BATCH YEAR 2006 HARISH STENTER – SUPRA 5 DLXI ALMAC FINISH INSPECTION MACHINE YEAR 2006 SHRI NARAYAN COTEX FINISH PLAITING MACHINE YEAR 2006 Learn More

COMPLETE WEAVING PLANT YEAR 2005-2006WEAVING MACHINES BENNINGER BEN DIRECT WARPER YEAR 2006 BEAM DIAMETER 1000mm, WIDTH 2200mm V-CREEL – 1024 ENDS, AUTOMATIC CUTTING AT CREEL CHANGE ELECTRICAL STOP MOTION, MECHANICAL TENSIONER MICROPROCESSOR CONTROL SUCKER MOENUS SIZING MACHINE YEAR 2006 SIZING MACHINE SUCKER MOENUS Z 14, WIDTH 3400mm 1000mm FLANG DIAMETER, 14 DRYING CYLINDERS 2 SOW BOXES, 2 DIP AND 2 NIP, 24 WARP BEAMS CREEL, FULLY AUTOMATIC PLC CONTROL SIZE MIXING COOLER, 1200 LITERS SIZE STORAGE VESSEL, 1200 LITERS STAUBLI DELTA AUTO DRAWING IN MACHINE YEAR 2006 AUTO DRAWING IN MACHINE, STAUBLI DELTA 110 3400mm, YARN MODULE (HM5), HEALD MODULE (HM2) REED MODULE (HM6), DROP WIRE MODULE (HM3) AND CONTROL MODULE JAYTEX WARP TYING MACHINE YEAR 2005 WARP TYEING MACHINE JAYTEX TROLLEY WITH TRANSFORMER WITH 2 NOS. TYING FRAMES SETIA KIJJI REED CLEANING MACHINE YEAR 2006 SETIA KIJJI – ULTRA SONIC CLEANING MACHINE REED CLEANER CONSISTS OF RINSING UNIT ULTRASONIC UNIT DRYING UNIT, SEMI AUTOMATIC PROCESS USING PLC. (18 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 3E+06 EACH – 16 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI ELECTRONIC DOBBY 16 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (48 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 3E+06 – 10 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI CAM MOTION 10 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (24 UNITS) TSUDAKOMA AIRJET LOOM ZAX 9100 YEAR 2006 2E+06 – 6 SHAFTS AIRJET LOOM TSUDAKOMA ZAX 9100, 3400mm, STAUBLI CAM MOTION 6 SHAFTS, 2/4 WEFT INSERTION, CRANK BEAT UP, LENO SELVEDGE ELECTRONIC LET OFF, ELECTRONIC TAKE UP, 1.5 BEAMS, 1.5 CLOTH ROLLS (2 UNITS) GREY INSPECTION MACHINE YEAR 2006 INSPECTION TABLE IS LAMINATED, PUSH BUTTON CONTROLS ARE GIVEN ON THE DRIVE BOX ON THE RIGHT HAND SIDE, CLOTH CAN RUN IN FORWARD AS WELL AS IN REVERSE DIRECTION FABRIC RUNS FACE IN/FACE OUT SPECIAL JOGGING OR INCHING DEVICE FABRIC FOLDING MACHINE YEAR 2006 SWINGING MOTION IS MINIMIZED TO ENSURE HIGH MACHINE CAPACITY AND INCREASE OUTPUT FOLDING BLADES ARE MOUNTED ON A CARRIAGE WHICH HAS A TO AND FRO MOVEMENT ACHIEVED BY SPECIAL STEEL ROLLER CHAIRS BALE PRESS YEAR 2001 BATH BEI HYDRAULIC BALE PRESS MACHINE FABRIC PROCESSING SINGEING MACHINE YAMUNA SINGEING MACHINE WIDER WIDTH – YEAR 2006 (2 UNITS) HYDRAULIC JIGGER KUSTER CALICO YEAR 2006 3E+06 VERTICAL DRYING RANGE YEAR 2006 CONTINUOUS DYEING RANGE – KUSTER CALICO KUSTER CALICO COLD PAD BATCH YEAR 2006 HARISH STENTER – SUPRA 5 DLXI ALMAC FINISH INSPECTION MACHINE YEAR 2006 SHRI NARAYAN COTEX FINISH PLAITING MACHINE YEAR 2006 Learn More -

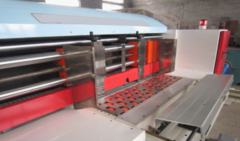

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More -

L-1502 DOUBLE COLUMN COMPUTER CONTROLLED ELECTRONIC UTM MODEL UE2410 TENSILE TESTER (FOR FOAM OR FABRIC)

L-1502 DOUBLE COLUMN COMPUTER CONTROLLED ELECTRONIC UTM MODEL UE2410 TENSILE TESTER (FOR FOAM OR FABRIC)REFERENCE NUMBER: L-1502

Learn More

MODEL: UE2410

QUANTITY: 1 -

BEMATIC/BOMBI NONWOVEN AIRLAID LINE YEAR 2012FIBRE OPENING/ AND MIXING LINE: 2 BALE OPENERS TYPE AC-1500, WORKING WIDTH 1500mm, INCL. FEEDING CONVEYOR. 1 BALE OPENER TYPE AS-204 (FOR MELT FIBRE DOSING), WITH ELECTRONIC WEIGHING TYPE SP-205. 1 TYPE AFM 700, WIDTH 700mm, LENGTH 7500mm. 1 MIXING OPENER TYPE AF 700, WORKING WIDTH 700mm., OPENING ROLLERS WITH NEEDLES. 1 FINE OPENER TYPE SF-1500, WORKING WITH 1500mm, 500KG/H WITH DOSING SHAFT. 1 FILTER STATION FOR TRANSPORT AIR, TYPE CF DOUBLE BAG FILTER. 1 ELECTRONIC CONTROL PANEL WITH TOUCHSCREEN. AIRLAID LINE: 1 DOSING MACHINE BEMABLOW, WORKING WIDTH 2500mm WITH ELECTRONIC CONTROLLED DOSING CAPACITY. 1 AIRLAID WEB BUILDER TYPE FORMER T-MAX WORKING WITH 2700mm WEB HEIGHT 50-350mm, WEB WEIGHT 300 TILL 300GT/M2. 1 ELECTRONIC CONTINUING BAND WEIGHING DEVICE BEMAMULTISCALE, FOR WEB FROM AIRLAID WEB BUILDER, WITH FEEDBACK TO AIRLAID MACHINE. 1 FILTER STATION FOR TRANSPORT AIR TYPE CF, DOUBLE BAG FILTER. 1 ELECTRONIC CONTROL PANEL WITH TOUCHSCREEN. SPRAYING AND DRYING. 1 PRAYING CABIN BOMBI, 2600mm WORKING WIDTH. 1 THERMOBONDING OVEN BOMBI 2012, TYPE TFP/2N/2.7M, 2 DRYING SECTIONS, GAS HEATED, INCL. CALIBRATING ZONE, 2 STATIC FILTERS, 11.0 RESP. 5.5KW, OVEN LENGTH 12000mm. 1 CALANDER BOMBI 2012, TYPE CAL/2C/2.7M. 1 COOLING SECTION BOMBI 2012, TYPE RAF. 1 LENGTH- AND CROSS CUTTER BOMBI 2012, TYPE TG2.7/2+2. 1 ELECTRONIC CONTROL PANEL/ PROGRAMMER WITH TOUCHSCREEN. - ABOVE LINE CAN PROCESS FLAX, HEMP, REGENERATED FIBRES, POLYESTER AND LOW MELT FIBRES. - PRODUCTION 500KG/H. - CONSUMPTION: GAS 45M³/H, ELECTRICITY 90KW/H. Learn More

BEMATIC/BOMBI NONWOVEN AIRLAID LINE YEAR 2012FIBRE OPENING/ AND MIXING LINE: 2 BALE OPENERS TYPE AC-1500, WORKING WIDTH 1500mm, INCL. FEEDING CONVEYOR. 1 BALE OPENER TYPE AS-204 (FOR MELT FIBRE DOSING), WITH ELECTRONIC WEIGHING TYPE SP-205. 1 TYPE AFM 700, WIDTH 700mm, LENGTH 7500mm. 1 MIXING OPENER TYPE AF 700, WORKING WIDTH 700mm., OPENING ROLLERS WITH NEEDLES. 1 FINE OPENER TYPE SF-1500, WORKING WITH 1500mm, 500KG/H WITH DOSING SHAFT. 1 FILTER STATION FOR TRANSPORT AIR, TYPE CF DOUBLE BAG FILTER. 1 ELECTRONIC CONTROL PANEL WITH TOUCHSCREEN. AIRLAID LINE: 1 DOSING MACHINE BEMABLOW, WORKING WIDTH 2500mm WITH ELECTRONIC CONTROLLED DOSING CAPACITY. 1 AIRLAID WEB BUILDER TYPE FORMER T-MAX WORKING WITH 2700mm WEB HEIGHT 50-350mm, WEB WEIGHT 300 TILL 300GT/M2. 1 ELECTRONIC CONTINUING BAND WEIGHING DEVICE BEMAMULTISCALE, FOR WEB FROM AIRLAID WEB BUILDER, WITH FEEDBACK TO AIRLAID MACHINE. 1 FILTER STATION FOR TRANSPORT AIR TYPE CF, DOUBLE BAG FILTER. 1 ELECTRONIC CONTROL PANEL WITH TOUCHSCREEN. SPRAYING AND DRYING. 1 PRAYING CABIN BOMBI, 2600mm WORKING WIDTH. 1 THERMOBONDING OVEN BOMBI 2012, TYPE TFP/2N/2.7M, 2 DRYING SECTIONS, GAS HEATED, INCL. CALIBRATING ZONE, 2 STATIC FILTERS, 11.0 RESP. 5.5KW, OVEN LENGTH 12000mm. 1 CALANDER BOMBI 2012, TYPE CAL/2C/2.7M. 1 COOLING SECTION BOMBI 2012, TYPE RAF. 1 LENGTH- AND CROSS CUTTER BOMBI 2012, TYPE TG2.7/2+2. 1 ELECTRONIC CONTROL PANEL/ PROGRAMMER WITH TOUCHSCREEN. - ABOVE LINE CAN PROCESS FLAX, HEMP, REGENERATED FIBRES, POLYESTER AND LOW MELT FIBRES. - PRODUCTION 500KG/H. - CONSUMPTION: GAS 45M³/H, ELECTRICITY 90KW/H. Learn More -

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More -

TT-3702 WORSTED SPINNING PLANT OF 4992 SPINDLES, YEAR 1987 TO 2022TT-3702 WORSTED SPINNING PLANT OF 4992 SPINDLES, YEAR 1987 TO 2022 WORKING CONDITION CONTAINER: 26/30 (DEPENDING FROM ACCESSORIES) Learn More

TT-3702 WORSTED SPINNING PLANT OF 4992 SPINDLES, YEAR 1987 TO 2022TT-3702 WORSTED SPINNING PLANT OF 4992 SPINDLES, YEAR 1987 TO 2022 WORKING CONDITION CONTAINER: 26/30 (DEPENDING FROM ACCESSORIES) Learn More -

YY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mmYY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mm ITEM 001 BALE OPENER (2 SETS) AND SEALED BALE OPENER (1 SET) ITEM 002 FIBER OPENING MACHINE (FOR LOW MELT FIBER OR PP) - 1 SET ITEM 003 PRE-OPENER – 1 SET ITEM 004 BIG CHAMBER BLENDER – 1 SET ITEM 005 MAIN-OPENER – 1 SET ITEM 006 VIBRATING FEEDER – 1 SET ITEM 007 CONDENSER – 2 SETS ITEM 008 AUTO-LEVER - 1 SET ITEM 009 AIR LAID MACHINE – 1 SET ITEM 010 AUTO-LEVER – 1 SET ITEM 011 BATT FEEDER – 1 SET ITEM 012 HIGH SPEED SINGLE SHAFT SINGLE BOARD PRE NEEDLE LOOM – 1 SET ITEM 013 HIGH SPEED SINGLE SHAFT SINGLE BOARD MAIN NEEDLE LOOM – 1 SET ITEM 014 DOUBLE BELT THERMAL-BONDED OVEN – 1 SET ITEM 015 DOUBLE-ROLLER CALENDER MACHINE – 1 SET ITEM 016 COOLING UNIT – 1 SET Learn More

YY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mmYY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mm ITEM 001 BALE OPENER (2 SETS) AND SEALED BALE OPENER (1 SET) ITEM 002 FIBER OPENING MACHINE (FOR LOW MELT FIBER OR PP) - 1 SET ITEM 003 PRE-OPENER – 1 SET ITEM 004 BIG CHAMBER BLENDER – 1 SET ITEM 005 MAIN-OPENER – 1 SET ITEM 006 VIBRATING FEEDER – 1 SET ITEM 007 CONDENSER – 2 SETS ITEM 008 AUTO-LEVER - 1 SET ITEM 009 AIR LAID MACHINE – 1 SET ITEM 010 AUTO-LEVER – 1 SET ITEM 011 BATT FEEDER – 1 SET ITEM 012 HIGH SPEED SINGLE SHAFT SINGLE BOARD PRE NEEDLE LOOM – 1 SET ITEM 013 HIGH SPEED SINGLE SHAFT SINGLE BOARD MAIN NEEDLE LOOM – 1 SET ITEM 014 DOUBLE BELT THERMAL-BONDED OVEN – 1 SET ITEM 015 DOUBLE-ROLLER CALENDER MACHINE – 1 SET ITEM 016 COOLING UNIT – 1 SET Learn More -

M-4833 FILLING MACHINEWITH SPECIAL DEVICE TO FIX THE COVER AND ELECTRONIC TABLE WITH BALANCE IT IS A MACHINE FOR FILLING CUSHIONS, SACS, BAGS ETC. WITH ALL KIND OF MATERIALS: FEATHER, POLYESTER, BALL FIBER, POLYURETHANE, COTTON, WOOL, ETC. ADJUSTABLE SPEED: UP TO 4000 RPM THE PARTICULAR SHAPE OF THE OUTLET PIPE ALLOWS TO FILL AIR-TIGHT LINING PILLOWS THE COMMAND TO THE DUMPERS IS GIVEN BY A PEDAL THANKS TO THE SPECIAL DEVICE TO BLOCK THE COVER, THE OPERATOR HAS BOTH HANDS FREE AND CAN WORK ON TWO POSITIONS AT A TIME WHEN THE LINE IS EQUIPPED WITH TWO FILLING MACHINES (AS PER DRAWING BELOW) CONTROL PANEL SPECIAL SEWING MACHINE Learn More

M-4833 FILLING MACHINEWITH SPECIAL DEVICE TO FIX THE COVER AND ELECTRONIC TABLE WITH BALANCE IT IS A MACHINE FOR FILLING CUSHIONS, SACS, BAGS ETC. WITH ALL KIND OF MATERIALS: FEATHER, POLYESTER, BALL FIBER, POLYURETHANE, COTTON, WOOL, ETC. ADJUSTABLE SPEED: UP TO 4000 RPM THE PARTICULAR SHAPE OF THE OUTLET PIPE ALLOWS TO FILL AIR-TIGHT LINING PILLOWS THE COMMAND TO THE DUMPERS IS GIVEN BY A PEDAL THANKS TO THE SPECIAL DEVICE TO BLOCK THE COVER, THE OPERATOR HAS BOTH HANDS FREE AND CAN WORK ON TWO POSITIONS AT A TIME WHEN THE LINE IS EQUIPPED WITH TWO FILLING MACHINES (AS PER DRAWING BELOW) CONTROL PANEL SPECIAL SEWING MACHINE Learn More -

T-8028 HIGH SPEED SOFT WINDING MACHINET-8028 HIGH SPEED SOFT WINDING MACHINE SIZE: 2050 X 750 X 1500mm SINGLE-SIDE CONFIGURATION: 6 SPINDLES/SET WEIGHT: 150KG QUANTITY: 1 SET (6 SPINDLES) Learn More

T-8028 HIGH SPEED SOFT WINDING MACHINET-8028 HIGH SPEED SOFT WINDING MACHINE SIZE: 2050 X 750 X 1500mm SINGLE-SIDE CONFIGURATION: 6 SPINDLES/SET WEIGHT: 150KG QUANTITY: 1 SET (6 SPINDLES) Learn More -

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More