Search results for: 'nonwoven o'

- Related search terms

- nonwoven m

- nonwoven machi

- nonwoven machin

- nonwoven ge

- Nonwoven c

-

TT-7451 COMPLETE AUTEFA NONWOVEN CARBON FIBRE RECYCLING LINE, WORKING WIDTH 2500mm, YEAR 2023TT-7451 COMPLETE AUTEFA NONWOVEN CARBON FIBRE RECYCLING LINE, WORKING WIDTH 2500mm, YEAR 2023 1. COMPLETE AUTEFA NONWOVEN CARBON FIBRE RECYCLING LINE 2. YEAR 2023 3. WORKING WIDTH 2500mm 4. RANGE: WIDE VARIETY OF ORGANIC AND INORGANIC FIBERS 5. (SUCH AS POLYPROPYLENE, POLYAMIDE, JUTE, HEMP AND FLAX) Learn More

TT-7451 COMPLETE AUTEFA NONWOVEN CARBON FIBRE RECYCLING LINE, WORKING WIDTH 2500mm, YEAR 2023TT-7451 COMPLETE AUTEFA NONWOVEN CARBON FIBRE RECYCLING LINE, WORKING WIDTH 2500mm, YEAR 2023 1. COMPLETE AUTEFA NONWOVEN CARBON FIBRE RECYCLING LINE 2. YEAR 2023 3. WORKING WIDTH 2500mm 4. RANGE: WIDE VARIETY OF ORGANIC AND INORGANIC FIBERS 5. (SUCH AS POLYPROPYLENE, POLYAMIDE, JUTE, HEMP AND FLAX) Learn More -

TT-6856 BHOSTALO & R. ESTEBAN-GUASCH-MIRA-FEHRER-TACOME DOUBLE NONWOVEN NEEDLEFELT LINE, 3600mm, YEAR 1982 TO 1996TT-6856 BHOSTALO & R. ESTEBAN-GUASCH-MIRA-FEHRER-TACOME DOUBLE NONWOVEN NEEDLEFELT LINE, 3600mm, YEAR 1982 TO 1996 1. BHOSTALO & R. ESTEBAN-GUASCH-MIRA-FEHRER-TACOME DOUBLE NONWOVEN NEEDLEFELT LINE 2. 3600mm 3. YEAR 1982 TO 1996 QUANTITY: 1 Learn More

TT-6856 BHOSTALO & R. ESTEBAN-GUASCH-MIRA-FEHRER-TACOME DOUBLE NONWOVEN NEEDLEFELT LINE, 3600mm, YEAR 1982 TO 1996TT-6856 BHOSTALO & R. ESTEBAN-GUASCH-MIRA-FEHRER-TACOME DOUBLE NONWOVEN NEEDLEFELT LINE, 3600mm, YEAR 1982 TO 1996 1. BHOSTALO & R. ESTEBAN-GUASCH-MIRA-FEHRER-TACOME DOUBLE NONWOVEN NEEDLEFELT LINE 2. 3600mm 3. YEAR 1982 TO 1996 QUANTITY: 1 Learn More -

TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024 THE FOLLOWING WEIGHTS OF NONWOVEN FABRIC CAN BE MADE ON THE PRODUCTION LINE: 200 TO 1000 G/M² LINE EFFICIENCY: 300 KG/H FINAL WORKING WIDTH OF THE NONWOVEN FABRIC: 2500mm POWER SUPPLY: 400 V, 50 Hz, INSTALLED POWER: 62 KW THE LINE IS EQUIPPED WITH MODERN CONTROL IN CONTROL CABINETS NECESSARY AREA FOR THE ROPE: LENGTH: 17000mm, WIDTH: 10000mm, Learn More

TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024 THE FOLLOWING WEIGHTS OF NONWOVEN FABRIC CAN BE MADE ON THE PRODUCTION LINE: 200 TO 1000 G/M² LINE EFFICIENCY: 300 KG/H FINAL WORKING WIDTH OF THE NONWOVEN FABRIC: 2500mm POWER SUPPLY: 400 V, 50 Hz, INSTALLED POWER: 62 KW THE LINE IS EQUIPPED WITH MODERN CONTROL IN CONTROL CABINETS NECESSARY AREA FOR THE ROPE: LENGTH: 17000mm, WIDTH: 10000mm, Learn More -

TT-3809 LABORATORY NEEDLEPUNCH LINE, WIDTH 800mm, YEAR 1974TT-3809 LABORATORY NEEDLEPUNCH LINE, WIDTH 800mm, YEAR 1974 MODEL: LABORATORY NEEDLEPUNCH LINE CONDITION: USED ELECTRICITY: 440/3/60 & 380/3/50 WIDTH: 800mm Learn More

TT-3809 LABORATORY NEEDLEPUNCH LINE, WIDTH 800mm, YEAR 1974TT-3809 LABORATORY NEEDLEPUNCH LINE, WIDTH 800mm, YEAR 1974 MODEL: LABORATORY NEEDLEPUNCH LINE CONDITION: USED ELECTRICITY: 440/3/60 & 380/3/50 WIDTH: 800mm Learn More -

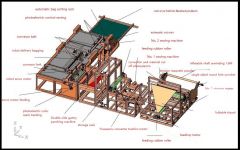

V-1805 FULLY AUTOMATIC DUST DISPOSABLE FACE MASK MACHINE

V-1805 FULLY AUTOMATIC DUST DISPOSABLE FACE MASK MACHINEMAKES MASKS WITH 3 PLIES FROM WHITE MELT-BLOWN FABRIC, AND BLUE NONWOVEN FABRIC & WHITE NONWOVEN FABRIC (SEE OFFER PICTURES)

THE 3 MASK LAYERS ARE COMPOSED OF:

NONWOVEN WHITE: T/ ONE MILLION MASKS 195 TO 200mm 25g 2800m

NONWOVEN BLUE: T/ ONE MILLION MASKS 175mm 25g 2800mm

MELT-BLOWN WHITE: T/ TWO MILLION MASKS 175 25g N95

MAIN MACHINE PARTS CONSTRUCTED WITH STAINLESS STEEL

MITSUBISHI BRAND PLCs

ULTRASONIC HEAD BRAND: HUIZHUAN

ULTRASONIC GENERATOR WATTAGE CAPACITY: 1500 TO 2000 WATTS

ULTRASONIC GENERATOR FREQUENCY: 20K

MIDDLE FABRIC LAYER IS SPUNBOND, MELTBLOWN AND SPUNBOND

ACTIVATED CARBON FABRIC NOT POSSIBLE, YET

OVERALL EQUIPMENT LAYOUT:

3. INTERMEDIATE WELDING AND SLICING

2. HEMMING, NASAL, WELDING

4. MASK CONVEYOR LINE

5. EARBAND MACHINE (1 CONVEYOR LINE)

6. EARBAND MACHINE (2 CONVEYOR LINE)

7. EAR STRAP MACHINE (1 ASSEMBLY WELDING)

8. EAR STRAP MACHINE (2 ASSEMBLY WELDING)

9. MASK LINE

10. MASK LINEPRODUCT DETAILS:

VOLTAGE: 220V, 50/60HZ

AUTOMATIC MASK MACHINE

POWER: 85KW

PRODUCTION OUTPUT: 100 MASKS PER MINUTE, THE MAXIMUM ACTUAL OUTPUT IS 5000 PER HOUR.

DIMENSIONS: 6500mm X 4500mm X 2000mm120 TO 150 MASKS PER MINUTE, ACTUAL DETECTION DATA

Learn More

DELIVERY TIME: 20 DAYS -

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More -

TT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mmTT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mm THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON TILL CA 30%. COVERSTOK, HYGIENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN TERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTHETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250 OC. ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16 GSM TO MAX 70 GSM (DUPLEX 70 GSM) QUANTITY: 1 Learn More

TT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mmTT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mm THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON TILL CA 30%. COVERSTOK, HYGIENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN TERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTHETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250 OC. ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16 GSM TO MAX 70 GSM (DUPLEX 70 GSM) QUANTITY: 1 Learn More -

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More -

P-4325 WET WIPES PRODUCTION LINE

P-4325 WET WIPES PRODUCTION LINEREFERENCE NUMBER: P-4325

WET WIPES PRODUCTION LINE

Model L40

Machine Characteristic

Control system: Multi-Axis Motion Controller

Drive element: servo motor

Operate interface: 10" LCD touch screen

Cutting: synchronous flail knife

Packing style: end seal & reciprocating type(connecting 2 packing machine need explain)

Unwinding structure: 40 sets, 40 electronic eyes detect online(16 sets big rolls material)

Auto splicing: film automatic splicing, label automatic switching

Frequency division detection: nonwoven, film, label detect respectively

Frequency division pulling: 2 sets dry wipes pulling , 2 sets wet wipes pulling

Auto splicing: film automatic splicing, label automatic switching

Frequency division detection: nonwoven ,film, label detect respectively

Metal detect: online metal detector

Inferior eliminate: aluminizing paste connector rejected online

Flow control: 2.5-4 times, flow meter control, no liquid recovery

Moisture type: 40 fluid pipes spray independently

SUS Agitate tank: 2 sets, 1000L stainless steel agitate tank

Liquid level control: electronic detection, auto control

Specifications

Raw material: spunlaced nonwoven, therbond etc. nonwovens

Raw material specification: max W220mm, φ1400mm, max W1050mm, φ1000mm

Axis QTY settings:40 rolls raw materials (auto splicing type 32 rolls)

Diameter of ventilating shaft: 3"

Suitable packing material :BOPP PET/PE PET/AL/PE etc. heat-seal material

Packing Film specification: max W420mm, φ350mm

Axis QTY settings: 2 sets film, automatic splicing without stopping machine

Diameter of ventilating shaft: 3"

Suitable label: transparent label & opaque label

Label size: max W100mm φ400mm

Axis QTY settings: 2 sets label, automatic switching without stopping(can be set as safety label)

Diameter of ventilating shaft: 3"

Folding type: single extraction & interfold type

Wet wipes size:L120-220mm W90-110mm

Open size: L120-220mm W150-220mm

Package size: L150-350mm W80-120mm H10-80mm

Design speed: 60bags/min &250cutting/min

Production speed: 50 bags/min &200 cutting/min

Machine space: L31000mm W2500mm H2100mm. L32600mm W3600mm H2100mm(auto splicing machine)

Power: AC 380V 50/60Hz 22KW(auto splicing machine:25KW)

Compressed air: 0.6-0.8Mpa 400L/min

Machine net weight :22000kg(auto splicing machine 25000Kg)

Option equipment: Coding machine Big roll material automatic splicingQUANTITY: 1

Learn More