Search results for: 'packaging'

- Related search terms

- packaging engineer

- packaging design ai

- packaging line

- Packaging Source

-

TT-6073 ANTIBACTERIAL DISINFECTING WET WIPES PACKAGING MACHINE, YEAR 2020TT-6073 ANTIBACTERIAL DISINFECTING WET WIPES PACKAGING MACHINE, YEAR 2020 QUANTITY: 1 Learn More

TT-6073 ANTIBACTERIAL DISINFECTING WET WIPES PACKAGING MACHINE, YEAR 2020TT-6073 ANTIBACTERIAL DISINFECTING WET WIPES PACKAGING MACHINE, YEAR 2020 QUANTITY: 1 Learn More -

TT-3480 MATTHYS ROLL PACKAGING LINE, WORKING WIDTH 6700mm, YEAR 2018TT-3480 MATTHYS ROLL PACKAGING LINE, WORKING WIDTH 6700mm, YEAR 2018 QUANTITY: 1 Learn More

TT-3480 MATTHYS ROLL PACKAGING LINE, WORKING WIDTH 6700mm, YEAR 2018TT-3480 MATTHYS ROLL PACKAGING LINE, WORKING WIDTH 6700mm, YEAR 2018 QUANTITY: 1 Learn More -

YY-2389 KERLIX BANDAGE PACKAGING MACHINE, WORKING FREQUENCY 6 TO 10 CUT PER MINYY-2389 KERLIX BANDAGE PACKAGING MACHINE, WORKING FREQUENCY 6 TO 10 CUT PER MIN QUANTITY: 1 Learn More

YY-2389 KERLIX BANDAGE PACKAGING MACHINE, WORKING FREQUENCY 6 TO 10 CUT PER MINYY-2389 KERLIX BANDAGE PACKAGING MACHINE, WORKING FREQUENCY 6 TO 10 CUT PER MIN QUANTITY: 1 Learn More -

TT-1713 BATHROOM TISSUE CONVERTING LINES AND PACKAGING EQUIPMENT, YEAR 1980 TO 1995TT-1713 BATHROOM TISSUE CONVERTING LINES AND PACKAGING EQUIPMENT, YEAR 1980 TO 1995 ITEM 001 PERINI SINCRO 7.6/0/M 102” BATHROOM TISSUE LINE - YEAR: 1995 ITEM 002 PERINI SINCRO 7.6/0 102” BATHROOM TISSUE LINE - YEAR: 1995 ITEM 003 PCMC 250 84” BATHROOM TISSUE LINE - YEAR: 1990 ITEM 004 PCMC 250 84” BATHROOM TISSUE LINE - YEAR: 1990 ITEM 005 PCMC 150 84” BATHROOM TISSUE LINE - YEAR: 1980’S ITEM 006 PCMC 150 84” BATHROOM TISSUE LINE - YEAR: 1980’S Learn More

TT-1713 BATHROOM TISSUE CONVERTING LINES AND PACKAGING EQUIPMENT, YEAR 1980 TO 1995TT-1713 BATHROOM TISSUE CONVERTING LINES AND PACKAGING EQUIPMENT, YEAR 1980 TO 1995 ITEM 001 PERINI SINCRO 7.6/0/M 102” BATHROOM TISSUE LINE - YEAR: 1995 ITEM 002 PERINI SINCRO 7.6/0 102” BATHROOM TISSUE LINE - YEAR: 1995 ITEM 003 PCMC 250 84” BATHROOM TISSUE LINE - YEAR: 1990 ITEM 004 PCMC 250 84” BATHROOM TISSUE LINE - YEAR: 1990 ITEM 005 PCMC 150 84” BATHROOM TISSUE LINE - YEAR: 1980’S ITEM 006 PCMC 150 84” BATHROOM TISSUE LINE - YEAR: 1980’S Learn More -

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More -

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

V-1288 MERELLO ME-305 PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009REFERENCE NUMBER: V-1288

MERELLO ME-305PILLOW & QUILTS PACKAGING SYSTEM, 10 to 12 UNITS PER MINUTE YEAR 2009

WRAPS PILLOWS AND CUSHIONS BETWEEN 35X35 AND 150X70cm IN POLYETHYLENE TUBE, WITHOUT LATERAL SEALS

HIGH QUALITY BAGS, MORE ESTHETICAL AND VERY WELL ADJUSTED. INCLUDES OPTIONAL PRINTER FOR LABELS DIRECTLY ON THE BAG, PUNCHES HANDLES AND DETECTS CENTERED LOGOS. MINIMUM WASTE, ENERGY SAVINGS.

AUTOMATIC CYCLE: IN-FEED, WRAPPING, COMPRESSION AND SEALING. EASY AND FAST CHANGE OF THE ROLL, MÁX. ROLL: 500 mm.. CYCLE CONTROLLED BY PLC WITH TOUCH SCREEN. SURFACE OCCUPATION: 4.5X2M (EXTRA BIG DIMENSIONS AVAILABLE AS OPTION).

HIGH PRODUCTIVITY: 10/12 UNITS PER MINUTE

WELL-ENGINEERED MACHINE FOR FLATTENING AND WRAPPING CUSHIONS FOR “FLAT PACK” OPERATIONS

THIS IS IDEAL FOR STORING AND SHIPPING PILLOWS AND CUSHIONS IN A MINIMAL AMOUNT OF SPACE

AUTOMATICALLY WRAPS EVERY TYPE OF PILLOW BETWEEN 40CM x 40CM (16”x16”) TO 110CM x 80CM (42”x32”)

CYCLES UP TO 8 PER MINUTE

AUTOMATICALLY ADJUSTS TO VARYING SIZES

PLASTIC ROLLS ARE EASILY CHANGES

THE MACHINE FORMS A TUBE STYLE BAG FROM A POLYETHYLENE ROLL, WITH PERFECT SIZE ADJUSTMENT AND REQUIRES NO LATERAL SEALING. CHANGING THE POLYETHYLENE ROLL IS FAST AND EASY, AND DIFFERENT SIZES CAN BE USED WITHOUT ADJUSTMENT

CUTS ARE MADE BY A MAINTENANCE-FREE, SMOKELESS COLD BLADE

A TOUCH SCREEN PLC CONTROL DISPLAYS INPUT PARAMETERS AND CYCLE INFORMATION

ELECTRONIC INVERTER ENABLES SMOOTH MOTORIZED MOVEMENTS

OPTIONAL VIDEO JET THERMAL PRINTER CAN PRINT PRODUCT DATA AND BAR CODES DIRECTLY ON FINISHED PACKAGE

MACHINE DIMENSIONS ARE: 4.5M x 2M (14.75’ x 6.5’)

SAVES SPACE AND MATERIAL EXPENSE BY EXTRACTING AIR FROM THE BAG DURING PACKAGING PROCESS

QUANTITY: 1

Learn More -

M-5370 MATTHYS PACKAGING MACHINE YEAR 1999 WIDTH 2400mmREFERENCE NUMBER: M-5370 (220BKTCXX1) L MATTHYS PACKAGING MACHINE YEAR 1999 WIDTH 2400mm MATTHYS PACKAGING MACHINE YEAR 1999 WORKING WIDTH MAXIMUM 2400mm LENGTH AND TRAVERSE THERMIC WELDING MAXIMUM ROLL DIAMETER 50 CM QUANTITY AVAILABLE: 1 Learn More

M-5370 MATTHYS PACKAGING MACHINE YEAR 1999 WIDTH 2400mmREFERENCE NUMBER: M-5370 (220BKTCXX1) L MATTHYS PACKAGING MACHINE YEAR 1999 WIDTH 2400mm MATTHYS PACKAGING MACHINE YEAR 1999 WORKING WIDTH MAXIMUM 2400mm LENGTH AND TRAVERSE THERMIC WELDING MAXIMUM ROLL DIAMETER 50 CM QUANTITY AVAILABLE: 1 Learn More -

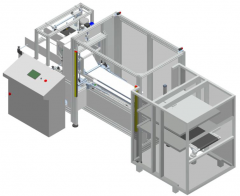

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More -

YY-3113 TBS PACK PACKAGING LINE, YEAR 2020YY-3113 TBS PACK PACKAGING LINE, YEAR 2020 CONDITION AS NEW, ONLY BEEN IN OPERATION FOR A FEW WEEKS. Learn More

YY-3113 TBS PACK PACKAGING LINE, YEAR 2020YY-3113 TBS PACK PACKAGING LINE, YEAR 2020 CONDITION AS NEW, ONLY BEEN IN OPERATION FOR A FEW WEEKS. Learn More -

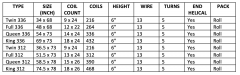

U-1371 BONNELL INNERSPRING TABLE, size in inches, coil count, height, wire gauge, coil height, type of packaging. Table is according to American standard sized Twin-Full-Queen-KingU-1371BONNELL INNERSPRING TABLE, size in inches, coil count, height, wire gauge, coil height, type of packaging. Table is according to American standard sized Twin-Full-Queen-King Learn More

U-1371 BONNELL INNERSPRING TABLE, size in inches, coil count, height, wire gauge, coil height, type of packaging. Table is according to American standard sized Twin-Full-Queen-KingU-1371BONNELL INNERSPRING TABLE, size in inches, coil count, height, wire gauge, coil height, type of packaging. Table is according to American standard sized Twin-Full-Queen-King Learn More