Search results for: 'Foam cutt'

- Related search terms

- Cutti

- cutti'

- Cutting+m

- cutti''

- CUTTING S'

-

T-6502 COMPLETE CORRUGATED PLANT, YEAR 1992 TO 2023T-6502 COMPLETE CORRUGATED PLANT, YEAR 1992 TO 2023 Learn More

T-6502 COMPLETE CORRUGATED PLANT, YEAR 1992 TO 2023T-6502 COMPLETE CORRUGATED PLANT, YEAR 1992 TO 2023 Learn More -

YY-1828 MULTI-BLADE HORIZONTAL CUTTING MACHINE (16 BLADES)YY-1828 MULTI-BLADE HORIZONTAL CUTTING MACHINE (16 BLADES) THIS MACHINE IS MAINLY APPLIED TO CUT THE FOAM BLOCK CONTINUOUSLY INTO THICK FOAM SHEETS. IT IS WITH TOUCH SCREEN & PLC AUTO CONTROL, AND EACH SET OF BLADES CAN BE CONTROLLED SEPARATELY. Learn More

YY-1828 MULTI-BLADE HORIZONTAL CUTTING MACHINE (16 BLADES)YY-1828 MULTI-BLADE HORIZONTAL CUTTING MACHINE (16 BLADES) THIS MACHINE IS MAINLY APPLIED TO CUT THE FOAM BLOCK CONTINUOUSLY INTO THICK FOAM SHEETS. IT IS WITH TOUCH SCREEN & PLC AUTO CONTROL, AND EACH SET OF BLADES CAN BE CONTROLLED SEPARATELY. Learn More -

YY-1481 FULL-AUTOMATIC FOLDING MACHINE OF 4-PLY LAP FOAM, 15 PIECES PER MINUTEYY-1481 FULL-AUTOMATIC FOLDING MACHINE OF 4-PLY LAP FOAM, 15 PIECES PER MINUTE FEATURE: - USED FOR FULL-AUTOMATIC FOLDING OF SURGICAL TOWEL, LAP FOAM AND ABDOMINAL TOWEL. - GAUZE ROLL RUNNING ON THE EQUIPMENT WHICH IS AUTOMATICALLY FEEDING, CUTTING, HEMMING, PRESSING, FOLDING AND YARD OPERATING NEATLY. - EQUIPPED WITH 5-6 CNC MOTORS, THE PARAMETER CAN BE MODIFIED IN THE MAN-MACHINE INTERFACE, WHICH WILL BE VERY CONVENIENT TO CHANGE THE PRODUCT VARIETY. - FURTHERMORE, IT CONFIGURES AUTOMATIC DISCHARGING MACHINE, WHICH WITH HIGHER DEGREE OF AUTOMATION, DISCHARGING RESET AUTOMATICALLY AFTER THE OPERATION. - ADVANTAGES OF FULL-AUTOMATIC FOLDING MACHINE: FIRSTLY, THE PRODUCT SIZE IS ACCURATE AND APPEARANCE TIDY. SECONDLY, MACHINE FOLDING TO REDUCE THE SECONDARY POLLUTION, IMPROVE THE PRODUCT QUALITY. AT LAST, IT CAN SHARPLY REDUCE THE LABOR COST, THE INVESTMENT COSTS WILL BE RECOVERED IN HALF YEAR. Learn More

YY-1481 FULL-AUTOMATIC FOLDING MACHINE OF 4-PLY LAP FOAM, 15 PIECES PER MINUTEYY-1481 FULL-AUTOMATIC FOLDING MACHINE OF 4-PLY LAP FOAM, 15 PIECES PER MINUTE FEATURE: - USED FOR FULL-AUTOMATIC FOLDING OF SURGICAL TOWEL, LAP FOAM AND ABDOMINAL TOWEL. - GAUZE ROLL RUNNING ON THE EQUIPMENT WHICH IS AUTOMATICALLY FEEDING, CUTTING, HEMMING, PRESSING, FOLDING AND YARD OPERATING NEATLY. - EQUIPPED WITH 5-6 CNC MOTORS, THE PARAMETER CAN BE MODIFIED IN THE MAN-MACHINE INTERFACE, WHICH WILL BE VERY CONVENIENT TO CHANGE THE PRODUCT VARIETY. - FURTHERMORE, IT CONFIGURES AUTOMATIC DISCHARGING MACHINE, WHICH WITH HIGHER DEGREE OF AUTOMATION, DISCHARGING RESET AUTOMATICALLY AFTER THE OPERATION. - ADVANTAGES OF FULL-AUTOMATIC FOLDING MACHINE: FIRSTLY, THE PRODUCT SIZE IS ACCURATE AND APPEARANCE TIDY. SECONDLY, MACHINE FOLDING TO REDUCE THE SECONDARY POLLUTION, IMPROVE THE PRODUCT QUALITY. AT LAST, IT CAN SHARPLY REDUCE THE LABOR COST, THE INVESTMENT COSTS WILL BE RECOVERED IN HALF YEAR. Learn More -

A-2609 FIBER CARDING & CUSHION FILLING MACHINEA-2609 FIBER CARDING & CUSHION FILLING MACHINE • THE MACHINE IS MADE UP OF FIBER FEEDER & CARDING MACHINE, RECYCLE FOAM CUTTER, BLOWER, FILLING MACHINE AND MIXING MACHINE • IT IS MAINLY USED FOR CUSHION PRODUCTION AND PROCESSING • IT CAN MIX MORE THAN TWO KIND OF MATERIALS, SUCH AS EIDERDOWN, POLYESTER FIBER, FOAM PARTICLES AND SO ON. ALL KINDS OF MATERIALS CAN BE CONTROLLED AT A DESIRED RATE Learn More

A-2609 FIBER CARDING & CUSHION FILLING MACHINEA-2609 FIBER CARDING & CUSHION FILLING MACHINE • THE MACHINE IS MADE UP OF FIBER FEEDER & CARDING MACHINE, RECYCLE FOAM CUTTER, BLOWER, FILLING MACHINE AND MIXING MACHINE • IT IS MAINLY USED FOR CUSHION PRODUCTION AND PROCESSING • IT CAN MIX MORE THAN TWO KIND OF MATERIALS, SUCH AS EIDERDOWN, POLYESTER FIBER, FOAM PARTICLES AND SO ON. ALL KINDS OF MATERIALS CAN BE CONTROLLED AT A DESIRED RATE Learn More -

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSION

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSIONREFERENCE NUMBER: L-1760

Learn More

FOR PUNCHING HOLES IN PU FOAM

WORKING WIDTH: 2100mm

QUANTITY: 1 -

E-2896 CONVOLUTER

E-2896 CONVOLUTERE-2896 CONVOLUTER

MODEL: 2150

CONVOLUTING WIDTH MAX: W 2150 mm (84")

CONVOLUTING PIN DEPTH: 30 mm (1.18")

CONVOLUTING RUNNING SPEED: 0 TO 25 RPM

TOTAL POWER: 10.74 KW

CUTTING SPEED: 0 TO 25 METERS PER MINUTE

CUTTER BLADE TOTAL LENGTH: 9800 mm

BLADE WIDTH x THICKNESS: 50mm x 0.65mm

MACHINE WEIGHT: 2500 KG

MACHINE OVERALL DIMENSIONS: 15.4 FEET WIDE X 4.1 FEET DEEP X 5 FEET TALL

MAXIMUM HEIGHT OF FOAM: 200mm (8”)

THE HEADS ARE ROUND HEADS:

-THE DIAMETER OF EACH HEAD IS 16mm

-THE HEIGHT IS 30mm

-THE DISTANCE OF THE CENTER TO CENTER OF A PAIR HEADS IS 50mm.

Learn More

THIS MACHINE IS A COMBINATION CONVOLUTER-CUTTING MACHINE.

PRODUCES APPROPRIATE MATERIAL PACKAGING FOR ELECTRONICS, DELICATE INSTRUMENTS, FOR CAR SEATING AND MATTRESS INDUSTRY, AS WELL AS EXPENSIVE ARTICLE PACKAGING AND HIGH DENSITY FOAM. -

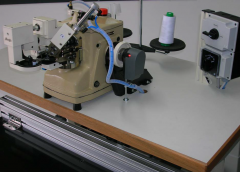

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More -

TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024 COATING LINE FROM BATH MAT PLANT LENGTH 97000mm WIDTH 7000mm ARTOS LATEX FOR BATHMATSB YEAR OF CONSTRUCTION: 2024 WORKING WIDTH: 1000mm TO 2600mm MAXIMUM SETTING WIDTH: 2750mm SPEED: 1.7 METERS TO 35 METERS PER MINUTE Learn More

TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024TT-6094 COATING LINE FROM BATH MAT PLANT, WIDTH 7000mm, YEAR 2024 COATING LINE FROM BATH MAT PLANT LENGTH 97000mm WIDTH 7000mm ARTOS LATEX FOR BATHMATSB YEAR OF CONSTRUCTION: 2024 WORKING WIDTH: 1000mm TO 2600mm MAXIMUM SETTING WIDTH: 2750mm SPEED: 1.7 METERS TO 35 METERS PER MINUTE Learn More -

TT-5858 CNC MACHINE FOR HORIZONTAL CUTTING OF PUR, YEAR 2019TT-5858 CNC MACHINE FOR HORIZONTAL CUTTING OF PUR, YEAR 2019 CNC MACHINE FOR HORIZONTAL CUTTING OF PUR FOAM MANUFACTURED BY THE GERMAN MANUFACTURER ALBRECHT BAEUMER AND THEN MODERNIZED IN 2019 AND ADAPTED IN ACCORDANCE WITH THE REQUIREMENTS OF EUROPEAN DIRECTIVES EXTERNAL DIMENSIONS WITH FENCING AND LIGHT BARRIER APPROX. 7000mm X 8000mm THE CNC IS ADAPTED TO CUT BLOCKS UP TO 2400MM WIDE AND 1300mm HIGH AND IS EQUIPPED WITH A CONTROL PANEL CONTAINING, AMONG OTHERS, A 12-INCH TOUCH PANEL. QUANTITY: 1 Learn More

TT-5858 CNC MACHINE FOR HORIZONTAL CUTTING OF PUR, YEAR 2019TT-5858 CNC MACHINE FOR HORIZONTAL CUTTING OF PUR, YEAR 2019 CNC MACHINE FOR HORIZONTAL CUTTING OF PUR FOAM MANUFACTURED BY THE GERMAN MANUFACTURER ALBRECHT BAEUMER AND THEN MODERNIZED IN 2019 AND ADAPTED IN ACCORDANCE WITH THE REQUIREMENTS OF EUROPEAN DIRECTIVES EXTERNAL DIMENSIONS WITH FENCING AND LIGHT BARRIER APPROX. 7000mm X 8000mm THE CNC IS ADAPTED TO CUT BLOCKS UP TO 2400MM WIDE AND 1300mm HIGH AND IS EQUIPPED WITH A CONTROL PANEL CONTAINING, AMONG OTHERS, A 12-INCH TOUCH PANEL. QUANTITY: 1 Learn More -

TT-3630 HERMAN SCHWABE DIE CUTTING PRESS, SIZE 32” X 64”, CAPACITY 110 TONTT-3630 HERMAN SCHWABE DIE CUTTING PRESS, SIZE 32” X 64”, CAPACITY 110 TON QUANTITY: 1 Learn More

TT-3630 HERMAN SCHWABE DIE CUTTING PRESS, SIZE 32” X 64”, CAPACITY 110 TONTT-3630 HERMAN SCHWABE DIE CUTTING PRESS, SIZE 32” X 64”, CAPACITY 110 TON QUANTITY: 1 Learn More