Search results for: 'packaging'

- Related search terms

- packaging engineer

- packaging design ai

- packaging line

- Packaging Source

-

T-7374 GELBO FLEX TESTER, 50 Hz, STROKE DISTANCE 80 OR 155mm - NEWT-7374 GELBO FLEX TESTER, 50 Hz, STROKE DISTANCE 80 OR 155mm - NEW SPECIFICATIONS: RATE OF CYCLES: 45 PER MIN STANDARDS: ASTM F392 CONDITIONING LEVELS A-E STROKE DISTANCE: 80 OR 155mm TWISTING ANGLE: 400 DEGREES OR 440 DEGREES POWER: 110 OR 230 VAC, 50 Hz, 700 VAC DIMENSION: HEIGHT 410 x WIDTH 1130 x DEPTH 380mm WEIGHT: 45 KGS, UNPACKED MICROPROCESSOR & LCD DISPLAY HOME POSITION FOR EASY MACHINE SET-UP QUANTITY: 1 Learn More

T-7374 GELBO FLEX TESTER, 50 Hz, STROKE DISTANCE 80 OR 155mm - NEWT-7374 GELBO FLEX TESTER, 50 Hz, STROKE DISTANCE 80 OR 155mm - NEW SPECIFICATIONS: RATE OF CYCLES: 45 PER MIN STANDARDS: ASTM F392 CONDITIONING LEVELS A-E STROKE DISTANCE: 80 OR 155mm TWISTING ANGLE: 400 DEGREES OR 440 DEGREES POWER: 110 OR 230 VAC, 50 Hz, 700 VAC DIMENSION: HEIGHT 410 x WIDTH 1130 x DEPTH 380mm WEIGHT: 45 KGS, UNPACKED MICROPROCESSOR & LCD DISPLAY HOME POSITION FOR EASY MACHINE SET-UP QUANTITY: 1 Learn More -

AA-1177 3D FULL PACK – AUTOMATIC MATTRESS COMPRESS AND ROLL PACKING MACHINEAA-1177 3D FULL PACK – AUTOMATIC MATTRESS COMPRESS AND ROLL PACKING MACHINE INNOVATIVE PACKAGING SYSTEM USER FRIENDLY MACHINE SAVING SHIPPING AND STORAGE COSTS Learn More

AA-1177 3D FULL PACK – AUTOMATIC MATTRESS COMPRESS AND ROLL PACKING MACHINEAA-1177 3D FULL PACK – AUTOMATIC MATTRESS COMPRESS AND ROLL PACKING MACHINE INNOVATIVE PACKAGING SYSTEM USER FRIENDLY MACHINE SAVING SHIPPING AND STORAGE COSTS Learn More -

AA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTEAA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTE 1. CARTONING FORM: HORIZONTAL CARTONING 2. CARTONING SPEED: 30 TO 40 BOXES PER MINUTE 3. PROCESS REQUIREMENTS: AUTOMATIC BOX OPENING, CARTONING, GLUE SPRAYING, BOX SEALING 4. INCOMING DIRECTION: FROM LEFT TO RIGHT 5. VOLTAGE: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER) 6. THE INDENTATION OF THE CARTON IS GENERALLY 0.4mm DEEP, AND THE CARTON NEEDS TO HAVE A PRE-FOLDING EFFECT. IF THE BOX IS OPENED MANUALLY, IT CANNOT BE FORMED, AND THE MACHINE CANNOT OPEN THE BOX. QUANTITY: 1 Learn More

AA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTEAA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTE 1. CARTONING FORM: HORIZONTAL CARTONING 2. CARTONING SPEED: 30 TO 40 BOXES PER MINUTE 3. PROCESS REQUIREMENTS: AUTOMATIC BOX OPENING, CARTONING, GLUE SPRAYING, BOX SEALING 4. INCOMING DIRECTION: FROM LEFT TO RIGHT 5. VOLTAGE: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER) 6. THE INDENTATION OF THE CARTON IS GENERALLY 0.4mm DEEP, AND THE CARTON NEEDS TO HAVE A PRE-FOLDING EFFECT. IF THE BOX IS OPENED MANUALLY, IT CANNOT BE FORMED, AND THE MACHINE CANNOT OPEN THE BOX. QUANTITY: 1 Learn More -

M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS- 3 PUNCH AND 810 PADS PER MINUTE

M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS- 3 PUNCH AND 810 PADS PER MINUTEMODEL: 96

DESIGNED FOR PRODUCTION OF VARIOUS TYPES OF COTTON PADS

ALSO CALLED COTTON ROUNDS, COTTON SQUARES, DISC COTTON, FACIAL COTTON

COTTON PADS FOR HYGIENIC USE, COSMETIC USE, INDUSTRIAL USE, AND MEDICAL APPLICATIONS

PRODUCT OUTPUT DEPENDS ON THE SIZE OF THE PADS AND CAN REACH UP TO 1080 PIECES/MINUTE

VARIOUS SHAPES OF COTTON PADS CAN BE PRODUCED AUTOMATICALLY IF SEPARATE TOOLS OF DIFFERENT SHAPES OR SIZES ARE INSTALLED

THE COTTON PAD PRODUCER HAS THE OPTION OF MANUFACTURING EITHER EMBOSSED OR PLAIN COTTON PADS

THE PRODUCT IS PACKAGED IN POLYBAGS IN SEMI AUTOMATIC MODE

THE MACHINE CAN ALSO BE CONNECTED TO THE AUTOMATIC PACKAGING DEVICE TO OBTAIN DIFFERENT KINDS OF PACKAGING

3 PUNCH MOULD

MAXIMUM PERFORMANCE 810 ROUND PADS PER MINUTE

EACH STROKE OF THE PUNCHING UNIT CUTS 4 ROUNDS AT ONE TIMEQUANTITY: 1

Learn More -

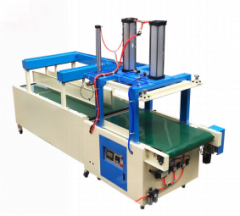

J-1948 PILLOW & CUSHION COMPRESSION PACKING MACHINE- NEW -AUTOMATIC , 12 PILLOWS PER MINUTE

J-1948 PILLOW & CUSHION COMPRESSION PACKING MACHINE- NEW -AUTOMATIC , 12 PILLOWS PER MINUTEREDUCES VOLUME FOR STORAGE AND TRANSPORTATION

USES COMPRESSED AIR AND PLASTIC COMPOSITE FILM BAGS FOR PACKAGING ITEMS AFTER COMPRESSION

EQUIPPED WITH AUTOMATIC TRANSMISSION TO COMPRESS AND FILM ITEMS UNINTERRUPTED

STANDARD MODEL EQUIPPED WITH ONE WORKSTATION WITH SINGLE SEAL (OPTIONAL ONE WORKSTATION WITH DOUBLE SEALS)

PLC TOUCH SCREEN OPERATION, USER FRIENDLY INTERFACE

CONSTANT TEMPERATURE CONTROL FUNCTION TO PREVENT BAG BURNSVOLTAGE AND POWER: 220 V SINGLE-PHASE, 0.5 KW, 50 Hz

AIR PRESSURE: 0.4 – 0.8 MPA

PACKING CAPACITY: : 8 TO 12 ITEMS PER MINUTE

PRESS BOARD SIZE: LENGTH 700mm x WIDTH 900mm

MAXIMUM COMPRESSION THICKNESS: 500mm (AIR CYLINDER TRAVEL)

SEAL LENGTH: 880mm x 10mm

OVERALL DIMENSIONS: LENGTH 3390mm x WIDTH 940mm x HEIGHT 2010mm

POWER: 1.5 KW

NET WEIGHT: 350 KG

GROSS WEIGHT: 400 KGQUANTITY: 1

Learn More -

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

L-5324 K-CUP COFFEE CAPSULE ROTARY FILLING AND SEALING MACHINE

L-5324 K-CUP COFFEE CAPSULE ROTARY FILLING AND SEALING MACHINEREFERENCE NUMBER: L-5324

Learn More

K-CUP COFFEE CAPSULE ROTARY FILLING AND SEALING MACHINE -

R-7121 TENSILE TESTER FOR PLASTIC FILMS, ADHESIVE TAPES, RUBBER, HARDNESS- BRAND NOVASTAR

R-7121 TENSILE TESTER FOR PLASTIC FILMS, ADHESIVE TAPES, RUBBER, HARDNESS- BRAND NOVASTARREFERENCE NUMBER: R-7121

SOFTWARE: TOUCH SCREEN AND COMPUTER OPERATED

CAPACITY: 5 kN

STANDARDS: ASTMD3575, ASTMD3574

SPEED UP TO 40 INCHES PER MININCLUDES:

Learn More

TEST A DENSITY TEST, 1% PRECISION, 200G (ELECTRIC BALANCE)

TEST D CONSTANT COMPRESSION TEST

QUANTITY: 1 -

U-1123 SOAP PRODUCTION LINE 1000kg/HR

U-1123 SOAP PRODUCTION LINE 1000kg/HRPRODUCT DETAILS

PRODUCT TYPE SOAP BARS–LAUNDRY GRADELearn MorePRODUCT SIZE1KG BARPRODUCT DIMENSIONS 370MM X 39MM X 60MM -

R-3272 ROASTING PLANT - HAS GARANTI, GUMP 777E, JABEZ BURNS SAMPLER - 60 KILOS

R-3272 ROASTING PLANT - HAS GARANTI, GUMP 777E, JABEZ BURNS SAMPLER - 60 KILOSR-3272 ROASTING PLANT - HAS GARANTI, GUMP 777E, JABEZ BURNS SAMPLER - 60 KILOS

60 KILOS HAS GARANTI WITH A REAL CARBON STEEL DRUM (THAT IS GOOD NEWS) THAT IS 15 YEARS OLD AND STOOD THE TEST OF TIME. CONSTANT PREVENTATIVE MAINTENANCE, SO IT IS SOLID.

UNIVERSAL BUCKET ELEVATOR LOADER

DESTONER

FLOOR SCALES

RACKS

JABEZ BURNS DUST COLLECTION SYSTEM FOR LOADER

OLD TIME BAR NUN SWIFTER GREEN COFFEE CLEANER - NOT BEING USED . . . THIS IS A WORKING ANTIQUE. MAKES A GOOD DISCUSSION PIECE.

JABES BURNS 4 BARREL SAMPLE ROASTER IN REALLY NICE TO EXCELLENT CONDITION - LIKE AN ANTIQUE THAT IS STILL WORKING AND WILL BE FOR AS LONG AS THE NEW OWNER IS LIVING.

E10 AGTRON COLOR READER

OLD TIMER WRIGHT MONOBAG TWIN PACKAGING MACHINE - LEFT SIDE SET FOR POUCHES AND R SIDE FOR 1 POUND BAGS. WRIGHT STILL SUPPORTS THIS MACHINE.

5 POUND BULK BAG - NET WEIGH SYSTEM - INCLUDING A FILLING LADDER

TRADITIONAL RO-TAP MACHINE AND SCREENS FOR TESTING GROUND COFFEE

THE IMPORTANT THING HERE IS SIMPLE OCS PRODUCTION LINE FOR LITTLE DOLLARS AND SOME RE-INSTALLATION TIME.

3 PHASE POWER.

NAPTURAL GASQUANTITY: 1

Learn More