Search results for: 'Thi'

- Related search terms

- Thie

- Thies i ma

- thib

- thibe

- Thies dyeing

-

J-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEWJ-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEW TOTAL POWER: 45 KW VOLTAGE: PER CUSTOMER REQUIREMENT, SPECIFY WHEN ORDERING TOTAL WEIGHT: 15000 KGS OVERALL DIMENSIONS: 12300 x 3400 x 3000mm WITH CE CERTIFICATE REQUIRES (2) 40-FOOT HIGH CUBE CONTAINERS TO SHIP QUANTITY: 1 Learn More

J-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEWJ-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEW TOTAL POWER: 45 KW VOLTAGE: PER CUSTOMER REQUIREMENT, SPECIFY WHEN ORDERING TOTAL WEIGHT: 15000 KGS OVERALL DIMENSIONS: 12300 x 3400 x 3000mm WITH CE CERTIFICATE REQUIRES (2) 40-FOOT HIGH CUBE CONTAINERS TO SHIP QUANTITY: 1 Learn More -

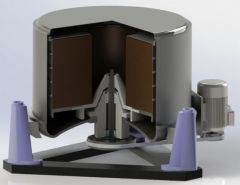

AA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETERAA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETER THIS CENTRIFUGAL EXTRACTOR IS USED TO PREDRY ALL KINDS OF FIBERS AFTER DYEING, HAS A MODULAR STRUCTURE TECHNICIAL SPECIFICATIONS: 1. BASKET DIAMETER: Ø500 TO Ø1800 mm 2. BASKET DEPTH: 750 mm 3. ROLLING BASKET: AISI304L STAINLESS PERFORATED STEEL 4. EXTERNAL BASKET: AISI304L STAINLESS STEEL 5. BASKET THICKNESS: 4mm 6. OUTER BASKET THICKNESS: 4mm 7. DRIVE MOTOR: 22 KW/H SPEED 1500 RPM 8. STRENGTH CIRCLE (USED TO INCREASE THE STRENGTH OF THE INNER BASKET (ROTATING PART) : 20 x 20 AISI304L STAINLESS PLATE (4 PIECES) 9. BEARING BLOCK: 3 PIECES, SKF/FAG BEARING 10. SPEED CONTROL: INVERTER CONTROL 11. BREAKING: INVERTER CONTROL EXTERNAL BREAKING SYSTEM Learn More

AA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETERAA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETER THIS CENTRIFUGAL EXTRACTOR IS USED TO PREDRY ALL KINDS OF FIBERS AFTER DYEING, HAS A MODULAR STRUCTURE TECHNICIAL SPECIFICATIONS: 1. BASKET DIAMETER: Ø500 TO Ø1800 mm 2. BASKET DEPTH: 750 mm 3. ROLLING BASKET: AISI304L STAINLESS PERFORATED STEEL 4. EXTERNAL BASKET: AISI304L STAINLESS STEEL 5. BASKET THICKNESS: 4mm 6. OUTER BASKET THICKNESS: 4mm 7. DRIVE MOTOR: 22 KW/H SPEED 1500 RPM 8. STRENGTH CIRCLE (USED TO INCREASE THE STRENGTH OF THE INNER BASKET (ROTATING PART) : 20 x 20 AISI304L STAINLESS PLATE (4 PIECES) 9. BEARING BLOCK: 3 PIECES, SKF/FAG BEARING 10. SPEED CONTROL: INVERTER CONTROL 11. BREAKING: INVERTER CONTROL EXTERNAL BREAKING SYSTEM Learn More -

SEMICONDUCTOR AND SOLAR PANEL PRODUCTION EQUIPMENTREFERENCE NUMBER: T-6947 SEMICONDUCTOR AND SOLAR PANEL PRODUCTION EQUIPMENT IN ADDITION THERE ARE SOME MORE SEMICONDUCTOR AND SOLAR PANEL PRODUCTION EQUIPMENT AVAILABLE, SUCH AS: SINGULUS SINGULAR ICP-PECVD COATING SYSTEM FOR CRYSTALLINE SOLAR CELLS LEYBOLD H3200 INLINE SPUTTER FOR THIN FILM (CIS/CIGS) SOLAR MODULES LEYBOLD H1700 INLINE SPUTTER FOR THIN FILM (CIS/CIGS) SOLAR MODULES AMAT ATON 1600 SPUTTER DR. SCHENK SOLARINSPECT QUALITY MEASUREMENT SYSTEM INNOLAS IMPALA MULTIBEAM LASER STRUCTURIZER ENVIRON FALK 15 M3/H ULTRAPURE WATER PLANT MEIER VACUUMLAMINATOR ICOLAM 42/24 SYNRAD CO2 LASER MARKING SYSTEM MUEGGE MAGNETRON HEAD 3KW MH 3000 4 JET EDGE DECOATING SYSTEMS Learn More

SEMICONDUCTOR AND SOLAR PANEL PRODUCTION EQUIPMENTREFERENCE NUMBER: T-6947 SEMICONDUCTOR AND SOLAR PANEL PRODUCTION EQUIPMENT IN ADDITION THERE ARE SOME MORE SEMICONDUCTOR AND SOLAR PANEL PRODUCTION EQUIPMENT AVAILABLE, SUCH AS: SINGULUS SINGULAR ICP-PECVD COATING SYSTEM FOR CRYSTALLINE SOLAR CELLS LEYBOLD H3200 INLINE SPUTTER FOR THIN FILM (CIS/CIGS) SOLAR MODULES LEYBOLD H1700 INLINE SPUTTER FOR THIN FILM (CIS/CIGS) SOLAR MODULES AMAT ATON 1600 SPUTTER DR. SCHENK SOLARINSPECT QUALITY MEASUREMENT SYSTEM INNOLAS IMPALA MULTIBEAM LASER STRUCTURIZER ENVIRON FALK 15 M3/H ULTRAPURE WATER PLANT MEIER VACUUMLAMINATOR ICOLAM 42/24 SYNRAD CO2 LASER MARKING SYSTEM MUEGGE MAGNETRON HEAD 3KW MH 3000 4 JET EDGE DECOATING SYSTEMS Learn More -

INDUSTRIAL ELECTROSPINNING MACHINEREFERENCE NUMBER: A-2471 INDUSTRIAL ELECTROSPINNING MACHINE A MASS PRODUCTION MACHINE OF ELECTROSPINNING. ALUMINUM FRAME STRUCTURE MAKES IT POSSIBLE FOR EXTENDING DIFFERENT FUNCTIONS. THE SPINNERET USED IS MULTI-NEEDLE ARRAYS, FROM 64 TO 384 NEEDLES ARE EQUIPPED. THE LENGTH AND WIDTH CAN BE MADE ACCORDING TO CUSTOMER'S REQUIREMENT. ROLL TO ROLL COLLECTOR AND CONTINUOUS COLLECTOR CAN BE USED BASED ON THE THICKNESS OF REQUIRED FIBER SHEET. FOR SOLUTIONS, A MULTI-CHANNEL PUMP WILL BE SUPPLIED FOR LONG TIME PRODUCTION OR NONE-STOP PRODUCTION. FEATURES: - EQUIPPED WITH BOTH POSITIVE & NEGATIVE HIGH VOLTAGE SUPPLY DEVICES - EQUIPPED WITH UNWINDING & WINDING MACHINES - CONTINUOUS ELECTROSPINNING & WINDING - ALUMINUM ALLOY FRAME STRUCTURE, MULTI-FUNCTIONS EXPANSIBLE - MULTI-NEEDLES IN ARRAYS. 16 NEEDLES X N ROWS, UP TO 384 NEEDLES - SPINNERET MOVING MACHINERY ENSURES EVEN FIBER SHEET - ONLINE AUTO-CLEAN DEVICE FOR NEEDLES - THICKNESS OF THE FIBER SHEET IS CONTROLLABLE - CE & FCC CERTIFICATE SPINNERET STANDARD:16 NEEDLES X 8 GROUPS =128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ADJUSTED FREELY ACCORDING TO THE REQUIREMENTS OF USE) X-Y-Z MOTION SYSTEM - THE NOZZLE CAN BE MOVED UP AND DOWN IN THE Z DIRECTION THROUGH THE TOUCH SCREEN CONTROL TO DETERMINE THE APPROPRIATE SPINNING DISTANCE. - THE NOZZLE CAN MOVE BACK AND FORTH ALONG THE YAXIS DIRECTION OF THE TANGENT DIRECTION OF THE RECEIVING FILM TO PREPARE A UNIFORM FIBER FILM. - THE NOZZLE AUTOMATIC ONLINE CLEANING DEVICE SCANS ALONG THE X-AXIS DIRECTION. COLLECTOR - STAINLESS STEEL PLATE / MESH SERVES AS A CARRIER FOR THE FIBER MEMBRANE SUBSTRATE. - CONNECTED WITH NEGATIVE HIGH VOLTAGE. - RECEIVER BOARD WIDTH: 500 mm - SPINNING DISTANCE: 80 TO 300 mm ADJUSTABLE WINDER AND UNWINDER - AUTOMATICALLY CALCULATE THE ROLL DIAMETER OF THE LOADED MATERIAL AND CONTROL THE TENSION BETWEEN THE UNWINDING AND SPINNING SECTIONS. - CONSTANT FEEDING SPEED. THE FEEDING SPEED RANGE IS 0 TO 5000 mm / min. - ONLINE HOT PRESSING FUNCTION MODULE. AFTER THE SPINNING IS COMPLETED, BEFORE THE WINDING, A TEMPERATURE-CONTROLLED HOT PRESSING DEVICE (ROOM TEMPERATURE TO 60 ° C) IS USED FOR HOT PRESSING. (OPTIONAL THIRD LAYER MATERIAL STICKING AND REWINDING DEVICE). - CAN BE OPERATED BY TOUCH SCREEN. - DO NOT USE METAL FILM AS THE RECEIVING CARRIER. SYRINGE PUMP - 200ML X 4N CHANNEL - FLOW RATE: 0.1ML / H TO 1280 ML / H - SPECIALLY DESIGNED FOR ELECTRO-SPINNING AND RESISTANT TO HIGH VOLTAGE. HIGH VOLTAGE DEVICE -0 TO 50KV, DIGITAL DISPLAY --50KV ~ 0 KV, DIGITAL DISPLAY -OUTPUT CURRENT: <1 MA -CONTINUOUSLY ADJUSTABLE CONTROL SYSTEM -PLC CONTROL SYSTEM, 7-INCH TOUCH SCREEN. -CONTROL THE MOVEMENT OF THE NOZZLE. -CONTROL THE NOZZLE TO MOVE UP AND DOWN. -YOU CAN SET THE MOVEMENT TIME, STROKE AND SPEED OF THE NOZZLE. -CONTROL THE FREQUENCY OF NOZZLE CLEANING. -SPINNING PROCESS PARAMETER RECORDS. ENVIRONMENTAL CONTROL SYSTEM -PROVIDE INTERFACE TO LET IN DRY AMBIENT HUMIDITY AIR. -AN EXTERNAL DEHUMIDIFIER CAN BE USED TO CONTROL THE AMBIENT HUMIDITY. THE EXTERNAL DEHUMIDIFIER NEEDS TO BE SELECTED ACCORDING TO THE SIZE OF THE WORKSHOP. THIS EQUIPMENT DOES NOT INCLUDE THIS DEHUMIDIFIER. EXHAUST SYSTEM -BOTTOM UP, AND FOUR FANS ARE PUMPED AT THE SAME TIME. -THE DISCHARGE VOLUME OF A SINGLE UNIT IS 5 TO 150 M3 / H, AND THE RATE IS ADJUSTABLE. THE COMBINED DISCHARGE VOLUME OF THE TWO EXHAUST FANS IS 10 TO 300M3 / H. THE EXTRACTOR IS DRAWN FROM THE MIDDLE. IN THIS WAY, THE HIGH-SPEED AIR VENTILATION MINIMIZES THE RELATIVE DISTURBANCE TO THE SPINNING. THE EXHAUST FAN IS A SILENT EXHAUST FAN. SAFETY -AUTOMATIC POWER-OFF DEVICE FOR OPENING THE DOOR. -RESIDUAL STATIC ELECTRICITY REMOVAL DEVICE. -EMERGENCY STOP SWITCH. -GROUND AT MULTIPLE POINTS. -ALARM DEVICE AFTER THE CONTROL PARAMETERS EXCEED THE LIMIT. CHAMBER -THE CHAMBER IS MADE OF ALUMINUM ALLOY FRAME. -THE FRONT AND SIDE WINDOWS OF THE CABINET ARE MADE OF TEMPERED GLASS. -MULTI-POINT TEMPERATURE AND HUMIDITY COLLECTION AND DISPLAY. -THE PROCESS CAN BE OBSERVED WITH THE NAKED EYE. -AIR INLET: HOT AND DRY AIR CAN BE INTRODUCED TO QUICKLY ADJUST THE HUMIDITY INSIDE THE CHAMBER. POWER SOURCE -220 VOLTS AND 50/60 Hz -TOTAL POWER: 10KW NUMBER OF NEEDLES: 128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ARBITRARILY REDUCED ACCORDING TO THE SOLVENT USAGE) FLOW RATE OF EACH NEEDLE: (~ 3ML ± 50%) / HOUR TOTAL FLOW OF THE WHOLE MACHINE: ABOUT (400ML ± 50%) / HOUR SOLUTION CONCENTRATION: 10 TO 20% 8 HOURS SOLUTION PROCESSING CAPACITY: ABOUT (3L ± 50%) / 8 HOURS SOLID CONTENT (WEIGHT OF FIBER PRODUCED): (300G ± 50%) / 8 HOURS ACCORDING TO THE APPROXIMATE PRODUCTION OF FIBER MATERIAL WITH A GRAM WEIGHT OF 2GSM. WINDING AND UNWINDING SPEED: 50M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 25 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 200 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: 600 SQUARE METERS BASED ON THE PRODUCTION OF FIBER MATERIAL WITH A GRAMMAGE OF 0.02G / ㎡, APPROXIMATELY: WINDING AND UNWINDING SPEED: 5000M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 2500 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 20,000 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: ABOUT 60,000 SQUARE METERS Learn More

INDUSTRIAL ELECTROSPINNING MACHINEREFERENCE NUMBER: A-2471 INDUSTRIAL ELECTROSPINNING MACHINE A MASS PRODUCTION MACHINE OF ELECTROSPINNING. ALUMINUM FRAME STRUCTURE MAKES IT POSSIBLE FOR EXTENDING DIFFERENT FUNCTIONS. THE SPINNERET USED IS MULTI-NEEDLE ARRAYS, FROM 64 TO 384 NEEDLES ARE EQUIPPED. THE LENGTH AND WIDTH CAN BE MADE ACCORDING TO CUSTOMER'S REQUIREMENT. ROLL TO ROLL COLLECTOR AND CONTINUOUS COLLECTOR CAN BE USED BASED ON THE THICKNESS OF REQUIRED FIBER SHEET. FOR SOLUTIONS, A MULTI-CHANNEL PUMP WILL BE SUPPLIED FOR LONG TIME PRODUCTION OR NONE-STOP PRODUCTION. FEATURES: - EQUIPPED WITH BOTH POSITIVE & NEGATIVE HIGH VOLTAGE SUPPLY DEVICES - EQUIPPED WITH UNWINDING & WINDING MACHINES - CONTINUOUS ELECTROSPINNING & WINDING - ALUMINUM ALLOY FRAME STRUCTURE, MULTI-FUNCTIONS EXPANSIBLE - MULTI-NEEDLES IN ARRAYS. 16 NEEDLES X N ROWS, UP TO 384 NEEDLES - SPINNERET MOVING MACHINERY ENSURES EVEN FIBER SHEET - ONLINE AUTO-CLEAN DEVICE FOR NEEDLES - THICKNESS OF THE FIBER SHEET IS CONTROLLABLE - CE & FCC CERTIFICATE SPINNERET STANDARD:16 NEEDLES X 8 GROUPS =128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ADJUSTED FREELY ACCORDING TO THE REQUIREMENTS OF USE) X-Y-Z MOTION SYSTEM - THE NOZZLE CAN BE MOVED UP AND DOWN IN THE Z DIRECTION THROUGH THE TOUCH SCREEN CONTROL TO DETERMINE THE APPROPRIATE SPINNING DISTANCE. - THE NOZZLE CAN MOVE BACK AND FORTH ALONG THE YAXIS DIRECTION OF THE TANGENT DIRECTION OF THE RECEIVING FILM TO PREPARE A UNIFORM FIBER FILM. - THE NOZZLE AUTOMATIC ONLINE CLEANING DEVICE SCANS ALONG THE X-AXIS DIRECTION. COLLECTOR - STAINLESS STEEL PLATE / MESH SERVES AS A CARRIER FOR THE FIBER MEMBRANE SUBSTRATE. - CONNECTED WITH NEGATIVE HIGH VOLTAGE. - RECEIVER BOARD WIDTH: 500 mm - SPINNING DISTANCE: 80 TO 300 mm ADJUSTABLE WINDER AND UNWINDER - AUTOMATICALLY CALCULATE THE ROLL DIAMETER OF THE LOADED MATERIAL AND CONTROL THE TENSION BETWEEN THE UNWINDING AND SPINNING SECTIONS. - CONSTANT FEEDING SPEED. THE FEEDING SPEED RANGE IS 0 TO 5000 mm / min. - ONLINE HOT PRESSING FUNCTION MODULE. AFTER THE SPINNING IS COMPLETED, BEFORE THE WINDING, A TEMPERATURE-CONTROLLED HOT PRESSING DEVICE (ROOM TEMPERATURE TO 60 ° C) IS USED FOR HOT PRESSING. (OPTIONAL THIRD LAYER MATERIAL STICKING AND REWINDING DEVICE). - CAN BE OPERATED BY TOUCH SCREEN. - DO NOT USE METAL FILM AS THE RECEIVING CARRIER. SYRINGE PUMP - 200ML X 4N CHANNEL - FLOW RATE: 0.1ML / H TO 1280 ML / H - SPECIALLY DESIGNED FOR ELECTRO-SPINNING AND RESISTANT TO HIGH VOLTAGE. HIGH VOLTAGE DEVICE -0 TO 50KV, DIGITAL DISPLAY --50KV ~ 0 KV, DIGITAL DISPLAY -OUTPUT CURRENT: <1 MA -CONTINUOUSLY ADJUSTABLE CONTROL SYSTEM -PLC CONTROL SYSTEM, 7-INCH TOUCH SCREEN. -CONTROL THE MOVEMENT OF THE NOZZLE. -CONTROL THE NOZZLE TO MOVE UP AND DOWN. -YOU CAN SET THE MOVEMENT TIME, STROKE AND SPEED OF THE NOZZLE. -CONTROL THE FREQUENCY OF NOZZLE CLEANING. -SPINNING PROCESS PARAMETER RECORDS. ENVIRONMENTAL CONTROL SYSTEM -PROVIDE INTERFACE TO LET IN DRY AMBIENT HUMIDITY AIR. -AN EXTERNAL DEHUMIDIFIER CAN BE USED TO CONTROL THE AMBIENT HUMIDITY. THE EXTERNAL DEHUMIDIFIER NEEDS TO BE SELECTED ACCORDING TO THE SIZE OF THE WORKSHOP. THIS EQUIPMENT DOES NOT INCLUDE THIS DEHUMIDIFIER. EXHAUST SYSTEM -BOTTOM UP, AND FOUR FANS ARE PUMPED AT THE SAME TIME. -THE DISCHARGE VOLUME OF A SINGLE UNIT IS 5 TO 150 M3 / H, AND THE RATE IS ADJUSTABLE. THE COMBINED DISCHARGE VOLUME OF THE TWO EXHAUST FANS IS 10 TO 300M3 / H. THE EXTRACTOR IS DRAWN FROM THE MIDDLE. IN THIS WAY, THE HIGH-SPEED AIR VENTILATION MINIMIZES THE RELATIVE DISTURBANCE TO THE SPINNING. THE EXHAUST FAN IS A SILENT EXHAUST FAN. SAFETY -AUTOMATIC POWER-OFF DEVICE FOR OPENING THE DOOR. -RESIDUAL STATIC ELECTRICITY REMOVAL DEVICE. -EMERGENCY STOP SWITCH. -GROUND AT MULTIPLE POINTS. -ALARM DEVICE AFTER THE CONTROL PARAMETERS EXCEED THE LIMIT. CHAMBER -THE CHAMBER IS MADE OF ALUMINUM ALLOY FRAME. -THE FRONT AND SIDE WINDOWS OF THE CABINET ARE MADE OF TEMPERED GLASS. -MULTI-POINT TEMPERATURE AND HUMIDITY COLLECTION AND DISPLAY. -THE PROCESS CAN BE OBSERVED WITH THE NAKED EYE. -AIR INLET: HOT AND DRY AIR CAN BE INTRODUCED TO QUICKLY ADJUST THE HUMIDITY INSIDE THE CHAMBER. POWER SOURCE -220 VOLTS AND 50/60 Hz -TOTAL POWER: 10KW NUMBER OF NEEDLES: 128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ARBITRARILY REDUCED ACCORDING TO THE SOLVENT USAGE) FLOW RATE OF EACH NEEDLE: (~ 3ML ± 50%) / HOUR TOTAL FLOW OF THE WHOLE MACHINE: ABOUT (400ML ± 50%) / HOUR SOLUTION CONCENTRATION: 10 TO 20% 8 HOURS SOLUTION PROCESSING CAPACITY: ABOUT (3L ± 50%) / 8 HOURS SOLID CONTENT (WEIGHT OF FIBER PRODUCED): (300G ± 50%) / 8 HOURS ACCORDING TO THE APPROXIMATE PRODUCTION OF FIBER MATERIAL WITH A GRAM WEIGHT OF 2GSM. WINDING AND UNWINDING SPEED: 50M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 25 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 200 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: 600 SQUARE METERS BASED ON THE PRODUCTION OF FIBER MATERIAL WITH A GRAMMAGE OF 0.02G / ㎡, APPROXIMATELY: WINDING AND UNWINDING SPEED: 5000M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 2500 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 20,000 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: ABOUT 60,000 SQUARE METERS Learn More -

L-2693 HORIZONTAL AND VERTICAL CUTTER FOR FOAM

L-2693 HORIZONTAL AND VERTICAL CUTTER FOR FOAMREFERENCE NUMBER: L-2693

Learn More

HORIZONTAL FOAM CUTTER

MACHINE EXTERNAL SIZE: 7800mm LONG X 4200mm WIDE X 2400mm HIGH

VERTICAL FOAM CUTTER

EXTERNAL SIZE: 4650mm LONG X 4000mm WIDE X 2450mm HIGH

QUANTITY: 1 -

L-2044 FOAM COMPRESSION TESTER

L-2044 FOAM COMPRESSION TESTERREFERENCE NUMBER: L-2044

Learn More

MACHINE SIZE (W X D X H) 700 X 560 X 1200mm

QUANTITY: 1 -

L-1781 FOAM PILLOW DRILL MODEL 101 50 X 50mm HOLE SIZE 10mm 1 PILLOW PER MINUTE

L-1781 FOAM PILLOW DRILL MODEL 101 50 X 50mm HOLE SIZE 10mm 1 PILLOW PER MINUTEREFERENCE NUMBER: L-1781

Learn More

OVERALL SIZE: 2300mm LONG X 2500mm X WIDE X 2200mm HIGH

QUANTITY: 1 -

L-1744 FOAM PILLOW DRILL MODEL 9101 25 X 25mm HOLE SIZE 10mm 1 PILLOW PER 5 MINUTES

L-1744 FOAM PILLOW DRILL MODEL 9101 25 X 25mm HOLE SIZE 10mm 1 PILLOW PER 5 MINUTESREFERENCE NUMBER: L-1744

Learn More

MODEL: 9101

OVERALL SIZE (APPROX.): 2300mm LONG X 2500mm WIDE X 2200mm HIGH

QUANTITY: 1 -

L-1723 EVA CUTTING MACHINE MAX FOAM WIDTH 1800mm

L-1723 EVA CUTTING MACHINE MAX FOAM WIDTH 1800mmREFERENCE NUMBER: L-1723

Learn More

MAXIMUM FOAM WIDTH: 1800mm

QUANTITY: 1