Search results for: 'electric con'

- Related search terms

- Contro

- Control pa

- condition

- control+p

- Control pa'||'

-

G-4426 SLAUGHTER LINE FOR CATTLE (300 PD) AND SHEEP (1000 PD)REFERENCE NUMBER: G-4426 SLAUGHTER LINE FOR CATTLE (300 PD) AND SHEEP (1000 PD) QUANTITY AVAILABLE: 1 Learn More

G-4426 SLAUGHTER LINE FOR CATTLE (300 PD) AND SHEEP (1000 PD)REFERENCE NUMBER: G-4426 SLAUGHTER LINE FOR CATTLE (300 PD) AND SHEEP (1000 PD) QUANTITY AVAILABLE: 1 Learn More -

M-4832 SEMI-AUTOMATIC BAGGING MACHINEvREFERENCE NUMBER: M-4832 SEMI-AUTOMATIC BAGGING MACHINE QUANTITY AVAILABLE: 1 Learn More

M-4832 SEMI-AUTOMATIC BAGGING MACHINEvREFERENCE NUMBER: M-4832 SEMI-AUTOMATIC BAGGING MACHINE QUANTITY AVAILABLE: 1 Learn More -

M-5102 NEGATIVE & POSITIVE RAPIER HERCULES WEAVING MACHINES WIDTH 5500mm – FOR HEAVY FABRICSREFERENCE NUMBER: M-5102 (1212FPDWXX11) L NEGATIVE & POSITIVE RAPIER HERCULES WEAVING MACHINES WIDTH 5500mm – FOR HEAVY FABRICS NEGATIVE & POSITIVE RAPIER HERCULES H5500 WEAVING MACHINES 20 SHAFTS NOMINAL WIDTH 5500mm MAXIMUM REED WIDTH 5500mm MINIMUM REED WIDTH 4400mm STANDARD BASIC MACHINE FOR VOLTAGE 440 V AND FREQUENCY OF 60 HZ DIRECT DRIVE MOTOR, SPEED CONTROLLED BY MICROPROCESSOR WITHOUT CHANGE OF PULLEY, WITHOUT CLUTCH SYSTEM, WITH (15%-40%) ELECTRIC POWER SAVING DEPENDING FROM TYPE OF WOVEN FABRIC SHEDDING MACHINE: STAUBLI DOBBY MODEL 2668 20 RODS SHAFTS TYPE GROB HEALD FRAME WITH UNDER MOTION 20 LEVER DRC CASTLE ELECTRIC CABINET WITH MICROPROCESSOR, ELECTRONIC PICK FINDING, ELECTRONIC LET-OFF, ELECTRONIC TAKE-UP UNIT WITH INDEPENDENT MOTOR ELECTRONIC WEFT COLOUR SELECTOR IN EXECUTION FOR 8 COLORS TAKE-UP WITH ROLLER DIAMETER 219mm 6 TWIN BEAM DIAMETER 219mm WITH FLANGE 1000mm Q3 JUMBO BACK REST BAR FOR HERCULES WEFT DENSITY VARIABLE PROGRAMMABLE BY THE OPERATOR AT YOUR CHOICE HORIZONTAL CREEL 4 COLOURS AND SUPPORT FOR 8 CONE 4 WEFT FEEDERS ROJ CHRONO X3 3 WEFT BRAKES FOR EVERY CHRONO X3 (TOTAL 12 PCS) TO BE SELECT AS PER CUSTOMER WEFT YARN WEFT CONTROLLING UNIT ELTEX MODEL G3W. DEROULÈ LATERAL MINI CREELS SUPPORT FOR 24 CONES LATERAL MOTORIZED LENO SYSTEM HEATING SCISSOR-CUTTING LATERAL TEMPLES: TO BE DEFINED DEPENDING THE FABRIC CHARACTERISTIC 20 FRAMES GROB TYPE 331 C TYPE DRC S227 GROBTEX ALFIX-U 14.000 GROB HEALDS TYPE 8 X 3.8 TYPE GROZ AETEX SP 0.38 331 8.0X3.8 I CR (7000PCS PER PACK) 1 WARP STOP MOTION 6-30 GROB FKW LED 14.000 GROB DROP WIRE TYPE GROZ EOU 1405 180X11X0.50 ZN (2000PCS PER PACK) SETS OF NEGATIVE RAPIERS & TAPE (LEFT AND RIGHT SIDE) SETS OF POSITIVE RAPIERS & TAPE (LEFT AND RIGHT SIDE) POSITIVE RAPIER KIT (FULL COMPONENT) CENTRAL GEARBOX ALREADY INSTALLED AND COLOR SELECTOR ALREADY ASSEMBLED FOR POSITIVE VERSION APPLICATION (TO REDUCE TIME OF CONVERSION) SETS AND EQUIPMENT OF LOOM TOOL CASE WITH TOTAL TOOLS LIKE TECHNICIANS INCLUDING NR. 2 TORQUE TOOL EXTRA SPARE PARTS THE TOTAL MACHINE SUPPLY WILL ALSO INCLUDE 2 SETS OF NEGATIVE RAPIERS (LEFT AND RIGHT SIDE) 2 SETS OF NEGATIVE TAPES (LEFT AND RIGHT SIDE) 2 SETS OF POSITIVE RAPIERS (LEFT AND RIGHT SIDE) 2 SETS OF POSITIVE TAPES (LEFT AND RIGHT SIDE) 1 POSITIVE RAPIER KIT (FULL COMPONENT) 1 SET AND EQUIPMENT OF LOOM 1 TOOL CASE WITH TOTAL TOOLS LIKE TECHNICIANS INCLUDE 2 TORQUE TOOLS EXTRA SPARE PARTS 1500EUR/MACHINE WARRANTY: ONE YEAR FROM MACHINE ERECTION OR AFTER 3 MONTHS DELIVERY DATE QUANTITY: 1 Learn More

M-5102 NEGATIVE & POSITIVE RAPIER HERCULES WEAVING MACHINES WIDTH 5500mm – FOR HEAVY FABRICSREFERENCE NUMBER: M-5102 (1212FPDWXX11) L NEGATIVE & POSITIVE RAPIER HERCULES WEAVING MACHINES WIDTH 5500mm – FOR HEAVY FABRICS NEGATIVE & POSITIVE RAPIER HERCULES H5500 WEAVING MACHINES 20 SHAFTS NOMINAL WIDTH 5500mm MAXIMUM REED WIDTH 5500mm MINIMUM REED WIDTH 4400mm STANDARD BASIC MACHINE FOR VOLTAGE 440 V AND FREQUENCY OF 60 HZ DIRECT DRIVE MOTOR, SPEED CONTROLLED BY MICROPROCESSOR WITHOUT CHANGE OF PULLEY, WITHOUT CLUTCH SYSTEM, WITH (15%-40%) ELECTRIC POWER SAVING DEPENDING FROM TYPE OF WOVEN FABRIC SHEDDING MACHINE: STAUBLI DOBBY MODEL 2668 20 RODS SHAFTS TYPE GROB HEALD FRAME WITH UNDER MOTION 20 LEVER DRC CASTLE ELECTRIC CABINET WITH MICROPROCESSOR, ELECTRONIC PICK FINDING, ELECTRONIC LET-OFF, ELECTRONIC TAKE-UP UNIT WITH INDEPENDENT MOTOR ELECTRONIC WEFT COLOUR SELECTOR IN EXECUTION FOR 8 COLORS TAKE-UP WITH ROLLER DIAMETER 219mm 6 TWIN BEAM DIAMETER 219mm WITH FLANGE 1000mm Q3 JUMBO BACK REST BAR FOR HERCULES WEFT DENSITY VARIABLE PROGRAMMABLE BY THE OPERATOR AT YOUR CHOICE HORIZONTAL CREEL 4 COLOURS AND SUPPORT FOR 8 CONE 4 WEFT FEEDERS ROJ CHRONO X3 3 WEFT BRAKES FOR EVERY CHRONO X3 (TOTAL 12 PCS) TO BE SELECT AS PER CUSTOMER WEFT YARN WEFT CONTROLLING UNIT ELTEX MODEL G3W. DEROULÈ LATERAL MINI CREELS SUPPORT FOR 24 CONES LATERAL MOTORIZED LENO SYSTEM HEATING SCISSOR-CUTTING LATERAL TEMPLES: TO BE DEFINED DEPENDING THE FABRIC CHARACTERISTIC 20 FRAMES GROB TYPE 331 C TYPE DRC S227 GROBTEX ALFIX-U 14.000 GROB HEALDS TYPE 8 X 3.8 TYPE GROZ AETEX SP 0.38 331 8.0X3.8 I CR (7000PCS PER PACK) 1 WARP STOP MOTION 6-30 GROB FKW LED 14.000 GROB DROP WIRE TYPE GROZ EOU 1405 180X11X0.50 ZN (2000PCS PER PACK) SETS OF NEGATIVE RAPIERS & TAPE (LEFT AND RIGHT SIDE) SETS OF POSITIVE RAPIERS & TAPE (LEFT AND RIGHT SIDE) POSITIVE RAPIER KIT (FULL COMPONENT) CENTRAL GEARBOX ALREADY INSTALLED AND COLOR SELECTOR ALREADY ASSEMBLED FOR POSITIVE VERSION APPLICATION (TO REDUCE TIME OF CONVERSION) SETS AND EQUIPMENT OF LOOM TOOL CASE WITH TOTAL TOOLS LIKE TECHNICIANS INCLUDING NR. 2 TORQUE TOOL EXTRA SPARE PARTS THE TOTAL MACHINE SUPPLY WILL ALSO INCLUDE 2 SETS OF NEGATIVE RAPIERS (LEFT AND RIGHT SIDE) 2 SETS OF NEGATIVE TAPES (LEFT AND RIGHT SIDE) 2 SETS OF POSITIVE RAPIERS (LEFT AND RIGHT SIDE) 2 SETS OF POSITIVE TAPES (LEFT AND RIGHT SIDE) 1 POSITIVE RAPIER KIT (FULL COMPONENT) 1 SET AND EQUIPMENT OF LOOM 1 TOOL CASE WITH TOTAL TOOLS LIKE TECHNICIANS INCLUDE 2 TORQUE TOOLS EXTRA SPARE PARTS 1500EUR/MACHINE WARRANTY: ONE YEAR FROM MACHINE ERECTION OR AFTER 3 MONTHS DELIVERY DATE QUANTITY: 1 Learn More -

SINGLE CHOCOLATE DEPOSITING LINEONE SHOT CHOCOLATE DEPOSITING LINE PLC CONTROL SYSTEM CHOCOLATE DEPOSITING HEAD TEN LAYER CHOCOLATE COOLING TUNNEL MOULD SIZES: 275 X 175 X 24mm 300 X 225 X 30mm 280 X 220 X 30mm 266 X 212 X 24mm SUGAR GRINDER (1 SET) DIMENSION (LXWXH)mm: 800 X 600 X 1360mm POWER(KW): 4 CAPACITY: 100~180KGS/H MAIN DRIVE SPEED: 4800RPM SMASHING FINENES: 20~1300 MESH WEIGHT: 200KG IMPACT SMASHING AFTER ENTERING THE PULVERIZING ROOM, MATERIAL IS IMPACTED BY SIX FAST ROTATING HAMMERS AND SMASHED THROUGH THE IMPACT BETWEEN THE MATERIAL AND THE TOOTH RING THE SMASHING FINENESS IS DECIDED BY THE SCREEN MESH IT IS SUITABLE FOR SMASHING GRANULATED SUGAR 200L FAT MELTING TANK (1 SET) DIMENSION (LXWXH)mm: Φ735 X 1100mm POWER(KW): 7.5 OIL MELTING CAPACITY: 2 X120=240KGS OIL MELTING TIME: 30~60MIN HEATING METHOD: STEAM AND POWER HEATING OIL MELTING TEMPERATURE: 40~65°C 500L CHOCOLATE CONCHE (4 SETS) DIMENSION (LXWXH)mm: 2000 X 1860 X 1280mm POWER(KW): 20 MAXIMUM CAPACITY: 500L FINENESS: 20~25UM MAIN DRIVE SPEED: 33RPM FINE MILLING TIME: 16~22H THESE REFINER/CONCHES ARE ESSENTIAL DURING CHOCOLATE PROCESSING, SUPPLIED OCMPLETE WITH MASTER CONTROL CONSOLE AND POWER ASSISTED PRESSURE CONTROL FOR INCREASING AND DECREASING OF PRESSURE. THE MACHINE IS FITTED WITH ITS OWN EXTRACT UNIT AND THE DELIVERY END IS FITTED WITH A SAMPLING VALVE AND TAKES OFF VALVE. THIS MACHINE WILL PRODUCE HIGH QUALITY MILK, DARK AND WHITE CHOCOLATES, PRALINES, TRUFFLES, COMPOUNDS AND MANY OTHER PRODUCTS. 500L CHOCOLATE WARM HOLDING TANK (4 SETS) DIMENSION (LXWXH)mm: Φ1035 X 1480mm POWER(KW): 8.6 MAXIMUM CAPACITY: 500L MAIN DRIVE SPEED: 22.5RPM MAIN MOTOR POWER: 1.1KW ELECTRICAL HEATING POWER: 5KW HEAT HOLDING POWER: 2.5KW WEIGHT: 515KG CHOCOLATE ROTOR PUMP (2 SETS) DIMENSION (LXWXH)mm: 800 X 390 X 350mm POWER(KW): 1.5 MODEL: SJB35 CAQPACITY: 35 LITER/MIN DELIVERY LIFT: 8M MAIN DRIVE SPEED: 165~300RPM CALIBER: 40mm CHOCOLATE BALL MILL CHOCOLATE DEPOSITOR ONE SHOT CHOCOLATE DEPOSITING LINE (1 SET) DIMENSION (LXWXH)mm: 16000 X 1200 X 2150mm POWER(KW): 18 OND CHOCOLATE DEPOSITOR, TWO HOPPERS PRODUCTION CAPACITRY: 1~2T/8H DEPOSITING SPEED: 8-10 TIMES/MIN REFRIGERATOR’S CAPACITY: 15,000-21,800KCAL/H SPECIAL FOR CHOCOLATE POURING AND DEPOSITING CONTROLLED BY MECHANICAL AND ELECTRICAL SYSTEM PRODUCTION UNIT INCLUDES MOULD HEATING, POURING, VIBRATING, COOLING, DISCHARGING, AND CONVEYING WITH AUTOMATIC OPERATION FOR PRODUCING PURE CHOCOLATE, CENTER FILLING CHOCOLATE OR COMPOUND, DOUBLE COLORS CHOCOLATE, AND GRANULE MIXED CHOCOLATE, ETC. WITH SMOOTH AND BEAUTIFUL SURFACE, ACCURATE WEIGHT – IDEAL FOR HIGH QUALITY CHOCOLATE ONE CHOCOLATE MOULDS HEATING ONE SHOT CHOCOLATE DEPOSITOR CHOCOLATE VIBRATING TEN LAYER CHOCOLATE COOLING TUNNEL PLC CONTROL SYSTEM (TAIWAN BREAD) CHOCOLATE MOULDS (200 PCS) DIMENSION (LXWXH)mm: 300 X 225 X 30mm (CAN BE CHANGED BY CUSTOMER’S NEEDS) 250L CHOCOLATE TEMPERING MACHINE ( 1 SET) DIMENSION (LXWXH)mm: 950 X 850 X 1600mm POWER(KW): 12 CAPACITY: 200L TO 350L/H TEMPERING RANGE: 27°C TO 40°C HOT WATER PUMP: 95KW CHOCOLATE LIQUOR PRESSURE: 2MPA WATER PRESSURE: 2.3MPA WEIGHT: 1300KG PLC CONTROLLED FULLY AUTOMATIC CHOCOLATE CONTINUOUS TEMPERING MACHINE WHICH IS CENTRALLY CONTROLLED BY AN ELECTRONIC TEMPERATURE REGULATOR AND AN ELECTROMAGNETIC ON/OFF VALVE TO MAINTAIN THE HIGH QUALITY AND SUPER SURFACE GLOSS OF THE CHOCOLATES. IN ADDITION TO A CHOCOLATE STORAGE TANK, FEEDING PUMP, AND A YX TEMPERING MACHINE WHICH CAN ENSURE THE DE-CRYSTALLIZATION AND CONSTANT TEMPERATURE IN FEED OF CHOCOLATE MASS. TWJ IS DESIGNED FOR THE APPLICATIONS SUCH AS MOULDING AND ENROBING IN WHICH THE EXCESS MASS CAN BE RETURNED TO THE TEMPERING MACHINE. CONNECTING PIPES AND VALVES (SS) Learn More

SINGLE CHOCOLATE DEPOSITING LINEONE SHOT CHOCOLATE DEPOSITING LINE PLC CONTROL SYSTEM CHOCOLATE DEPOSITING HEAD TEN LAYER CHOCOLATE COOLING TUNNEL MOULD SIZES: 275 X 175 X 24mm 300 X 225 X 30mm 280 X 220 X 30mm 266 X 212 X 24mm SUGAR GRINDER (1 SET) DIMENSION (LXWXH)mm: 800 X 600 X 1360mm POWER(KW): 4 CAPACITY: 100~180KGS/H MAIN DRIVE SPEED: 4800RPM SMASHING FINENES: 20~1300 MESH WEIGHT: 200KG IMPACT SMASHING AFTER ENTERING THE PULVERIZING ROOM, MATERIAL IS IMPACTED BY SIX FAST ROTATING HAMMERS AND SMASHED THROUGH THE IMPACT BETWEEN THE MATERIAL AND THE TOOTH RING THE SMASHING FINENESS IS DECIDED BY THE SCREEN MESH IT IS SUITABLE FOR SMASHING GRANULATED SUGAR 200L FAT MELTING TANK (1 SET) DIMENSION (LXWXH)mm: Φ735 X 1100mm POWER(KW): 7.5 OIL MELTING CAPACITY: 2 X120=240KGS OIL MELTING TIME: 30~60MIN HEATING METHOD: STEAM AND POWER HEATING OIL MELTING TEMPERATURE: 40~65°C 500L CHOCOLATE CONCHE (4 SETS) DIMENSION (LXWXH)mm: 2000 X 1860 X 1280mm POWER(KW): 20 MAXIMUM CAPACITY: 500L FINENESS: 20~25UM MAIN DRIVE SPEED: 33RPM FINE MILLING TIME: 16~22H THESE REFINER/CONCHES ARE ESSENTIAL DURING CHOCOLATE PROCESSING, SUPPLIED OCMPLETE WITH MASTER CONTROL CONSOLE AND POWER ASSISTED PRESSURE CONTROL FOR INCREASING AND DECREASING OF PRESSURE. THE MACHINE IS FITTED WITH ITS OWN EXTRACT UNIT AND THE DELIVERY END IS FITTED WITH A SAMPLING VALVE AND TAKES OFF VALVE. THIS MACHINE WILL PRODUCE HIGH QUALITY MILK, DARK AND WHITE CHOCOLATES, PRALINES, TRUFFLES, COMPOUNDS AND MANY OTHER PRODUCTS. 500L CHOCOLATE WARM HOLDING TANK (4 SETS) DIMENSION (LXWXH)mm: Φ1035 X 1480mm POWER(KW): 8.6 MAXIMUM CAPACITY: 500L MAIN DRIVE SPEED: 22.5RPM MAIN MOTOR POWER: 1.1KW ELECTRICAL HEATING POWER: 5KW HEAT HOLDING POWER: 2.5KW WEIGHT: 515KG CHOCOLATE ROTOR PUMP (2 SETS) DIMENSION (LXWXH)mm: 800 X 390 X 350mm POWER(KW): 1.5 MODEL: SJB35 CAQPACITY: 35 LITER/MIN DELIVERY LIFT: 8M MAIN DRIVE SPEED: 165~300RPM CALIBER: 40mm CHOCOLATE BALL MILL CHOCOLATE DEPOSITOR ONE SHOT CHOCOLATE DEPOSITING LINE (1 SET) DIMENSION (LXWXH)mm: 16000 X 1200 X 2150mm POWER(KW): 18 OND CHOCOLATE DEPOSITOR, TWO HOPPERS PRODUCTION CAPACITRY: 1~2T/8H DEPOSITING SPEED: 8-10 TIMES/MIN REFRIGERATOR’S CAPACITY: 15,000-21,800KCAL/H SPECIAL FOR CHOCOLATE POURING AND DEPOSITING CONTROLLED BY MECHANICAL AND ELECTRICAL SYSTEM PRODUCTION UNIT INCLUDES MOULD HEATING, POURING, VIBRATING, COOLING, DISCHARGING, AND CONVEYING WITH AUTOMATIC OPERATION FOR PRODUCING PURE CHOCOLATE, CENTER FILLING CHOCOLATE OR COMPOUND, DOUBLE COLORS CHOCOLATE, AND GRANULE MIXED CHOCOLATE, ETC. WITH SMOOTH AND BEAUTIFUL SURFACE, ACCURATE WEIGHT – IDEAL FOR HIGH QUALITY CHOCOLATE ONE CHOCOLATE MOULDS HEATING ONE SHOT CHOCOLATE DEPOSITOR CHOCOLATE VIBRATING TEN LAYER CHOCOLATE COOLING TUNNEL PLC CONTROL SYSTEM (TAIWAN BREAD) CHOCOLATE MOULDS (200 PCS) DIMENSION (LXWXH)mm: 300 X 225 X 30mm (CAN BE CHANGED BY CUSTOMER’S NEEDS) 250L CHOCOLATE TEMPERING MACHINE ( 1 SET) DIMENSION (LXWXH)mm: 950 X 850 X 1600mm POWER(KW): 12 CAPACITY: 200L TO 350L/H TEMPERING RANGE: 27°C TO 40°C HOT WATER PUMP: 95KW CHOCOLATE LIQUOR PRESSURE: 2MPA WATER PRESSURE: 2.3MPA WEIGHT: 1300KG PLC CONTROLLED FULLY AUTOMATIC CHOCOLATE CONTINUOUS TEMPERING MACHINE WHICH IS CENTRALLY CONTROLLED BY AN ELECTRONIC TEMPERATURE REGULATOR AND AN ELECTROMAGNETIC ON/OFF VALVE TO MAINTAIN THE HIGH QUALITY AND SUPER SURFACE GLOSS OF THE CHOCOLATES. IN ADDITION TO A CHOCOLATE STORAGE TANK, FEEDING PUMP, AND A YX TEMPERING MACHINE WHICH CAN ENSURE THE DE-CRYSTALLIZATION AND CONSTANT TEMPERATURE IN FEED OF CHOCOLATE MASS. TWJ IS DESIGNED FOR THE APPLICATIONS SUCH AS MOULDING AND ENROBING IN WHICH THE EXCESS MASS CAN BE RETURNED TO THE TEMPERING MACHINE. CONNECTING PIPES AND VALVES (SS) Learn More -

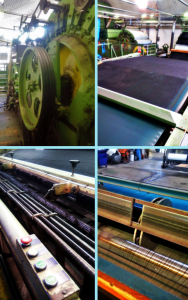

TT-5852 MASCOTT PLUS 25-30 CROSSLAPPER AND MONO_1AB_27-3000 NEEDLE LOOMTT-5852 MASCOTT PLUS 25-30 CROSSLAPPER AND MONO_1AB_27-3000 NEEDLE LOOM Learn More

TT-5852 MASCOTT PLUS 25-30 CROSSLAPPER AND MONO_1AB_27-3000 NEEDLE LOOMTT-5852 MASCOTT PLUS 25-30 CROSSLAPPER AND MONO_1AB_27-3000 NEEDLE LOOM Learn More -

V-2067 (LIST) LAMINATING LINE FOR FOAM PANELS (GLUE LAMINATOR), GLENRO (ONE LINE), YEAR 2019– SOLD TOGETHER – CANNOT BE SEPARATEDV-2067 (LIST) LAMINATING LINE FOR FOAM PANELS (GLUE LAMINATOR), GLENRO (ONE LINE), YEAR 2019– SOLD TOGETHER – CANNOT BE SEPARATED REFERENCE NUMBER: TT-2036 ATLANTA ATTACHMENT COMPANY BELT CONVEYOR LOADING, DIMENSION 7FT X 8FT X 3FT, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2037 ATLANTA ATTACHMENT COMPANY - APER GLUE LAMINATOR, WORKING WIDTH 84”, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2038 GLENRO OVEN, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2039 ATLANTA ATTACHMENT COMPANY BELT CONVEYOR, DIMENSION 7FT X 10.5FT X 3FT, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2040 ATLANTA ATTACHMENT COMPANY BELT CONVEYOR ASSEMBLY, DIMENSION 7FT X 10.5FT X 3FT, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2041 ATLANTA ATTACHMENT COMPANY PRESS, YEAR 2019 POLY USED QUANTITY: 1 TOTAL QUANTITY: ONE LINE (SOLD TOGETHER) Learn More

V-2067 (LIST) LAMINATING LINE FOR FOAM PANELS (GLUE LAMINATOR), GLENRO (ONE LINE), YEAR 2019– SOLD TOGETHER – CANNOT BE SEPARATEDV-2067 (LIST) LAMINATING LINE FOR FOAM PANELS (GLUE LAMINATOR), GLENRO (ONE LINE), YEAR 2019– SOLD TOGETHER – CANNOT BE SEPARATED REFERENCE NUMBER: TT-2036 ATLANTA ATTACHMENT COMPANY BELT CONVEYOR LOADING, DIMENSION 7FT X 8FT X 3FT, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2037 ATLANTA ATTACHMENT COMPANY - APER GLUE LAMINATOR, WORKING WIDTH 84”, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2038 GLENRO OVEN, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2039 ATLANTA ATTACHMENT COMPANY BELT CONVEYOR, DIMENSION 7FT X 10.5FT X 3FT, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2040 ATLANTA ATTACHMENT COMPANY BELT CONVEYOR ASSEMBLY, DIMENSION 7FT X 10.5FT X 3FT, YEAR 2019 USED QUANTITY: 1 REFERENCE NUMBER: TT-2041 ATLANTA ATTACHMENT COMPANY PRESS, YEAR 2019 POLY USED QUANTITY: 1 TOTAL QUANTITY: ONE LINE (SOLD TOGETHER) Learn More -

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More -

MELT BLOWN CLOTH PRODUCTION LINE 600mmREFERENCE NUMBER: A-2488 MELT BLOWN CLOTH PRODUCTION LINE 600mm SPECIFICATIONS: PLASTIC AUTOMATIC CHARGER • FEEDING CAPACITY: 200 KG / H • AIR PUMP POWER: 0.75 KW HOPPER PLASTIC DRYER • HOPPER CUBIC CAPACITY: 100 L • FEEDING CAPACITY: 50 KG • HEATING POWER: 3.7 KW • BLOWER POWER: 0.12 KW SJ55/30 SINGLE SCREW EXTRUDER • SCREW, BARREL: SCREW AND BARREL MATERIAL 38CRMOALA, NITRIDE • SCREW DIAMETER: 55 mm • SCREW L/D: 30:1 • MAIN MOTOR POWER: 15 KW SIEMENS STANDARD • MOTOR MAIN MOTOR SPEED ADJUSTMENT: 15 KW ABB INVERTER • BARREL HEATING: CASTING - HEATER WITH AIR COOLING • HEATING POWER: 2.8 KW X 4 ZONES • GEAR BOX: ZLYJ SERIES RIGID GEAR BOX • EXTRUSION CAPACITY: 15 TO 40 KG/H HYDRAULIC SCREEN CHANGER • MOTOR POWER: 1.1 KW • STRUCTURE: DOUBLE POSITION, PLATE TYPE • HEATERS: STAINLESS STEEL HEATING BAR METERING PUMP • MOTOR POWER: 2.2KW • CAPACITY: 30CC • SPEED CONTROL: • HEATERS: STAINLESS STEEL HEATING BAR T-DIE • STRUCTURE: T-DIE • MATERIAL OF MOULD: HIGH QUALITY ALLOYED STEEL, SURFACE CHROME PLATED • FLOW CHANNEL CHROME PLATED, POLISHED • SPECIFICATION OF PRODUCT: WIDTH 600 mm • AIR INCOME HOLES: 12 PCS, HIGH PRECISION TEMPERATURE CONTROL FORMING MACHINE • MOTOR POWER: 1.5 KW • SPEED CONTROL: INVERTER • SUCTION FAN: 5.5 KW ELECTROSTATIC ELECTRET DEVICE • INCLUDES ELECTROSTATIC GENERATOR, VOLTAGE REGULATOR, ELECTRET FRAME • APPLICATION: GENERATE ELECTROSTATIC CHARGE, INCREASES THE FILTERING EFFICIENCY • MOTOR POWER: 2.2 KW • BLADES: 4 PCS • HAULING SPEED CONTROL: ADOPTABB INVERTER COLIER • COILING SHAFT: 2 PCS • COMPACTION: BY PNEUMATIC CONTROL • COILING METHOD: BY SELF FRICTION SCREW AIR COMPRESSOR • MOTOR POWER: 37 KW • STRUCTURE: SCREW TYPE, LOW NOISY • PLC CONTROL AIR FILTER • CAPACITY: 7 M3/min • PRESSURE: 1.0 MPA • FILTRATION EFFICIENCY: 3 MICRON / 5 PPM AIR DRYER • CAPACITY: 6 NM3/min • PRESSURE: 1 MPA • POWER: 2 HP AIR TANK • VOLUME: 1000 L • PRESSURE: 1.05 MPA HOT AIR SYSTEM • HEATING POWER: 60 KW • HEATING TYPE: ELECTRIC HEATING • WITH HEAT INSULATION LAYER Learn More

MELT BLOWN CLOTH PRODUCTION LINE 600mmREFERENCE NUMBER: A-2488 MELT BLOWN CLOTH PRODUCTION LINE 600mm SPECIFICATIONS: PLASTIC AUTOMATIC CHARGER • FEEDING CAPACITY: 200 KG / H • AIR PUMP POWER: 0.75 KW HOPPER PLASTIC DRYER • HOPPER CUBIC CAPACITY: 100 L • FEEDING CAPACITY: 50 KG • HEATING POWER: 3.7 KW • BLOWER POWER: 0.12 KW SJ55/30 SINGLE SCREW EXTRUDER • SCREW, BARREL: SCREW AND BARREL MATERIAL 38CRMOALA, NITRIDE • SCREW DIAMETER: 55 mm • SCREW L/D: 30:1 • MAIN MOTOR POWER: 15 KW SIEMENS STANDARD • MOTOR MAIN MOTOR SPEED ADJUSTMENT: 15 KW ABB INVERTER • BARREL HEATING: CASTING - HEATER WITH AIR COOLING • HEATING POWER: 2.8 KW X 4 ZONES • GEAR BOX: ZLYJ SERIES RIGID GEAR BOX • EXTRUSION CAPACITY: 15 TO 40 KG/H HYDRAULIC SCREEN CHANGER • MOTOR POWER: 1.1 KW • STRUCTURE: DOUBLE POSITION, PLATE TYPE • HEATERS: STAINLESS STEEL HEATING BAR METERING PUMP • MOTOR POWER: 2.2KW • CAPACITY: 30CC • SPEED CONTROL: • HEATERS: STAINLESS STEEL HEATING BAR T-DIE • STRUCTURE: T-DIE • MATERIAL OF MOULD: HIGH QUALITY ALLOYED STEEL, SURFACE CHROME PLATED • FLOW CHANNEL CHROME PLATED, POLISHED • SPECIFICATION OF PRODUCT: WIDTH 600 mm • AIR INCOME HOLES: 12 PCS, HIGH PRECISION TEMPERATURE CONTROL FORMING MACHINE • MOTOR POWER: 1.5 KW • SPEED CONTROL: INVERTER • SUCTION FAN: 5.5 KW ELECTROSTATIC ELECTRET DEVICE • INCLUDES ELECTROSTATIC GENERATOR, VOLTAGE REGULATOR, ELECTRET FRAME • APPLICATION: GENERATE ELECTROSTATIC CHARGE, INCREASES THE FILTERING EFFICIENCY • MOTOR POWER: 2.2 KW • BLADES: 4 PCS • HAULING SPEED CONTROL: ADOPTABB INVERTER COLIER • COILING SHAFT: 2 PCS • COMPACTION: BY PNEUMATIC CONTROL • COILING METHOD: BY SELF FRICTION SCREW AIR COMPRESSOR • MOTOR POWER: 37 KW • STRUCTURE: SCREW TYPE, LOW NOISY • PLC CONTROL AIR FILTER • CAPACITY: 7 M3/min • PRESSURE: 1.0 MPA • FILTRATION EFFICIENCY: 3 MICRON / 5 PPM AIR DRYER • CAPACITY: 6 NM3/min • PRESSURE: 1 MPA • POWER: 2 HP AIR TANK • VOLUME: 1000 L • PRESSURE: 1.05 MPA HOT AIR SYSTEM • HEATING POWER: 60 KW • HEATING TYPE: ELECTRIC HEATING • WITH HEAT INSULATION LAYER Learn More -

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

TT-4596 ELECTRONIC CONE TO CONE WINDER, YEAR 1997TT-4596 ELECTRONIC CONE TO CONE WINDER, YEAR 1997 QUANTITY: 1 Learn More

TT-4596 ELECTRONIC CONE TO CONE WINDER, YEAR 1997TT-4596 ELECTRONIC CONE TO CONE WINDER, YEAR 1997 QUANTITY: 1 Learn More