Search results for: 'Filling mac'

- Related search terms

- machi

- machine''

- mac'

- Machine c''

- Machin''

-

Z-1768 ARO-250L/H PVC RO WATER PURIFICATION MACHINEZ-1768 ARO-250L/H PVC RO WATER PURIFICATION MACHINE CAPACITY: 250L/H, DESIGN VOLUME: 250H/L WATER CONDUCTIVITY: PURE WATER MACHINE: ≤80US/mm SIZE: φ250 X 1250 (mm) BARREL HEIGHT: 2/3 OF PILLAR HEIGHT WORK PRESSURE: ≤0.8Mpa FILTER MEDIUM: REFINED QUARTZ SAND QUANTITY: 1 Learn More

Z-1768 ARO-250L/H PVC RO WATER PURIFICATION MACHINEZ-1768 ARO-250L/H PVC RO WATER PURIFICATION MACHINE CAPACITY: 250L/H, DESIGN VOLUME: 250H/L WATER CONDUCTIVITY: PURE WATER MACHINE: ≤80US/mm SIZE: φ250 X 1250 (mm) BARREL HEIGHT: 2/3 OF PILLAR HEIGHT WORK PRESSURE: ≤0.8Mpa FILTER MEDIUM: REFINED QUARTZ SAND QUANTITY: 1 Learn More -

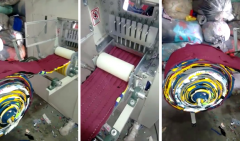

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTER

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERREFERENCE NUMBER: J-2326

QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERQUILTING MACHINE FOR RAGS

SEWS RAGS CONTINUOUSLY

SEW HEAD: 7 NEEDLES AND 7 LOOPERS

MAKES A CHAIN STITCH ON THE CONVEYED RAGS

USES OVERLOCK THREAD

DISTANCE BETWEEN NEEDLES: 250mm (ENSURES THAT EVEN SMALL RAGS ARE SEWN)

1 HP MOTOR, 3-PHASE, 220 VOLT

WITH FREQUENCY INVERTER TO ADJUST THE ROTATION SPEED OF THE MOTOR AS NEEDED

HEIGHT: 1800mm

WIDTH: 960mm

DEPTH; 370mm

CONVEYOR WIDTH: 200mm

CONVEYOR LENGTH: 1560mm

MACHINE TOTAL LENGTH WITH CONVEYOR: 2800mmAFTER SEWING, THE QUILT IS TRANSPORTED OUT INTO ROLLS WHICH CAN BE CUT ACCORDING TO CUSTOMER NEEDS

Learn More

OPERATION: PLACE A LARGER RAG AS THE BOTTOM LAYER, SMALLER RAGS AS FILLING, AND ANOTHER LARGER RAG AS THE TOP LAYER. OPERATION REQUIRES 2 TO 3 OPERATORS.

TO REDUCE THE NUMBER OF OPERATORS REQUIRED, A FIBER ROLL AS CAN BE USED AS THE LOWER LAYER. THIS ALSO INCREASES THE PRODUCTION RATE.

DAILY PRODUCTION: VARIES BETWEEN 300 TO 500 KG PER 8 HOURS OF OPERATION

FOR KNIT FABRICS SUCH AS COTTON, VISCOSE, SWEATSHIRT FLEECE, NYLON STRETCH-FABRIC, PIQUET AND POPELINE

THERE IS NO MATERIAL WASTE AS THE MACHINE USES 100% OF THE RAGS

WORKING WIDTH: 12 INCHES

NEEDLE SPACING: 1 INCH

WITH LOOPER STRUCTURE SIMILAR TO THE DIAGRAM BELOW (REDUCES BOTTOM THREAD BREAKAGE)

MACHINE IS NEW, MADE TO ORDER

LEAD TIME: 10 DAYS -

R-3272 ROASTING PLANT - HAS GARANTI, GUMP 777E, JABEZ BURNS SAMPLER - 60 KILOS

R-3272 ROASTING PLANT - HAS GARANTI, GUMP 777E, JABEZ BURNS SAMPLER - 60 KILOSR-3272 ROASTING PLANT - HAS GARANTI, GUMP 777E, JABEZ BURNS SAMPLER - 60 KILOS

60 KILOS HAS GARANTI WITH A REAL CARBON STEEL DRUM (THAT IS GOOD NEWS) THAT IS 15 YEARS OLD AND STOOD THE TEST OF TIME. CONSTANT PREVENTATIVE MAINTENANCE, SO IT IS SOLID.

UNIVERSAL BUCKET ELEVATOR LOADER

DESTONER

FLOOR SCALES

RACKS

JABEZ BURNS DUST COLLECTION SYSTEM FOR LOADER

OLD TIME BAR NUN SWIFTER GREEN COFFEE CLEANER - NOT BEING USED . . . THIS IS A WORKING ANTIQUE. MAKES A GOOD DISCUSSION PIECE.

JABES BURNS 4 BARREL SAMPLE ROASTER IN REALLY NICE TO EXCELLENT CONDITION - LIKE AN ANTIQUE THAT IS STILL WORKING AND WILL BE FOR AS LONG AS THE NEW OWNER IS LIVING.

E10 AGTRON COLOR READER

OLD TIMER WRIGHT MONOBAG TWIN PACKAGING MACHINE - LEFT SIDE SET FOR POUCHES AND R SIDE FOR 1 POUND BAGS. WRIGHT STILL SUPPORTS THIS MACHINE.

5 POUND BULK BAG - NET WEIGH SYSTEM - INCLUDING A FILLING LADDER

TRADITIONAL RO-TAP MACHINE AND SCREENS FOR TESTING GROUND COFFEE

THE IMPORTANT THING HERE IS SIMPLE OCS PRODUCTION LINE FOR LITTLE DOLLARS AND SOME RE-INSTALLATION TIME.

3 PHASE POWER.

NAPTURAL GASQUANTITY: 1

Learn More -

E-9860 FIBER OPENING MACHINEINVENTORY NUMBER: E-9860 FIBER OPENING MACHINE USED TO OPEN POLYESTER FIBERS FOR PILLOW FILLING, PLUSH STUFFED TOY, SOFA, CUSHION, BEDDING, DECORATIVE PILLOW AND QUILT ETC. THE MACHINE IS MAINLY USED FOR OPENING REGULAR OR HOLLOW CONJUGATE SILICONIZED POLYESTER FIBER SHORTER THAN 100mm LENGTH (4 INCHES). HIGH OUTPUT. WITH METAL ALARM SYSTEM PROTECTING THE OPENER ROLLER, AVOIDING DAMAGE TO ROLLS. ASSEMBLED WITH METALLIC SELF-LOCK WIRE SO THAT THE FIBER CAN BE OPENED FOR MORE THAN 98% AND NOT BE DAMAGED. 150KG TO 320KG PRODUCTION PER HOUR DEPENDING ON THE DIFFERENT MACHINE MODELS AND FIBERS. BALANCED ROLLERS. ELECTRONIC OVERLOAD PROTECTION. QUANTITY AVAILABLE: 1 Learn More

E-9860 FIBER OPENING MACHINEINVENTORY NUMBER: E-9860 FIBER OPENING MACHINE USED TO OPEN POLYESTER FIBERS FOR PILLOW FILLING, PLUSH STUFFED TOY, SOFA, CUSHION, BEDDING, DECORATIVE PILLOW AND QUILT ETC. THE MACHINE IS MAINLY USED FOR OPENING REGULAR OR HOLLOW CONJUGATE SILICONIZED POLYESTER FIBER SHORTER THAN 100mm LENGTH (4 INCHES). HIGH OUTPUT. WITH METAL ALARM SYSTEM PROTECTING THE OPENER ROLLER, AVOIDING DAMAGE TO ROLLS. ASSEMBLED WITH METALLIC SELF-LOCK WIRE SO THAT THE FIBER CAN BE OPENED FOR MORE THAN 98% AND NOT BE DAMAGED. 150KG TO 320KG PRODUCTION PER HOUR DEPENDING ON THE DIFFERENT MACHINE MODELS AND FIBERS. BALANCED ROLLERS. ELECTRONIC OVERLOAD PROTECTION. QUANTITY AVAILABLE: 1 Learn More -

M-4832 SEMI-AUTOMATIC BAGGING MACHINEvREFERENCE NUMBER: M-4832 SEMI-AUTOMATIC BAGGING MACHINE QUANTITY AVAILABLE: 1 Learn More

M-4832 SEMI-AUTOMATIC BAGGING MACHINEvREFERENCE NUMBER: M-4832 SEMI-AUTOMATIC BAGGING MACHINE QUANTITY AVAILABLE: 1 Learn More -

TT-8619 TETRA PAK A3 FLEX 1000 B BEVERAGE PRODUCTION MACHINETT-8619 TETRA PAK A3 FLEX 1000 B BEVERAGE PRODUCTION MACHINE 1. CONDITION: EXCELLENT (USED) 2. FUNCTIONALITY: FULLY FUNCTIONAL 3. UPDATE: 23.09.2025 QUANTITY: 1 Learn More

TT-8619 TETRA PAK A3 FLEX 1000 B BEVERAGE PRODUCTION MACHINETT-8619 TETRA PAK A3 FLEX 1000 B BEVERAGE PRODUCTION MACHINE 1. CONDITION: EXCELLENT (USED) 2. FUNCTIONALITY: FULLY FUNCTIONAL 3. UPDATE: 23.09.2025 QUANTITY: 1 Learn More -

TT-7804 TETRA PAK JUICE STERILIZER TA SAD 3300 TETRA THERM ASEPTIC DRINK + TETRA ALEX20, YEAR 1998TT-7804 TETRA PAK JUICE STERILIZER TA SAD 3300 TETRA THERM ASEPTIC DRINK + TETRA ALEX20, YEAR 1998 1. CONDITION USED 2. MACHINE TYPE: BEVERAGE PRODUCTION MACHINE QUANTITY: 1 Learn More

TT-7804 TETRA PAK JUICE STERILIZER TA SAD 3300 TETRA THERM ASEPTIC DRINK + TETRA ALEX20, YEAR 1998TT-7804 TETRA PAK JUICE STERILIZER TA SAD 3300 TETRA THERM ASEPTIC DRINK + TETRA ALEX20, YEAR 1998 1. CONDITION USED 2. MACHINE TYPE: BEVERAGE PRODUCTION MACHINE QUANTITY: 1 Learn More -

YY-2468 BALL LOLLIPOP FORMING LINE, NOMINAL CAPACITY AROUND 750 LOLLIPOPS PER MINUTEYY-2468 BALL LOLLIPOP FORMING LINE, NOMINAL CAPACITY AROUND 750 LOLLIPOPS PER MINUTE ALL STILL SET UP IN THE FACTORY. Learn More

YY-2468 BALL LOLLIPOP FORMING LINE, NOMINAL CAPACITY AROUND 750 LOLLIPOPS PER MINUTEYY-2468 BALL LOLLIPOP FORMING LINE, NOMINAL CAPACITY AROUND 750 LOLLIPOPS PER MINUTE ALL STILL SET UP IN THE FACTORY. Learn More -

V-2065 (LIST) ATLANTA ATTACHMENT ROLLPACKER (ONE MACHINE) – SOLD TOGETHER – CANNOT BE SEPARATEDV-2065 (LIST)ATLANTA ATTACHMENT ROLLPACKER (ONE MACHINE) – SOLD TOGETHER – CANNOT BE SEPARATED MAXIMUM MATTRESS HEIGHT: 21 INCHES MAXIMUM MATTRESS WIDTH: 85 INCHES MACHINE IS CURRENTLY FULLY ASSEMBLED AND OPERATIONAL. REFERENCE NUMBER: TT-2043 ATLANTA ATTACHMENT COMPANY ROLL PACKER, YEAR 2017 QUANTITY: 1 REFERENCE NUMBER: TT-2044 ATLANTA ATTACHMENT COMPANY MATTRESS FOLDER, YEAR 2017 USED QUANTITY: 1 REFERENCE NUMBER: TT-2045 ATLANTA ATTACHMENT COMPANY MATTRESS VACCUM/SEAL, YEAR 2017 USED QUANTITY: 1 REFERENCE NUMBER: TT-2046 (090) (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY (BRAND NEW) ATLANTA ATTACHMENT COMPANY MATTRESS FILLER MODEL 11458-CONV – NEW, YEAR 2017 FOR FILLING ZIPPERED MATTRESSES FROM THE SIDE, 90 INCHES WIDE, 24 INCHES THICK HEAVY DUTY FOR SPRING AND FOAM MATTRESSES NEW QUANTITY: 1 REFERENCE NUMBER: TT-2047 (091) ATLANTA ATTACHMENT COMPANY FLIP TABLE, DIMENSION 80” X 96”, YEAR 2017 (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY USED QUANTITY: 1 REFERENCE NUMBER: TT-2048 (092) ATLANTA ATTACHMENT COMPANY AIR TABLE, DIMENSION 84” X 80”, YEAR 2018 (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY USED QUANTITY: 1 TOTAL QUANTITY: 1 ATLANTA ATTACHMENT ROLLPACKER Learn More

V-2065 (LIST) ATLANTA ATTACHMENT ROLLPACKER (ONE MACHINE) – SOLD TOGETHER – CANNOT BE SEPARATEDV-2065 (LIST)ATLANTA ATTACHMENT ROLLPACKER (ONE MACHINE) – SOLD TOGETHER – CANNOT BE SEPARATED MAXIMUM MATTRESS HEIGHT: 21 INCHES MAXIMUM MATTRESS WIDTH: 85 INCHES MACHINE IS CURRENTLY FULLY ASSEMBLED AND OPERATIONAL. REFERENCE NUMBER: TT-2043 ATLANTA ATTACHMENT COMPANY ROLL PACKER, YEAR 2017 QUANTITY: 1 REFERENCE NUMBER: TT-2044 ATLANTA ATTACHMENT COMPANY MATTRESS FOLDER, YEAR 2017 USED QUANTITY: 1 REFERENCE NUMBER: TT-2045 ATLANTA ATTACHMENT COMPANY MATTRESS VACCUM/SEAL, YEAR 2017 USED QUANTITY: 1 REFERENCE NUMBER: TT-2046 (090) (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY (BRAND NEW) ATLANTA ATTACHMENT COMPANY MATTRESS FILLER MODEL 11458-CONV – NEW, YEAR 2017 FOR FILLING ZIPPERED MATTRESSES FROM THE SIDE, 90 INCHES WIDE, 24 INCHES THICK HEAVY DUTY FOR SPRING AND FOAM MATTRESSES NEW QUANTITY: 1 REFERENCE NUMBER: TT-2047 (091) ATLANTA ATTACHMENT COMPANY FLIP TABLE, DIMENSION 80” X 96”, YEAR 2017 (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY USED QUANTITY: 1 REFERENCE NUMBER: TT-2048 (092) ATLANTA ATTACHMENT COMPANY AIR TABLE, DIMENSION 84” X 80”, YEAR 2018 (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY USED QUANTITY: 1 TOTAL QUANTITY: 1 ATLANTA ATTACHMENT ROLLPACKER Learn More -

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More