Search results for: 'Machine fl'

- Related search terms

- machine''

- Machine op

- Machine+we

- Machine c''

- Machine fe'

-

L-1427 PROJECT FOR FOAM COMPRESSOR MACHINE FOR PAUL DECRAFT

L-1427 PROJECT FOR FOAM COMPRESSOR MACHINE FOR PAUL DECRAFTREFERENCE NUMBER: L-1427

SCREW FEED 6FT

PART #: 99030A276BRONZE NUT – 2 PIECES

PART #: 95072A361MOUNTING FLANGE – 2 PIECES

PART #: 95082A644

¾ INCH SCREW FEED 6FT

PART #: 99030A275

BRONZE NUT – 2 PIECES

PART #: 59072A351

MOUNTING FLANGE – 2 PIECES

PART #: 325895082A643

CONVEYOR BELT 45FT

PART #: 5999K5FLANGE MOUNT BEARINGS – 16 PIECES

Learn More

PART #: 5968K75

PILLOW BLOCK BEARINGS – 4 PIECES

PART #: 7728756

CHAIN – 50 FT

PART #: 6261K173

SPROKETS – 10 PIECES

PART #: 6733K146

AIR CYLINDER

PART #: 6498K662

AIR CYLINDER

PART #: 6498K232

1 X 2 TUBING – 250 FT

PART #: N/A

2 3/8” FLAT STEEL – 60 FEET

PART #: N/A

SHEET STEEL – 4FT X 8FT X ¼” – 2 PIECES

PART #: N/A

SHEET STEEL – 18 GAUGE – 4FT X 8FT – 5 PIECES

PART #: N/A

1 5/8 COLD ROLL SOLID – 40FT

PART #: N/A

1 INCH COLD ROLL SOLID – 20FT

PART #: N/A

3 INCH COLD ROLL SOLID

PART #: N/A -

R-3250 GIESEN COFFEE ROASTER AND SELKIRK OXIDIZER - 15 KILOS

R-3250 GIESEN COFFEE ROASTER AND SELKIRK OXIDIZER - 15 KILOSR-3250 GIESEN COFFEE ROASTER AND SELKIRK OXIDIZER - 15 KILOS

AN EXCEPTIONAL OPPORTUNITY FOR READY TO BE DELIVERED/INSTALLED EQUIPMENT CREATED BY A CHANGED BUSINESS MODEL.

GIESEN W15A

DOUBLE EXHAUST/ROAST PROFILE SYSTEM

NATURAL GAS

240V/60 HZ

COLOR: RED

AVAILABLE WITH SELKIRK TO-2CS321 THERMAL OXIDIZER (USED)GIESEN BROCHURE

SPECIFICATIONS:

GIESEN W15A

CAPACITY: 500 GRAM - 15 KG GREEN BEANS / PER BATCH / M. 60 KG/H

DRIVES: DIRECT FREQUENCY DRIVE MOTOR. ADJUSTABLE DRUM SPEED CONTROL AND ADJUSTABLE ROAST FAN SPEED CONTROL.

ROAST DRUM: DIGITAL PRESSION CONTROL. CAST IRON DRUM WITH HIGH PERFORMANCE BEARINGS.

HEATING SYSTEM: GAS BURNER BY PROPANE GAS (LPG, BOTTLE GAS) OR CITY GAS.

VOLTAGE: 1 PHASE 230V / 50-60 HZ

PAINTING: FREE CHOICE AND CUSTOMIZED / RAL CODES

ROAST ROOF: FREE CHOICE AND CUSTOMIZED

DIMENSIONS: LENGTH 1900mm X WIDTH 962mm X HEIGHT 2000mm

EXHAUST PIPE: EXHAUST PIPE DIAMETER FOR ROAST AIR: ∅ 200mmTHERMAL OXIDIZER FOR GIESEN W15 ROASTER

SELKIRK SPECIALIZES IN THERMAL AFTERBURNERS FOR COFFEE ROASTING MACHINES FROM 10 TO 120 KGS PER BATCH. AFTERBURNERS ARE DESIGNED OF QUALITY MATERIALS FOR LONG SERVICE LIFE. INTEGRATED EFFICIENT GAS BURNERS WHICH REDUCE OPERATING COSTS. BURNER CONFORMS TO UL 295 STANDARD FOR COMMERCIAL/INDUSTRIAL GAS BURNERS. AFTERBURNER DESIGN PROVIDES LONG RETENTION TIMES TO ELIMINATE SMOKE AND ODORS FROM THE ROASTING PROCESS. STANDARD AFTERBURNER OPERATING TEMPERATURE IS 1250 F, BUT CAN EASILY BE ADJUSTED TO MEET LOCAL AIR QUALITY REQUIREMENTS. GAS BURNER IS COMPLETELY SELF MODULATING, AND OPERATOR CONTROLS ARE DESIGNED FOR EASE OF USE.OXIDIZER SPECIFICATIONS:

TO-2CS321 THERMAL OXIDIZER WITH THE FOLLOWING DESIGN FEATURES:

WAYNE COMBUSTION LC 1500 BURNER WITH 1.5 MILLION BTU PER HOUR MAXIMUM INPUT.

DUNGS MULTIBLOC SAFETY VALVE MBC VEF 2500.

DUNGS LOW AND HIGH GAS PRESSURE SWITCHES.

SIEMENS LME SERIES FLAME SAFETY CONTROLLER.

FLAME SENSING ROD FOR FLAME VERIFICATION.

FULLY MODULATING TO MODULATE AT PRE-SET OPERATING TEMPERATURE;

BURNER AND CONTROLS CONFORM TO UL 295 STANDARD FOR COMMERCIAL INDUSTRIAL GAS HEATING EQUIPMENT.

OPERATOR FRIENDLY CONTROL SYSTEM.

TO-2CS321 DIMENSIONS:

OUTSIDE DIAMETER: 36"

OVERALL HEIGHT FROM FLOOR: 82"

INLET DIAMETER: 6"

OUTLET DIAMETER: 10"

EXTERIOR TO BE POWDERCOATED CARBON STEEL MATTE BLACK (OPTIONAL COLORS AVAILABLE).

4" OF HIGH DENSITY CERAMIC INSULATION BETWEEN INTERIOR AND EXTERIOR SURFACES.QUANTITY: 1

Learn More -

R-3249 GIESEN COFFEE ROASTER W15A SELKIRK OXIDIZER - 15 KILOS

R-3249 GIESEN COFFEE ROASTER W15A SELKIRK OXIDIZER - 15 KILOSR-3249 GIESEN COFFEE ROASTER W15A SELKIRK OXIDIZER - 15 KILOS

AN EXCEPTIONAL OPPORTUNITY FOR READY TO BE DELIVERED/INSTALLED EQUIPMENT CREATED BY A CHANGED BUSINESS MODEL.

NATURAL GAS

240V/60 HZ

BLACK/SILVERSELKIRK SPECIALIZES IN THERMAL AFTERBURNERS FOR COFFEE ROASTING MACHINES FROM 10 TO 120 KGS PER BATCH. AFTERBURNERS ARE DESIGNED OF QUALITY MATERIALS FOR LONG SERVICE LIFE. INTEGRATED EFFICIENT GAS BURNERS WHICH REDUCE OPERATING COSTS. BURNER CONFORMS TO UL 295 STANDARD FOR COMMERCIAL/INDUSTRIAL GAS BURNERS. AFTERBURNER DESIGN PROVIDES LONG RETENTION TIMES TO ELIMINATE SMOKE AND ODORS FROM THE ROASTING PROCESS. STANDARD AFTERBURNER OPERATING TEMPERATURE IS 1250 F, BUT CAN EASILY BE ADJUSTED TO MEET LOCAL AIR QUALITY REQUIREMENTS. GAS BURNER IS COMPLETELY SELF MODULATING, AND OPERATOR CONTROLS ARE DESIGNED FOR EASE OF USE.

OXIDIZER SPECIFICATIONS:

TO-2CS321 THERMAL OXIDIZER WITH THE FOLLOWING DESIGN FEATURES:

WAYNE COMBUSTION LC 1500 BURNER WITH 1.5 MILLION BTU PER HOUR MAXIMUM INPUT.

DUNGS MULTIBLOC SAFETY VALVE MBC VEF 2500.

DUNGS LOW AND HIGH GAS PRESSURE SWITCHES.

SIEMENS LME SERIES FLAME SAFETY CONTROLLER.

FLAME SENSING ROD FOR FLAME VERIFICATION.

FULLY MODULATING TO MODULATE AT PRE-SET OPERATING TEMPERATURE;

BURNER AND CONTROLS CONFORM TO UL 295 STANDARD FOR COMMERCIAL INDUSTRIAL GAS HEATING EQUIPMENT.

OPERATOR FRIENDLY CONTROL SYSTEM.

TO-2CS321 DIMENSIONS:

OUTSIDE DIAMETER: 36"

OVERALL HEIGHT FROM FLOOR: 82"

INLET DIAMETER: 6"

OUTLET DIAMETER: 10"

EXTERIOR TO BE POWDERCOATED CARBON STEEL MATTE BLACK (OPTIONAL COLORS AVAILABLE).

4" OF HIGH DENSITY CERAMIC INSULATION BETWEEN INTERIOR AND EXTERIOR SURFACES.QUANTITY: 1

Learn More -

TT-8230 MASTER BAG 300X SQUARE BOTTOM PAPER BAG MACHINE, YEAR 2025TT-8230 MASTER BAG 300X SQUARE BOTTOM PAPER BAG MACHINE, YEAR 2025 1. MASTER BAG 300X – SQUARE BOTTOM PAPER BAG MACHINE 2. YEAR: 2025 Learn More

TT-8230 MASTER BAG 300X SQUARE BOTTOM PAPER BAG MACHINE, YEAR 2025TT-8230 MASTER BAG 300X SQUARE BOTTOM PAPER BAG MACHINE, YEAR 2025 1. MASTER BAG 300X – SQUARE BOTTOM PAPER BAG MACHINE 2. YEAR: 2025 Learn More -

TT-7132 COMPLETE COTTON RING SPINNING PLANT TOYODA, 36,970 SPINDLES, YEAR 2018, WITH MURATA QPRO PLUS LINK WINDERSTT-7132 COMPLETE COTTON RING SPINNING PLANT TOYODA, 36,970 SPINDLES, YEAR 2018, WITH MURATA QPRO PLUS LINK WINDERS Learn More

TT-7132 COMPLETE COTTON RING SPINNING PLANT TOYODA, 36,970 SPINDLES, YEAR 2018, WITH MURATA QPRO PLUS LINK WINDERSTT-7132 COMPLETE COTTON RING SPINNING PLANT TOYODA, 36,970 SPINDLES, YEAR 2018, WITH MURATA QPRO PLUS LINK WINDERS Learn More -

YY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINEYY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINE Learn More

YY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINEYY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINE Learn More -

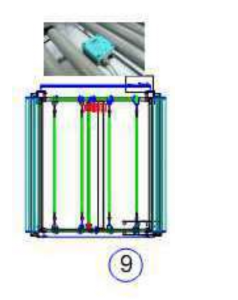

YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY)YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY) Z 600 E - FOR FOAM WITH TRICOT ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS QUANTITY: 3 Learn More

YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY)YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY) Z 600 E - FOR FOAM WITH TRICOT ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS QUANTITY: 3 Learn More -

T-9989 TRUTZCHLER - TOYOTA - MURATA COMPLETE 37000 SPINDLE RING SPINNING PLANT, YEAR 2018T-9989 TRUTZCHLER - TOYOTA - MURATA COMPLETE 37000 SPINDLE RING SPINNING PLANT, YEAR 2018 WITH THE TOP OF THE LINE UP TRUTZSCHLER BACK PROCESS, TOYOTA RING FRAME AND MURATEC QPRO LINK CORNER Learn More

T-9989 TRUTZCHLER - TOYOTA - MURATA COMPLETE 37000 SPINDLE RING SPINNING PLANT, YEAR 2018T-9989 TRUTZCHLER - TOYOTA - MURATA COMPLETE 37000 SPINDLE RING SPINNING PLANT, YEAR 2018 WITH THE TOP OF THE LINE UP TRUTZSCHLER BACK PROCESS, TOYOTA RING FRAME AND MURATEC QPRO LINK CORNER Learn More -

YY-2033 GAUZE SWAB FOLDING MACHINE WITHOUT EDGE (7.5 X 7.5 X 8 TO 12 PLY)YY-2033 GAUZE SWAB FOLDING MACHINE WITHOUT EDGE (7.5 X 7.5 X 8 TO 12 PLY) THE MACHINE HAS KNIFE HOLDER PROTECTION SWITCH THE MACHINE HAS A SAFETY COVER. MACHINE SIZE: 2300 X 1700 X 2000. MACHINE WEIGHT: 800KG. QUANTITY: 1 Learn More

YY-2033 GAUZE SWAB FOLDING MACHINE WITHOUT EDGE (7.5 X 7.5 X 8 TO 12 PLY)YY-2033 GAUZE SWAB FOLDING MACHINE WITHOUT EDGE (7.5 X 7.5 X 8 TO 12 PLY) THE MACHINE HAS KNIFE HOLDER PROTECTION SWITCH THE MACHINE HAS A SAFETY COVER. MACHINE SIZE: 2300 X 1700 X 2000. MACHINE WEIGHT: 800KG. QUANTITY: 1 Learn More -

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOURREFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

REFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

Learn More