Search results for: 'automatic+cuttin'

- Related search terms

- automatic+cutting+ma

- automatic+cutting

- automatic+cutting+machine

- automatic+cutting+ma'

-

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More -

V-1816 AUTOMATIC RESPIRATOR REPLACEMENT FILTER MAKING MACHINE

V-1816 AUTOMATIC RESPIRATOR REPLACEMENT FILTER MAKING MACHINEAUTOMATIC RESPIRATOR REPLACEMENT FILTER MAKING MACHINE IS ALSO CALLED A PARTICULATE RESPIRATOR FILTER MAKING MACHINE OR HALF FACE RESPIRATOR FILTER MAKING MACHINE, IT’S MADE UNDER MATURE TECHNOLOGY THAT SUPPORTS AUTOMATICALLY MATERIAL FEEDING, WELDING, PUNCHING AND CUTTING, REPLACEMENT FILTER FORMING, THIS MACHINE IS EASY TO OPERATE, BY CHANGING THE ROLLER, IT CAN PRODUCE DIFFERENT SHAPES OF FILTER. THIS MACHINE INCORPORATES ADVANCED ULTRASONIC WELDING AND EQUIPPED WITH CONSTANT TEMPERATURE CONTROLLER WHICH ENSURES THE FILTER FIRMLY AND CLEARLY WELDED.

FEATURES:

1. ADVANCED ULTRASONIC TECHNOLOGY WITH FIRM WELDING EFFECT, IT’S EQUIPPED WITH PULL AND PUSH TYPE MATERIAL FEEDING WHICH MAKES IT EASIER OPERATING.

2. THE MOLD (PATTERN ROLLER) CAN BE CUSTOMIZED TO PRODUCE DIFFERENT FILTERS.

3. THE WELDING LINE IS CLEAR AND FIRM.

ITEM NAME

TECHNICAL PARAMETERS

QTY

REMARK

SPECIFICATION

1800mm X 1200mm X 1800mm

1

HONGDA

WEIGHT

500KG

EFFICIENCY

20 TO 30PCS/MIN

VOLTAGE

220V/380V

AIR PRESSURE

3-6KG/CM²

FREQUENCY

15/20KHZ

POWER

4200W

MOLD SERVO MOTOR

SGM7G-09AFC61 4.4KW

1

YASKAWA

ULTRASONIC POWER SERVO MOTOR

SGM7G-13AFC61 1.3KW

2

YASKAWA

MATERIAL PULLING SERVO MOTOR

SGM7G-09AFC61 0.85KW

2

YASKAWA

MATERIAL FEEDING/CORRECTING/INDENTATION MOTOR

130BYG-350A

4

SONGYANG

POUCHING MOTOR

110BYG-350B

4

SONGYANG

110 STEPPER MOTOR

110BYG-350A

10

SONGYANG

UP AND LOWER MOTOR

90BYG-350A

2

SONGYANG

STEPPER MOTOR 56

SY57STH56-2004A

8

SONGYANG

DIRECT CURRENT MOTOR

0.4KW

2

DIRECT CURRENT MOTOR

0.6KW

1

ASYNCHRONOUS THREE-PHASE MOTOR

90S-6

1

0.75KW

FREQUENCY CONVERTER

AVF200-0152

1

1.5KW

MAIN PNEUMATIC COMPONENTS: AIRTAC (TAIWAN); MAIN ELECTRICAL COMPONENTS: PANASONIC (JAPAN), SICK (GERMANY), DONLIM (CHINA&JAPAN), ETC.

EMAIL US FOR PRICE & PICTURES

INCLUDE OUR REFERENCE NUMBER

Learn More -

J-2640 DYEING AND FINISHING PLANT FOR SALE

J-2640 DYEING AND FINISHING PLANT FOR SALEREFERENCE NUMBER: J-2640

DYEING AND FINISHING PLANT FOR SALEITEM 001

THIES SAMPLE DYEING MACHINE

MODEL: MINISOFT SAMPLE

CAPACITY: 50 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 002

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

3 PORT SPLIT/SPLIT

CAPACITY: 900 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 003

THIES DYEING MACHINE

MODEL: ECOSOFT PLUS

2 PORT SPLIT/SPLIT

CAPACITY: 600 KGS

YEAR: 1999

MICROPROCESSOR CONTROL

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 004

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

1 PORT SPLIT/SPLIT

CAPACITY: 300 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: A460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 005

GASTON COUNTY DYEING MACHINE

MODEL: AQUAFLOW

2 PORT

CAPACITY; 250 KGS

YEAR: 1987

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING AND UNLOADING REEL

QUANTITY: 1ITEM 006

THIES DYEING MACHINE

MODEL: SOFT TRD

2 TUBE

CAPACITY: 700 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 007 (also our J-2647)

LAFER OPEN WIDTH COMPACTOR MACHINE

MODEL: KSA 500 2400/2200

YEAR: 1998

LAFER TEXEN CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY, VERTICAL PIN CHAIN, WITH PLATE GUIDES, RAIL OPENING, PINNING BRUSHES, PINS ONLY, WITH SUPPORT SECTION FOR THE FABRIC IN THE CENTER, AT 10’ THERE IS A STEAMING SECTION, TOTAL LENGTH OF THE TENTER IS 30’, WITH AUTOMATIC LUBRICATION FOR THE CHAIN

• KSA 500 COMPACTOR BENCH WITH TEXEN CONTROLS

• TENSIONLESS FABRIC CONVEYOR

• PLAITOR AND FABRIC SCRAY WITH OPTICAL LOAD SENSOR

• INLINE INSPECTION BATCHER MACHINE, WITHH A BACK LIGHTED BOARD, MANUAL CUT

• SCALE TO WEIGHT THE FABRIC

QUANTITY: 1ITEM 008 (also our J-2648)

SANTEX TUBULAR 4-ROLL EXTRACTION PAD

MODEL: SANTASTRETCH PLUS 140

YEAR: 1998

COMPOSED OF TURNTABLE, DETWISTER, TUBULAR 4-ROLL PAD WITH WET SPREADERS, PLAITOR

WITH ADDITION TANKS FOR SOFTENER

REEL FABRIC PLAITOR EXIT

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 009

SANTEX CONVEYOR DRYER FOR OPEN WIDTH AND TUBULAR FABRIC

MODEL: SANTASHRINK 4/5240

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER TO

• (2) SANTEX 2-ROLL PADS, RUBBER OVER RUBBER, 102” WIDE x 12” DIAMETER, STAINLESS STEEL PAN, 10-TON PAD, SWING-AWAY PAN, TENSION BAR WITH 2 STAINLESS STEEL MIXING TANKS, 75 GALLONS EACH

• DRIVEN SCROLL ROLLS WITH EDGE GUIDE CONTROL, WIDTH 95”

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY 45°, YEAR 1998, VERTICAL PIN CHAIN, 30’ LONG WITH TANDEMATIC PLATE GUIDES, RAIL GUIDES, PINNING BRUSHES, GUIDE SUPPORT FOR THE FABRIC, FABRIC CONVEYOR TO ENTER BOTH TUBULAR OR OPEN WIDTH FABRIC TO

• CONVEYOR DRYER 100” WIDE, 5 ZONES, 3-PASS WITH MAXON BURNERS, 5 CIRCULATING FANS TO CONVEYOR BELT TO PLAITOR

• ALL MOTORS AND SANTEX CONTROLS AND MONITORS

QUANTITY: 1ITEM 010

SANTEX AG TUBULAR COMPACTOR MACHINE

MODEL: SANTASPREAD 140

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSIONS BAR ENTRY

• OPERATOR’S PLATFORM

• TENSION DEVICE

• DRIVEN SPREADER BARS

• STEAMING DEVICE

• TUBULAR COMPACTING BENCH

• FELT BLANKET ONTO THE CONVEYOR BELT

• PRECISION PLAITOR

• TABELTOP ELECTRONIC SCALE

QUANTITY: 1ITEM 011

COMET NAPPER

MODEL: PEGSO-X4

YEAR: 1998

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

24 ROLLS WITH TURNING BARS FOR TUBULAR 90” WIDE

XYCOM CONTROLS

12-BAG COLLECTION SYSTEM AND PLAITOR

YEAR: 1996

QUANTITY: 1ITEM 012

STENTEX TENTER FRAME

MODEL: STENTOTHERM 3300

YEAR: 1999

STENTEX CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION ENTRY TO TEXT-STAR TYPE GUIDER TO 2 ROLL PAD

• ADDITION TANK TOP SCRAY PAD TO TEXT-STAR TYPE GUIDER

• TWO ROLL PAD R/R 10 TON

• OPERATOR’S PLATFORM

• WORKING WIDTH 1800mm

• HORIZONTAL PIN CHAIN, KNIT ENTRY

• TANDEMATIC SPLITLEVEL DECURLERS

• OVERFEED

• PINNING BRUSHES

• STEAM BOX

• RAIL GUIDERS, 20 FEET ENTRY, 8 ZONES

• 80 FEET HOUSING

• SCREEN MONITORS

• GAS FIRED, MAXON OVEPAK 408 BURNERS

• HONEYWELL CONTROLS

• 3 FEET COOLING ZONE

• 2 COOLING CANS, SELVEDGE TRIMMERS

• PLIATOR, SCRAY

• ZONE IN LINE INSPECTION BATCHER

QUANTITY: 1ITEM 013

ZIMMER ROTARY SCREEN PRINTING MACHINE

MODEL: R92-S153

YEAR: 1993

COMPOSED OF:

• TENSION BAR SKY ENTRY

• SCRAY

• CORINO BRUSH

• CORINO PRINT GUIDER

• ZIMMER PRINTER, 8 COLOR, 86” BLANEKT

• PRINT CONVEYOR DRYER, 30’ LONG, 3-ZONE, GAS FIRED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 014

Learn More

SAFETY SWITCH BULLET NOSE SLITTER

MODEL: CUTTING

WITH REEL FABRIC PLIATOR

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1 -

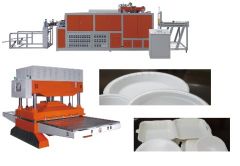

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINE

L-5818 POLYSTYRENE FOAM PLATE FORMING MACHINEREFERENCE NUMBER: L-5818

POLYSTYRENE FOAM PLATE FORMING MACHINE

RATED POWER: 90 KW

SHEET WIDTH: 800 TO 1080mm

MAX FORMING AREA: 1000 X 1300mm

WORKING SPEED: 17 TO 22 TIMES PER MINUTE

This machine is semi-automatic.

After forming, hydraulic cutting machine will be needed to cut out each product.

QUANTITY: 1

Learn More -

L-2532 POLYETHYLENE FOAM PLANK PRODUCTION LINE MODEL 180 1000 TO 2000mm WIDTH 2 TO 18mm THICKNESS

L-2532 POLYETHYLENE FOAM PLANK PRODUCTION LINE MODEL 180 1000 TO 2000mm WIDTH 2 TO 18mm THICKNESSREFERENCE NUMBER: L-2532

Learn More

MODEL: 180

1000 TO 2000mm WIDTH -

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSION

L-1760 AUTOMATIC FOAM PUNCHING MACHINE HOLE SIZE 6mm TO 86mm WIDTH 2100mm FULL WIDTH VERSIONREFERENCE NUMBER: L-1760

Learn More

FOR PUNCHING HOLES IN PU FOAM

WORKING WIDTH: 2100mm

QUANTITY: 1 -

P-5032 RIETER G30 RING FRAME WITH AUTODOFFER YEAR 1997 960 SPINDLES

P-5032 RIETER G30 RING FRAME WITH AUTODOFFER YEAR 1997 960 SPINDLESP-5032 RIETER G30 RING FRAME WITH AUTODOFFER YEAR 1997 960 SPINDLES

RIETER

MODEL: G30

RING FRAME

YEAR: 1997

DOFFING: AUTOMATIC

NUMBER OF SPINDLES PER MACHINE: 960

SPINDLE GUAGE: 70mm

BOBBIN LENGTH: 210mm

DRAFTING MAKE: RIETER

DRAFTING TYPE: P3-1

CRADEL SIZE: SHORT – 36mm

TOP CLEARER ROLLER: NOT AVAILABLE

BOTTOM CLEARER ROLLER: NOT AVAILABLE

RING DIAMETERIN mm: 27/27/27

RING DIAMETER: 42mm

RING FLANGE: ONE

SPINDLE TYPE: PLUG

SPINDLE WHARVE: 21

SPINDLE DRIVE: 4 SPINDLE DRIVE

ABC RING: AVAILABLE

NUMBER OF CREEL ROWS: 5

TYPE OF GRIPPER: OUTER

YARN CUTTING: SPINDLE

BOBBIN CONVEYING: PEG TRAY

OHTC: AVAILABLE

OHTC MAKE: OTHER

INVERTER: AVAILABLE

EXHAUST AIR: DOWNWARDS

VOLTAGE: 440

FREQUENCY: 50QUANTITY: 5

Learn More -

C-4362 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (NON POP UP), WIDTH 3000mm

C-4362 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (NON POP UP), WIDTH 3000mmC-4362 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (NON POP UP), WIDTH 3000mm

Y-6 BABY WIPES FOLDING MACHINE

PRODUCTION FLOW: UNROLLING - SLITTING FABRIC INTO LANES - FOLDING - WETTING - CUTTING – PILE & COUNTING - DELIVERING

MAIN TECHNICAL PARAMETER (SUITABLE TO WET TISSUE FOR LARGE SIZE PACKING)

PRODUCT TYPE: BABY WIPES (NON CROSS FOLDING)

PRODUCT SPEED: 200 TO 270 CUTS/MIN (SET ON PLC)

SUITABLE RAW MATERIAL: AIR LAID PAPER, SPUNLACE/HOT-ROLLING NONWOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40 TO 80G/㎡

FOLDING WAY: “Z” SHAPE (NON-POP UP)

LENGTH OF WET TISSUE: 140 TO 185mm (SET ON PLC)

FREQUENCY OF RECEIVING PAPER: 14 TO 20 TIMES/MIN (SET ON PLC)

POWER SUPPLY: 380V 50HZ

POWER: 4KW

SIZE OF RAW MATERIAL: (1000 TO 1250) × Ø1000 (mm, W×DIA)

WET TISSUE UNFOLDED SIZE: (140 TO 185) × (150 TO 200) (mm, L×W)

WET TISSUE FOLDED SIZE: (140 TO 185) × (80 TO 110) (mm, L×W)

MATERIAL SUPPLY SYSTEM: SERVO MOTOR

CUTTING SYSTEM: CONVERTER MOTOR

PILING SYSTEM: SERVO MOTOR

POWER SUPPLY: 380V 50HZ

POWER: 6KW

SIZE OF MACHINE: 5200 × 3000 × 1800 (mm, L×W×H)

WEIGHT OF MACHINE: 1500 KG

OPTIONAL MAKING: Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINEQUANTITY: 1

Learn More -

C-4361 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (POP UP & NON POP UP), WIDTH 3000mm

C-4361 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (POP UP & NON POP UP), WIDTH 3000mmC-4361 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (POP UP & NON POP UP), WIDTH 3000mm

Y-6 BABY WIPES FOLDING MACHINE

(POSSIBLE TO ADD ONE MORE RAW MATERIAL SHELF TO BE Y-12)

PS: Y-12 IS ADD ANOTHER RAW MATERIAL SHELF ON THE BASE OF Y-6

PRODUCTION FLOW: UNROLLING - SLITTING FABRIC INTO LANES - FOLDING - WETTING - CUTTING – PILE & COUNTING - DELIVERING

MAIN TECHNICAL PARAMETER (SUITABLE TO WET TISSUE FOR LARGE SIZE PACKING)

PRODUCT TYPE: BABY WIPES (NON CROSS FOLDING)

PRODUCT SPEED: 200 TO 270 CUTS/MIN (SET ON PLC)

SUITABLE RAW MATERIAL: AIR LAID PAPER, SPUNLACE/HOT-ROLLING NONWOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40 TO 80 G/㎡

FOLDING WAY: “Z” SHAPE (NON-POP UP AND POP UP)

LENGTH OF WET TISSUE: 140 TO 185mm (SET ON PLC)

FREQUENCY OF RECEIVING PAPER: 14 TO 20 TIMES/MIN (SET ON PLC)

POWER SUPPLY: 380V 50HZ

POWER: 4KW

SIZE OF RAW MATERIAL: (1000 TO 1250) × Ø1000 (mm, W×DIA)

WET TISSUE UNFOLDED SIZE: (140 TO 185) × (150 TO 200) (mm, L×W)

WET TISSUE FOLDED SIZE: (140 TO 185) × (80 TO 110) (mm, L×W)

MATERIAL SUPPLY SYSTEM: SERVO MOTOR

CUTTING SYSTEM: CONVERTER MOTOR

PILING SYSTEM: SERVO MOTOR

POWER SUPPLY: 380V 50HZ

POWER: 6KW

SIZE OF MACHINE: 5200 × 3000 × 1800 (mm, L×W×H)

WEIGHT OF MACHINE: 1500 KG

OPTIONAL MAKING: Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

CANISTER WET WIPES MACHINEQUANTITY: 1

Learn More -

P-4337 WET TOWEL MAKING MACHINE.(HALF FOLD TYPE)

P-4337 WET TOWEL MAKING MACHINE.(HALF FOLD TYPE)REFERENCE NUMBER: P-4337

WET TOWEL MAKING MACHINE.(HALF FOLD TYPE)

Model: L60

SPECIFICATIONS:

Model: Z, V, W,Z+Z...

Packing Item: Non-woven fabric

Capacity: 450-640 sheets/min or 20-80bags/min

Raw Material Size: parent roll dia: 1000mm,Core dia:76.2mm

Wet towel Size: Length 100mm. Width: 50-100mm (adjustable)

Open size: Length 200mmx Width(150-250)mm

Products size:Length:130-350mm Width:50-120mm, Thickness:5-45mm

Wetting System: Moistening system complete with 100%-400%, automatic, excess liquid

Cutting system: stainless steel round cutter

Counter system: electronic meter

Feeding system: by manual

Hole system: synchronization rotary cutter

Label system: synchronization sticker

Power: 3 phase AC 380V 50/60Hz 8KW

Machine space: L:5000mmXW 4300mm XH1900mm (L)

Machine weight: 2000kg

Remarks: Machine made by stainless steel. Special size by order

OPTION EQUIPMENT

Coding machine Stainless steel storage tankQUANTITY: 1

Learn More