Search results for: 'machine+can'

- Related search terms

- machine+can+0

-

R-3274 GP90 PROBAT ROASTER - 90 KILOS

R-3274 GP90 PROBAT ROASTER - 90 KILOSR-3274 GP90 PROBAT ROASTER - 90 KILOS

THIS MACHINE WAS THE SMALLEST MACHINE IN A LARGE PROBAT PLANT AND NOT USED EVEN DAILY - THEN THAT PLANT MOVED INTO A BIG NEW BUILDING AND THEY NEVER RE-INSTALLED THE MACHINE - SO IT SAT FOR THE LAST 10 YEARS THINKING "SOMEDAY" WE WOULD PUT IT BACK INTO USE . . . BUT THAT DAY NEVER HAPPENED . . . SO GET RID OF IT.

WE KNEW THE ORIGINAL SALE AND INSTALLATION BACK IN THE EARLY 70'S AND HAVE MONITORED THIS EQUIPMENT (IN AND OUT OF SERVICE) FOR ALL THIS TIME AND NOW WE ARE PLEASED THAT IT CAN GO OUT AND GET INTO ACTUAL USE. THIS MACHINE IS IN TOP CONDITION - AND ALL THAT IS NEEDED IS TO VERIFY THE GREASE IN THE BEARINGS AND START ROASTING AGAIN.

SET FOR PROPANE GAS - BUT CAN BE CONVERTED TO NATURAL GAS AS NEEDED.

240 V 3 PHASE POWER IN 60HZALL SET FOR EASY US OR NORTH AMERICAN INSTALLATION. CAN SHIP IMMEDIATELY. PROBAT AND INDEPENDENT PARTS ARE ALL AVAILABLE AS OR IF NEEDED. THIS IS A HEALTHY MACHINE.

QUANTITY: 1

Learn More -

K-5426 MICRO FIBER OPENERSREFERENCE NUMBER: K-5426 MICRO FIBER OPENERS Learn More

K-5426 MICRO FIBER OPENERSREFERENCE NUMBER: K-5426 MICRO FIBER OPENERS Learn More -

YY-2402 SEMI-AUTOMATIC PRODUCTION LINE FOR ROUND COTTON PADSYY-2402 SEMI-AUTOMATIC PRODUCTION LINE FOR ROUND COTTON PADS PURPOSE OF MACHINE: THIS MACHINE CAN PRODUCE FACIAL COTTON PADS IN VARIOUS SHAPES OF COTTON PADS. FOR EACH DIFFERENT SHAPE OF SIZE, A SEPARATE TOOL IS NEEDED. QUANTITY: 1 Learn More

YY-2402 SEMI-AUTOMATIC PRODUCTION LINE FOR ROUND COTTON PADSYY-2402 SEMI-AUTOMATIC PRODUCTION LINE FOR ROUND COTTON PADS PURPOSE OF MACHINE: THIS MACHINE CAN PRODUCE FACIAL COTTON PADS IN VARIOUS SHAPES OF COTTON PADS. FOR EACH DIFFERENT SHAPE OF SIZE, A SEPARATE TOOL IS NEEDED. QUANTITY: 1 Learn More -

J-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPESJ-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPES LABEL SHEARING AND FOLDING MACHINE AUTOMATIC SLIDING PATH OF LABEL ABLE TO SHEAR AND FOLD 5 TYPES OF LABELS BY ONLY REPLACING THE MOLD ADJUSTABLE LABEL LENGTH WITHOUT ANY TOOLS AND CAN BE SEPARATELY FITTED WITH ELECTRONIC EYE SYSTEM IF NEEDED USED FOR PRINTING LABELS AND CUTTING AND FOLDING WITHOUT PUSH-LINE SHEARING AND FOLDING TYPES: END FOLD, CENTER FOLD, TRIANGLE FOLD, LENGTHFOLD CUTTING LENGTH: 15 TO 16mm CUTTING WIDTH: 10 TO 75mm CUTTER TYPE: COOLED SHEARING, HOT SHEARING CUTTING SPEED: 30 TO 200 METERS PER MINUTE POWER: 220 VOLTS, SINGLE PHASE, 60 OR 50 Hz TOTAL POWER: 1.8 KW HORSEPOWER: ½ HP WEIGHT: 295 KG PACKED DIMENSIONS: 1100 x 950 x 1620mm QUANTITY: 1 Learn More

J-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPESJ-4056 LABEL CUTTING AND FOLDING MACHINE, HIGHLY CONFIGURABLE FOR MULTIPLE LABEL TYPES LABEL SHEARING AND FOLDING MACHINE AUTOMATIC SLIDING PATH OF LABEL ABLE TO SHEAR AND FOLD 5 TYPES OF LABELS BY ONLY REPLACING THE MOLD ADJUSTABLE LABEL LENGTH WITHOUT ANY TOOLS AND CAN BE SEPARATELY FITTED WITH ELECTRONIC EYE SYSTEM IF NEEDED USED FOR PRINTING LABELS AND CUTTING AND FOLDING WITHOUT PUSH-LINE SHEARING AND FOLDING TYPES: END FOLD, CENTER FOLD, TRIANGLE FOLD, LENGTHFOLD CUTTING LENGTH: 15 TO 16mm CUTTING WIDTH: 10 TO 75mm CUTTER TYPE: COOLED SHEARING, HOT SHEARING CUTTING SPEED: 30 TO 200 METERS PER MINUTE POWER: 220 VOLTS, SINGLE PHASE, 60 OR 50 Hz TOTAL POWER: 1.8 KW HORSEPOWER: ½ HP WEIGHT: 295 KG PACKED DIMENSIONS: 1100 x 950 x 1620mm QUANTITY: 1 Learn More -

R-7289 FADIS ITALY SYNCRO M HANK AND MUFF MAKING MACHINE, YEAR 2009

R-7289 FADIS ITALY SYNCRO M HANK AND MUFF MAKING MACHINE, YEAR 2009FADIS ITALY SYNCRO M HANKING MACHINE

Learn More

YEAR 2009

MUFF MACHINE 50 POSITIONS TOTAL (1 MC = 35 POS) (2ND MC = 15 POS)

BOBBIN TO HANK / MUFF WINDING

POSSIBILITY TO EXTEND 20 POSITIONS MORE

EITHER BOBBIN-TO-HANK OR HANK-TO-CONE 1-1.200 M/MIN

EACH POSITION WORKS WITH METERED QUANTITY

EACH POSITION CAN RUN A DIFFERENT YARN

TRANSPORT - FIT IN 2 X 40 FT CONTAINERS EXCELLENT CONDITION

(ALL POSITIONS ARE WORKING PERFECTLY, LAST FADIS MAINTENANCE IN 11/2016)

QUANTITY: 2 -

TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003 1. SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE 2. YEAR: 2003 3. BRAND: SUCKER MULLER HACOBA Learn More

TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003 1. SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE 2. YEAR: 2003 3. BRAND: SUCKER MULLER HACOBA Learn More -

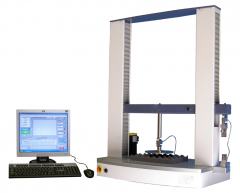

L-1511 UNIVERSAL TESTING MACHINE FOR FOAM OR FABRIC

L-1511 UNIVERSAL TESTING MACHINE FOR FOAM OR FABRICREFERENCE NUMBER: L-1511

Learn More

UNIVERSAL TESTING MACHINE

QUANTITY: 1 -

P-4326 BABY WET WIPES PRODUCTION LINE

P-4326 BABY WET WIPES PRODUCTION LINEREFERENCE NUMBER: P-4326

BABY WET WIPES PRODUCTION LINE

Model L80

Machine Characteristic

Control system: Multi-Axis Motion Controller

Drive element: servo motor

Operate interface: 10" LCD touch screen

Cutting: synchronous flail knife

Packing style: automatic distribute,2 sets packing machine can respective online

Unwinding structure: 80 electronic eyes detect online (auto splicing machine: 32 sets)

Frequency division detection: 80 electronic eyes detect online

Frequency division pulling: 4 sets dry wipes pulling , 2 sets wet wipes pulling

Auto splicing: film automatic splicing, label automatic switching

Frequency division detection: nonwoven ,film, label detect respectively

Metal detect: online metal detector

Inferior eliminate: aluminizing paste connector rejected online

Flow control: 2.5-4 times, flow meter control, no liquid recovery

Moisture type: 80 fluid pipes spray independently

SUS Agitate tank: 2 sets, 1000L stainless steel agitate tank

Liquid level control: electronic detection, auto control

Specifications

Raw material: spunlaced nonwoven, therbond etc. nonwovens

Raw material specification: max W220mm, φ1400mm, max W1050mm, φ1000mm

Axis QTY settings:80 rolls raw materials (auto splicing type 32 rolls)

Diameter of ventilating shaft: 3"

Suitable packing material :BOPP PET/PE PET/AL/PE etc. heat-seal material

Packing Film specification: max W420mm, φ350mm

Axis QTY settings: 2 sets film, automatic bonding without stopping machine

Diameter of ventilating shaft: 3"

Suitable label: transparent label & opaque label

Label size: max W100mm φ400mm

Axis QTY settings: 2 sets label, automatic switching without stopping(can be set as safety label)

Diameter of ventilating shaft: 3"

Folding type: single extraction & interfold type

Wet wipes size:L120-250mm W90-110mm

Open size: L120-250mm W150-220mm

Package size: L150-350mm W80-120mm H20-100mm

Design speed: 120bags/min &250cutting/min

Production speed: 100 bags/min &200 cutting/min

Machine space: L54000mm W3500mm H2100mm, L57000mm W4600mm H2100mm(auto splicing machine)

Power: AC 380V 50/60Hz 35KW(auto splicing machine:40KW)

Compressed air: 0.6-0.8Mpa 500L/min

Machine net weight :30000kg(auto splicing machine 35000Kg)

Option equipment: Coding machine Big roll material automatic splicingQUANTITY: 1

Learn More -

M-5189 ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE)REFERENCE NUMBER: M-5189 (13132M16K12UX) L ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE) ROUND COTTON PADS MAKING MACHINE MODEL: XR MACHINE CAN MAKE PADS TYPE ROUND AND OVAL AVERAGE PRODUCTIVITY: 1200 PIECES PER MINUTE OUTPUT OF PADS: 4 LINES EMBOSSING POSSIBLE MULTILAYER COTTON PADS POSSIBLE TO MAKE WITH MACHINE (I.E. 3PLY: NON-WOVEN LAYER + COTTON LAYER + NON-WOVEN LAYER) PACKING METHOD: MANUAL QUANTITY AVAILABLE: 1 Learn More

M-5189 ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE)REFERENCE NUMBER: M-5189 (13132M16K12UX) L ROUND COTTON PADS MAKING MACHINE (1200 PIECES PER MINUTE) ROUND COTTON PADS MAKING MACHINE MODEL: XR MACHINE CAN MAKE PADS TYPE ROUND AND OVAL AVERAGE PRODUCTIVITY: 1200 PIECES PER MINUTE OUTPUT OF PADS: 4 LINES EMBOSSING POSSIBLE MULTILAYER COTTON PADS POSSIBLE TO MAKE WITH MACHINE (I.E. 3PLY: NON-WOVEN LAYER + COTTON LAYER + NON-WOVEN LAYER) PACKING METHOD: MANUAL QUANTITY AVAILABLE: 1 Learn More -

M-1020 COMBINATION FIBER AND POLYSTYRENE PELLET FILLING MACHINEA) HOPPER MODEL L1500 MIXING SYSTEM B) OPENER MODEL F1000 – FOR THE FIRST OPENING OF THE FIBERS C)DISPENSER SILOS MODEL C5 D) SHREDDING MACHINE – SHREDDING FOAM MODEL F430 E) FILLING MACHINE WITH ELECTRONIC CONTROL WEIGHT MODEL W11 F) SPECIAL SEWING MACHINE MODEL 164C Learn More

M-1020 COMBINATION FIBER AND POLYSTYRENE PELLET FILLING MACHINEA) HOPPER MODEL L1500 MIXING SYSTEM B) OPENER MODEL F1000 – FOR THE FIRST OPENING OF THE FIBERS C)DISPENSER SILOS MODEL C5 D) SHREDDING MACHINE – SHREDDING FOAM MODEL F430 E) FILLING MACHINE WITH ELECTRONIC CONTROL WEIGHT MODEL W11 F) SPECIAL SEWING MACHINE MODEL 164C Learn More