Search results for: 'Need n'

-

F-1430 FEATHER FILLING MACHINE MODEL SR-180

F-1430 FEATHER FILLING MACHINE MODEL SR-180REFERENCE NUMBER: F-1430

FEATHER FILLING MACHINE MODEL SR-180

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• TYPE : SR-180/280/380/480

• DIMENSION: 1200 x 1500 x 2000MM

• VOLTAGE: 200/380/415V 50/60HZ 3PHASE

• POWER: 2.2 KW

• FILLING RANGE: 0.5-10 /1-50 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±0.2G/±0.5G

• AIR PRESSURE: 0.5-0.8MPA

• THE COMPUTERIZED DOWN & FEATHER WEIGHING FILLING MACHINE IS MAINLY USED TO FILL JACKETS, SLEEPING BAGS, CUSHIONS, PILLOWS, PADS, COMFORTERS ETC WITH A COMPUTERIZED WEIGHING SYSTEM.

• TWO HOPPER-SYSTEM FOR CONSTANT SUPPLY.

• THE VACUUM FILLING FUNCTION DOES NOT HURT THE MATERIAL AND KEEPS THE ORIGINAL ELASTICITY AND SOFT HAND FEELING.

• ACCURATE WEIGHING RESULTS; THE TOLERANCE IS WITHIN 0.2 TO

0.5 GRAM (DEPENDING ON THE RANGE OF MEASURE). IT CAN BE ADJUSTED ACCORDING TO THE PRODUCTION REQUIREMENT AND CHOOSE GROUP ERROR OR SINGLE PIECE ERROR FROM THE CONTROL PANEL

• THE WHOLE LINE CAN BE HANDLED BY ONLY 1 OPERATOR BY VERY SIMPLE

OPERATION WHICH SAVES YOU A BIG AMOUNT OF LABOR COSTS.

• ALL THE MATERIALS ARE INSIDE THE HOPPERS WITHOUT PRODUCING ANY DUST THAT AFFECTS THE WORKING AREA

• KEY ELECTRICAL COMPONENTS IMPORTED

• THE WHOLE LINE OPERATION IS CONTROLLED BY PLC SYSTEM

• ACCORDING TO DIFFERENT QUANTITY AND QUALITY PRODUCTION REQUIREMENTS THE MACHINE CONTROL PANEL CAN BE SET UP FOR 100 GROUPS OF RECIPES AND EACH RECIPE CAN BE 50 SETS OF DIFFERENT WEIGHT VALUE FOR FILLING OPTIONS

• THE AVERAGE FILLING TIME CAN BE 4 TO 10 SECONDS (DEPENDING ON THE ACCURACY) AND THE FILLING TIME CAN BE ADJUSTE

• DIFFERENT REQUIREMENTS OF THE CUSTOMER CAN BE CONSIDERED BY OUR PROFESSIONAL ENGINEERS TO WORK ON OUR MACHINES SO THEY ARE SUITABLE FOR YOUR PARTICULAR NEEDS

• MATERIAL HOPPER: 1200 x 1500 x 2000MM 1PCS

• WEIGHING SYSTEM: 1200 x 400 x 1000MM 1PCS

• FILLING TABLE :1200 x 550 x 1500 1PCS

• PLC CONTROL SYSTEM AND CONTROL PANEL: 1SETS

• BLOWER: 1PCS

• PIPE SYSTEM

Learn More -

TT-3420 DILO HYPER PUNCH NEEDLE LOOM – NEW, WORKING WIDTH 1250mm, YEAR 2004 BUT NEVER UNPACKEDTT-3420 DILO HYPER PUNCH NEEDLE LOOM – NEW, WORKING WIDTH 1250mm, YEAR 2004 BUT NEVER UNPACKED DILO HIGH SPEED NEEDLE LOOM ORIGINAL PACKED CARBON FIBRE BAR QUANTITY: 1 Learn More

TT-3420 DILO HYPER PUNCH NEEDLE LOOM – NEW, WORKING WIDTH 1250mm, YEAR 2004 BUT NEVER UNPACKEDTT-3420 DILO HYPER PUNCH NEEDLE LOOM – NEW, WORKING WIDTH 1250mm, YEAR 2004 BUT NEVER UNPACKED DILO HIGH SPEED NEEDLE LOOM ORIGINAL PACKED CARBON FIBRE BAR QUANTITY: 1 Learn More -

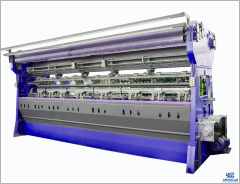

YY-2451 DOUBLE NEEDLE BAR NET RASCHEL KNITTING MACHINE, ISO SLITTING AND EXTENSION MACHINE & AUTO CUTTINGYY-2451 DOUBLE NEEDLE BAR NET RASCHEL KNITTING MACHINE, ISO SLITTING AND EXTENSION MACHINE & AUTO CUTTING ITEM 001 DOUBLE NEEDLE BAR NET RASCHEL KNITTING MACHINE QUANTITY: 1 SET ITEM 002 ISO SLITTING AND EXTENSION MACHINE QUANTITY: 2 SETS ITEM 003 AUTO CUTTING QUANTITY: 1 SET Learn More

YY-2451 DOUBLE NEEDLE BAR NET RASCHEL KNITTING MACHINE, ISO SLITTING AND EXTENSION MACHINE & AUTO CUTTINGYY-2451 DOUBLE NEEDLE BAR NET RASCHEL KNITTING MACHINE, ISO SLITTING AND EXTENSION MACHINE & AUTO CUTTING ITEM 001 DOUBLE NEEDLE BAR NET RASCHEL KNITTING MACHINE QUANTITY: 1 SET ITEM 002 ISO SLITTING AND EXTENSION MACHINE QUANTITY: 2 SETS ITEM 003 AUTO CUTTING QUANTITY: 1 SET Learn More -

P-3201 CARDING AND NEEDLING LINE, WIDTH 6000mm, YEAR 2005

P-3201 CARDING AND NEEDLING LINE, WIDTH 6000mm, YEAR 2005P-3201 CARDING AND NEEDLING LINE, WIDTH 6000mm, YEAR 2005

OFFER 001

CARDING AND NEELDING LINE

YEAR: 2005 (STARTED AT 2006)

WIDTH: 6000mmCONSISTS OF:

OFFER 002

FALUBAZ FEEDING AND MIXING LINEOFFER 003

FOR CARDING MACHINE WMZ+ZOFFER 004

AUTOMATEX CROSS LAPPER FA 5000/TC AUTOMATEOFFER 005

ASSELIN GILL BOXOFFER 006

AUTOMATEX NEEDLING MACHINE PR 160/TOFFER 007

AUTOMATEX NEEDLING MACHINE AG 160/TBOFFER 008

BELMATEX COMPENSATOR WITH WINDERQUANTITY: 1 LINE

Learn More -

TT-3323 DILO-SPINNBAU NONWOVEN NEEDLEPUNCH GEOTEXTILE LINE, WIDTH 3000mm, YEAR 1986TT-3323 DILO-SPINNBAU NONWOVEN NEEDLEPUNCH GEOTEXTILE LINE, WIDTH 3000mm, YEAR 1986 BRAND: DILO NON WOVEN MODEL: CARDING MACHINE SPINNBAU TYPE 216 2300mm, CROSS-LAPPER AUTEFA, 2500-3500mm, DILO ODI 35, DILO ODII 35, DILP OUG II 30, CURRENTLY RUNNING POLYESTER FIBER WITH A DENSITY OF 60 TO 500 GSM. CONDITION: USED YEAR: 1986 CATEGORY: NON WOVEN SUBCATEGORY: TEXTILE AND LEATHER MANUFACTURING QUANTITY: 1 Learn More

TT-3323 DILO-SPINNBAU NONWOVEN NEEDLEPUNCH GEOTEXTILE LINE, WIDTH 3000mm, YEAR 1986TT-3323 DILO-SPINNBAU NONWOVEN NEEDLEPUNCH GEOTEXTILE LINE, WIDTH 3000mm, YEAR 1986 BRAND: DILO NON WOVEN MODEL: CARDING MACHINE SPINNBAU TYPE 216 2300mm, CROSS-LAPPER AUTEFA, 2500-3500mm, DILO ODI 35, DILO ODII 35, DILP OUG II 30, CURRENTLY RUNNING POLYESTER FIBER WITH A DENSITY OF 60 TO 500 GSM. CONDITION: USED YEAR: 1986 CATEGORY: NON WOVEN SUBCATEGORY: TEXTILE AND LEATHER MANUFACTURING QUANTITY: 1 Learn More -

TT-2261 THIBEAU/CORMATEX/FEHRER/AUTEFA NEEDLE-PUNCHED LINE, CAPACITY 450 KG/HTT-2261 THIBEAU/CORMATEX/FEHRER/AUTEFA NEEDLE-PUNCHED LINE, CAPACITY 450 KG/H CONDITION: USED QUANTITY: 1 Learn More

TT-2261 THIBEAU/CORMATEX/FEHRER/AUTEFA NEEDLE-PUNCHED LINE, CAPACITY 450 KG/HTT-2261 THIBEAU/CORMATEX/FEHRER/AUTEFA NEEDLE-PUNCHED LINE, CAPACITY 450 KG/H CONDITION: USED QUANTITY: 1 Learn More -

TT-6305 ASSELIN NEEDLE PUNCH NONWOVEN LINE, WORKING WIDTH 2100mmTT-6305 ASSELIN NEEDLE PUNCH NONWOVEN LINE, WORKING WIDTH 2100mm 1. BRAND: ASSELIN NONWOVEN 2. WITH NEEDLE LOOMS 3. CONDITION: USED 4. WORKING WIDTH: 2100mm QUANTITY: 1 Learn More

TT-6305 ASSELIN NEEDLE PUNCH NONWOVEN LINE, WORKING WIDTH 2100mmTT-6305 ASSELIN NEEDLE PUNCH NONWOVEN LINE, WORKING WIDTH 2100mm 1. BRAND: ASSELIN NONWOVEN 2. WITH NEEDLE LOOMS 3. CONDITION: USED 4. WORKING WIDTH: 2100mm QUANTITY: 1 Learn More -

TT-4122 DILO NEEDLE LOOM, 4500mm, 40mm STROKE, SINGLE BOARD, 6000 N/M, 1500 RPM, FOR STRAIGHT RIBS ONLY, NO PATTERNS, MODEL DI-LOOP VS 45TT-4122 DILO NEEDLE LOOM, 4500mm, 40mm STROKE, SINGLE BOARD, 6000 N/M, 1500 RPM, FOR STRAIGHT RIBS ONLY, NO PATTERNS, MODEL DI-LOOP VS 45 BRAND: DILO NEEDLE LOOMS CONDITION: USED CATEGORY: NEEDLE LOOMS QUANTITY: 1 Learn More

TT-4122 DILO NEEDLE LOOM, 4500mm, 40mm STROKE, SINGLE BOARD, 6000 N/M, 1500 RPM, FOR STRAIGHT RIBS ONLY, NO PATTERNS, MODEL DI-LOOP VS 45TT-4122 DILO NEEDLE LOOM, 4500mm, 40mm STROKE, SINGLE BOARD, 6000 N/M, 1500 RPM, FOR STRAIGHT RIBS ONLY, NO PATTERNS, MODEL DI-LOOP VS 45 BRAND: DILO NEEDLE LOOMS CONDITION: USED CATEGORY: NEEDLE LOOMS QUANTITY: 1 Learn More -

T-9642 DILO NEEDLE LOOM WITH DILO FEEDING SYSTEM, WORKING WIDTH 2500mm, YEAR 1986 TO 1989T-9642 DILO NEEDLE LOOM WITH DILO FEEDING SYSTEM, WORKING WIDTH 2500mm, YEAR 1986 TO 1989 YEAR OF CONSTRUCTION: 1986 (NEEDLE LOOM), 1989 (FEEDING SYSTEM) ADDITIONAL: FEEDING SYSTEM REBUILT / UPGRADED IN 2020 QUANTITY: 1 COMPLETE LINE Learn More

T-9642 DILO NEEDLE LOOM WITH DILO FEEDING SYSTEM, WORKING WIDTH 2500mm, YEAR 1986 TO 1989T-9642 DILO NEEDLE LOOM WITH DILO FEEDING SYSTEM, WORKING WIDTH 2500mm, YEAR 1986 TO 1989 YEAR OF CONSTRUCTION: 1986 (NEEDLE LOOM), 1989 (FEEDING SYSTEM) ADDITIONAL: FEEDING SYSTEM REBUILT / UPGRADED IN 2020 QUANTITY: 1 COMPLETE LINE Learn More -

TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024 THE FOLLOWING WEIGHTS OF NONWOVEN FABRIC CAN BE MADE ON THE PRODUCTION LINE: 200 TO 1000 G/M² LINE EFFICIENCY: 300 KG/H FINAL WORKING WIDTH OF THE NONWOVEN FABRIC: 2500mm POWER SUPPLY: 400 V, 50 Hz, INSTALLED POWER: 62 KW THE LINE IS EQUIPPED WITH MODERN CONTROL IN CONTROL CABINETS NECESSARY AREA FOR THE ROPE: LENGTH: 17000mm, WIDTH: 10000mm, Learn More

TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024 THE FOLLOWING WEIGHTS OF NONWOVEN FABRIC CAN BE MADE ON THE PRODUCTION LINE: 200 TO 1000 G/M² LINE EFFICIENCY: 300 KG/H FINAL WORKING WIDTH OF THE NONWOVEN FABRIC: 2500mm POWER SUPPLY: 400 V, 50 Hz, INSTALLED POWER: 62 KW THE LINE IS EQUIPPED WITH MODERN CONTROL IN CONTROL CABINETS NECESSARY AREA FOR THE ROPE: LENGTH: 17000mm, WIDTH: 10000mm, Learn More