Search results for: 'POLYES'

- Related search terms

- polyester

- polyester mach

- polyester FIBER PRODUCTION

- polyester FIBER'

- Polyester processing

-

K-9173 DOWN, FEATHER, POLY, SILK BEDDING QUILTS, BEDSPREADS, PILLOWS, MATTRESS PROTECTORS, FILLING MATERIALSNATURAL PRODUCTS SYNTHETIC PRODUCTS BEDDING PRODUCTS FILLING MATERIALS Learn More

K-9173 DOWN, FEATHER, POLY, SILK BEDDING QUILTS, BEDSPREADS, PILLOWS, MATTRESS PROTECTORS, FILLING MATERIALSNATURAL PRODUCTS SYNTHETIC PRODUCTS BEDDING PRODUCTS FILLING MATERIALS Learn More -

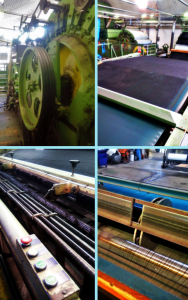

R-6814 LIROPOL TOWEL KNITTING MACHINES, RIUS WARPER, CREELS

R-6814 LIROPOL TOWEL KNITTING MACHINES, RIUS WARPER, CREELSREFERENCE NUMBER: R-6814

LIROPOL TOWEL KNITTING MACHINES, RIUS WARPER, CREELS

(2) X LIROPOL TOWEL KNITTING MACHINES – RUNNING,

MODEL 114133 – YEAR 1994

MACHINE WIDTH 2500mm

GAUGE 12 (NEEDLES PER INCH)

(1) X RIUS WARPER MODEL A-3 30/30

(1) X CREEL WITH STOP MOTION 260 POSITIONS – FOR COTTON

(1) X CREEL FOR WARPER 260 POSITIONS, FOR POLYESTER YARN, WITH HYDRAULIC TENSION CONTROL

(60) X ALUMINUM WARP BEAMS FOR COTTON 21 x 30

(30) X WARP BEAMS, 21 x 21 FOR POLYESTER

(1) X MOTORIZED PLATFORM FOR RIUS WARPER

Learn More -

T-9889 LIBA RASCHEL WARP KNITTING MACHINES, YEAR 1980 TO 1989T-9889 LIBA RASCHEL WARP KNITTING MACHINES, YEAR 1980 TO 1989 ITEM 001 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 4 ITEM 002 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 1 ITEM 003 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 8 ITEM 004 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 1 ITEM 005 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 2 AVAILABLE IMMEDIATELY Learn More

T-9889 LIBA RASCHEL WARP KNITTING MACHINES, YEAR 1980 TO 1989T-9889 LIBA RASCHEL WARP KNITTING MACHINES, YEAR 1980 TO 1989 ITEM 001 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 4 ITEM 002 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 1 ITEM 003 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 8 ITEM 004 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 1 ITEM 005 LIBA RASCHEL WARP KNIT MACHINE QUANTITY: 2 AVAILABLE IMMEDIATELY Learn More -

TT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mmTT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mm THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON TILL CA 30%. COVERSTOK, HYGIENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN TERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTHETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250 OC. ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16 GSM TO MAX 70 GSM (DUPLEX 70 GSM) QUANTITY: 1 Learn More

TT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mmTT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mm THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON TILL CA 30%. COVERSTOK, HYGIENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN TERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTHETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250 OC. ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16 GSM TO MAX 70 GSM (DUPLEX 70 GSM) QUANTITY: 1 Learn More -

K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLCREFERENCE NUMBER: K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLC AUTOMATIC PILLOW MACHINE POWER: 23.45 KW CAPACITY: 6-8 PIECES/MIN CONTROL SYSTEM: SIEMENS PLC LABOR: 1 PERSON VOLTAGE: 380V, 50HZ, 3-PHASE FIBER OPENING RATE: 98% UP WEIGHT: 3650KG CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm MICRO FIBER 0.6D-15D QUANTITY AVAILABLE: 1 Learn More

K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLCREFERENCE NUMBER: K-6063 AUTOMATIC PILLOW FILLING MACHINE SIEMENS PLC AUTOMATIC PILLOW MACHINE POWER: 23.45 KW CAPACITY: 6-8 PIECES/MIN CONTROL SYSTEM: SIEMENS PLC LABOR: 1 PERSON VOLTAGE: 380V, 50HZ, 3-PHASE FIBER OPENING RATE: 98% UP WEIGHT: 3650KG CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm MICRO FIBER 0.6D-15D QUANTITY AVAILABLE: 1 Learn More -

M-3416 BALL FIBER PRODUCTION LINESREFERENCE NUMBER: M-3416 (880ARUGHH7) L BALL FIBER PRODUCTION LINES QUANTITY AVAILABLE: 2 Learn More

M-3416 BALL FIBER PRODUCTION LINESREFERENCE NUMBER: M-3416 (880ARUGHH7) L BALL FIBER PRODUCTION LINES QUANTITY AVAILABLE: 2 Learn More -

M-5064 TSUDAKOMA WIDE WIDTH WATER JET WEAVING LOOMS FOR ACETATE YEAR 2006 WIDTH 3400mmREFERENCE NUMBER: M-5064 (121225HTJ11UX) L TSUDAKOMA WIDE WIDTH WATER JET WEAVING LOOMS FOR ACETATE YEAR 2006 WIDTH 3400mm TSUDAKOMA WATER JET LOOMS MANUFACTURING YEAR: 2006 WIDTH: 3400mm 2 WEFT FEEDERS CRANK SHEDDING 6 SHAFTS THESE LOOMS ARE SPECIAL EXECUTION OF TSUDAKOMA SPECIALLY PRODUCED FOR WIDE WIDTH WATER JET WEAVING SAMPLE WARP CAN BE SIZED FOR TRIAL AND CUSTOMER CAN SEE IT DURING RUNNING IF REQUESTED, 1 PIECE BEAM CAN ALSO BE SUPPLIED FOR ACETATE RUNNING NOW AT 450ppm AT 95% EFFICIENCY INCLUDES 1.5 PCS BEAM AND 1 PC REED QUANTITY AVAILABLE: 36 Learn More

M-5064 TSUDAKOMA WIDE WIDTH WATER JET WEAVING LOOMS FOR ACETATE YEAR 2006 WIDTH 3400mmREFERENCE NUMBER: M-5064 (121225HTJ11UX) L TSUDAKOMA WIDE WIDTH WATER JET WEAVING LOOMS FOR ACETATE YEAR 2006 WIDTH 3400mm TSUDAKOMA WATER JET LOOMS MANUFACTURING YEAR: 2006 WIDTH: 3400mm 2 WEFT FEEDERS CRANK SHEDDING 6 SHAFTS THESE LOOMS ARE SPECIAL EXECUTION OF TSUDAKOMA SPECIALLY PRODUCED FOR WIDE WIDTH WATER JET WEAVING SAMPLE WARP CAN BE SIZED FOR TRIAL AND CUSTOMER CAN SEE IT DURING RUNNING IF REQUESTED, 1 PIECE BEAM CAN ALSO BE SUPPLIED FOR ACETATE RUNNING NOW AT 450ppm AT 95% EFFICIENCY INCLUDES 1.5 PCS BEAM AND 1 PC REED QUANTITY AVAILABLE: 36 Learn More -

TT-2154 TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE, YEAR 1986TT-2154 TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE, YEAR 1986 THE LINE COMPOSED BY: 1. TRUTZSCHLER MODEL MWS 1000, FIBRE OPENER WITH WEIGHING DEVICE (2 PIECES) 2. TRUTZSCHLER MODEL FBM 1000, FIBRE BLENDER WITH CONVEYOR BELT 3. TEMAFA MODEL FFO, FINE OPENER 4. TRUTZSCHLER MODEL FBK 2500, EXACTAFEED CHUTE FEED 5. SPINNBAU CARD DOUBLE DOFFER MODEL 2000 6. RAMISCH KLEINEWEFERS CALENDER TYPE: 2 ROLL CALENDER 7. AURA THERMAL OIL BOILER (ELECTRIC) MODEL E 10 – 220 8. EDELMANN SLITTING - WINDING MACHINE, MODEL 620 – 08 LINES ARE WORKING POLYPROPYLENE POLYESTER POLYAMID, VISCOSE COTTON COVERSTOK, HIGYENE NONWOVENS, DRAPES GOWNS, FILTERS, DRAY WIPES. THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON (UP TO 30% COTTON), COVERSTOK, HIGYENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY. PES OR PET 30GSM AT 80 M/MIN 230 °C WIDTH 2000mm = PRODUCING ABOUT 10,000 SQUARE METERS PER HOUR, UTILIZING 320 KG OF POLYESTER FIBERS PER HOUR. CAPACITY OF LINE 120000mm/MIN KG PER HOUR OUTPUT IN KG/HR DEPEND ON GSM: G/SQUARE METER SPEED, ROLERS TEMPERATURES: EG: 44GSM PRODUCTION 250KG/H TO INCREASE PRODUCTION MORE AND MORE. IT DEPENDS ON THE TYPE OF PROCESSING MIN AND MAXIMUM GSM 16 TO 50 GSM MAXIMUM OUTPUT WIDTH OF THE FINISHED PRODUCT 2200mm HOW IS THE HEATING OF CALENDERING DONE: ELECTRIC POW Learn More

TT-2154 TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE, YEAR 1986TT-2154 TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE, YEAR 1986 THE LINE COMPOSED BY: 1. TRUTZSCHLER MODEL MWS 1000, FIBRE OPENER WITH WEIGHING DEVICE (2 PIECES) 2. TRUTZSCHLER MODEL FBM 1000, FIBRE BLENDER WITH CONVEYOR BELT 3. TEMAFA MODEL FFO, FINE OPENER 4. TRUTZSCHLER MODEL FBK 2500, EXACTAFEED CHUTE FEED 5. SPINNBAU CARD DOUBLE DOFFER MODEL 2000 6. RAMISCH KLEINEWEFERS CALENDER TYPE: 2 ROLL CALENDER 7. AURA THERMAL OIL BOILER (ELECTRIC) MODEL E 10 – 220 8. EDELMANN SLITTING - WINDING MACHINE, MODEL 620 – 08 LINES ARE WORKING POLYPROPYLENE POLYESTER POLYAMID, VISCOSE COTTON COVERSTOK, HIGYENE NONWOVENS, DRAPES GOWNS, FILTERS, DRAY WIPES. THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON (UP TO 30% COTTON), COVERSTOK, HIGYENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY. PES OR PET 30GSM AT 80 M/MIN 230 °C WIDTH 2000mm = PRODUCING ABOUT 10,000 SQUARE METERS PER HOUR, UTILIZING 320 KG OF POLYESTER FIBERS PER HOUR. CAPACITY OF LINE 120000mm/MIN KG PER HOUR OUTPUT IN KG/HR DEPEND ON GSM: G/SQUARE METER SPEED, ROLERS TEMPERATURES: EG: 44GSM PRODUCTION 250KG/H TO INCREASE PRODUCTION MORE AND MORE. IT DEPENDS ON THE TYPE OF PROCESSING MIN AND MAXIMUM GSM 16 TO 50 GSM MAXIMUM OUTPUT WIDTH OF THE FINISHED PRODUCT 2200mm HOW IS THE HEATING OF CALENDERING DONE: ELECTRIC POW Learn More -

TT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mmTT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mm TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250°C ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16GSM TO MAX 50GSM (DUPLEX 70GSM) EXIT TRIMMED WIDTH: 2000mm Learn More

TT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mmTT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mm TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250°C ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16GSM TO MAX 50GSM (DUPLEX 70GSM) EXIT TRIMMED WIDTH: 2000mm Learn More -

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More