Search results for: 'Paper bags'

- Related search terms

- paper bag machines

- Paper Roll Making Machine

- paper rewin

- paper rewindi

- paper rewinding ma

-

TT-4305 MASTER BAG 350 MAKING MACHINE, WIDTH 250mm, YEAR 2024TT-4305 MASTER BAG 350 MAKING MACHINE, WIDTH 250mm, YEAR 2024 CATEGORY: BAG MAKING BRAND: MASTER BAG MODEL: 350 YEAR: 2024 QUANTITY: 1 Learn More

TT-4305 MASTER BAG 350 MAKING MACHINE, WIDTH 250mm, YEAR 2024TT-4305 MASTER BAG 350 MAKING MACHINE, WIDTH 250mm, YEAR 2024 CATEGORY: BAG MAKING BRAND: MASTER BAG MODEL: 350 YEAR: 2024 QUANTITY: 1 Learn More -

TT-3639 BAG MANUFACTURER MACHINE TO PRODUCE ECO FRIENDLY PAPERBAGS THAT ARE MAINLY USED IN BAKERIES, PHARMACIES, FASTFOOD AND RESTAURANTS – NEW, WIDTH 1000mm, YEAR 2023TT-3639 BAG MANUFACTURER MACHINE TO PRODUCE ECO FRIENDLY PAPERBAGS THAT ARE MAINLY USED IN BAKERIES, PHARMACIES, FASTFOOD AND RESTAURANTS – NEW, WIDTH 1000mm, YEAR 2023 BAG MANUFACTURER MACHINE TO PRODUCE ECO FRIENDLY PAPERBAGS THAT ARE MAINLY USED IN BAKERIES, PHARMACIES, FASTFOOD AND RESTAURANTS NEW YEAR: 2023 Learn More

TT-3639 BAG MANUFACTURER MACHINE TO PRODUCE ECO FRIENDLY PAPERBAGS THAT ARE MAINLY USED IN BAKERIES, PHARMACIES, FASTFOOD AND RESTAURANTS – NEW, WIDTH 1000mm, YEAR 2023TT-3639 BAG MANUFACTURER MACHINE TO PRODUCE ECO FRIENDLY PAPERBAGS THAT ARE MAINLY USED IN BAKERIES, PHARMACIES, FASTFOOD AND RESTAURANTS – NEW, WIDTH 1000mm, YEAR 2023 BAG MANUFACTURER MACHINE TO PRODUCE ECO FRIENDLY PAPERBAGS THAT ARE MAINLY USED IN BAKERIES, PHARMACIES, FASTFOOD AND RESTAURANTS NEW YEAR: 2023 Learn More -

TT-3385 MASTER BAG 350, WIDTH 250mm, YEAR 2023TT-3385 MASTER BAG 350, WIDTH 250mm, YEAR 2023 CATEGORY BAG MAKING BRAND MASTER BAG MODEL 350 YEAR 2023 QUANTITY: 1 Learn More

TT-3385 MASTER BAG 350, WIDTH 250mm, YEAR 2023TT-3385 MASTER BAG 350, WIDTH 250mm, YEAR 2023 CATEGORY BAG MAKING BRAND MASTER BAG MODEL 350 YEAR 2023 QUANTITY: 1 Learn More -

TT-3167 GARANT 3030 NG FLAT & GUSSETED BAG MACHINE, WIDTH 60 TO 380mm, YEAR 2012TT-3167 GARANT 3030 NG FLAT & GUSSETED BAG MACHINE, WIDTH 60 TO 380mm, YEAR 2012 AVAILABILITY: IMMEDIATE INSPECTION QUANTITY: 1 Learn More

TT-3167 GARANT 3030 NG FLAT & GUSSETED BAG MACHINE, WIDTH 60 TO 380mm, YEAR 2012TT-3167 GARANT 3030 NG FLAT & GUSSETED BAG MACHINE, WIDTH 60 TO 380mm, YEAR 2012 AVAILABILITY: IMMEDIATE INSPECTION QUANTITY: 1 Learn More -

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More -

P-4338 TOILET TISSUE PAPER PACKING MACHINE

P-4338 TOILET TISSUE PAPER PACKING MACHINEREFERENCE NUMBER: P-4338

TOILET TISSUE PAPER PACKING MACHINE

Model: TL-R

Machine Characteristic

Control system: PLC

Drive element: servo motor

Operate interface: LCD touch screen

Packing style: back sealing by interfold sealing type, end sealing by flat type

Detection online: roll tissue deliver detect

Auto feeding: servo motor synchronous feeding

Specifications

Suitable production: paper in roll adaptable

Production size: L90-230mm,φ80-130mm

Suitable packing material: OPP CPP PE etc. heat-seal material

Packing Film specification: max W450mm,φ350mm

Diameter of ventilating shaft :3"

Production speed: 80 bags/min design 100 bags/min

Machine space: L7250mm W1900mm H1650mm

Power: AC380V 50/60Hz 15KW

Compressed air:0.6-0.8Mpa 0.5m³ /min

Machine net weight: 1500kg

Option equipment: Coding machine, Roll paper storage machine, Roll paper flail knifeQUANTITY: 1

Learn More -

T-8543 4 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 60 TO 120 BAGS PER MINUTET-8543 4 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 60 TO 120 BAGS PER MINUTE 4 SIDE SEALING WET WIPES MACHINE DRIVE MODE: AUTOMATIC STABLE SPEED: 60 TO 120 BAGS PER MINUTE MACHINE SIZE (L X W X H): 3000mm × 2500mm × 1800mm QUANTITY: 1 Learn More

T-8543 4 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 60 TO 120 BAGS PER MINUTET-8543 4 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 60 TO 120 BAGS PER MINUTE 4 SIDE SEALING WET WIPES MACHINE DRIVE MODE: AUTOMATIC STABLE SPEED: 60 TO 120 BAGS PER MINUTE MACHINE SIZE (L X W X H): 3000mm × 2500mm × 1800mm QUANTITY: 1 Learn More -

TT-3899 F+K FLAT BOTTOM / HOLWEG PERFORATION / W+H BAG MACHINESTT-3899 F+K FLAT BOTTOM / HOLWEG PERFORATION / W+H BAG MACHINES ITEM 001 F+K FLAT BOTTOM BAG MACHINE (GREEN) NO PRINTER ITEM 002 HOLWEG RS.1 (MACHINE F6- BLUE) HOLWEG PERFORATION BAG MACHINE IN OPERATION ITEM 003 W+H /GERMAN MADE/ MACHINE FOR THE PRODUCTION OF TRIANGULAR CONICAL BAGS BY W&H ROTATION IN LINE WITH A 2 COLOR PRINTER. YEAR OF PRODUCTION: UNKNOWN – A GOOD CONDITION – SEE PHOTO ATTACHED- VIDEO ON DEMAND Learn More

TT-3899 F+K FLAT BOTTOM / HOLWEG PERFORATION / W+H BAG MACHINESTT-3899 F+K FLAT BOTTOM / HOLWEG PERFORATION / W+H BAG MACHINES ITEM 001 F+K FLAT BOTTOM BAG MACHINE (GREEN) NO PRINTER ITEM 002 HOLWEG RS.1 (MACHINE F6- BLUE) HOLWEG PERFORATION BAG MACHINE IN OPERATION ITEM 003 W+H /GERMAN MADE/ MACHINE FOR THE PRODUCTION OF TRIANGULAR CONICAL BAGS BY W&H ROTATION IN LINE WITH A 2 COLOR PRINTER. YEAR OF PRODUCTION: UNKNOWN – A GOOD CONDITION – SEE PHOTO ATTACHED- VIDEO ON DEMAND Learn More -

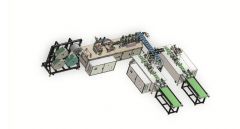

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTE

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTEITEM 001 - MASK PRODUCTION MACHINE WITH (2) ULTRASONIC EAR STRAP WELDING DEVICES

FOR THE PRODUCTION OF SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% (N95)

CAPACITY: 50 FOLDED N95 MASKS PER MINUTE

MASK DIMENSIONS: 175mm x 95mm

MATERIAL TYPE: 3 LAYERS OF POLYPROPYLENE NONWOVEN COMPOSITE FIBER

OPERATION CONTROLLED BY LCD TOUCH SCREEN

AUTOMATICALLY ALIGNS 3 ROLLS OF MATERIAL TO FEED IN (OUTER, FILTER AND INNER LAYERS)

PRESSES BOTH SIDES TOGETHER SYMMETRICALLY WHILE WELDING WITH ULTRASONIC HEAD

SPLITS TO 2 SERPATE WELDING DEVICES FOR EARLOOPS AND SENDS TO DIGITAL COUNTER

EARLOOPS ARE FINISHED WITH ULTRASONIC CUTTING AND WELDING

NOSE BRIDGE CAN BE PRODUCED WITH AUTOMATIC FEEDING, CUTTING AND ULTRASONIC WELDING

ULTRASONIC HEADS

VOLTAGE: 220 VOLTS

WATTS CAPACITY: 1500 WATT

FREQUENCY (KHZ): 20 KHZ

WARRANTY PERIOD FOR HEADS: 1 YEAR

COMPONENT MANUFACTURERS

SERVO MOTOR: PANASONIC / SCHNEIDER

CONTROL SYSTEM: PROPRIETARY

ULTRASONIC GENERATOR: PROPRIETARY, 220 VOLTS, 1.5 KW, 20 KHZ

SENSOR: OMRON / SICK

PNEUMATIC COMPONENT: SMC / FESTO

BELT: SAMSUNG / BANDO

MAIN BODY: PRE-MADE MATERIAL, WELDED ASSEMBLY

BEARINGS: NSK

BALL SCREWS: HIWIN

SECURITY DEVICE: SICK (SAFETY DEVICES TO PROTECT WORKERS)

TOTAL POWER: 4 KW

MACHINE MUST BE STOPPED TO FEED NEW ROLL OF MATERIAL

END OF ROLL DETECTOR INCLUDED: WHEN FABRIC IS FINISHED THE MACHINE WILL ALARM AND STOP

AIR PRESSURE: 0.6 MPa

VOLTAGE: 220 VOLTS, 60 Hz

DIMENSIONS: 6400mm x 4700mm x 1700mm

INCLUDES ELECTRONIC MANUAL BOOK (STORED ON USB MEMORY) AND WARRANTY CARD

OPTIONS (INQUIRE FOR PRICING): EAR STRAP FOLDER

ITEM 001 QUANTITY: 1 MASK PRODUCTION MACHINE AND 2 ULTRASONIC WELDING DEVICES FOR EAR STRAPS

ITEM 002 AUTOMATIC BAGGING MACHINE

SUITABLE FOR AUTOMATIC BAGGING OPERATIONS FOR VARIOUS MASK TYPES

MOTOR CONTROL SYSTEM: SERVO (3), AUTOMATICALLY SETS BAG LENGTH (UP TO 400mm) FOR SPECIFIED BAGGING LENGTH, WITH ANTI-AIR BAG , AUTOMATICALLY DETECTS PRODUCT BASE POINT AND MATERIAL POSITION, AUTOMATIC STOP WHEN OUT OF MATERIAL & STARTS WHEN MATERIAL IS PRESENT

FAST & CONVENIENT SETTING OF PARAMETERS, STORES SETS OF PARAMETERS FOR MULTIPLE PRODUCTS, OPERATOR CAN CHOOSE PARAMETERS ACCORDING TO PRODUCT SIZES

DIAGNOSTICS SYSTEM CLEARS ERROR & RESETS IN SINGLE STEP

HIGHLY SENSITIVE PHOTOELECTRIC EYE COLOR MARK TRACKER, DIGITAL INPUT SEAL/CUT POSITION MAKES SEAL & CUT POSITIONS MORE ACCURATE

TEMPERATURE CONTROLLED WITH INDEPENDENT PID, ALLOWS FOR VARIOUS MATERIALS IN PACKAGING

SIMPLE TRANSMISSION SYSTEM ALLOWS FOR EASY MAINTENANCE AND RELIABILITY

ALL CONTROLS SET BY SOFTWARE ALLOWING FOR ADJUSTING OF FUNCTIONS AND UPGRADES

MATERIALS

PVC FILM (HEAT SEALING), BOPP, OPP, CPP, ALUMINIZED PET FILM, ALUMINUM-PLASTIC FILM, PAPER FILM, PAPER GLUE, OTHER SINGLE- OR MULTIPLE-LAYERED HEAT-SEALED DIALYZABLE MATERIALS, ETC.

LENGTH OF PACKAGE BAGS: ≤400mm

WIDTH OF PACKAGE BAGS: 100 TO 165mm

HEIGHT OF PRODUCT: 55mm MAXIMUM

LENGTH OF FILM: 360mm MAXIMUM

DIAMETER OF FILM ROLL: 320mm MAXIMUM

CAPACITY/SPEED OF PACKAGING: 40 TO 230 BAGS PER MINUTE (1 TO 20 PIECES PER BAG)

POWER: 220 VOLTS, 50 OR 60 Hz, 2.4 KW

DIMENSIONS: 4050mm x 750mm x 1450mm

WEIGHT: APPROXIMATELY 300 KGS

COMPONENT MANUFACTURERS

TOUCH SCREEN: WEINVIEW

SERVO MOTOR: DORNA / WEIDE

SERVO CONTROLLER: DORNA / WEIDE

PROXIMITY SWITCH: OMRON

PHOTOELECTRIC SWITCH: OETAI

TEMPERATURE CONTROLLER: YATAI

SOLID STATE RELAY: SCHNEIDER

INTERMEDIATE RELAY: WEIDMUELLER

OPTIONS, INQUIRE FOR PRICING: STRAIGHT GRAIN SEALING, STAINLESS STEEL FRAME, CODE STAMPER (PRODUCTION DATE), EXHAUST (PINHOLE EXHAUST FEATURE)

ITEM 002 QUANTITY: 1 BAGGING MACHINE

ENTIRE LINE COMPOSED OF ITEM 001 AND ITEM 002

Learn More -

M-7783 CONSTANTA TEEPACK STRING AND TAG TEABAGGING MACHINES

M-7783 CONSTANTA TEEPACK STRING AND TAG TEABAGGING MACHINESREFERENCE NUMBER: M-7783

CONSTANTA TEEPACK STRING AND TAG TEABAGGING MACHINES

TEABAGGING MACHINES

TYPE: STRING AND TAG

MAKE: TEEPACK

MODEL: CONSTANTA

DOUBLE CHAMBER FILTER BAG WITH NATURAL FILTER PAPER (NOT HEAT-SEALABLE), WITH THREAD/TAG, CLOSED BY

PREFER TO BE SOLD AS ONE GROUP OF MACHINES

QUANTITY: 6

Learn More