Search results for: 'backing'

-

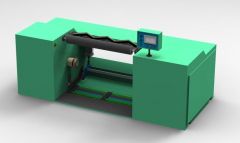

T-6391 GUILLOTINE CUTTING MACHINE FOR NON-WOVEN, WIDTH 2400mm, YEAR 1997 TO 1998

T-6391 GUILLOTINE CUTTING MACHINE FOR NON-WOVEN, WIDTH 2400mm, YEAR 1997 TO 1998KNEE LEVER SCISSORS

Learn More

MAKE MOHR / FLEISSNER

CUTTING WIDTH: 2400mm

YEAR 1997 - EXCHANGE THE WHOLE CUTTING BARK AND BACKING KNIFES

YEAR 1998 - HYDRAULIC UNIT COMPLETELY NEW

YEAR 1998 - KNIFE BAR SYSTEM AND LOWER KNIFE COMPLETELY NEW

KNIFE BAR HAS TWO-SIDED HOLD DOWN WITH KNIFE GUIDE, KNIFE AND LOWER KNIFE AS NEW

HYDRAULIC CYLINDER SEAL KIT - NEW

HYDRAULIC OIL - NEW

MACHINE IS IN GOOD CONDITION

BLADE IS IN GOOD CONDITION

WE ARE CUTTING WOOL FLEECE UP TO 4000 GR/M² WITHOUT ANY PROBLEMS

POWER: 400 V, 50 HZ, 8.0 KW

SPACE REQUIREMENTS: L: 4250mm X B 1900mm X H 2600mm

THIS MACHINE IS AVAILABLE IMMEDIATELY -

E-4400 QUILTED FOAM WASTE REPROCESSING MACHINEINVENTORY NUMBER: E-4400 QUILTED FOAM WASTE REPROCESSING MACHINE THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING QUANTITY AVAILABLE: 1 Learn More

E-4400 QUILTED FOAM WASTE REPROCESSING MACHINEINVENTORY NUMBER: E-4400 QUILTED FOAM WASTE REPROCESSING MACHINE THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING QUANTITY AVAILABLE: 1 Learn More -

K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW)REFERENCE NUMBER: K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW) THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING. THE MACHINE'S CUTTING TOOLS ARE IMPORTED FROM GERMANY. THE MACHINE CAN CUT THE FOAM INTO REGULAR PIECES AND WITHOUT PRODUCING WASTE POWDER AND CAN ALSO CUT QUILTED FOAM FABRIC WASTE; FOR EXAMPLE MATTRESS TICKING WITH FIBERFILL AND NONWOVEN-BACKING. ORDINARILY QUILTED FABRIC WASTE CANNOT BE REUSED BUT WITH OUR QUILTED FABRIC WASTE AND FOAM CUTTING MACHINE, THE MANUFACTURER CAN RECLAIM THIS WASTE. BY CUTTING THE QUILTED FABRIC WASTE IT IS TRANSFORMED INTO LITTLE PIECES, AND IT CAN BE USED AS FILLING MATERIAL FOR PILLOWS, CUSHIONS, ETC. QUANTITY AVAILABLE: 1 Learn More

K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW)REFERENCE NUMBER: K-3236 QUILTED FOAM WASTE REPROCESSING MACHINE (NEW) THIS MACHINE IS SUITABLE FOR FOAM WASTE REPROCESSING OR FOAM RECYCLING. THE MACHINE'S CUTTING TOOLS ARE IMPORTED FROM GERMANY. THE MACHINE CAN CUT THE FOAM INTO REGULAR PIECES AND WITHOUT PRODUCING WASTE POWDER AND CAN ALSO CUT QUILTED FOAM FABRIC WASTE; FOR EXAMPLE MATTRESS TICKING WITH FIBERFILL AND NONWOVEN-BACKING. ORDINARILY QUILTED FABRIC WASTE CANNOT BE REUSED BUT WITH OUR QUILTED FABRIC WASTE AND FOAM CUTTING MACHINE, THE MANUFACTURER CAN RECLAIM THIS WASTE. BY CUTTING THE QUILTED FABRIC WASTE IT IS TRANSFORMED INTO LITTLE PIECES, AND IT CAN BE USED AS FILLING MATERIAL FOR PILLOWS, CUSHIONS, ETC. QUANTITY AVAILABLE: 1 Learn More -

M-5212 MARTINDALE ABRASION AND PILLING TESTERSREFERENCE NUMBER: M-5212 (131311DCP12UC) L MARTINDALE ABRASION AND PILLING TESTERS MARTINDALE ABRASION AND PILLING TESTERS MODEL: C13C TO DETERMINE THE ABRASION AND PILLING RESISTANCE OF ALL KINDS OF TEXTILE STRUCTURES SAMPLES ARE RUBBED AGAINST KNOWN ABRADENTS AT LOW PRESSURES AND IN CONTINUOUSLY CHANGING DIRECTIONS AND THE AMOUNT OF ABRASION OR PILLING IS COMPARED AGAINST STANDARD PARAMETERS. THE UNIQUE DESIGN ALLOWS REMOVAL OF INDIVIDUAL SAMPLE HOLDERS FOR EXAMINATION WITHOUT LIFTING THE TOP MOTION PLATE STANDARD SAMPLE HOLDERS AND 9 AND 12KPA WEIGHTS ARE INCLUDED FEATURES: FIVE TEST PATTERNS (24 x 24, 24 x 60, 60 x 60 LISSAJOUS FIGURE CURVE, 60, 24 STRAIGHT LINE PATTERN) TWO KINDS OF COUNTING METHODS, POSITIVE COUNTING AND NEGATIVE COUNTING METHOD GUIDE PLATE DESIGN WITHOUT TURNING OVER, SAMPLE WITHOUT MOVEMENT PLC MODULARIZATION CONTROL, SEVEN INCHES COLOR TOUCH SCREEN SERVO SYSTEM SYSTEMATIC ELECTRIC MOTOR IS WITH STABLE OPERATION AND WITHOUT NOISE FULL ALUMINUM COVER PLATE, MODULES OF STAINLESS STEEL GRINDING HEAD AND HEAVY PUNCH, ETC. KEY SPECIFICATIONS: CONTROL MODE: PLC CONTROL AND TOUCH SCREEN DISPLAY COUNTER RANGE: 0 – 999999 TIMES RELATIVE MOVEMENT SPEED (HOLDER AND PLATFORM): 50±2R/MIN (20-70R/MIN SETTABLE) SAMPLING HAMMER MASS: 2385±10G WEIGHT: 148KG DIMENSION: 89 x 72 x 65CM STANDARDS: ISO 5470, ISO 12945, ISO 12947, ASTM 4966/4970 STANDARD ACCESSORIES: WEIGHT 9 AND 12 KPA STANDARD ABRADENTS FABRIC – 2 PCS FOR EACH HEAD STANDARD BACKING FOAM 38mm BOX OF 60PCS STANDARD WOVEN FELT DISCS 140mm – 2 PCS FOR EACH HEAD STANDARD WOVEN FELT DISCS 90mm – 2 PCS FOR EACH HEAD PHOTOGRAPHS (COPY ONE) ENGLISH MANUAL CERTIFICATE OF QUALITY OPTIONAL ACCESSORIES: SAMPLE CUTTER 38mm, 90mm, 140mm PHOTOGRAPHS (MADE IN UK) QUANTITY: 1 Learn More

M-5212 MARTINDALE ABRASION AND PILLING TESTERSREFERENCE NUMBER: M-5212 (131311DCP12UC) L MARTINDALE ABRASION AND PILLING TESTERS MARTINDALE ABRASION AND PILLING TESTERS MODEL: C13C TO DETERMINE THE ABRASION AND PILLING RESISTANCE OF ALL KINDS OF TEXTILE STRUCTURES SAMPLES ARE RUBBED AGAINST KNOWN ABRADENTS AT LOW PRESSURES AND IN CONTINUOUSLY CHANGING DIRECTIONS AND THE AMOUNT OF ABRASION OR PILLING IS COMPARED AGAINST STANDARD PARAMETERS. THE UNIQUE DESIGN ALLOWS REMOVAL OF INDIVIDUAL SAMPLE HOLDERS FOR EXAMINATION WITHOUT LIFTING THE TOP MOTION PLATE STANDARD SAMPLE HOLDERS AND 9 AND 12KPA WEIGHTS ARE INCLUDED FEATURES: FIVE TEST PATTERNS (24 x 24, 24 x 60, 60 x 60 LISSAJOUS FIGURE CURVE, 60, 24 STRAIGHT LINE PATTERN) TWO KINDS OF COUNTING METHODS, POSITIVE COUNTING AND NEGATIVE COUNTING METHOD GUIDE PLATE DESIGN WITHOUT TURNING OVER, SAMPLE WITHOUT MOVEMENT PLC MODULARIZATION CONTROL, SEVEN INCHES COLOR TOUCH SCREEN SERVO SYSTEM SYSTEMATIC ELECTRIC MOTOR IS WITH STABLE OPERATION AND WITHOUT NOISE FULL ALUMINUM COVER PLATE, MODULES OF STAINLESS STEEL GRINDING HEAD AND HEAVY PUNCH, ETC. KEY SPECIFICATIONS: CONTROL MODE: PLC CONTROL AND TOUCH SCREEN DISPLAY COUNTER RANGE: 0 – 999999 TIMES RELATIVE MOVEMENT SPEED (HOLDER AND PLATFORM): 50±2R/MIN (20-70R/MIN SETTABLE) SAMPLING HAMMER MASS: 2385±10G WEIGHT: 148KG DIMENSION: 89 x 72 x 65CM STANDARDS: ISO 5470, ISO 12945, ISO 12947, ASTM 4966/4970 STANDARD ACCESSORIES: WEIGHT 9 AND 12 KPA STANDARD ABRADENTS FABRIC – 2 PCS FOR EACH HEAD STANDARD BACKING FOAM 38mm BOX OF 60PCS STANDARD WOVEN FELT DISCS 140mm – 2 PCS FOR EACH HEAD STANDARD WOVEN FELT DISCS 90mm – 2 PCS FOR EACH HEAD PHOTOGRAPHS (COPY ONE) ENGLISH MANUAL CERTIFICATE OF QUALITY OPTIONAL ACCESSORIES: SAMPLE CUTTER 38mm, 90mm, 140mm PHOTOGRAPHS (MADE IN UK) QUANTITY: 1 Learn More -

M-4788 ER-WE-PA EXTRUSION COATER LAMINATOR YEAR 1985 WEB WIDTH 1575mmREFERENCE NUMBER: M-4788 (1111KYWJXX10) L ER-WE-PA EXTRUSION COATER LAMINATOR YEAR 1985 WEB WIDTH 1575mm ER-WE-PA EXTRUSION COATER LAMINATOR, 1985 YEAR WEB WIDTH: 1575 mm (62 IN) L/D(S): 30:1 DRIVE SYSTEM: DC DRIVE SPEED: 366 MPM (1200 FPM) EXTRUDER(S): ER-WE-PA PRIME COATER: NONE SIZE(S): 4-1/2" 3-1/2" PRIMARY UNWIND: NONE SECONDARY UNWIND: NONE REWIND: NONE DRYER TYPE: NONE USED ER-WE-PA EXTRUSION COATER LAMINATOR STATION EQUIPPED WITH EXTRUSION COATER WITH 27" DIAMETER X 72" FACE CHILL ROLL 7.5" DIAMETER RUBBER COVERED NIP ROLL, 12" DIAMETER CHROME BACKING ROLL, 14" DIAMETER SECONDARY CHILL ROLL, RAZOR EDGE TRIM SECTION 72" EDI/WELEX AUTOFLEX SHEET EXTRUSION DIE DIE WITH EXTERNAL DECKLING 4.5" AND 3.5" ER-WE-PA EXTRUDERS WITH 30:1 L/D; EXTRUDERS MOUNTED ON XYZ CARRIAGE. MACHINE DOES NOT INCLUDE AN UNWIND OR REWIND. QUANTITY AVAILABLE: 1 Learn More

M-4788 ER-WE-PA EXTRUSION COATER LAMINATOR YEAR 1985 WEB WIDTH 1575mmREFERENCE NUMBER: M-4788 (1111KYWJXX10) L ER-WE-PA EXTRUSION COATER LAMINATOR YEAR 1985 WEB WIDTH 1575mm ER-WE-PA EXTRUSION COATER LAMINATOR, 1985 YEAR WEB WIDTH: 1575 mm (62 IN) L/D(S): 30:1 DRIVE SYSTEM: DC DRIVE SPEED: 366 MPM (1200 FPM) EXTRUDER(S): ER-WE-PA PRIME COATER: NONE SIZE(S): 4-1/2" 3-1/2" PRIMARY UNWIND: NONE SECONDARY UNWIND: NONE REWIND: NONE DRYER TYPE: NONE USED ER-WE-PA EXTRUSION COATER LAMINATOR STATION EQUIPPED WITH EXTRUSION COATER WITH 27" DIAMETER X 72" FACE CHILL ROLL 7.5" DIAMETER RUBBER COVERED NIP ROLL, 12" DIAMETER CHROME BACKING ROLL, 14" DIAMETER SECONDARY CHILL ROLL, RAZOR EDGE TRIM SECTION 72" EDI/WELEX AUTOFLEX SHEET EXTRUSION DIE DIE WITH EXTERNAL DECKLING 4.5" AND 3.5" ER-WE-PA EXTRUDERS WITH 30:1 L/D; EXTRUDERS MOUNTED ON XYZ CARRIAGE. MACHINE DOES NOT INCLUDE AN UNWIND OR REWIND. QUANTITY AVAILABLE: 1 Learn More -

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More