Search results for: 'mat''

-

G-3179 FOAM MATTRESS COVERING MACHINEREFERENCE NUMBER G-3179 FOAM MATTRESS COVERING MACHINE MODEL: 303 DIMENSIONS: 2500 X 1350 X 1540MM POWER: 3KW NET WEIGHT: 500KG CAPACITY: 20SECONDS/PCS MATTRESS WIDTH: 750-2000MM MATTRESS THICKNESS: 150-300MM(MINIMUM IS: 15CM, MAXIMUM IS: 30CM) QUANTITY AVAILABLE: 1 Learn More

G-3179 FOAM MATTRESS COVERING MACHINEREFERENCE NUMBER G-3179 FOAM MATTRESS COVERING MACHINE MODEL: 303 DIMENSIONS: 2500 X 1350 X 1540MM POWER: 3KW NET WEIGHT: 500KG CAPACITY: 20SECONDS/PCS MATTRESS WIDTH: 750-2000MM MATTRESS THICKNESS: 150-300MM(MINIMUM IS: 15CM, MAXIMUM IS: 30CM) QUANTITY AVAILABLE: 1 Learn More -

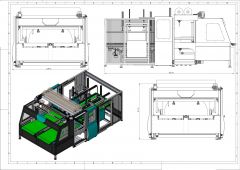

J-3671 AUTOMATIC MATTRESS PACKING MACHINEJ-3671 AUTOMATIC MATTRESS PACKING MACHINE PRODUCTION CAPACITY: 30 SECONDS PER MATTRESS WITH PNEUMATIC PRESS WITH AUTOMATIC SIZING SYSTEM WITH AUTOMATIC WATER-COOLING SYSTEM (GIVES A BETTER SEAL) POWER REQUIREMENT: 6.5 KW / 380 VOLTS QUANTITY: 1 Learn More

J-3671 AUTOMATIC MATTRESS PACKING MACHINEJ-3671 AUTOMATIC MATTRESS PACKING MACHINE PRODUCTION CAPACITY: 30 SECONDS PER MATTRESS WITH PNEUMATIC PRESS WITH AUTOMATIC SIZING SYSTEM WITH AUTOMATIC WATER-COOLING SYSTEM (GIVES A BETTER SEAL) POWER REQUIREMENT: 6.5 KW / 380 VOLTS QUANTITY: 1 Learn More -

TT-6324 MATTRESS WRAPPER MACHINE, WIDTH 2200mm, YEAR 2022TT-6324 MATTRESS WRAPPER MACHINE, WIDTH 2200mm, YEAR 2022 1. MATTRESS WRAPPER MACHINE 2. MANUFACTURING YEAR 2022 3. AND THE DELIVERY DATE IS 2023 QUANTITY: 1 Learn More

TT-6324 MATTRESS WRAPPER MACHINE, WIDTH 2200mm, YEAR 2022TT-6324 MATTRESS WRAPPER MACHINE, WIDTH 2200mm, YEAR 2022 1. MATTRESS WRAPPER MACHINE 2. MANUFACTURING YEAR 2022 3. AND THE DELIVERY DATE IS 2023 QUANTITY: 1 Learn More -

YY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPMYY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPM FEATURES: 1. MAXIMUM SPEED: 3000RPM; 2. PRODUCTIVITY: 10 M/MIN; 3. ZIPPER WIDTH: 32mm (OTHERS SIZES CAN BE CUSTOMIZED); 4. FINISHED PRODUCTS WIDTH: ≤350mm (CUSTOMIZABLE); 5. ZIPPER RELATIVE POSITION CAN BE ADJUSTED ACCORDING TO THE PRODUCT TECHNICS; 6. SYNCHRONOUS CUTTER DESIGN, PNEUMATIC CONTROL CUTTER PRESSURE, EASY TO MAKE ADJUSTMENT; 7. MATTRESS BORDER LEFT-RIGHT LIMITS SET-GUIDE MECHANISM, APPLY FOR BORDER WIDTH AND LEFT RIGHT POSITION ADJUSTMENT; 8. AUTOMATIC THREAD BREAKAGE DETECT. 9. PRODUCTION OUTPUT COUNTING FUNCTION. 10. AUTOMATIC WINDING FUNCTION. 11. MATTRESS BORDER WIDTH: MAXIMUM 350mm, OTHER WIDTH CAN BE CUSTOMIZED; 12. WITH PNEUMATIC CUTTING KNIFE; 13. WITH THREAD BROKEN DETECTIVE FUNCTION; 14. WITH PRODUCTION COUNTING FUNCTION; 15. WITH AUTO RE-ROLLING FUNCTION; 16. STITCH TYPE: MULTI-NEEDLES DOUBLE THREAD CHAIN STITCH; 17. NEEDLE QUANTITY: 4 NEEDLES; 18. STITCH LINE DISTANCE: 1/4-1/2-1/4; 19. STITCH LENGTH: 5-6 STITCHES PER INCH; 20. MAX SEWING THICKNESS: 8mm; 21. POWER: SINGLE PHASE, 220V; 22. POWER CAPACITY: 2.2KW; 23. INSTALLATION SIZE: 4100X1100X1900mm. QUANTITY: 1 Learn More

YY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPMYY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPM FEATURES: 1. MAXIMUM SPEED: 3000RPM; 2. PRODUCTIVITY: 10 M/MIN; 3. ZIPPER WIDTH: 32mm (OTHERS SIZES CAN BE CUSTOMIZED); 4. FINISHED PRODUCTS WIDTH: ≤350mm (CUSTOMIZABLE); 5. ZIPPER RELATIVE POSITION CAN BE ADJUSTED ACCORDING TO THE PRODUCT TECHNICS; 6. SYNCHRONOUS CUTTER DESIGN, PNEUMATIC CONTROL CUTTER PRESSURE, EASY TO MAKE ADJUSTMENT; 7. MATTRESS BORDER LEFT-RIGHT LIMITS SET-GUIDE MECHANISM, APPLY FOR BORDER WIDTH AND LEFT RIGHT POSITION ADJUSTMENT; 8. AUTOMATIC THREAD BREAKAGE DETECT. 9. PRODUCTION OUTPUT COUNTING FUNCTION. 10. AUTOMATIC WINDING FUNCTION. 11. MATTRESS BORDER WIDTH: MAXIMUM 350mm, OTHER WIDTH CAN BE CUSTOMIZED; 12. WITH PNEUMATIC CUTTING KNIFE; 13. WITH THREAD BROKEN DETECTIVE FUNCTION; 14. WITH PRODUCTION COUNTING FUNCTION; 15. WITH AUTO RE-ROLLING FUNCTION; 16. STITCH TYPE: MULTI-NEEDLES DOUBLE THREAD CHAIN STITCH; 17. NEEDLE QUANTITY: 4 NEEDLES; 18. STITCH LINE DISTANCE: 1/4-1/2-1/4; 19. STITCH LENGTH: 5-6 STITCHES PER INCH; 20. MAX SEWING THICKNESS: 8mm; 21. POWER: SINGLE PHASE, 220V; 22. POWER CAPACITY: 2.2KW; 23. INSTALLATION SIZE: 4100X1100X1900mm. QUANTITY: 1 Learn More -

TT-8638 FISHMEAL PLANT, 10 MT PER HOUR RAW MATERIAL INTAKETT-8638 FISHMEAL PLANT, 10 MT PER HOUR RAW MATERIAL INTAKE 1. COMPLETE PROCESSING LINE 2. CONSISTING OF: INFEED MILL BREAKER, ATLAS VERTICAL COOKER, ATLAS SCREW PRESS, ATLAS DISC DRYER, ALFA LAVAL DECANTER, FLOTTWEG TRICANTER, 3 EFFECT EVAPORATOR, COOLING TOWERS, MORISA BOILERS, CONVEYING, CONTROLS AND ADDITIONAL INFRASTRUCTURE. Learn More

TT-8638 FISHMEAL PLANT, 10 MT PER HOUR RAW MATERIAL INTAKETT-8638 FISHMEAL PLANT, 10 MT PER HOUR RAW MATERIAL INTAKE 1. COMPLETE PROCESSING LINE 2. CONSISTING OF: INFEED MILL BREAKER, ATLAS VERTICAL COOKER, ATLAS SCREW PRESS, ATLAS DISC DRYER, ALFA LAVAL DECANTER, FLOTTWEG TRICANTER, 3 EFFECT EVAPORATOR, COOLING TOWERS, MORISA BOILERS, CONVEYING, CONTROLS AND ADDITIONAL INFRASTRUCTURE. Learn More -

H-1289 SEMI-AUTOMATIC MATTRESS COMPRESSION MACHINE, PRESS PLATE TYPEH-1289 SEMI-AUTOMATIC MATTRESS COMPRESSION MACHINE, PRESS PLATE TYPE VACUUM COMPRESSED PACKING FOR MATTRESS COMPRESSION MAINLY USED FOR ALL TYPES OF FOAM MATTRESSES OR SPRING MATTRESSES • MAXIMUM LIFTING DISTANCE: 500mm • TOTAL MACHINE MAXIMUM PRESSURE : 50 TONS • OIL PUMP POWER : 7.5 KW • OIL CYLINDER QUANTITY : 4 • MACHINE VOLUME: 13 CUBIC METERS, REQUIRES (1) 20-FOOT CONTAINER TO SHIP QUANTITY: 1 Learn More

H-1289 SEMI-AUTOMATIC MATTRESS COMPRESSION MACHINE, PRESS PLATE TYPEH-1289 SEMI-AUTOMATIC MATTRESS COMPRESSION MACHINE, PRESS PLATE TYPE VACUUM COMPRESSED PACKING FOR MATTRESS COMPRESSION MAINLY USED FOR ALL TYPES OF FOAM MATTRESSES OR SPRING MATTRESSES • MAXIMUM LIFTING DISTANCE: 500mm • TOTAL MACHINE MAXIMUM PRESSURE : 50 TONS • OIL PUMP POWER : 7.5 KW • OIL CYLINDER QUANTITY : 4 • MACHINE VOLUME: 13 CUBIC METERS, REQUIRES (1) 20-FOOT CONTAINER TO SHIP QUANTITY: 1 Learn More -

K-8622 MATTRESS WRAPPER -FULLY AUTOMATIC HIGH CAPACITY-WITH PRESSINGREFERENCE NUMBER: K-8622 MATTRESS WRAPPER -FULLY AUTOMATIC HIGH CAPACITY-WITH PRESSING WITH SELP-ADJUSTMENT FOR PACKING DIFFERENT SIZES OF PRODUCTS IT ALLOWS UP TO 2 WRAPS PER MINUTE WITH EXCELLENT QUALITY THANKS TO 2 TONS PRESS AND TIGHTENING MECHANISMS MAX. PRESS LOAD CAPACITY: 2 TONS MAX. MATTRESS SIZE: 210 CM X 210 CM SETUP AREA: 3.5 M X 6.5 M QUANTITY AVAILABLE: 1 Learn More

K-8622 MATTRESS WRAPPER -FULLY AUTOMATIC HIGH CAPACITY-WITH PRESSINGREFERENCE NUMBER: K-8622 MATTRESS WRAPPER -FULLY AUTOMATIC HIGH CAPACITY-WITH PRESSING WITH SELP-ADJUSTMENT FOR PACKING DIFFERENT SIZES OF PRODUCTS IT ALLOWS UP TO 2 WRAPS PER MINUTE WITH EXCELLENT QUALITY THANKS TO 2 TONS PRESS AND TIGHTENING MECHANISMS MAX. PRESS LOAD CAPACITY: 2 TONS MAX. MATTRESS SIZE: 210 CM X 210 CM SETUP AREA: 3.5 M X 6.5 M QUANTITY AVAILABLE: 1 Learn More -

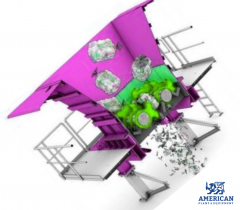

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More -

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTER

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTERABLE TO DO ROLLING TESTS ON MATTRESSES

DURABILITY TEST FOR THE BED SURFACE:

1. USES INDEPENDENT CONTROL SYSTEM. PLC CONTROL SEPARATELY. COOPERATE WITH COLOR TOUCH SCREEN. IT IS

CONVENIENT AND VISUAL TO OPERATE. THE TESTING PROCESS AND THE RUNNING STATUS BE CLEAR TO US, TEST TIMES CAN

BE SET FREELY.

2. SPECIAL LIFT DEVICE IS CONVENIENT TO LIFT UP THE HEAVY ROLLER AND EASY TO MOVE IT TO THE TEST AREA OF THE

MATTRESS. THEN PUT DOWN THE ROLLER AND MAKE ITS OWN WEIGHT FULLY LOAD TO THE SURFACE OF THE MATTRESS.

3.ROLLER CAN MOVE UP AND DOWN IN THE TESTING PROCESS, TO ADAPT TO CONCAVE AND CONVEX SURFACE OF THE

MATTRESS.

4. WHEN DOING DURABILITY TEST OF EDGE, ROLLER CAN BE MOVED TO THE “PARKING” AREA BEHIND THE INSTRUMENT.

5. DURABILITY TEST FOR THE EDGE IS DRIVEN BY SERVO MOTOR; IT IS QUIET, STEADY AND RELIABLE TO OPERATE.

6. INCORPORATES ADVANCED PHOTOELECTRIC SENSE TECHNOLOGY. THE BEGINNING POSITION OF THE CENTER LINE OF THE

CUSHION SURFACE RETURN TO THE HOME POSITION AUTOMATICALLY.

DURABILITY TEST FOR BED EDGE :

ADOPT INDEPENDENT CONTROL SYSTEM, USING DEDICATED HIGH-PRECISION AND HIGH INTELLIGENT ARAM CONTROLLER

AND SPECIAL TEST SOFTWARE. IT CAN RUN UNDER WINDOWS SYSTEM ON PC, IT IS OPERATED ALL BY SOFTWARE, THE

INTERFACE OF SOFTWARE IS EASY TO OPERATE.

SPECIAL TEST SOFTWARE ON PC, WINDOWS OPERATING PAGE, A HIGH DEGREE OF COMPATIBILITY.

TEST PROGRAM HAS ALREADY BEEN SET ON THE SOFTWARE ON PC ACCORDING TO THE TEST REQUIREMENT. A KEY TO TEST.

IT IS CONVENIENT FOR OPERATOR TO LEARN AND SAVE THE TRAINING TIME.

THE CURVE WINDOW OF TEST SOFTWARE DISPLAY THE VALUES OF FORCE AND SHIFT IN REAL TIME, COORDINATE MODEL.

LOADING CUSHION ON THE EDGE AND LOADING CUSHION WHICH IS USED FOR MEASURING USE GENERIC CONNECTION

HEAD THAT CAN BE IN INTERCHANGED. SHARING A SET OF DRIVING DEVICE, SAVE SPACE AND COST.

ADJUSTABLE RACK. THE PRESSURE PLATE CAN BE ADJUSTED THE POSITION ALONG THE DIRECTION OF X AND Y. IT CAN

MEASURE EACH POINT OF THE MATTRESS. IT IS DIFFERENT FROM THE TRADITION WAY TO SEPARATE. THE TEST CAN BE

FINISHED WITHOUT MOVING THE SAMPLE.

SAVE A LOT OF TESTING TIME, GREATLY REDUCES THE WORKING INTENSITY, OPERATORS CAN ACHIEVE SINGLE OPERATION,

SAVE THE COMPANY COST.

FORCE SENSOR AVOIDS DAMAGE TO THE CORE COMPONENTS BECAUSE IT CAN MAKE PROTECTION WHEN IT IS OVERLOAD.ROLLING TEST SPEED: 16±2CYCLES PER MINUTE (OR SPECIFIED BY CUSTOMER)

Learn More

CYLINDER ROLLER: 1400N, THE MIDDLE DIAMETER: 300mm, BOTH ENDS DIAMETER: 250mm, LENGTH: 1000

HEXAGON STYLE WOODEN ROLLER: SIZE AS STANDARD REQUIREMENT

COUNTER: 0~999999 CAN BE SET.

THE CONTROL WAY OF ROLLING: TOUCH SCREEN + PLC CONTROL

LOADING CUSHION ON THE EDGE: BUTTOCKS SHAPE, 380mm X 495mm

LOADING PARTS ON THE EDGE: THE MIDPOINT ON THE LONG EDGE OF THE MATTRESS.200 mm FROM EDGE.

LOADING FORCE ON THE EDGE: 1000N

LOADING TIME ON THE EDGE: 3S

POSITION OF MEASUREMENT: MATTRESS CENTER, LEFT AND RIGHT ARE BOTH 250mm, THE MIDPOINT ON THE LONG EDGE

OF THE MATTRESS 200 mm INWARD.

LOADING PLATE OF MEASUREMENT: DIAMETER 355mm, RADIUS OF CURVATURE OF THE END R800mm

CAPACITY OF FORCE SENSOR: 2KN

LOADING SPEED OF MEASUREMENT: 90±5mm/MIN

STROKE: 500mm

DRIVE MOTOR: SERVO MOTOR -

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINE

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINEREFERENCE NUMBER: M-6042 (880699GY7RX) L

VACUUM PRESSING AND ROLLING UP MATTRESSES LINECOMPLETE LINE FOR VACUUM PRESSING AND ROLLING UP MATTRESSES

PRODUCTION: 3 MATTRESSES PER MINUTE

CAN WORK: VISCO / POLYURETHANE / LATEX / BONNELL SPRING / POCKET SPRING / ETC.QUANTITY: 1

Learn More