Search results for: 'packaging line'

- Related search terms

- packaging

- line pvc l

- Line bleach co

- packaging design ai

- Packaging Source

-

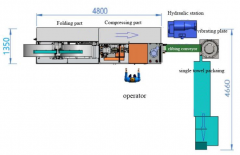

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More -

TT-7723 ASEPTIC FILLING LINE TETRA PAK A3 FLEX 1000S UP TO 9000 L/H, YEAR 2010TT-7723 ASEPTIC FILLING LINE TETRA PAK A3 FLEX 1000S UP TO 9000 L/H, YEAR 2010 1. COMPLETE BOTTLING LINE 2. BRAND: TETRA PAK® 3. YEAR: 2010 4. SPEED: 9000 L/H 5. PRODUCTS: DAIRY, JUICE QUANTITY: 1 Learn More

TT-7723 ASEPTIC FILLING LINE TETRA PAK A3 FLEX 1000S UP TO 9000 L/H, YEAR 2010TT-7723 ASEPTIC FILLING LINE TETRA PAK A3 FLEX 1000S UP TO 9000 L/H, YEAR 2010 1. COMPLETE BOTTLING LINE 2. BRAND: TETRA PAK® 3. YEAR: 2010 4. SPEED: 9000 L/H 5. PRODUCTS: DAIRY, JUICE QUANTITY: 1 Learn More -

TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2003 3. CONDITION USED 4. OPERATING HOURS: 38,750 H QUANTITY: 1 Learn More

TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2003 3. CONDITION USED 4. OPERATING HOURS: 38,750 H QUANTITY: 1 Learn More -

TT-7207 ASEPTIC FILLING LINE TETRA PAK A3 FLEX 1000S UP TO 9000 L/H, YEAR 2012TT-7207 ASEPTIC FILLING LINE TETRA PAK A3 FLEX 1000S UP TO 9000 L/H, YEAR 2012 1. BRAND: TETRA PAK® 2. YEAR: 2012 3. SPEED: 9000 L/H 4. PRODUCTS: DAIRY, JUICE QUANTITY: 1 Learn More

TT-7207 ASEPTIC FILLING LINE TETRA PAK A3 FLEX 1000S UP TO 9000 L/H, YEAR 2012TT-7207 ASEPTIC FILLING LINE TETRA PAK A3 FLEX 1000S UP TO 9000 L/H, YEAR 2012 1. BRAND: TETRA PAK® 2. YEAR: 2012 3. SPEED: 9000 L/H 4. PRODUCTS: DAIRY, JUICE QUANTITY: 1 Learn More -

TT-6345 COMPLETE KRONES BEVERAGE CAN FILLING LINE WITH 32 VALVE KRONES CAN FILLER / FERRUM CAN SEAMER, YEAR 2017TT-6345 COMPLETE KRONES BEVERAGE CAN FILLING LINE WITH 32 VALVE KRONES CAN FILLER / FERRUM CAN SEAMER, YEAR 2017 1. THIS 2017 KRONES BEVERAGE CAN FILLING LINE IS A GREAT LOW TO MID SPEED SOLUTION FOR YOUR BEVERAGE PACKAGING REQUIREMENT. 2. THE LINE WAS LAST RUNNING BEER INTO STANDARD AND SLEEK ALUMINUM BEVERAGE CANS WITH 202 ENDS. 3. DOWNSTREAM PACKAGING ALLOWS FOR CANS TO BE PACKED INTO CARTON MULTIPACKS, OR CARTONS MULTIPACKS INTO TRAYS. 4. THE COLUMBIA CASE PALLETIZER IS SEAMLESSLY PAIRED WITH INTEGRATED PALLET STRETCH WRAPPER. QUANTITY: 1 Learn More

TT-6345 COMPLETE KRONES BEVERAGE CAN FILLING LINE WITH 32 VALVE KRONES CAN FILLER / FERRUM CAN SEAMER, YEAR 2017TT-6345 COMPLETE KRONES BEVERAGE CAN FILLING LINE WITH 32 VALVE KRONES CAN FILLER / FERRUM CAN SEAMER, YEAR 2017 1. THIS 2017 KRONES BEVERAGE CAN FILLING LINE IS A GREAT LOW TO MID SPEED SOLUTION FOR YOUR BEVERAGE PACKAGING REQUIREMENT. 2. THE LINE WAS LAST RUNNING BEER INTO STANDARD AND SLEEK ALUMINUM BEVERAGE CANS WITH 202 ENDS. 3. DOWNSTREAM PACKAGING ALLOWS FOR CANS TO BE PACKED INTO CARTON MULTIPACKS, OR CARTONS MULTIPACKS INTO TRAYS. 4. THE COLUMBIA CASE PALLETIZER IS SEAMLESSLY PAIRED WITH INTEGRATED PALLET STRETCH WRAPPER. QUANTITY: 1 Learn More -

TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED 4. MACHINE TYPE: BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 5. BRAND: TETRA PAK 6. MODEL: BOTTLING PLANT 7. CONDITION: USED 8. OPERATING HOURS: 500 H QUANTITY: 1 Learn More

TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED 4. MACHINE TYPE: BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 5. BRAND: TETRA PAK 6. MODEL: BOTTLING PLANT 7. CONDITION: USED 8. OPERATING HOURS: 500 H QUANTITY: 1 Learn More -

YY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINEYY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINE THE PLANT WAS USED IN FULLY CONTINUOUS OPERATION WHICH MEANS 24 / 7 FOR 350 DAYS PER YEAR. BULK MATERIALS OF ALL TYPES (PET BOTTLE FLAKES, RESINS / GRANULE CHIPS, REGRINDS OF VARIOUS TYPES OF MATERIALS AND AGGLOMERATES) WERE USED AS INPUT MATERIAL FROM THE EUROPEAN MARKET, BUT ALSO FROM ALL OVER THE WORLD. THE REGENERATED FIBERS PRODUCED WERE BETWEEN 3 DEN AND 25 DEN AND COULD BE USED FOR MANY DIFFERENT APPLICATIONS, SUCH AS AUTOMOTIVE, GEOTEXTILES, TECHNICAL TEXTILES AND ALL GENERAL TEXTILE SECTORS – ALWAYS IN 100% RECYCLED FIBERS. PREDOMINANTLY THE LINE WAS PRODUCING A HIGH QUALITY BLACK STAPLE FIBER! Learn More

YY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINEYY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINE THE PLANT WAS USED IN FULLY CONTINUOUS OPERATION WHICH MEANS 24 / 7 FOR 350 DAYS PER YEAR. BULK MATERIALS OF ALL TYPES (PET BOTTLE FLAKES, RESINS / GRANULE CHIPS, REGRINDS OF VARIOUS TYPES OF MATERIALS AND AGGLOMERATES) WERE USED AS INPUT MATERIAL FROM THE EUROPEAN MARKET, BUT ALSO FROM ALL OVER THE WORLD. THE REGENERATED FIBERS PRODUCED WERE BETWEEN 3 DEN AND 25 DEN AND COULD BE USED FOR MANY DIFFERENT APPLICATIONS, SUCH AS AUTOMOTIVE, GEOTEXTILES, TECHNICAL TEXTILES AND ALL GENERAL TEXTILE SECTORS – ALWAYS IN 100% RECYCLED FIBERS. PREDOMINANTLY THE LINE WAS PRODUCING A HIGH QUALITY BLACK STAPLE FIBER! Learn More -

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More -

TT-6295 TETRA PAK BOTTLING PLANT BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6295 TETRA PAK BOTTLING PLANT BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED QUANTITY: 1 Learn More

TT-6295 TETRA PAK BOTTLING PLANT BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6295 TETRA PAK BOTTLING PLANT BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED QUANTITY: 1 Learn More -

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More