Search results for: 'line''

-

C-3784 NEEDLING LINE, WORKING WIDTH 2500mm TO 7400mm, YEAR 1994 TO 1997REFERENCE NUMBER: C-3784 NEEDLING LINE, WORKING WIDTH 2500mm TO 7400mm, YEAR 1994 TO 1997 DETAILS: OFFER 001 NEEDLING LINE YEAR: 1994 TO 1997 WORKING WIDTH: 6500mm CONSISTING OF: OFFER 002 HERGETH DOUBLE DOFFER CARD YEAR: 1997 WORKING WIDTH: 2500mm AVANTRAIN + 1 SWIFT UP TO 950 KG/H QUANTITY: 1 OFFER 003 ASSELIN 658 PROFILE CROSS-LAPPER YEAR: 1994 INPUT: 2500mm OUTPUT: 6800mm UP TO 120 M/MIN QUANTITY: 1 OFFER 004 FEHRER NL9 PRE-NEEDLE LOOM YEAR: 1994 WORKING WIDTH: 7400mm DOWNSTROKE STROKE: 60mm 2658 NEEDLES/M QUANTITY: 1 OFFER 005 FEHRER NL42 FINISHING NEEDLE LOOM YEAR: 1994 WORKING WIDTH: 7000mm UPSTROKE & DOWNSTROKE STROKE: 70mm 9702 NEEDLES/M QUANTITY: 1 OFFER 006 WINDING UNIT YEAR: 1994 WORKING WIDTH: 7000mm QUANTITY: 1 QUANTITY AVAILABLE: 1 LINE Learn More

C-3784 NEEDLING LINE, WORKING WIDTH 2500mm TO 7400mm, YEAR 1994 TO 1997REFERENCE NUMBER: C-3784 NEEDLING LINE, WORKING WIDTH 2500mm TO 7400mm, YEAR 1994 TO 1997 DETAILS: OFFER 001 NEEDLING LINE YEAR: 1994 TO 1997 WORKING WIDTH: 6500mm CONSISTING OF: OFFER 002 HERGETH DOUBLE DOFFER CARD YEAR: 1997 WORKING WIDTH: 2500mm AVANTRAIN + 1 SWIFT UP TO 950 KG/H QUANTITY: 1 OFFER 003 ASSELIN 658 PROFILE CROSS-LAPPER YEAR: 1994 INPUT: 2500mm OUTPUT: 6800mm UP TO 120 M/MIN QUANTITY: 1 OFFER 004 FEHRER NL9 PRE-NEEDLE LOOM YEAR: 1994 WORKING WIDTH: 7400mm DOWNSTROKE STROKE: 60mm 2658 NEEDLES/M QUANTITY: 1 OFFER 005 FEHRER NL42 FINISHING NEEDLE LOOM YEAR: 1994 WORKING WIDTH: 7000mm UPSTROKE & DOWNSTROKE STROKE: 70mm 9702 NEEDLES/M QUANTITY: 1 OFFER 006 WINDING UNIT YEAR: 1994 WORKING WIDTH: 7000mm QUANTITY: 1 QUANTITY AVAILABLE: 1 LINE Learn More -

C-2479 NONWOVEN LINE, WIDTH 2500mm, CROSS LAPPER WIDTH 6000mm, GAS OVEN 3400mmREFERENCE NUMBER: C-2479 NONWOVEN LINE, WIDTH 2500mm, CROSS LAPPER WIDTH 6000mm, GAS OVEN 3400mm SPECIFICATIONS: NONWOVEN LINE THE LINE IS CONSISTING OF: 1 PC. CARDING MACHINE, 2500 MM WORKING WIDTH. 1 PC. CROSS LAPPER HERGETH, 6000 MM WORKING WIDTH. 1 PC. GAS HEATED 3-FLOOR OVEN MARIO BOMBI, 3400 MM WIDTH. QUANTITY AVAILABLE: 1 Learn More

C-2479 NONWOVEN LINE, WIDTH 2500mm, CROSS LAPPER WIDTH 6000mm, GAS OVEN 3400mmREFERENCE NUMBER: C-2479 NONWOVEN LINE, WIDTH 2500mm, CROSS LAPPER WIDTH 6000mm, GAS OVEN 3400mm SPECIFICATIONS: NONWOVEN LINE THE LINE IS CONSISTING OF: 1 PC. CARDING MACHINE, 2500 MM WORKING WIDTH. 1 PC. CROSS LAPPER HERGETH, 6000 MM WORKING WIDTH. 1 PC. GAS HEATED 3-FLOOR OVEN MARIO BOMBI, 3400 MM WIDTH. QUANTITY AVAILABLE: 1 Learn More -

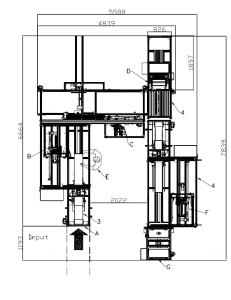

C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011REFERENCE NUMBER: C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011 SPECIFICATIONS: AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM WORKING WIDTH 1300mm YEAR OF CONSTRUCTION 2010 to 2011. THE AIRLAY LINE IS CONSISTING OF THE FOLLOWING COMPONENTS: BALE OPENER WITH SCALE TO MEASURE THE WEIGHT. CONVEYOR BELT. OPENER. AIRLAY UNIT. CONVEYOR BELT. THERMOBONDING OVEN. EDGE TRIM UNIT. PANEL CUTTER, FULLY AUTOMATIC. LOADING DEVICE TO LOAD READY MADE PANELS ONTO A PALETTE. THE THERMOBONDING OVEN IS MADE BY SICAM AND IS GAS HEATED. QUANTITY AVAILABLE: 1 Learn More

C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011REFERENCE NUMBER: C-2478 AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM, WIDTH 1300mm, YEAR 2010 TO 2011 SPECIFICATIONS: AIRLAY LINE WITH THERMOBONDING OVEN CORMATEX / SICAM WORKING WIDTH 1300mm YEAR OF CONSTRUCTION 2010 to 2011. THE AIRLAY LINE IS CONSISTING OF THE FOLLOWING COMPONENTS: BALE OPENER WITH SCALE TO MEASURE THE WEIGHT. CONVEYOR BELT. OPENER. AIRLAY UNIT. CONVEYOR BELT. THERMOBONDING OVEN. EDGE TRIM UNIT. PANEL CUTTER, FULLY AUTOMATIC. LOADING DEVICE TO LOAD READY MADE PANELS ONTO A PALETTE. THE THERMOBONDING OVEN IS MADE BY SICAM AND IS GAS HEATED. QUANTITY AVAILABLE: 1 Learn More -

C-1149 HOUGET DUESBERG BOSSON CARDING LINE HDB, WIDTH 2500MM, WITH 12 X 8 GOOD ENDSREFERENCE NUMBER: C-1149 HOUGET DUESBERG BOSSON CARDING LINE HDB, WIDTH 2500MM, WITH 12 X 8 GOOD ENDS SPECIFICATIONS: CARDING LINE HDB HOUGET DUESBERG BOSSON 2500 MM WORKING WIDTH. THE LINE IS CONSISTING OF: 1 AUTOMATIC FEEDER WITH AUTOMATIC WEIGHING DEVICE. 1 FEEDER-IN. 1 FIRST ROLLER WITH COMBER AND MOTOR BLOC. 1 SLIVER CONVEYOR-SPREADER BELT. 1 SECOND ROLLER WITH COMBER AND MOTOR BLOC WITH FREQUENCY VARIATOR. 1 CONTINUOUS DOUBLE FRICTION BLOC. 1 SOFT END WINDING DEVICE WITH 12X8 GOOD ENDS. 1 EDGE VACUUM CLEANER, SWITCH BOARD, VÖGEL GREASING DEVICE. DOUBLE ELECTRONIC SPEED MEASURING DEVICE, COMPLETE IN OPERATION. QUANTITY AVAILABLE: 1 Learn More

C-1149 HOUGET DUESBERG BOSSON CARDING LINE HDB, WIDTH 2500MM, WITH 12 X 8 GOOD ENDSREFERENCE NUMBER: C-1149 HOUGET DUESBERG BOSSON CARDING LINE HDB, WIDTH 2500MM, WITH 12 X 8 GOOD ENDS SPECIFICATIONS: CARDING LINE HDB HOUGET DUESBERG BOSSON 2500 MM WORKING WIDTH. THE LINE IS CONSISTING OF: 1 AUTOMATIC FEEDER WITH AUTOMATIC WEIGHING DEVICE. 1 FEEDER-IN. 1 FIRST ROLLER WITH COMBER AND MOTOR BLOC. 1 SLIVER CONVEYOR-SPREADER BELT. 1 SECOND ROLLER WITH COMBER AND MOTOR BLOC WITH FREQUENCY VARIATOR. 1 CONTINUOUS DOUBLE FRICTION BLOC. 1 SOFT END WINDING DEVICE WITH 12X8 GOOD ENDS. 1 EDGE VACUUM CLEANER, SWITCH BOARD, VÖGEL GREASING DEVICE. DOUBLE ELECTRONIC SPEED MEASURING DEVICE, COMPLETE IN OPERATION. QUANTITY AVAILABLE: 1 Learn More -

M-1769 FROZEN FRENCH FRIES PRODUCTION LINEREFERENCE NUMBER: M-1769 (660VSYKXX5) FROZEN FRENCH FRIES PRODUCTION LINE CAPACITY FROM 100KG PER HOUR TO 1200KG PER HOUR, EVEN LARGER CAPACITY AVAILABLE FRYING MACHINE CAPACITY IS 300 TO 500KG PER HOUR QUANTITY AVAILABLE: 1 Learn More

M-1769 FROZEN FRENCH FRIES PRODUCTION LINEREFERENCE NUMBER: M-1769 (660VSYKXX5) FROZEN FRENCH FRIES PRODUCTION LINE CAPACITY FROM 100KG PER HOUR TO 1200KG PER HOUR, EVEN LARGER CAPACITY AVAILABLE FRYING MACHINE CAPACITY IS 300 TO 500KG PER HOUR QUANTITY AVAILABLE: 1 Learn More -

G-5039 CHICKEN SLAUGHTER LINE 500 PER SHIFT (NEW)REFERENCE NUMBER: G-5039 CHICKEN SLAUGHTER LINE 500 PER SHIFT (NEW) QUANTITY AVAILABLE: 1 Learn More

G-5039 CHICKEN SLAUGHTER LINE 500 PER SHIFT (NEW)REFERENCE NUMBER: G-5039 CHICKEN SLAUGHTER LINE 500 PER SHIFT (NEW) QUANTITY AVAILABLE: 1 Learn More -

G-4249 CHICKEN SLAUGHTERING LINE 1500 PER HOURREFERENCE NUMBER: G-4249 CHICKEN SLAUGHTERING LINE 1500 PER HOUR QUANTITY AVAILABLE: 1 Learn More

G-4249 CHICKEN SLAUGHTERING LINE 1500 PER HOURREFERENCE NUMBER: G-4249 CHICKEN SLAUGHTERING LINE 1500 PER HOUR QUANTITY AVAILABLE: 1 Learn More -

G-3569 CHICKEN SLAUGHTER LINE (1500/HR)REFERENCE NUMBER: G-3569 CHICKEN SLAUGHTER LINE (1500/HR) QUANTITY AVAILABLE: 1 Learn More

G-3569 CHICKEN SLAUGHTER LINE (1500/HR)REFERENCE NUMBER: G-3569 CHICKEN SLAUGHTER LINE (1500/HR) QUANTITY AVAILABLE: 1 Learn More -

M-1426 COMPLETE PILLOW SEWING/FILLING/PACKING LINEREFERENCE NUMBER: M-1426 COMPLETE PILLOW SEWING/FILLING/PACKING LINE PILLOW LINE FULL AUTOMATIC PROCESS THIS LINE IS COMPLETE OF: PILLOW MAKING + AUTOMATIC LABELING DEVICE SHAKER PILLOW BAGGING + FLYER INSERTION DEVICE QUANTITY AVAILABLE: 1 Learn More

M-1426 COMPLETE PILLOW SEWING/FILLING/PACKING LINEREFERENCE NUMBER: M-1426 COMPLETE PILLOW SEWING/FILLING/PACKING LINE PILLOW LINE FULL AUTOMATIC PROCESS THIS LINE IS COMPLETE OF: PILLOW MAKING + AUTOMATIC LABELING DEVICE SHAKER PILLOW BAGGING + FLYER INSERTION DEVICE QUANTITY AVAILABLE: 1 Learn More -

M-1487 CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mmREFERENCE NUMBER: M-1487 (660125KJH5RXM) CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mm CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC MEZZERA BIANCO ROLLERS WIDTH: 3800 mm WORKING WIDTH: 3600 mm YEAR OF CONSTRUCTION: 2000 COMPOSED OF: - DOUBLE INTRODUCTION, FRAME MANUFACTURED IN PAINTED FE PROFILES , SLINGING BY ADJUSTABLE FLYWHEELS, 2 GROUPS OF WIDENING-CENTRING ROLLERS E+L KF20, FABRIC GUIDING ROLLERS IN AISI 316, DRAGGING CALANDER WITH 3 ROLLERS. - BY-PASS AND SYNCHRONIZATION BRIDGE COMPOSED OF : FRAME IN CARBON STEEL FE37, GROUP OF GUIDING ROLLERS IN STAINLESS STEEL COMPLETE WITH SELF-ALIGNED BEARINGS TO GUIDE THE FABRIC TO THE FOLLOWING SECTION . - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH, MOD. ACTIVA 20, WITH SIMPLE FABRIC DWELLING - INTERMEDIATE SEPARATOR FOR TANK SPLITTING - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - DELIVERY GROUP WITH PNEUMATIC FOULARD OF 10 TON RUBBER/EBONITE, COMPLETE WITH BEARING FRAME AND PROTECTION CASING. RUBBER ROLLER WITH HIGH SQUEEZING EFFECT ROLLIN - SECOND DISCHARGING STACK - PUMP FOR THE BATH RECYCLING IN THE NEUTRALIZATION PART - PH-METER WITH DOSING PUMP TO NEUTRALIZE IN THE FIRST SECTION OF THE LAST TANK - BIG BATCHER, ADHERING TYPE, DRIVEN BY MOTOR WITH VARIABLE SPEED. - SLAT WIDENING UNIT FOR DOUBLE ROW - 2 DUCTING FOR THE WATER RECOVERY BETWEEN THE 2 WASHING UNITS IN OPEN WIDTH - 3 TEMPERATURE AUTOMATIC CONTROLS PER EACH WASHING UNIT - 4 SETS OF PROPORTIONAL VALVES WITH LITER COUNTER - COMPLETE MOTORIZATION OF THE LINE WITH MOTORS GROUP, ELECTRIC CONTROL CABINET AND SYNOPTICAL PANEL. - VERTICAL DRYER RAMALLUMIN COMPOSED OF 2 COLUMNS WITH 8 ROLLERS, IN ORDER TO DRY BOTH FACES OF THE FABRIC, FOR A TOTAL OF 16 DRYING ROLLERS. O MAX. WORKING WIDTH: 3600 mm. O MAX. MECHANICAL SPEED: 80 MT./MIN. O MAX. WEIGHT OF THE FABRIC, IN WIDTH 3400 mm 900 GR./LINEAR METER O FORESEEN WORKING SPEED WITH FABRIC W=3400mm W=850 GR. 40/45 MT./MIN. O FORESEEN WORKING SPEED WITH FABRIC W=3400 W=425 GR. 80 MT./MIN. O MODIFIED, AS FOLLOWS, WITH ADDITIONS OF : 2 COOLING ROLLERS, 1 SET OF ACCESSORIES FOR THE FEEDING AND RETURN OF THE COOLING WATER, SET OF COMPONENTS FOR THE CONTROL, 4 RETURN CYLINDERS, COMPENSATING GROUP ON THE INTRODUCTION SIDE, 3 SUCTIONING HOODS, 1 EXHAUSTER. Learn More

M-1487 CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mmREFERENCE NUMBER: M-1487 (660125KJH5RXM) CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mm CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC MEZZERA BIANCO ROLLERS WIDTH: 3800 mm WORKING WIDTH: 3600 mm YEAR OF CONSTRUCTION: 2000 COMPOSED OF: - DOUBLE INTRODUCTION, FRAME MANUFACTURED IN PAINTED FE PROFILES , SLINGING BY ADJUSTABLE FLYWHEELS, 2 GROUPS OF WIDENING-CENTRING ROLLERS E+L KF20, FABRIC GUIDING ROLLERS IN AISI 316, DRAGGING CALANDER WITH 3 ROLLERS. - BY-PASS AND SYNCHRONIZATION BRIDGE COMPOSED OF : FRAME IN CARBON STEEL FE37, GROUP OF GUIDING ROLLERS IN STAINLESS STEEL COMPLETE WITH SELF-ALIGNED BEARINGS TO GUIDE THE FABRIC TO THE FOLLOWING SECTION . - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH, MOD. ACTIVA 20, WITH SIMPLE FABRIC DWELLING - INTERMEDIATE SEPARATOR FOR TANK SPLITTING - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - DELIVERY GROUP WITH PNEUMATIC FOULARD OF 10 TON RUBBER/EBONITE, COMPLETE WITH BEARING FRAME AND PROTECTION CASING. RUBBER ROLLER WITH HIGH SQUEEZING EFFECT ROLLIN - SECOND DISCHARGING STACK - PUMP FOR THE BATH RECYCLING IN THE NEUTRALIZATION PART - PH-METER WITH DOSING PUMP TO NEUTRALIZE IN THE FIRST SECTION OF THE LAST TANK - BIG BATCHER, ADHERING TYPE, DRIVEN BY MOTOR WITH VARIABLE SPEED. - SLAT WIDENING UNIT FOR DOUBLE ROW - 2 DUCTING FOR THE WATER RECOVERY BETWEEN THE 2 WASHING UNITS IN OPEN WIDTH - 3 TEMPERATURE AUTOMATIC CONTROLS PER EACH WASHING UNIT - 4 SETS OF PROPORTIONAL VALVES WITH LITER COUNTER - COMPLETE MOTORIZATION OF THE LINE WITH MOTORS GROUP, ELECTRIC CONTROL CABINET AND SYNOPTICAL PANEL. - VERTICAL DRYER RAMALLUMIN COMPOSED OF 2 COLUMNS WITH 8 ROLLERS, IN ORDER TO DRY BOTH FACES OF THE FABRIC, FOR A TOTAL OF 16 DRYING ROLLERS. O MAX. WORKING WIDTH: 3600 mm. O MAX. MECHANICAL SPEED: 80 MT./MIN. O MAX. WEIGHT OF THE FABRIC, IN WIDTH 3400 mm 900 GR./LINEAR METER O FORESEEN WORKING SPEED WITH FABRIC W=3400mm W=850 GR. 40/45 MT./MIN. O FORESEEN WORKING SPEED WITH FABRIC W=3400 W=425 GR. 80 MT./MIN. O MODIFIED, AS FOLLOWS, WITH ADDITIONS OF : 2 COOLING ROLLERS, 1 SET OF ACCESSORIES FOR THE FEEDING AND RETURN OF THE COOLING WATER, SET OF COMPONENTS FOR THE CONTROL, 4 RETURN CYLINDERS, COMPENSATING GROUP ON THE INTRODUCTION SIDE, 3 SUCTIONING HOODS, 1 EXHAUSTER. Learn More