Search results for: '300/4.5'

-

J-3231 HIGH-PRECISION HORIZONTAL FOAM CUTTING MACHINE WITH VACUUM SYSTEM -CAN CUT 8 LB FOAM DENSITY DOWN TO 1.5mm THINJ-3231HIGH-PRECISION HORIZONTAL FOAM CUTTING MACHINE WITH VACUUM SYSTEM -CAN CUT 8 LB FOAM DENSITY DOWN TO 1.5mm THIN MACHINE EXTERNAL DIMENSIONS: LENGTH 6000 x WIDTH 4250mm x HEIGHT 2600mm SPARE PARTS INCLUDED: 3 BLADES, 4 GRINDING WHEELS, 1 SET OF MAINTENANCE TOOLS WITH 1 YEAR CE CERTIFICATE QUANTITY: 1 Learn More

J-3231 HIGH-PRECISION HORIZONTAL FOAM CUTTING MACHINE WITH VACUUM SYSTEM -CAN CUT 8 LB FOAM DENSITY DOWN TO 1.5mm THINJ-3231HIGH-PRECISION HORIZONTAL FOAM CUTTING MACHINE WITH VACUUM SYSTEM -CAN CUT 8 LB FOAM DENSITY DOWN TO 1.5mm THIN MACHINE EXTERNAL DIMENSIONS: LENGTH 6000 x WIDTH 4250mm x HEIGHT 2600mm SPARE PARTS INCLUDED: 3 BLADES, 4 GRINDING WHEELS, 1 SET OF MAINTENANCE TOOLS WITH 1 YEAR CE CERTIFICATE QUANTITY: 1 Learn More -

Z-1601 CUSHION COVERING MACHINEZ-1601 CUSHION COVERING MACHINE DIMENSION: 1630mm X 1350mm X 1800mm POWER: 0.8W WEIGHT: 300 KG QUANTITY: 1 Learn More

Z-1601 CUSHION COVERING MACHINEZ-1601 CUSHION COVERING MACHINE DIMENSION: 1630mm X 1350mm X 1800mm POWER: 0.8W WEIGHT: 300 KG QUANTITY: 1 Learn More -

AA-1175 AUTOMATIC KN95 MASK MACHINE LINE DUCK BILL TYPEAA-1175 AUTOMATIC KN95 MASK MACHINE LINE DUCK BILL TYPE MACHINE PARAMETERS: DIMENSIONS: - FILM MACHINE x 1 SET: 1450 x 920 x 1350mm - EAR STRAP MACHINE x 3 SETS: 850 x 550 x 1400mm x 3 - BANDING MACHINE x 2 SETS: 980 x 430 x 1100mm x 2 - FEEDING MATERIAL FRAME x 1 SET: 3500 x 2050 x 950mm TOTAL VOLUME WEIGHT: 2128 TO 2300T Learn More

AA-1175 AUTOMATIC KN95 MASK MACHINE LINE DUCK BILL TYPEAA-1175 AUTOMATIC KN95 MASK MACHINE LINE DUCK BILL TYPE MACHINE PARAMETERS: DIMENSIONS: - FILM MACHINE x 1 SET: 1450 x 920 x 1350mm - EAR STRAP MACHINE x 3 SETS: 850 x 550 x 1400mm x 3 - BANDING MACHINE x 2 SETS: 980 x 430 x 1100mm x 2 - FEEDING MATERIAL FRAME x 1 SET: 3500 x 2050 x 950mm TOTAL VOLUME WEIGHT: 2128 TO 2300T Learn More -

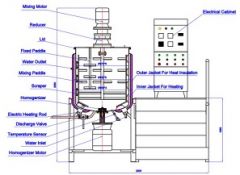

Z-1564 500 L LIQUID WASHING HOMOGENIZER MIXERSZ-1564 500 L LIQUID WASHING HOMOGENIZER MIXERS MAIN STRUCTURE: MIXING POT, ELECTRIC CONTROL SYSTEM, OPERATION PLATFORM ESTIMATED PRODUCTION TIME AND CAPACITY FOR REF • MIXING + HOMOGENIZER + HEATING • REMARK: 2 TO 2.5 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 1500 IT’S TO 2000 DAY. • MIXING + HOMOGENIZER • REMARK: 2 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 2000 IT’S DAY. • MIXING ONLY • REMARK: 1 TO 1.5 HOURS PER BATCH, IF 8 HOURS DAY, 2500 IT’S TO 4000 DAY. QUANTITY: 1 Learn More

Z-1564 500 L LIQUID WASHING HOMOGENIZER MIXERSZ-1564 500 L LIQUID WASHING HOMOGENIZER MIXERS MAIN STRUCTURE: MIXING POT, ELECTRIC CONTROL SYSTEM, OPERATION PLATFORM ESTIMATED PRODUCTION TIME AND CAPACITY FOR REF • MIXING + HOMOGENIZER + HEATING • REMARK: 2 TO 2.5 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 1500 IT’S TO 2000 DAY. • MIXING + HOMOGENIZER • REMARK: 2 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 2000 IT’S DAY. • MIXING ONLY • REMARK: 1 TO 1.5 HOURS PER BATCH, IF 8 HOURS DAY, 2500 IT’S TO 4000 DAY. QUANTITY: 1 Learn More -

PICANOL AIR JET TERRY LOOMS, YEAR 1978 TO 2001, JACQUARDREFERENCE NUMBER: T-6926 PICANOL AIR JET TERRY LOOMS, YEAR 1978 TO 2001, JACQUARD ITEM 001 AIR JET JACQUARD TERRY LOOMS MOD GUNNE TERRY PLUS H 2600 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2001 6 COLORS 6 FEEDER IRO N6 PILE BEAM 1250 N 6 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-64-36 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2001 LOOM N1 1408 HOOKS LOOM N 4 2688 HOOKS QUANTITY: 2 ITEM 002 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 3400 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2003 6 COLORS 6 FEEDER IRO N9 PILE BEAM 1250 N9 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-64-36 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2003 LOOMS N 41-42-43 1664 HOOKS INSTALLED LOOM N 44 2216 HOOKS INSTALLED QUANTITY: 4 ITEM 003 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 2600+3400 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2004 6 COLORS 6 FEEDER IRO N2PILE BEAM 1250 N2GROUND BEAM 1000 H2600 N2PILE BEAM 1250 N2GROUND BEAM 1000 H3400 SEPARATE ROLLER FERBER MOD ES-64-36+ES63 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2004 LOOM N45 2688 HOOKS LOOM N 46 1856 HOOKS QUANTITY: 2 ITEM 004 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 3600 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2007 6 COLORS 6 FEEDER IRO N6 PILE BEAM 1250 N6 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-63+ES64 YEAR 2001 DOUBLE JACQUARD STAUBLI DX 80-F YEAR 2007 LOOM N47 1952 HOOKS LOOM N 48 2600 HOOKS QUANTITY: 2 ITEM 005 AIR JET LOOMS PICANOL MOD PICANOL OMNI-2-P H 3400 2 COL 6 CAMME FOR FLAT FABRIC DOBBY CAMS MOTION STAUBLI TYPE 1600 08-1995 2 FEEDER PICANOL 2231 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 1995 N12 GROUND BEAM 1000 QUANTITY: 2 ITEM 006 GROUP BLOWING AND DUST ASPIRATOR MAGITEX X JACQUARD STAUBLI 49 MT MAGITEX X PICANOL LOOMS 53 MT QUANTITY: 2 ITEM 007 SPECIAL FORK LIFT FOR BEAM FERBER MOD BZ-S MAX LOADING 2700 KG MAX WIDTH BEAM 3900mm MAX DIAMETER BEAM 1250mm SPECIAL FORK LIFT FOR BEAM STIPI MOD TE MAX LOADING 1500 KG ITEM 008 KNOTTER STAUBLI TOPMATIC MOD TPM 210-PC CART FOR KNOTTER H 3600 KNOTTER ZELWEGER USTER TYPE UMM ITEM 009 TUFTING LOOM FOR BATHMATS PICKERING YEAR 1978 REED WIDTH 960mm CREEL 280 BOBBIN 400/300mm DIAMETER JUMBO BOBBIN 30 X 27 X 24 LOOM FOR VELVET BATH CARPET G.T SUPPLIES ENGENEERING LTD GB REED WIDTH 800mm CREEL 420 POSITION 40/28 DIAMETER 2 GROUP BLOWING AND DUST ASPIRATOR MAGITEX X MATS LOOM 52X2 MT ITEM 010 AIR COMPRESSOR BOGE MOD SF150 AIR PRESSURE 8 BAR POWER 110+4KW AIR PRODUCTION 18.40 MT3 X MINUTE YEAR 2006 AIR COMPRESSOR BOGE MOD S 75 AIR PRESSURE 8 BAR POWER 110+4KW AIR PRODUCTION 9.10 MT3 X MINUTE YEAR 1996 Learn More

PICANOL AIR JET TERRY LOOMS, YEAR 1978 TO 2001, JACQUARDREFERENCE NUMBER: T-6926 PICANOL AIR JET TERRY LOOMS, YEAR 1978 TO 2001, JACQUARD ITEM 001 AIR JET JACQUARD TERRY LOOMS MOD GUNNE TERRY PLUS H 2600 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2001 6 COLORS 6 FEEDER IRO N6 PILE BEAM 1250 N 6 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-64-36 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2001 LOOM N1 1408 HOOKS LOOM N 4 2688 HOOKS QUANTITY: 2 ITEM 002 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 3400 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2003 6 COLORS 6 FEEDER IRO N9 PILE BEAM 1250 N9 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-64-36 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2003 LOOMS N 41-42-43 1664 HOOKS INSTALLED LOOM N 44 2216 HOOKS INSTALLED QUANTITY: 4 ITEM 003 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 2600+3400 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2004 6 COLORS 6 FEEDER IRO N2PILE BEAM 1250 N2GROUND BEAM 1000 H2600 N2PILE BEAM 1250 N2GROUND BEAM 1000 H3400 SEPARATE ROLLER FERBER MOD ES-64-36+ES63 YEAR 2001 DOUBLE JACQUARD STAUBLI CX 870 YEAR 2004 LOOM N45 2688 HOOKS LOOM N 46 1856 HOOKS QUANTITY: 2 ITEM 004 AIR JET JACQUARD TERRY LOOMS MOD PICANOL TERRY-6-J H 3600 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 2007 6 COLORS 6 FEEDER IRO N6 PILE BEAM 1250 N6 GROUND BEAM 1000 SEPARATE ROLLER FERBER MOD ES-63+ES64 YEAR 2001 DOUBLE JACQUARD STAUBLI DX 80-F YEAR 2007 LOOM N47 1952 HOOKS LOOM N 48 2600 HOOKS QUANTITY: 2 ITEM 005 AIR JET LOOMS PICANOL MOD PICANOL OMNI-2-P H 3400 2 COL 6 CAMME FOR FLAT FABRIC DOBBY CAMS MOTION STAUBLI TYPE 1600 08-1995 2 FEEDER PICANOL 2231 AIR PRESSURE 8 ATM YEAR OF CONSTRUCTION 1995 N12 GROUND BEAM 1000 QUANTITY: 2 ITEM 006 GROUP BLOWING AND DUST ASPIRATOR MAGITEX X JACQUARD STAUBLI 49 MT MAGITEX X PICANOL LOOMS 53 MT QUANTITY: 2 ITEM 007 SPECIAL FORK LIFT FOR BEAM FERBER MOD BZ-S MAX LOADING 2700 KG MAX WIDTH BEAM 3900mm MAX DIAMETER BEAM 1250mm SPECIAL FORK LIFT FOR BEAM STIPI MOD TE MAX LOADING 1500 KG ITEM 008 KNOTTER STAUBLI TOPMATIC MOD TPM 210-PC CART FOR KNOTTER H 3600 KNOTTER ZELWEGER USTER TYPE UMM ITEM 009 TUFTING LOOM FOR BATHMATS PICKERING YEAR 1978 REED WIDTH 960mm CREEL 280 BOBBIN 400/300mm DIAMETER JUMBO BOBBIN 30 X 27 X 24 LOOM FOR VELVET BATH CARPET G.T SUPPLIES ENGENEERING LTD GB REED WIDTH 800mm CREEL 420 POSITION 40/28 DIAMETER 2 GROUP BLOWING AND DUST ASPIRATOR MAGITEX X MATS LOOM 52X2 MT ITEM 010 AIR COMPRESSOR BOGE MOD SF150 AIR PRESSURE 8 BAR POWER 110+4KW AIR PRODUCTION 18.40 MT3 X MINUTE YEAR 2006 AIR COMPRESSOR BOGE MOD S 75 AIR PRESSURE 8 BAR POWER 110+4KW AIR PRODUCTION 9.10 MT3 X MINUTE YEAR 1996 Learn More -

ENTRY LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - STARTER KITREFERENCE NUMBER: A-2481 ENTRY LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - STARTER KIT THIS ELECTROSPINNING SYSTEM IS DESIGNED FOR LOW-COST, SMALL-SCALE NANOFIBER RESEARCH, PRODUCING RESULTS FROM A SINGLE-NOZZLE CONFIGURATION IN A COMPACT UNIT. SPINNING DISTANCE, FLOW RATE AND APPLIED VOLTAGE ARE EASILY ADJUSTABLE IN SIDE-BY-SIDE SPINNING SYSTEM. SPECIFICATIONS: SPINNING-TYPE: SIDE BY SIDE SPINNING CHASSIS: ENCLOSED CHASSIS FOR SPINNING AREA COLLECTOR MATERIAL: STAINLESS STEEL TOTAL WEIGHT: APPROX.10 KGS DIMENSIONS: 210 X 170 X 190 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 30 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.170 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA DIRECTLY FEED INTO NOZZLE NUMBER OF NOZZLES: 1 NOZZLE NOZZLE MATERIAL: STAINLESS STEEL COMPATIBLE WITH ALL STANDARD SYRINGE NOZZLES SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 0 TO ∞ DISTANCE ADJUSTMENT METHOD: MANUAL DISTANCE CONTROL STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 180 X 300 mm UNIQUE USER INTERFACE 4.3" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 500 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 8 KGS. Learn More

ENTRY LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - STARTER KITREFERENCE NUMBER: A-2481 ENTRY LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - STARTER KIT THIS ELECTROSPINNING SYSTEM IS DESIGNED FOR LOW-COST, SMALL-SCALE NANOFIBER RESEARCH, PRODUCING RESULTS FROM A SINGLE-NOZZLE CONFIGURATION IN A COMPACT UNIT. SPINNING DISTANCE, FLOW RATE AND APPLIED VOLTAGE ARE EASILY ADJUSTABLE IN SIDE-BY-SIDE SPINNING SYSTEM. SPECIFICATIONS: SPINNING-TYPE: SIDE BY SIDE SPINNING CHASSIS: ENCLOSED CHASSIS FOR SPINNING AREA COLLECTOR MATERIAL: STAINLESS STEEL TOTAL WEIGHT: APPROX.10 KGS DIMENSIONS: 210 X 170 X 190 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 30 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.170 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA DIRECTLY FEED INTO NOZZLE NUMBER OF NOZZLES: 1 NOZZLE NOZZLE MATERIAL: STAINLESS STEEL COMPATIBLE WITH ALL STANDARD SYRINGE NOZZLES SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 0 TO ∞ DISTANCE ADJUSTMENT METHOD: MANUAL DISTANCE CONTROL STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 180 X 300 mm UNIQUE USER INTERFACE 4.3" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 500 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 8 KGS. Learn More -

ADVANCED LEVEL MULTI NOZZLE ELECTROSPINNING UNIT - 8 NOZZLESREFERENCE NUMBER: A-2476 ADVANCED LEVEL MULTI NOZZLE ELECTROSPINNING UNIT - 8 NOZZLES FULLY AUTOMATED ELECTROSPINNING MACHINE IS DESIGNED TO CARRY ELECTROSPINNING RESEARCH TO A MORE ADVANCED LEVEL. MACHINE IS A HYBRID ELECTROSPINNING SYSTEM OF EIGHT NEEDLES. IT HAS A 314 X 220 mm NANOFIBER COATING AREA VIA A ROTATING DRUM COLLECTOR, ALSO A FLAT COLLECTOR OF 130 X 370 mm COMES WITH THE STANDARD CONFIGURATION. THE NE 300 HAS AN ELECTRICALLY INSULATED CABINET WITH HIGH DENSITY PE PARTS INERT TO CHEMICAL SOLUTIONS, WHICH ENABLES WORKING WITH MANY DIFFERENT SOLVENTS AND POLYMERS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATICALLY PAINTED STEEL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: 7000 SERIES ALUMINUM ALLOY, STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX.150 KGS DIMENSIONS: 770 X 675 X 1040 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 4 PCS NUMBER OF FEEDING PIPE SETS: UP TO 2 SETS NUMBER OF NOZZLES: UP TO 8 NOZZLES SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm COMPATIBLE WITH STANDARD SYRNIGE NOZZLES MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 1 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 8.5 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 16 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 33.5 TO 233.5 mm DISTANCE ADJUSTMENT PRECISION: 1 mm ROTATING COLLECTOR DRUM COLLECTOR MATERIAL: ALUMINUM DIMENSIONS OF DRUM: 100 X 220 mm FIBER DEPOSITION AREA: 314 X 220 mm DRUM ROTATING SPEED: 100 TO 500 RPM SURFACE SPEED: 52.3 CM/S TO 261.6 CM/S COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 30 TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm /SEC STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 370 X 130 mm UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION FULLY SEALED CABINET TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 1000 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 150 KGS. Learn More

ADVANCED LEVEL MULTI NOZZLE ELECTROSPINNING UNIT - 8 NOZZLESREFERENCE NUMBER: A-2476 ADVANCED LEVEL MULTI NOZZLE ELECTROSPINNING UNIT - 8 NOZZLES FULLY AUTOMATED ELECTROSPINNING MACHINE IS DESIGNED TO CARRY ELECTROSPINNING RESEARCH TO A MORE ADVANCED LEVEL. MACHINE IS A HYBRID ELECTROSPINNING SYSTEM OF EIGHT NEEDLES. IT HAS A 314 X 220 mm NANOFIBER COATING AREA VIA A ROTATING DRUM COLLECTOR, ALSO A FLAT COLLECTOR OF 130 X 370 mm COMES WITH THE STANDARD CONFIGURATION. THE NE 300 HAS AN ELECTRICALLY INSULATED CABINET WITH HIGH DENSITY PE PARTS INERT TO CHEMICAL SOLUTIONS, WHICH ENABLES WORKING WITH MANY DIFFERENT SOLVENTS AND POLYMERS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATICALLY PAINTED STEEL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: 7000 SERIES ALUMINUM ALLOY, STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX.150 KGS DIMENSIONS: 770 X 675 X 1040 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 4 PCS NUMBER OF FEEDING PIPE SETS: UP TO 2 SETS NUMBER OF NOZZLES: UP TO 8 NOZZLES SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm COMPATIBLE WITH STANDARD SYRNIGE NOZZLES MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 1 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 8.5 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 16 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 33.5 TO 233.5 mm DISTANCE ADJUSTMENT PRECISION: 1 mm ROTATING COLLECTOR DRUM COLLECTOR MATERIAL: ALUMINUM DIMENSIONS OF DRUM: 100 X 220 mm FIBER DEPOSITION AREA: 314 X 220 mm DRUM ROTATING SPEED: 100 TO 500 RPM SURFACE SPEED: 52.3 CM/S TO 261.6 CM/S COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 30 TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm /SEC STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 370 X 130 mm UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION FULLY SEALED CABINET TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 1000 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 150 KGS. Learn More -

INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2472 INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT MACHINE HAS A HIGH PRODUCTION CAPACITY. IT ALSO ENABLES EASY MONITORING AND MANAGEMENT OF ALL PARAMETERS THAT ARE EFFECTIVE IN THE PRODUCTION OF NANOFIBERS. FOR THE COMMERCIAL PRODUCTION, REPEATABLE PRODUCTION OF MATERIALS IN UNIFORM AND SPECIFIC STANDARDS HAS THE HIGHEST IMPORTANCE. MACHINE IS EQUIPPED WITH 132 ELECTROSPINNING NEEDLES AND A HOMOGENIZATION SYSTEM, ALLOWING THE SURFACE TO BE UNIFORMLY AND CONTINUOUSLY AT A WIDTH OF 1 METER. BECAUSE OF ITS ADVANCED AUTOMATION SYSTEM AND THE AIR CONDITIONING EQUIPMENT, IT ENABLES CONTINUOUS PRODUCTION AT THE HIGHEST SET QUALITY EVEN UNDER CHANGING ENVIRONMENTAL CONDITIONS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 600 KGS DIMENSIONS: 3650 x 1950 X 1940 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: IN THE SPINNERET 0-(+)60 KV VOLTAGE PRECISION: 0.1 KV MAXIMUM CURRENT: 3 MA PUMP SYSTEM FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML CONTINUES FEEDING PUMP SYSTEM FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 33 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 132 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: STANDARD NOZZLE: 0.8 mm (DIFFERENT DIAMETERS CAN BE USED) MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 25 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 150 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 50 mm TO 350 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 1000 mm SUBSTRATE WINDING SPEED: MAX. 0,1 M/ min TO MIN. 10 M/ min COATING HOMOGENEITY SYSTEM: X-AXIS STROKE OF COATING HOMOGENEITY SYSTEM: 30 mm TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12” TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 Hz @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 5000 X 3000 mm Learn More

INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2472 INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT MACHINE HAS A HIGH PRODUCTION CAPACITY. IT ALSO ENABLES EASY MONITORING AND MANAGEMENT OF ALL PARAMETERS THAT ARE EFFECTIVE IN THE PRODUCTION OF NANOFIBERS. FOR THE COMMERCIAL PRODUCTION, REPEATABLE PRODUCTION OF MATERIALS IN UNIFORM AND SPECIFIC STANDARDS HAS THE HIGHEST IMPORTANCE. MACHINE IS EQUIPPED WITH 132 ELECTROSPINNING NEEDLES AND A HOMOGENIZATION SYSTEM, ALLOWING THE SURFACE TO BE UNIFORMLY AND CONTINUOUSLY AT A WIDTH OF 1 METER. BECAUSE OF ITS ADVANCED AUTOMATION SYSTEM AND THE AIR CONDITIONING EQUIPMENT, IT ENABLES CONTINUOUS PRODUCTION AT THE HIGHEST SET QUALITY EVEN UNDER CHANGING ENVIRONMENTAL CONDITIONS. SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 600 KGS DIMENSIONS: 3650 x 1950 X 1940 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: IN THE SPINNERET 0-(+)60 KV VOLTAGE PRECISION: 0.1 KV MAXIMUM CURRENT: 3 MA PUMP SYSTEM FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML CONTINUES FEEDING PUMP SYSTEM FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 33 PCS NUMBER OF FEEDING PIPE SETS: 4 PCS NUMBER OF NOZZLES: 132 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: STANDARD NOZZLE: 0.8 mm (DIFFERENT DIAMETERS CAN BE USED) MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 3 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 25 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 150 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 50 mm TO 350 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 1000 mm SUBSTRATE WINDING SPEED: MAX. 0,1 M/ min TO MIN. 10 M/ min COATING HOMOGENEITY SYSTEM: X-AXIS STROKE OF COATING HOMOGENEITY SYSTEM: 30 mm TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 12” TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 Hz @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 5000 X 3000 mm Learn More -

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More -

T-6544 SYNTHETIC BLOOD PENETRATION TESTER FOR SURGICAL MASK

T-6544 SYNTHETIC BLOOD PENETRATION TESTER FOR SURGICAL MASKREFERENCE NUMBER: T-6544

SYNTHETIC BLOOD PENETRATION TESTER FOR SURGICAL MASK

TECHNICAL INDICATORS:

1. THE PROTRUDING SAMPLE FIXING DEVICE CAN SIMULATE THE ACTUAL USE STATE OF THE MASK, SET ASIDE THE TEST TARGET AREA WITHOUT DESTROYING THE SAMPLE, AND DISTRIBUTE THE SYNTHETIC BLOOD IN THE TARGET AREA OF THE SAMPLE.

2. THE SPECIAL FIXED-PRESSURE INJECTION DEVICE CAN EJECT A CERTAIN VOLUME OF SYNTHETIC BLOOD IN A CONTROLLED TIME.

3. IT CAN FULLY SIMULATE THE INJECTION SPEED CORRESPONDING TO THE AVERAGE BLOOD PRESSURE OF HUMAN BODY OF 10.6KPA, 16KPA AND 21.3KPA.

4. A FIXED TARGET PLATE IS SET TO BLOCK THE HIGH-PRESSURE EDGE PART OF THE INJECTED LIQUID FLOW AND ONLY ALLOW THE STEADY FLOW PART TO BE SPRAYED ON THE SAMPLE, WHICH INCREASES THE ACCURACY AND REPEATABILITY OF THE LIQUID VELOCITY SPRAYED ON THE SAMPLE.

STANDARDS:

MEDICAL RESPIRATOR TECHNICAL REQUIREMENTS, 5.5 SYNTHETIC BLOOD PENETRATION BARRIER PERFORMANCE

YY/T 0691-2008 INFECTIOUS PATHOGEN PROTECTION EQUIPMENT MEDICAL MASK RESISTANCE TO SYNTHETIC BLOOD PENETRABILITY TEST METHOD (FIXED VOLUME, HORIZONTAL INJECTION)

YY 0469-2011 MEDICAL SURGICAL MASK TECHNOLOGY REQUIRES A BLOOD PENETRATION TEST DEVICE

ISO 22609:2004 INFECTIOUS PATHOGEN PROTECTION EQUIPMENT MEDICAL MASK TEST METHOD FOR RESISTANCE TO SYNTHETIC BLOOD PENETRATION (FIXED VOLUME, HORIZONTAL INJECTION)

ASTM F1862-07 STANDARD TEST METHOD FOR RESISTANCE OF MEDICAL FACE MASKS TO BLOT BY SYNTHETIC BLOOD (HORIZONTAL PROJECTION OF FIXED VOLUME AT A KNOW VELOCITY)

TECHNICAL PARAMETERS:

1. INJECTION DISTANCE: 300mm ~ 305mm ADJUSTABLE

2. NOZZLE DIAMETER: 0.84mm

3. INJECTION SPEED: 450CM/S, 550CM/S, 635CM/S

4. WEIGHT: 35KG

5. POWER SOURCE: AC220V 50HZ

QUANTITY: 1

Learn More