Search results for: 'control+pr'

- Related search terms

- control+prog

- control+pro

- control+programs

- control+pro'[0]

- control+pro'

-

SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT - 18 NOZZLESREFERENCE NUMBER: A-2474 SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT - 18 NOZZLES MACHINE IS A COMPACT CONTINUOUS NANOFIBER PRODUCTION MACHINE. ITS MAJOR ADVANTAGE IS SCALABILITY, AS IT’S SUITABLE FOR BOTH PRODUCTION LINE AS WELL AS R&D PROJECTS. IT FUNCTIONS WITH 18 NOZZLES ENABLING HIGH PRODUCTIVITY FOR MASS PRODUCTION OF NANOFIBERS, HOWEVER IT CAN ALSO FUNCTION WITH SINGLE NOZZLE THEREFORE ENABLES WORKING ON SMALL-SCALE R&D PROJECTS. ITS UNIQUE DESIGN ENABLES PRODUCTION OF NANOFIBERS AND COMPOSITES, IT ACCOMMODATES TWO SYRINGE PUMPS AND TWO HIGH VOLTAGE POWER SUPPLIERS, MAKING IT POSSIBLE TO WORK SIMULTANEOUSLY WITH UP TO TWO DIFFERENT POLYMERS, INDEPENDENTLY CONTROLLABLE SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 350 KGS DIMENSIONS: 1585 X 1550 X 1950 mm HIGH VOLTAGE POWER SUPPLY NUMBER OF HV GENERATORS: 2 UNITS (1 FOR EACH SOLUTION FEEDING ROD) VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP NUMBER OF PUMPS: 2 UNITS FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML AVAILABLE SYRINGES: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 9 PCS NUMBER OF FEEDING PIPE SETS: 2 PCS NUMBER OF NOZZLES: 18 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 2 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 8 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 18 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 30 TO 280 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 300 mm SUBSTRATE WINDING SPEED: 0,01 M/MIN TO 1 M/min REPETITIVE WINDING MODE (OPTIONAL) COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 10 MM TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 2000 X 2000 mm Learn More

SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT - 18 NOZZLESREFERENCE NUMBER: A-2474 SEMI INDUSTRIAL SCALE MULTI NOZZLE ELECTROSPINNING UNIT - 18 NOZZLES MACHINE IS A COMPACT CONTINUOUS NANOFIBER PRODUCTION MACHINE. ITS MAJOR ADVANTAGE IS SCALABILITY, AS IT’S SUITABLE FOR BOTH PRODUCTION LINE AS WELL AS R&D PROJECTS. IT FUNCTIONS WITH 18 NOZZLES ENABLING HIGH PRODUCTIVITY FOR MASS PRODUCTION OF NANOFIBERS, HOWEVER IT CAN ALSO FUNCTION WITH SINGLE NOZZLE THEREFORE ENABLES WORKING ON SMALL-SCALE R&D PROJECTS. ITS UNIQUE DESIGN ENABLES PRODUCTION OF NANOFIBERS AND COMPOSITES, IT ACCOMMODATES TWO SYRINGE PUMPS AND TWO HIGH VOLTAGE POWER SUPPLIERS, MAKING IT POSSIBLE TO WORK SIMULTANEOUSLY WITH UP TO TWO DIFFERENT POLYMERS, INDEPENDENTLY CONTROLLABLE SPECIFICATIONS: SPINNING-TYPE: BOTTOM-UP SPINNING CHASSIS: ELECTROSTATIC PAINTED SHEET METAL FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: STAINLESS STEEL LED ILLUMINATION EXHAUST FAN ATMOSPHERE CONTROL (OPTIONAL) TOTAL WEIGHT: APPROX. 350 KGS DIMENSIONS: 1585 X 1550 X 1950 mm HIGH VOLTAGE POWER SUPPLY NUMBER OF HV GENERATORS: 2 UNITS (1 FOR EACH SOLUTION FEEDING ROD) VOLTAGE RANGE: 0 TO 40 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.125 MA HIGH PRECISION MICRO PUMP NUMBER OF PUMPS: 2 UNITS FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML AVAILABLE SYRINGES: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES ON EACH FEEDING PIPE SET: 9 PCS NUMBER OF FEEDING PIPE SETS: 2 PCS NUMBER OF NOZZLES: 18 PCS SINGLE NOZZLE PRODUCTION: AVAILABLE FEEDING PIPE MATERIAL: ALUMINUM NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 2 ML MINIMUM REQUIRED SOLUTION FOR EACH FEEDING PIPE SET: 8 ML MINIMUM REQUIRED SOLUTION FOR FULL LOADING: 18 ML SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 30 TO 280 mm DISTANCE ADJUSTMENT PRECISION: 1 mm COLLECTOR ROLL TO ROLL COLLECTOR FIBER DEPOSITION WIDTH: 300 mm SUBSTRATE WINDING SPEED: 0,01 M/MIN TO 1 M/min REPETITIVE WINDING MODE (OPTIONAL) COATING HOMOGENEITY SYSTEM: X-AXIS REPETITIVE MOTION STROKE OF COATING HOMOGENEITY SYSTEM: 10 MM TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm/SEC UNIQUE USER INTERFACE 9" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAVING & RECALLING ALL PARAMETERS VIA RECIPE & RECALL FUNCTION SAFETY FUNCTION SAFE DOOR EMERGENCY BUTTON & SAFETY RELAY HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 2000 X 2000 mm Learn More -

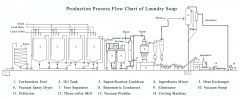

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

TT-5698 REIFENHAUSER BLOWN FILM LINE, 3 LAYERS, WIDTH 2300mm, YEAR 2003TT-5698 REIFENHAUSER BLOWN FILM LINE, 3 LAYERS, WIDTH 2300mm, YEAR 2003 REIFENHAUSER BLOWN FILM LINE USED FILM WIDTH 2300mm AUTOMATIC THICKNESS PROFILE CONTROL, DOUBLE WINDER BRAND: REIFENHAUSER YEAR: 2003 QUANTITY: 1 Learn More

TT-5698 REIFENHAUSER BLOWN FILM LINE, 3 LAYERS, WIDTH 2300mm, YEAR 2003TT-5698 REIFENHAUSER BLOWN FILM LINE, 3 LAYERS, WIDTH 2300mm, YEAR 2003 REIFENHAUSER BLOWN FILM LINE USED FILM WIDTH 2300mm AUTOMATIC THICKNESS PROFILE CONTROL, DOUBLE WINDER BRAND: REIFENHAUSER YEAR: 2003 QUANTITY: 1 Learn More -

TT-4529 GENERAL ELECTRIC TURBINE GENERATOR – NEW, NATURAL GAS, 90MW, 60Hz, 7EA + HRSG COGENERATION PLANT, YEAR 2015TT-4529 GENERAL ELECTRIC TURBINE GENERATOR – NEW, NATURAL GAS, 90MW, 60Hz, 7EA + HRSG COGENERATION PLANT, YEAR 2015 EQUIPMENT OVERVIEW NEW / NEVER-USED SURPLUS MANUFACTURED IN 2015 GE 71 EA 91.95 MW NATURAL GAS TURBINE GE 7A6 121000 KVA 60 Hz 13000 V AIR-COOLED GENERATOR COMPLETE WITH ACCESSORY BASE AND ANCILLARY EQUIPMENT OPTIONALLY AVAILABLE HEAT RECOVERY STEAM GENERATOR (HRSG) AND ANCILLARY EQUIPMENT CRATED AND PRESERVED TO OEM SCHEDULE IN CLIMATE CONTROLLED WAREHOUSES Learn More

TT-4529 GENERAL ELECTRIC TURBINE GENERATOR – NEW, NATURAL GAS, 90MW, 60Hz, 7EA + HRSG COGENERATION PLANT, YEAR 2015TT-4529 GENERAL ELECTRIC TURBINE GENERATOR – NEW, NATURAL GAS, 90MW, 60Hz, 7EA + HRSG COGENERATION PLANT, YEAR 2015 EQUIPMENT OVERVIEW NEW / NEVER-USED SURPLUS MANUFACTURED IN 2015 GE 71 EA 91.95 MW NATURAL GAS TURBINE GE 7A6 121000 KVA 60 Hz 13000 V AIR-COOLED GENERATOR COMPLETE WITH ACCESSORY BASE AND ANCILLARY EQUIPMENT OPTIONALLY AVAILABLE HEAT RECOVERY STEAM GENERATOR (HRSG) AND ANCILLARY EQUIPMENT CRATED AND PRESERVED TO OEM SCHEDULE IN CLIMATE CONTROLLED WAREHOUSES Learn More -

YY-2329 DS SIMPLICITY HOT MELT UNITSYY-2329 DS SIMPLICITY HOT MELT UNITS THE DS 4, 8, 16 HOT MELT UNITS ARE SIMPLE, INDUSTRIAL HOT MELT TANKS WITH CONSTANT PRESSURE PISTON PUMPS, PRECISION CONTROLS, AND THOROUGH GLUE FILTRATION. QUANTITY: 1 Learn More

YY-2329 DS SIMPLICITY HOT MELT UNITSYY-2329 DS SIMPLICITY HOT MELT UNITS THE DS 4, 8, 16 HOT MELT UNITS ARE SIMPLE, INDUSTRIAL HOT MELT TANKS WITH CONSTANT PRESSURE PISTON PUMPS, PRECISION CONTROLS, AND THOROUGH GLUE FILTRATION. QUANTITY: 1 Learn More -

K-4939 MATTRESS BORDER QUILTING MACHINE TWO SEW HEADS CONTROLLED BY CNC (COMPUTER)REFERENCE NUMBER: K-4939 MATTRESS BORDER QUILTING MACHINE TWO SEW HEADS CONTROLLED BY CNC (COMPUTER) PFAFF 5483 – CHAINSTITCH FULLY AUTOAMTIC PROCESS UP TO 20 M/MIN SEWING NO PATTERN LIMITATION QUANTITY AVAILABLE: 1 Learn More

K-4939 MATTRESS BORDER QUILTING MACHINE TWO SEW HEADS CONTROLLED BY CNC (COMPUTER)REFERENCE NUMBER: K-4939 MATTRESS BORDER QUILTING MACHINE TWO SEW HEADS CONTROLLED BY CNC (COMPUTER) PFAFF 5483 – CHAINSTITCH FULLY AUTOAMTIC PROCESS UP TO 20 M/MIN SEWING NO PATTERN LIMITATION QUANTITY AVAILABLE: 1 Learn More -

TT-8043 CERUTTI-28/128 R ROTOGRAVURE PRINTING PRESS, 9 COLORS, 1200mm, YEAR 1982 TO 2012 RETROFITTT-8043 CERUTTI-28/128 R ROTOGRAVURE PRINTING PRESS, 9 COLORS, 1200mm, YEAR 1982 TO 2012 RETROFIT 1. CERUTTI-28/128 R ROTOGRAVURE PRINTING PRESS 2. 9 COLORS 3. YEAR OF CONSTRUCTION: 1982 -1996 + 2012 RETROFIT 4. OFFER EX WORKS, EXCLUDING DISMANTLING LOADING: 5. AGAINST OFFER /GEGEN ANGEBOT 6. N°1 PB 32 - N°1 TR - N°6 ES 288 - N°2 EXTENDED ES 28/8 - N°1 EXTENDED ES 128 L2 - N°1 TR - N*1 RB 28 Learn More

TT-8043 CERUTTI-28/128 R ROTOGRAVURE PRINTING PRESS, 9 COLORS, 1200mm, YEAR 1982 TO 2012 RETROFITTT-8043 CERUTTI-28/128 R ROTOGRAVURE PRINTING PRESS, 9 COLORS, 1200mm, YEAR 1982 TO 2012 RETROFIT 1. CERUTTI-28/128 R ROTOGRAVURE PRINTING PRESS 2. 9 COLORS 3. YEAR OF CONSTRUCTION: 1982 -1996 + 2012 RETROFIT 4. OFFER EX WORKS, EXCLUDING DISMANTLING LOADING: 5. AGAINST OFFER /GEGEN ANGEBOT 6. N°1 PB 32 - N°1 TR - N°6 ES 288 - N°2 EXTENDED ES 28/8 - N°1 EXTENDED ES 128 L2 - N°1 TR - N*1 RB 28 Learn More -

TT-5705 SULZER L5300 AND L5400 LOOMS, WIDTH 1900mm, YEAR 2000 TO 2002, DOBBYTT-5705 SULZER L5300 AND L5400 LOOMS, WIDTH 1900mm, YEAR 2000 TO 2002, DOBBY ITEM 001 BRAND: SULZER MODEL: L5300 WIDTH: 1900mm YEAR OF MANUFACTURE: 2002 QUANTITY: 10 ITEM 002 BRAND: SULZER MODEL: L5300 WIDTH: 1900mm YEAR OF MANUFACTURE: 2001 QUANTITY: 8 ITEM 003 BRAND: SULZER MODEL: L5400 WIDTH: 1900mm YEAR OF MANUFACTURE: 2003 QUANTITY: 2 NOTE: ALL LOOMS HAVE A TANGENTIAL WINDER Learn More

TT-5705 SULZER L5300 AND L5400 LOOMS, WIDTH 1900mm, YEAR 2000 TO 2002, DOBBYTT-5705 SULZER L5300 AND L5400 LOOMS, WIDTH 1900mm, YEAR 2000 TO 2002, DOBBY ITEM 001 BRAND: SULZER MODEL: L5300 WIDTH: 1900mm YEAR OF MANUFACTURE: 2002 QUANTITY: 10 ITEM 002 BRAND: SULZER MODEL: L5300 WIDTH: 1900mm YEAR OF MANUFACTURE: 2001 QUANTITY: 8 ITEM 003 BRAND: SULZER MODEL: L5400 WIDTH: 1900mm YEAR OF MANUFACTURE: 2003 QUANTITY: 2 NOTE: ALL LOOMS HAVE A TANGENTIAL WINDER Learn More -

YY-3015 USED SUPERIOR 250 H.P. FIRETUBE PACKAGE BOILERYY-3015 USED SUPERIOR 250 H.P. FIRETUBE PACKAGE BOILER SUPERIOR PACKAGED 250 HP 4-PASS WET BACK BOILER YEAR BUILT: 2008 DESIGN PRESSURE: 150 PSIG/STEAM OPERATING PRESSURE: 135 PSIG OR LESS CAPACITY: 8.625 LB./HR. STEAM (FROM AND AT 212 DEGREES F.) FUEL: NATURAL GAS AND #2 FUEL OIL ELECTRICAL: 460 VOLTS QUANTITY: 1 Learn More

YY-3015 USED SUPERIOR 250 H.P. FIRETUBE PACKAGE BOILERYY-3015 USED SUPERIOR 250 H.P. FIRETUBE PACKAGE BOILER SUPERIOR PACKAGED 250 HP 4-PASS WET BACK BOILER YEAR BUILT: 2008 DESIGN PRESSURE: 150 PSIG/STEAM OPERATING PRESSURE: 135 PSIG OR LESS CAPACITY: 8.625 LB./HR. STEAM (FROM AND AT 212 DEGREES F.) FUEL: NATURAL GAS AND #2 FUEL OIL ELECTRICAL: 460 VOLTS QUANTITY: 1 Learn More -

TT-1794 BRAMPTON ENGINEERING 6” MONOLAYER BLOWN FILM LIINETT-1794 BRAMPTON ENGINEERING 6” MONOLAYER BLOWN FILM LIINE 6” BRAMPTON MONOLAYER LDPE LINE LINE IS IN STORAGE IN A WAREHOUSE, READY TO SHIP QUANTITY: 1 Learn More

TT-1794 BRAMPTON ENGINEERING 6” MONOLAYER BLOWN FILM LIINETT-1794 BRAMPTON ENGINEERING 6” MONOLAYER BLOWN FILM LIINE 6” BRAMPTON MONOLAYER LDPE LINE LINE IS IN STORAGE IN A WAREHOUSE, READY TO SHIP QUANTITY: 1 Learn More