Search results for: '300/4.5'

-

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTER

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTERABLE TO DO ROLLING TESTS ON MATTRESSES

DURABILITY TEST FOR THE BED SURFACE:

1. USES INDEPENDENT CONTROL SYSTEM. PLC CONTROL SEPARATELY. COOPERATE WITH COLOR TOUCH SCREEN. IT IS

CONVENIENT AND VISUAL TO OPERATE. THE TESTING PROCESS AND THE RUNNING STATUS BE CLEAR TO US, TEST TIMES CAN

BE SET FREELY.

2. SPECIAL LIFT DEVICE IS CONVENIENT TO LIFT UP THE HEAVY ROLLER AND EASY TO MOVE IT TO THE TEST AREA OF THE

MATTRESS. THEN PUT DOWN THE ROLLER AND MAKE ITS OWN WEIGHT FULLY LOAD TO THE SURFACE OF THE MATTRESS.

3.ROLLER CAN MOVE UP AND DOWN IN THE TESTING PROCESS, TO ADAPT TO CONCAVE AND CONVEX SURFACE OF THE

MATTRESS.

4. WHEN DOING DURABILITY TEST OF EDGE, ROLLER CAN BE MOVED TO THE “PARKING” AREA BEHIND THE INSTRUMENT.

5. DURABILITY TEST FOR THE EDGE IS DRIVEN BY SERVO MOTOR; IT IS QUIET, STEADY AND RELIABLE TO OPERATE.

6. INCORPORATES ADVANCED PHOTOELECTRIC SENSE TECHNOLOGY. THE BEGINNING POSITION OF THE CENTER LINE OF THE

CUSHION SURFACE RETURN TO THE HOME POSITION AUTOMATICALLY.

DURABILITY TEST FOR BED EDGE :

ADOPT INDEPENDENT CONTROL SYSTEM, USING DEDICATED HIGH-PRECISION AND HIGH INTELLIGENT ARAM CONTROLLER

AND SPECIAL TEST SOFTWARE. IT CAN RUN UNDER WINDOWS SYSTEM ON PC, IT IS OPERATED ALL BY SOFTWARE, THE

INTERFACE OF SOFTWARE IS EASY TO OPERATE.

SPECIAL TEST SOFTWARE ON PC, WINDOWS OPERATING PAGE, A HIGH DEGREE OF COMPATIBILITY.

TEST PROGRAM HAS ALREADY BEEN SET ON THE SOFTWARE ON PC ACCORDING TO THE TEST REQUIREMENT. A KEY TO TEST.

IT IS CONVENIENT FOR OPERATOR TO LEARN AND SAVE THE TRAINING TIME.

THE CURVE WINDOW OF TEST SOFTWARE DISPLAY THE VALUES OF FORCE AND SHIFT IN REAL TIME, COORDINATE MODEL.

LOADING CUSHION ON THE EDGE AND LOADING CUSHION WHICH IS USED FOR MEASURING USE GENERIC CONNECTION

HEAD THAT CAN BE IN INTERCHANGED. SHARING A SET OF DRIVING DEVICE, SAVE SPACE AND COST.

ADJUSTABLE RACK. THE PRESSURE PLATE CAN BE ADJUSTED THE POSITION ALONG THE DIRECTION OF X AND Y. IT CAN

MEASURE EACH POINT OF THE MATTRESS. IT IS DIFFERENT FROM THE TRADITION WAY TO SEPARATE. THE TEST CAN BE

FINISHED WITHOUT MOVING THE SAMPLE.

SAVE A LOT OF TESTING TIME, GREATLY REDUCES THE WORKING INTENSITY, OPERATORS CAN ACHIEVE SINGLE OPERATION,

SAVE THE COMPANY COST.

FORCE SENSOR AVOIDS DAMAGE TO THE CORE COMPONENTS BECAUSE IT CAN MAKE PROTECTION WHEN IT IS OVERLOAD.ROLLING TEST SPEED: 16±2CYCLES PER MINUTE (OR SPECIFIED BY CUSTOMER)

Learn More

CYLINDER ROLLER: 1400N, THE MIDDLE DIAMETER: 300mm, BOTH ENDS DIAMETER: 250mm, LENGTH: 1000

HEXAGON STYLE WOODEN ROLLER: SIZE AS STANDARD REQUIREMENT

COUNTER: 0~999999 CAN BE SET.

THE CONTROL WAY OF ROLLING: TOUCH SCREEN + PLC CONTROL

LOADING CUSHION ON THE EDGE: BUTTOCKS SHAPE, 380mm X 495mm

LOADING PARTS ON THE EDGE: THE MIDPOINT ON THE LONG EDGE OF THE MATTRESS.200 mm FROM EDGE.

LOADING FORCE ON THE EDGE: 1000N

LOADING TIME ON THE EDGE: 3S

POSITION OF MEASUREMENT: MATTRESS CENTER, LEFT AND RIGHT ARE BOTH 250mm, THE MIDPOINT ON THE LONG EDGE

OF THE MATTRESS 200 mm INWARD.

LOADING PLATE OF MEASUREMENT: DIAMETER 355mm, RADIUS OF CURVATURE OF THE END R800mm

CAPACITY OF FORCE SENSOR: 2KN

LOADING SPEED OF MEASUREMENT: 90±5mm/MIN

STROKE: 500mm

DRIVE MOTOR: SERVO MOTOR -

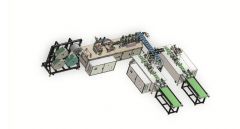

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWN

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWNPP CHIPS FOR MELTBLOWN: 1200 TO 2000

FABRIC WIDTH: 1600mm

2 SPINNING BEAMS FOR SPUNBOND & 1 FOR MELTBLOWN

BASIC WEIGHT: SMS 9 TO 80 GRAMS PER SQUARE METER

SS: 15 TO 100 GRAMS PER SQUARE METERPRODUCT:

SMS LAMINATED NONWOVEN FABRIC

SS SPUNBOND NONWOVEN FABRIC SS

M MELTBLOWN NONWOVEN FABRIC MTO MAKE HYGENIC FABRICS SUCH AS BABY DIAPERS, SANITARY NAPKINS, ADULT DIAPERS, MEDICAL OPERATION SUITS, OPERATION CAPS, OPERATIONS SHOES, MASKS, ETC.

CONSISTING OF:

3 X FEEDING SYSTEMS

AUTOMATIC VACUUM SUCTION FOR BOTH MAIN MATERIAL AND ADDITIVES

CAPACITY (SB + MB) 2 X 520 KGS/H, (SB) 2 X 200 KGS/HR

WITH THREE HOPPERS, THREE SUPPLIYING DEVICESSPUNBOND SYSTEM

2 X EXTRUDERS

DIAMETER: 150mm

CAPACITY: 450 KGS/HR

L/D 30:1

DRIVE POWER: 110 KW

HEATING POWER: 90 KW2 X RECYCLING SYSTEMS

DIAMETER: 105mm

CAPACITY: 100 KGS PER HOUR

L/D: 15:12 X MELT FILTERS

WORKING TEMPERATURE: UP TO 280 CELSIUS

FILTRATION CAPACITY: 520 KGS PER HOUR2 X METERING PUMPS

TYPE: GEAR PUMP

FLOW VOLUME: 250 ML/R

DESIGNING TEMPERATURE: 280 CELSIUS2 X MELT PIPELINES

WITH STATIC MIXER2 X MONOMER EXHAUSTER

INCLUDING BLOWER, CHILLER, PIPELINE, VALVE, INSULATION, ETC2 X SPINNING BEAMS

SINGLE COAT-HANGER MELT DISTRIBUTION

DESIGNING PRESSURE: 9MPA

WORKING TEMPERATURE: MAX 280 CELSIUS4 X SPINNERETS

HOLE DIAMETER: 0.45mm

L/D: 5:1

15,500 HOLESMELTBLOWN SYSTEM

1 X EXTRUDER

DIAMETER 120mm

CAPACITY: 280 KGS/HR

L/D: 30:1

DRIVE POWER: 75 KW

HEATING POWER: 80 KW1 X MELT FILTER

FILTRATION PRECISION: 20 TO 60 MICROMETERS

FILTRATION: 280 KGS PER HOUR1 X METERING PUMP

GEAR PUMP

MAX. FLOW VOLUME: 100ML/R

DESIGNED TEMPERATURE: 300 CELSIUS1 X MELT PIPELINE

WITH STATIC MIXER1 X SPINNING BEAM

INCLUDING STRETCHING CHANNEL, NOZZLE, ETC. WITH INSULATION MATERIAL

DESIGNED PRESSURE: 6 MPA2 X SPINNING DIE PACKS

COMPACT DIE PACKS

HOLE DIAMETER: 0.35mm

L/D: 12:1

# OF HOLES: 42HPI1 X SCREW BLOWER

INCLUDING MUFFLE, PRESSURE REDUCER VALVE, PIPELINE, ETC.

POWER: 200 KW1 X HOT AIR SYSTEM

FLOW VOLUME: 6000 CUBIC METERS PER HOUR

WORKING TEMP: MAX 350 CELSIUS

INCLUDING HEATER, STAINLESS STEEL PIPELINE, ETC.

POWER: 290 KW1 X OFF-LINE CONVEYOR

RANGE OF SPEED: 5 TO 100 METERS PER MINUTE1 X CONVEYOR

MECHANICAL SPEED: MAX 400 METERS PER MINUTE

BELT WIDTH AND PENETRATION

3800±10mm, 10000 CUBIC METERS PER H.M21 X CALENDAR

DOUBLE ROLLS HEATED BY OIL

PROCESS SPEED: 350 METERS PER MINUTE

EMBOSSING WIDTH: UP TO 2000mm

MAX LINEAR PRESSURE: 110 DAN/C

MAX. TEMP OF EMBOSSING ROLLER, 180 CELSIUS1 X WINDER

ONLINE CHANGING ROLL, ONLINE EDGE CUTTING, TENSION CONTROL

MAX. LINEAR SPEED: 350 METERS PER MINUTE

WIDTH: 1600mm

WIND DIAMETER: MAX 1500mm1 X SLITTER

MAX. LINE SPEED: 600 METERS PER MINUTE

MAX. WIND DIAMETER: 1200mm

MIN. SLITTING WIDE: 120mm

22 CIRCULAR BLADES1 X STEEL PLATFORM

1 X ELECTRICAL CONTROL SYSTEM

2 X OIL OVEN

1 X AIR CONDITIONING SYSTEM

1 X WATER COOLING SYSTEM

1 X CLEANING EQUIPMENTS FOR DIE PACK

1 X AUXILIARY PLATFORM

1 X AUXILIARY EQUIPMENTS

1 X LABORATORY TESTING DEVICE

Learn More -

J-2792 MEDICAL FACE MASK SYNTHETIC BLOOD PENETRATION TESTER

J-2792 MEDICAL FACE MASK SYNTHETIC BLOOD PENETRATION TESTERUSED FOR MEASURING THE RESISTANCE OF MEDICAL FACE MASKS TO PENETRATION BY A SPLASH OF SYNTHETIC BLOOD

BLOOD SPRAYING DISTANCE: 300 TO 310mm (APPROXIMATE, ADJUSTABLE)

NEEDLE INNER DIAMETER: 0.84mm

SPRAY SPEED: 4500mm PER SECOND, 5500mm PER SECOND, 6350mm PER SECOND

SIMULATED SYNTHETIC BLOOD PRESSURE: 10.6kPa, 16.0 kPa, 21.3 kPa, (i.e. 80mmHg, 120mmHg, 160mmHg)

SUPPORTS THE SPECIMEN MEDICAL FACE MASK ON THE TESTER’S CLAMPING DEVICE AND SPRAYS A FIXED VOLUME (~2ml) OF SYNTHETIC BLOOD SPLASHED HORIZONTALLY TO HIT THE MASK

TESTER CAN PROVIDE DIFFERENT BLOOD PRESSURES WITH PRECISION CONTROL VALVE TO GENERATE 2ml SYNTHETIC BLOOD WITH SURFACE TENSION OF 0.042 ± 0.002 N/m, WHICH MEETS THE REQUIREMENTS DEFINED IN STANDARDS BELOW:

ISO 22609

ASTM F1862

YY 0469-2011

GB/T 19083-2010LEAD TIME: 5 TO 7 WEEKS FROM RECEIPT OF ORDER

QUANTITY: 1

Learn More -

J-2752 FACE MASK PRODUCTION MACHINE – 120 PIECES PER MINUTE

J-2752 FACE MASK PRODUCTION MACHINE – 120 PIECES PER MINUTECOMPOSED OF

FACE MASK BLANK MAKING MACHINE

AUTOMATICALLY PRODUCES THE MAIN PART OF THE MASK

MACHINE HANDLES FEEDING, ALUMINUM STRIP INSERTION, CUTTING, FOLDING, ULTRASONIC WELDING, CUTTING

OUTPUT: 120 PIECES PER MINUTE

VOLTAGE: 220 VOLTS

POWER CONSUMPTION: 2.7 KW

DIMENSIONS: 3345 x 630 x 1830mm

CAN PRODUCE 3 TO 4 DIFFERENT MASK BLANKS ACCORDING TO PRODUCTION REQUIREMENTS

FOLDING LOCATION AND SIZE OF MASK IS ADJUSTABLE

COMPUTER CONTROLS AND PHOTOELECTRIC DETECTION ENSURE LOW FAILURE RATE AND HIGH RELIABILITY

FRAME CONSTRUCTED OF ALUMINUM ALLOY

QUANTITY: 1FACE MASK TRANSFERRING MACHINE

TRANSFERS THE MASKS TO THE ULTRASONIC EAR STRAP WELDING MACHINE

QUANTITY: 1ULTRASONIC EAR STRAP WELDING MACHINE

WELDS THE ELASTICS ON BOTH EDGES OF THE MASK

AUTOMATIC COUNTING

AUTOMATICALLY CONVEYS THE FINISHED MASKS TO PACKING PROCESS (PACKING BY HAND)

COMPUTER CONTROLS AND PHOTOELECTRIC DETECTION ENSURE LOW FAILURE RATE AND HIGH RELIABILITY

FRAME CONSTRUCTED OF ALUMINUM ALLOY

QUANTITY: 2PRODUCES MASKS WITH DIMENSIONS: 175mm x 95mm (ADULT SIZE)

FOR MASK TYPES: 2 LAYERS OF NONWOVEN CLOTH, 3 LAYERS OF NON-WOVEN FABRIC MASKS, 4 LAYERS OF ACTIVATED CARBON MASKS

• 2 LAYER FACIAL MASK: NONWOVEN, ALUMINUM STRIP, EAR STRAP WELDING

• 3 LAYER FACIAL MASK: NON-WOVEN, ALUMINUM STRIP, EARLOOP WELDING, FILTER COTTON (FILTER PAPER)

• ACTIVATED CARBON MASKS: NONWOVEN, ALUMINUM STRIP, EARLOOP WELDING, FILTER COTTON (FILTER PAPER), ACTIVATED CARBON CLOTHTECHNICAL PARAMETERS

OVERALL DIMENSIONS: 6500 L x 4000 W x 2000 H (mm)

PRODUCTION EFFICIENCY: 95%

PRODUCT SIZE: 175 x 95mm (ADULT SIZE)

FACIAL MASK LAYERS: 3 TO 4 LAYERS

POWER: 9 KW

AIR PRESSURE REQUIRED: 0.6 MPA

AIR CONSUMPTION: 300 LITERS PER MINUTE

WEIGHT: APPROXIMATELY 1800 KG

GROUND WEIGHT BEARING: ≤ 500KG/m2

ALL OF THE MAIN DRIVING PARTS ARE PROTECTED BY PROTECTIVE COVERQUANTITY: 1 COMPLETE LINE

Learn More -

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTE

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTEITEM 001 - MASK PRODUCTION MACHINE WITH (2) ULTRASONIC EAR STRAP WELDING DEVICES

FOR THE PRODUCTION OF SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% (N95)

CAPACITY: 50 FOLDED N95 MASKS PER MINUTE

MASK DIMENSIONS: 175mm x 95mm

MATERIAL TYPE: 3 LAYERS OF POLYPROPYLENE NONWOVEN COMPOSITE FIBER

OPERATION CONTROLLED BY LCD TOUCH SCREEN

AUTOMATICALLY ALIGNS 3 ROLLS OF MATERIAL TO FEED IN (OUTER, FILTER AND INNER LAYERS)

PRESSES BOTH SIDES TOGETHER SYMMETRICALLY WHILE WELDING WITH ULTRASONIC HEAD

SPLITS TO 2 SERPATE WELDING DEVICES FOR EARLOOPS AND SENDS TO DIGITAL COUNTER

EARLOOPS ARE FINISHED WITH ULTRASONIC CUTTING AND WELDING

NOSE BRIDGE CAN BE PRODUCED WITH AUTOMATIC FEEDING, CUTTING AND ULTRASONIC WELDING

ULTRASONIC HEADS

VOLTAGE: 220 VOLTS

WATTS CAPACITY: 1500 WATT

FREQUENCY (KHZ): 20 KHZ

WARRANTY PERIOD FOR HEADS: 1 YEAR

COMPONENT MANUFACTURERS

SERVO MOTOR: PANASONIC / SCHNEIDER

CONTROL SYSTEM: PROPRIETARY

ULTRASONIC GENERATOR: PROPRIETARY, 220 VOLTS, 1.5 KW, 20 KHZ

SENSOR: OMRON / SICK

PNEUMATIC COMPONENT: SMC / FESTO

BELT: SAMSUNG / BANDO

MAIN BODY: PRE-MADE MATERIAL, WELDED ASSEMBLY

BEARINGS: NSK

BALL SCREWS: HIWIN

SECURITY DEVICE: SICK (SAFETY DEVICES TO PROTECT WORKERS)

TOTAL POWER: 4 KW

MACHINE MUST BE STOPPED TO FEED NEW ROLL OF MATERIAL

END OF ROLL DETECTOR INCLUDED: WHEN FABRIC IS FINISHED THE MACHINE WILL ALARM AND STOP

AIR PRESSURE: 0.6 MPa

VOLTAGE: 220 VOLTS, 60 Hz

DIMENSIONS: 6400mm x 4700mm x 1700mm

INCLUDES ELECTRONIC MANUAL BOOK (STORED ON USB MEMORY) AND WARRANTY CARD

OPTIONS (INQUIRE FOR PRICING): EAR STRAP FOLDER

ITEM 001 QUANTITY: 1 MASK PRODUCTION MACHINE AND 2 ULTRASONIC WELDING DEVICES FOR EAR STRAPS

ITEM 002 AUTOMATIC BAGGING MACHINE

SUITABLE FOR AUTOMATIC BAGGING OPERATIONS FOR VARIOUS MASK TYPES

MOTOR CONTROL SYSTEM: SERVO (3), AUTOMATICALLY SETS BAG LENGTH (UP TO 400mm) FOR SPECIFIED BAGGING LENGTH, WITH ANTI-AIR BAG , AUTOMATICALLY DETECTS PRODUCT BASE POINT AND MATERIAL POSITION, AUTOMATIC STOP WHEN OUT OF MATERIAL & STARTS WHEN MATERIAL IS PRESENT

FAST & CONVENIENT SETTING OF PARAMETERS, STORES SETS OF PARAMETERS FOR MULTIPLE PRODUCTS, OPERATOR CAN CHOOSE PARAMETERS ACCORDING TO PRODUCT SIZES

DIAGNOSTICS SYSTEM CLEARS ERROR & RESETS IN SINGLE STEP

HIGHLY SENSITIVE PHOTOELECTRIC EYE COLOR MARK TRACKER, DIGITAL INPUT SEAL/CUT POSITION MAKES SEAL & CUT POSITIONS MORE ACCURATE

TEMPERATURE CONTROLLED WITH INDEPENDENT PID, ALLOWS FOR VARIOUS MATERIALS IN PACKAGING

SIMPLE TRANSMISSION SYSTEM ALLOWS FOR EASY MAINTENANCE AND RELIABILITY

ALL CONTROLS SET BY SOFTWARE ALLOWING FOR ADJUSTING OF FUNCTIONS AND UPGRADES

MATERIALS

PVC FILM (HEAT SEALING), BOPP, OPP, CPP, ALUMINIZED PET FILM, ALUMINUM-PLASTIC FILM, PAPER FILM, PAPER GLUE, OTHER SINGLE- OR MULTIPLE-LAYERED HEAT-SEALED DIALYZABLE MATERIALS, ETC.

LENGTH OF PACKAGE BAGS: ≤400mm

WIDTH OF PACKAGE BAGS: 100 TO 165mm

HEIGHT OF PRODUCT: 55mm MAXIMUM

LENGTH OF FILM: 360mm MAXIMUM

DIAMETER OF FILM ROLL: 320mm MAXIMUM

CAPACITY/SPEED OF PACKAGING: 40 TO 230 BAGS PER MINUTE (1 TO 20 PIECES PER BAG)

POWER: 220 VOLTS, 50 OR 60 Hz, 2.4 KW

DIMENSIONS: 4050mm x 750mm x 1450mm

WEIGHT: APPROXIMATELY 300 KGS

COMPONENT MANUFACTURERS

TOUCH SCREEN: WEINVIEW

SERVO MOTOR: DORNA / WEIDE

SERVO CONTROLLER: DORNA / WEIDE

PROXIMITY SWITCH: OMRON

PHOTOELECTRIC SWITCH: OETAI

TEMPERATURE CONTROLLER: YATAI

SOLID STATE RELAY: SCHNEIDER

INTERMEDIATE RELAY: WEIDMUELLER

OPTIONS, INQUIRE FOR PRICING: STRAIGHT GRAIN SEALING, STAINLESS STEEL FRAME, CODE STAMPER (PRODUCTION DATE), EXHAUST (PINHOLE EXHAUST FEATURE)

ITEM 002 QUANTITY: 1 BAGGING MACHINE

ENTIRE LINE COMPOSED OF ITEM 001 AND ITEM 002

Learn More -

PP-1138 FABRIC LIST WITH YARDS

PP-1138 FABRIC LIST WITH YARDS1. 5 ROLLS – CK6658 – RELIC – 115 YARDS

2. 13 ROLLS – CK6270 – 210 YARDS

3. 3 ROLLS – QUARUM LAMPE GREY – 92374 – 192.47 YARDS

4. 5 ROLLS – ORELAND BLACK STEELE – 344.80 YARDS

5. 8 ROLLS – CK5259 + 3 ROLLS – 125 YARDS

6. 2 ROLLS – WORLD LUX – CK7149 – 50 YARDS

7. 12 ROLLS – WORLD LUX – CK7150 – 250 YARDS ??

8. 6 ROLLS – VICTOR ELAS STEEL/NAT/BLK – D370942 – 186 YARDS

9. 2 ROLLS – EVA BAS/NAT/BLK – D370916 – 107.8 YARDS

10. 2 ROLLS – BLUE – PNL – CK5970 – 45 YARDS

11. 4 ROLLS – GREY – 10028 – 65 YARDS

12.

13. 3 ROLLS – QUARUM LAMPE BLUE – 92331 – 224.53 YARDS

14. 3 ROLLS – W272 EGGSHELL – 945094 – 300 YARDS

15. 6 ROLLS – W272 SILVER – 945100 – 150 YARDS

16.

17. 5 ROLLS – CREATIVE CT 15118 – 50 YARDS

18. 4 ROLLS – CREATIVE NAT/BLK/BET SILVER- CT0481 – 85 YARDS

19.

20.

21.

22.

23. 6 ROLLS – LORI WHITE – DUNCAN – DT002 – 270 YARDS

24. 5 ROLLS – ‘YC’ CK6054 – 25 YARDS

25. 2 ROLLS – POTTSTOWN GOLD – 120.4 YARDS

26. 3 ROLLS- MOET SOFT PLATINUM W7461 – 30 YARDS

27.

28.

29. 5 ROLLS – BORDEUX BE PORT – W5087 – 50 YARDS

30. 4 ROLLS – NATURAL NEW COOL THERAPY – CK 7240 – 127.30 YARDS

31. 2 ROLLS – NATURES DREAM – CK7247 – 65.7 YARDS

32.

33.

34. 3 ROLLS – YASMINE DIAMOND/NATURAL – M3929 – 49 YARDS

35.

36.

37. 3 ROLLS – KENDALL SILVERY – BLUE/ NATURAL BAMBOO – M3961- 50 YARDS

38. 5 ROLLS – LEGACY BLUE – CK6162 – 178.5 YARDS

39.

40. 21 ROLLS – CK7592 – 177 YARDS

41. 11 ROLLS – NEW WORLD LUXURY – CK7453 – 1 – 102.2 YARDS

42. 2 ROLLS- MAVIME STORM/NAT/SLATE FACE – M4148 – 57 YARDS

43. 4 ROLLS – LEGACY ETTA/FLEX PANEL – CK7595 – 80 YARDS

44. 8 ROLLS – LEGACY JB/CRADLE – CK7593 – 263.7 YARDS

45.

46. 1 ROLL – LAMERO RD ‘LA COLLECTION’ - TN43175 – L4189 – 48 YARDS

47. 1 ROLL – BLUE NEW – BLUE HOSTESS – CK7141 – 30 YARDS

48. 26 ROLLS – IRON SWART ACCTIK – MT 100252 – 726.40 YARDS

49. 26 ROLLS – EE SPAMDEX – MT 100095 – 727.20 YARDS

50.

51.

52. 10 ROLLS – CAROLYN 500 GR/M2 LAMPE – 353.05 YARDS

53. 3 ROLLS – JUDY CHARCOAL GREY – LAMPE – 100.52 YARDS

54. 3 ROLLS – CK7385 – 92 YARDS

55.

TOTAL: 6,173.57NOT ON LIST

1. MO6317 EXCALIBUR – 564.10 YARDS

2. RED HILL – DAYBREAK – 597.30 YARDS

3. SURYA M4234 – STORM-MANGO SLATE – 450 YARDS ??

4. SO526CI – DIAMOND NATURAL – EXCEPTIONAL – 105 YARDS

5. M3781 – NORMAND

6. DK961T NATIO1048 CULP ‘WORLD’

7. CT1710 – TT3 – DIAMOND DREAMZZ

TOTAL: 1,716.40PUT RED TAGS ON UNKNOWN ROLLS

GRAND TOTAL : 7,889.97 YARDAGE

Learn More -

J-1825 HIGH SPEED COMPUTERIZED CHAIN STITCH MULTI-NEEDLE QUILTING MACHINE, NEW - 1200 RPM

J-1825 HIGH SPEED COMPUTERIZED CHAIN STITCH MULTI-NEEDLE QUILTING MACHINE, NEW - 1200 RPMREFERENCE NUMBER: J-1825

HIGH SPEED COMPUTERIZED CHAIN STITCH MULTI-NEEDLE QUILTING MACHINE, NEW - 1200 RPMQUILTING WIDTH: 2450mm (96 INCHES)

CAPACITY: 60 TO 300 METERS PER HOUR

STITCH LENGTH: 3 TO 7mm

QUILTING THICKNESS: ≤80mm

NEEDLE BAR DISTANCE: 1 x 3 x 6

NEEDLE DISTANCE SIDEWAYS: 25.4mm (ONE INCH)

X-AXIS MOVEMENT DISPLACEMENT: 304.8mm (12 INCHES)

NEEDLE TYPE: 24/180 23/160 22/140 21/130

MAIN SHAFT SPEED: 500 TO 1200 RPM

VOLTAGE: 380V/50Hz, 220V/60Hz, 3-PHASE

POWER: 7 KW

DIMENSIONS: 5400 x 1650 x 2050mm

WEIGHT: 4800 KGCONTROLS BASED ON WINDOWS, CAD DRAWING

CONTINUOUS PATTERNS AND TACK & JUMP PATTERNS (360° AND 180°) ARE AVAILABLE

DELTA VFD (VARIABLE FREQUENCY DRIVER) DRIVES MAIN SHAFT (Z SHAFT)

PANASONIC SERVO DRIVER & MOTOR CONTROL THE SADDLE (X SHAFT) AND ROLLER (Y SHAFT)

AUTOMATIC STOP WHEN UP OR BOTTOM THREAD IS BROKEN

BOTH UP AND DOWN SAFETY INFRARED PROTECTIONQUANTITY: 1

Learn More -

J-1761 CNC VERTICAL FAST WIRE FOAM CUTTING MACHINE WITH CONVEYOR

J-1761 CNC VERTICAL FAST WIRE FOAM CUTTING MACHINE WITH CONVEYORREFERENCE NUMBER: J-1761

CNC VERTICAL FAST WIRE FOAM CUTTING MACHINE WITH CONVEYORMAXIMUM TABLE LENGTH: 3000mm

MAXIMUM PROCESSING WIDTH: 1500mm

MAXIMUM BUN HEIGHT: 1200mm

WIRE SPEED: 0 TO 10 METERS/MINUTE

PROCESSING PRECISION: +/- 0.5mm

TOOL SIZE: 11,300mm

OPERATED WITH WINDOWS 7 PC

COMPRESSED AIR: 6 BAR

BLADE BREAK PROTECTION SYSTEM INCLUDED

SELF-DIAGNOSIS SYSTEM INCLUDED

VOTLAGE: 220/380/415V , 50/60Hz , 3-PHASE

TOTAL POWER: 9KW

TOTAL WEIGHT: 2500KG

MACHINE EXTERNAL DIMENSIONS: (L) 6200 x (W) 3700 x (H) 2500mmLEAD TIME: APPROXIMATELY 25 DAYS FROM RECEIPT OF DEPOSIT

GUARANTEE: 1 YEARQUANTITY: 1

Learn More -

J-1590 CIBITEX EASYCOAT-DRY FABRIC DYEING PRE-TREATMENT UNIT

J-1590 CIBITEX EASYCOAT-DRY FABRIC DYEING PRE-TREATMENT UNITMAKE: CIBITEX

COMPACT UNIT FOR PRE-TREATMENT AND DRYING OF FABRICS PRINTED USING BOTH ACID, REACTIVE OR PIGMENTED INKS

MAXIMUM WORKING WIDTH: 1800mm

POWER INSTALLED: 82 Kw

VOLTAGE: 400 V 50Hz

MAXIMUM CYLINDERS TEMPERATURE: 210 °C

INTERNAL CONTENT (DEPENDING ON FABRIC): 300 M

MAX LOAD: 280 KG

COATING BASIC CAPACITY: 40 L

DIMENSIONS: 3500 X 4600 X 1890mm

WEIGHT: 4,935 KGQUANTITY: 1

Click here to watch the videos of this machine on YouTube.

Learn More -

L-5861 AUTOMOTIVE TIRE CORD & INDUSTRIAL YARN TWISTING PLANT

L-5861 AUTOMOTIVE TIRE CORD & INDUSTRIAL YARN TWISTING PLANTREFERENCE NUMBER: L-5861

AUTOMOTIVE TIRE CORD & INDUSTRIAL YARN TWISTING PLANT

PICANOL / GUNNE TIRE CORD LOOMS

QUANTITY: 1 PLANT

Learn More