Search results for: 'Addi'

- Related search terms

- Adding

- Addin

- additive increase

-

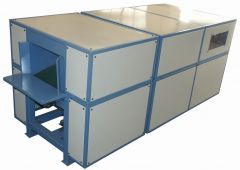

M-5305 QUILTED FABRIC WASTE & FOAM CUTTING MACHINE

M-5305 QUILTED FABRIC WASTE & FOAM CUTTING MACHINEREFERENCE NUMBER: M-5305

QUILTED FABRIC WASTE & FOAM CUTTING MACHINE

QUILTED FABRIC WASTE & FOAM CUTTING MACHINE

ADDITIONAL FAN FEEDING MACHINE MODEL 503

WITH 3 SERIES CUTTERS

WORKING WIDTH: 500mm

DIMENSIONS (LxWxH): 2850mm x 1240mm x 1270mm

CUTTING SIZE (WIDTH): 8mm

POSSIBLE THICKNESS: ≤ 60mm

CAPACITY: 250 TO 300 KG PER HOUR (CUTTING FOAM WASTE)

125 TO 160 KG PER HOUR (CUTTING QUILTED FABRIC WASTE)

POWER: 14.2 KW

WEIGHT: 1,300 KG

QUANTITY: 1 SET

Learn More -

M-5234 KUSTERS DYEING PADDER YEAR 1987 WORKING WIDTH 1800mmREFERENCE NUMBER: M-5234 (1313LBEMXX12) L KUSTERS DYEING PADDER YEAR 1987 WORKING WIDTH 1800mm KUSTERS DYEING PADDER MODEL 222.11.1800 WORKING WIDTH 1800mm YEAR 1987 TO 2002 QUANTITY AVAILABLE: 1 Learn More

M-5234 KUSTERS DYEING PADDER YEAR 1987 WORKING WIDTH 1800mmREFERENCE NUMBER: M-5234 (1313LBEMXX12) L KUSTERS DYEING PADDER YEAR 1987 WORKING WIDTH 1800mm KUSTERS DYEING PADDER MODEL 222.11.1800 WORKING WIDTH 1800mm YEAR 1987 TO 2002 QUANTITY AVAILABLE: 1 Learn More -

V-0026 CNC FOAM CONTOUR CUTTING MACHINE FOR HOLLOW TUBES AND OTHER SHAPES - BY WIRE SYSTEMREFERENCE NUMBER: V-0026 CNC FOAM CONTOUR CUTTING MACHINE FOR HOLLOW TUBES AND OTHER SHAPES - BY WIRE SYSTEM QUANTITY AVAILABLE: 1 Learn More

V-0026 CNC FOAM CONTOUR CUTTING MACHINE FOR HOLLOW TUBES AND OTHER SHAPES - BY WIRE SYSTEMREFERENCE NUMBER: V-0026 CNC FOAM CONTOUR CUTTING MACHINE FOR HOLLOW TUBES AND OTHER SHAPES - BY WIRE SYSTEM QUANTITY AVAILABLE: 1 Learn More -

M-5235 SAVIO POLAR E PREMIUM AUTO CONER YEAR 2014REFERENCE NUMBER: M-5235 (1313GWMHXX12) L SAVIO POLAR E PREMIUM AUTO CONER YEAR 2014 MAKER: SAVIO AUTO CONER TYPE: POLAR E PREMIUM MFG. YEAR: 2014 72 DRUMS / SET QUANTITY AVAILABLE: 2 Learn More

M-5235 SAVIO POLAR E PREMIUM AUTO CONER YEAR 2014REFERENCE NUMBER: M-5235 (1313GWMHXX12) L SAVIO POLAR E PREMIUM AUTO CONER YEAR 2014 MAKER: SAVIO AUTO CONER TYPE: POLAR E PREMIUM MFG. YEAR: 2014 72 DRUMS / SET QUANTITY AVAILABLE: 2 Learn More -

K-2812 BAUMER OFS 202 FOAM CUTTING MACHINE-REFURBISHED IN 2011REFERENCE NUMBER: K-2812 BAUMER OFS 202 FOAM CUTTING MACHINE-REFURBISHED IN 2011 QUANTITY AVAILABLE: 1 Learn More

K-2812 BAUMER OFS 202 FOAM CUTTING MACHINE-REFURBISHED IN 2011REFERENCE NUMBER: K-2812 BAUMER OFS 202 FOAM CUTTING MACHINE-REFURBISHED IN 2011 QUANTITY AVAILABLE: 1 Learn More -

M-2077 ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLEREFERENCE NUMBER: M-2077 (77082KHU6UX) ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLE COMPLETELY MODERNISED VERTICAL FOAM CUTTING MACHINE TYPE IS-M WITH TURNTABLE THAT IS NOW AVAILABLE. QUANTITY AVAILABLE: 1 Learn More

M-2077 ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLEREFERENCE NUMBER: M-2077 (77082KHU6UX) ALBRECHT BAUMER IS-M VERTICAL CUTTING MACHINE WITH TURNTABLE COMPLETELY MODERNISED VERTICAL FOAM CUTTING MACHINE TYPE IS-M WITH TURNTABLE THAT IS NOW AVAILABLE. QUANTITY AVAILABLE: 1 Learn More -

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

A-1210 DORNIER HTV 8/S 3500MM, YEAR 2000, AT2 PANEL, STAUBLI DOBBY 2668REFERENCE NUMBER: A-1210 (0101GHBXX12) A DORNIER HTV 8/S 3500MM, YEAR 2000, AT2 PANEL, STAUBLI DOBBY 2668 YEAR 2000 AT2 PANEL STAUBLI DOBBY 2668 WITH 20 LEVERS INSTALLED 10 GROB HARNESS FRAMES 6 CONTACT BARS HEDDLES AND DROPPERS AS FITTED 7 ECS UNITS 5 ROJ WEFT ACCUMULATORS 1.5 SINGLE BEAM 1.5 CLOTH ROLLS (SPECIALLY MADE BATCHING UNIT AVAILABLE AT ADDITIONAL COST) QUANTITY AVAILABLE: 3 Learn More

A-1210 DORNIER HTV 8/S 3500MM, YEAR 2000, AT2 PANEL, STAUBLI DOBBY 2668REFERENCE NUMBER: A-1210 (0101GHBXX12) A DORNIER HTV 8/S 3500MM, YEAR 2000, AT2 PANEL, STAUBLI DOBBY 2668 YEAR 2000 AT2 PANEL STAUBLI DOBBY 2668 WITH 20 LEVERS INSTALLED 10 GROB HARNESS FRAMES 6 CONTACT BARS HEDDLES AND DROPPERS AS FITTED 7 ECS UNITS 5 ROJ WEFT ACCUMULATORS 1.5 SINGLE BEAM 1.5 CLOTH ROLLS (SPECIALLY MADE BATCHING UNIT AVAILABLE AT ADDITIONAL COST) QUANTITY AVAILABLE: 3 Learn More -

A-1207 PICANOL OMNI PLUS 800 2P 1900MM STAUBLI 1661REFERENCE NUMBER: A-1207 (0101GHBXX12) A PICANOL OMNI PLUS 800 2P 1900MM STAUBLI 1661 QUANTITY AVAILABLE: 12 Learn More

A-1207 PICANOL OMNI PLUS 800 2P 1900MM STAUBLI 1661REFERENCE NUMBER: A-1207 (0101GHBXX12) A PICANOL OMNI PLUS 800 2P 1900MM STAUBLI 1661 QUANTITY AVAILABLE: 12 Learn More -

G-7433 MULTIFUNCTION MACHINE FOR SHREDDING FOAM, POLYESTER OR COTTON FIBER OPENING, MIXING AND PILLOW FILLINGMODEL 1600-H2Y-1360-1710-C7H SPECIFICATION 1.MIXING BOX: 1400 X 1200 X 2200mm 2.FOAM GRINDER: 2500 X 680 X 860mm 3.FIBER OPENER (1710-A7H): 2200 X 1080 X 1070mm VOLTAGE 220 VOLTS 60Hz POWER 0.75 X 2+5.5+4 +2.2 X 3 KW = 16.2 OUTPUT 100 TO 300 KG/H MIX PERCENTAGE ABOVE 98% LABOR 3 PERSONS WEIGHT 1530 KG LABOR 3 PERSONS WEIGHT 1530KG MACHINE DETAILS ONE FOAM SHREDDING MACHINE , ONE FIBER OPENING MACHINE, ONE FEEDING MACHINE, ONE MIXING BOX, TWO FIBER OR FOAM STUFFING NOZZLES (WITH FANS) STATIONS PRODUCT INTRODUCTION : THIS MACHINE IS A NEW MACHINE TO FILL PILLOWS, CUSHIONED SOFA SECTIONS, ETC. ITS GREAT ADVANTAGE IS THAT IT WILL NOT PRODUCE GRANULES AND BALL GRAINS WHEN MIXING CELLUCOTTON AND FOAM, PRODUCING A PRODUCT THAT FILLS WITH EXCELLENT ELASTICITY AND A SMOOTH SURFACE (FOR PILLOWS, A SMOOTH SURFACE IS ESPECIALLY IMPORTANT.) MAIN FUNCTION : IT CONSISTS OF A FOAM SHREDDER, A FIBER OPENER, A MIXING STATION AND TWO FILLING NOZZLES. BY SIMPLY PUTTING THE FOAM (INCLUDING SCRAP ),RAW COTTON (NON-CARDED AND CELLUCOTTON) INTO THE MACHINE, IT WILL AUTOMATICALLY OPEN THE CELLUCOTTON AND SHRED THE FOAM. THE DOSAGE RATIO OF EACH RAW MATERIAL CAN BE ADJUSTED OPTIONALLY, EVENLY MIX THEM AND THEN FILL INTO THE PRODUCT. QUANTITY: 1 Learn More

G-7433 MULTIFUNCTION MACHINE FOR SHREDDING FOAM, POLYESTER OR COTTON FIBER OPENING, MIXING AND PILLOW FILLINGMODEL 1600-H2Y-1360-1710-C7H SPECIFICATION 1.MIXING BOX: 1400 X 1200 X 2200mm 2.FOAM GRINDER: 2500 X 680 X 860mm 3.FIBER OPENER (1710-A7H): 2200 X 1080 X 1070mm VOLTAGE 220 VOLTS 60Hz POWER 0.75 X 2+5.5+4 +2.2 X 3 KW = 16.2 OUTPUT 100 TO 300 KG/H MIX PERCENTAGE ABOVE 98% LABOR 3 PERSONS WEIGHT 1530 KG LABOR 3 PERSONS WEIGHT 1530KG MACHINE DETAILS ONE FOAM SHREDDING MACHINE , ONE FIBER OPENING MACHINE, ONE FEEDING MACHINE, ONE MIXING BOX, TWO FIBER OR FOAM STUFFING NOZZLES (WITH FANS) STATIONS PRODUCT INTRODUCTION : THIS MACHINE IS A NEW MACHINE TO FILL PILLOWS, CUSHIONED SOFA SECTIONS, ETC. ITS GREAT ADVANTAGE IS THAT IT WILL NOT PRODUCE GRANULES AND BALL GRAINS WHEN MIXING CELLUCOTTON AND FOAM, PRODUCING A PRODUCT THAT FILLS WITH EXCELLENT ELASTICITY AND A SMOOTH SURFACE (FOR PILLOWS, A SMOOTH SURFACE IS ESPECIALLY IMPORTANT.) MAIN FUNCTION : IT CONSISTS OF A FOAM SHREDDER, A FIBER OPENER, A MIXING STATION AND TWO FILLING NOZZLES. BY SIMPLY PUTTING THE FOAM (INCLUDING SCRAP ),RAW COTTON (NON-CARDED AND CELLUCOTTON) INTO THE MACHINE, IT WILL AUTOMATICALLY OPEN THE CELLUCOTTON AND SHRED THE FOAM. THE DOSAGE RATIO OF EACH RAW MATERIAL CAN BE ADJUSTED OPTIONALLY, EVENLY MIX THEM AND THEN FILL INTO THE PRODUCT. QUANTITY: 1 Learn More