Search results for: 'air press'

- Related search terms

- Air

- air com

- air pressure

- air+press

- air+co

-

T-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKETT-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKET ADAPTATION RANGE: MAINLY FOR LARGE AND SMALL CELLS FILLED WITH DOWN COTTON, DOWN AND BEDDING DUVET FILLING, AND CAN BE FILLED WITH AIRTIGHT FABRICS PACKED WEIGHT: 43.55 KG PACKED DIMENSIONS: 630 x 770 x 700mm Learn More

T-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKETT-9663 AUTOMATIC SINGLE QUILT JACKET BAG COTTON GOOSE DOWN FEATHER COMFORTER FILLING MACHINE DOWN JACKET ADAPTATION RANGE: MAINLY FOR LARGE AND SMALL CELLS FILLED WITH DOWN COTTON, DOWN AND BEDDING DUVET FILLING, AND CAN BE FILLED WITH AIRTIGHT FABRICS PACKED WEIGHT: 43.55 KG PACKED DIMENSIONS: 630 x 770 x 700mm Learn More -

J-3689 LAMINATION LINE, WORKING WIDTH 2200mm, YEAR 2003 & 2005J-3689 LAMINATION LINE, WORKING WIDTH 2200mm, YEAR 2003 & 2005 COMPOSED OF: MEYER PST-2300 POWDER SCATTERING UNIT WORKING WIDTH 2200mm YEAR: 2005 QUANTITY: 1 SCHAETTI KANNEGIESSER TLM-V LAMINATION MACHINE OVEN IS ELECTRICALLY HEATED WORKING WIDTH : 2000mm FLATBED YEAR : 2003 RHOSS MODEL CWA/EX COOLER Learn More

J-3689 LAMINATION LINE, WORKING WIDTH 2200mm, YEAR 2003 & 2005J-3689 LAMINATION LINE, WORKING WIDTH 2200mm, YEAR 2003 & 2005 COMPOSED OF: MEYER PST-2300 POWDER SCATTERING UNIT WORKING WIDTH 2200mm YEAR: 2005 QUANTITY: 1 SCHAETTI KANNEGIESSER TLM-V LAMINATION MACHINE OVEN IS ELECTRICALLY HEATED WORKING WIDTH : 2000mm FLATBED YEAR : 2003 RHOSS MODEL CWA/EX COOLER Learn More -

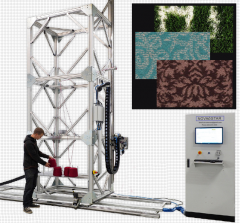

T-7649 NOVASTAR ROBOT HANDTUFTING MACHINET-7649 NOVASTAR ROBOT HANDTUFTING MACHINE ITEM 001 NOVASTAR ROBOT HANDTUFT STAR6.2-6X4 MACHINE IS COMPLETE AND INCLUDES ALL NECESSARY ACCESSORIES. 10000 X 4400mm PRODUCTION AREA INCLUDING FOLLOWING PARTS 1 PC MOVEABLE FRAME 10850 X 5850mm 2 PCS HOLDERS FOR FRAMES 1 UNIT CREEL WITH 6 SENSORS 1 PC YARNDETECTOR FOR TUFTHEAD 2 SET NEEDLES, 8 PCS DIAMETER 5mm, 8 PCS DIAMETER 6mm 10 PCS BLADE 2 PCS ANVIL 1 PC TOOLKIT FOR TUFTUNIT 1 TOOL FOR STRECHING OF BACKING BLADES, 10 PCS ANVIL, 2 PCS 1 SET FEED WHEELS, 2 PCS QUANTITY: 1 UNIT ITEM 002 FRAME 6000 X 4000mm (6850 X 4850) QUANTITY: 2 ITEM 003 SPARE PART KIT QUANTITY: 1 ITEM 004 NOVASTAR TUFT CAD, PLUG IN YOU NEED A LICENSE OF COREL DRAW 2020 Learn More

T-7649 NOVASTAR ROBOT HANDTUFTING MACHINET-7649 NOVASTAR ROBOT HANDTUFTING MACHINE ITEM 001 NOVASTAR ROBOT HANDTUFT STAR6.2-6X4 MACHINE IS COMPLETE AND INCLUDES ALL NECESSARY ACCESSORIES. 10000 X 4400mm PRODUCTION AREA INCLUDING FOLLOWING PARTS 1 PC MOVEABLE FRAME 10850 X 5850mm 2 PCS HOLDERS FOR FRAMES 1 UNIT CREEL WITH 6 SENSORS 1 PC YARNDETECTOR FOR TUFTHEAD 2 SET NEEDLES, 8 PCS DIAMETER 5mm, 8 PCS DIAMETER 6mm 10 PCS BLADE 2 PCS ANVIL 1 PC TOOLKIT FOR TUFTUNIT 1 TOOL FOR STRECHING OF BACKING BLADES, 10 PCS ANVIL, 2 PCS 1 SET FEED WHEELS, 2 PCS QUANTITY: 1 UNIT ITEM 002 FRAME 6000 X 4000mm (6850 X 4850) QUANTITY: 2 ITEM 003 SPARE PART KIT QUANTITY: 1 ITEM 004 NOVASTAR TUFT CAD, PLUG IN YOU NEED A LICENSE OF COREL DRAW 2020 Learn More -

AA-1169 PILLOW FILLING MACHINE WITH DOWN AND FEATHERAA-1169 PILLOW FILLING MACHINE WITH DOWN AND FEATHER MAIN SILO CAPACITY: 40KG IN TOTAL VOLTAGE: 220V/60Hz POWER: 2.3KW DIMENSIONS: 2500 x 1000 x 2500mm WEIGHT: 960KG Learn More

AA-1169 PILLOW FILLING MACHINE WITH DOWN AND FEATHERAA-1169 PILLOW FILLING MACHINE WITH DOWN AND FEATHER MAIN SILO CAPACITY: 40KG IN TOTAL VOLTAGE: 220V/60Hz POWER: 2.3KW DIMENSIONS: 2500 x 1000 x 2500mm WEIGHT: 960KG Learn More -

1000 L STABILITY CHAMBERREFERENCE NUMBER: A-2492 1000 L STABILITY CHAMBER SPECIFICATIONS: INNER CHAMBER SIZE: 1 X 1 X 1 mm EXTERNAL DIMENSION: 1.2 X 1.97 X 2.17 mm TEMPERATURE RANGE: 70 TO 180°C HUMIDITY RANGE: 10% TO 98% RH, WHEN THE TEMPERATURE IS ABOVE 60°C, THE HUMIDITY CAN ACHIEVE 10% RH TEMPERATURE & HUMIDITY FLUCTUATION: ±0.2℃, ±0.5% RH INDICATION RESOLUTION: 0.01℃, 0.1% RH TEMPERATURE & HUMIDITY UNIFORMITY: ±2℃, ±3% RH (TESTED WITH THE EMPTY CHAMBER, 30 MINUTES AFTER STABILIZATION) HEAT UP AND COOL DOWN TIME: HEATING RATE: AVERAGE 3 ℃/MINUTES; COOLING RATE: AVERAGE 1 ℃/MINUTE (UNLOADED TEST) MATERIAL: INNER CHAMBER: SUS#304 STAINLESS STEEL EXTERIOR STRUCTURE: STAINLESS STEEL PLATE + POWDER COATED INSULATION: GLASS WOOL & PUF PERSPIRATION RESISTANT: K STYLE TUBE ACCESSORIES • TEMPERATURE RESISTANT SILICONE GASKET: 1 PC • CABLE PORT:1 PC; OD: 100 mm • WINDOW LIGHT: 1 PC • MULTIPANE VIEW WINDOW: 1 PC • LOADING SHELVES: 2 PCS REFRIGERATION & HEATING SYSTEM • ORIGINAL IMPORTED HIGH EFFICIENCY COMPRESSOR • AIR COOLING CONDENSER • FIN – TUBE HEATER • ORIGINAL IMPORTED SOLENOID VALVES • INNER SPIRAL K – TYPE REFRIGERANT COPPER TUBE • U – TYPE FINNED ELECTRO - THERMAL TUBE • HEATING & COOLING SYSTEMS SEPARATED • SINGLE STAGE REFRIGERATING SYSTEM HUMIDIFYING & DEHUMIDIFYING SYSTEM • ELECTRIC & BYTE TYPE HUMIDIFYING SYSTEM • STAINLESS STEEL HUMIDIFYING BARREL WITH VIEW WINDOW FOR WATER LEVEL • ADP DEHUMIDIFYING WAY • OVER – TEMPERATURE AND OVERFLOW PROTECTION UNITS • HUMIDIFYING & DEHUMIDIFYING SYSTEMS SEPARATED CIRCLING & DRAIN SYSTEM • CENTRIFUGAL FAN & IMPORTED MOTOR • REVERSE UNIFLOW (AIR FLOW DIRECTION) • FLOW – THROWS WIND • DRAIN SYSTEM USES SWIRL TYPE OUTLET AND U – TRAP DEPOSITION UNIT PROGRAMABLE MICRO COMPUTER LCD TOUCH CONTROLLER • PROGRAMMABLE TOUCH CONTROLLER, USER - FRIENDLY, STABLE AND EASY USE • PROGRAMS: 99 SEGMENTS PER PROGRAM, 120 PROGRAMS, 120 CYCLING PER PROGRAM • PID & SSR CONTROL WAY, STABLE AND EASY USE • HAVE SLOP CONTROL FUNCTION FOR HEATING & COOLING, LINKED PTNS CAN BE EXECUTED • PID AUTOMATIC CALCULATION • MICRO COMPUTER MULTI FUNCTION CONTROLLER, MAIN COMPONENTS ’DATA AUTOMATICALLY OUTPUT INCLUDING COMPRESSORS, SOLENOIDS, HEATING UNITS, ETC • ERRORS OF MAIN COMPONENTS APPEAR ON THE LCD PANEL • THE BRIGHTNESS OF THE LCD PANEL CAN BE ADJUSTED • TIME SEQUENCE CONTROL INTERFACE RELAYS HAVE 3 GROUPS WHICH MANAGE THE OUTPUT OF OUTSIDE LOGIC UNITS INCLUDING SIGNAL, MECHANICAL AND POWER, ETC • PROGRAMS AUTO – SAVE FUNCTION IF POWER CUT OFF SUDDENLY • HAVE HOLD & ADV BUTTONS INPROGRAMS • AUTOMATICALLY SET THE HIGH & LOW TEMPERATURE LIMITS AFTER PROGRAMS SET • PASSWORD SET FUNCTION • SD CARD SLOT, 2 GB SD CARD, RS232 OR ETHERNET (RJ45) OPERATING ENVIRONMENT • AMBIENT TEMPERATURE: +25℃ (2) RH ≤85% PROTECTION • ELECTRICITY LEAK PROTECTION • LIGHTNING STRIKE PROTECTION, ZRN LIGHTNING ARRESTER INSIDE THE CONTROLLER • SENSOR DATES TRANSFERRED INSIDE THE MICRO COMPUTER • TEMP. SENSORS TO OPEN CIRCUIT OR SHORT CIRCUIT (+ - OVER) • THE FIRST LEVEL OVER TEMPERATURE PROTECTION • ERROR DETECTED UNITS • THE SECOND LEVEL OVER TEMPERATURE PROTECTION TO ELECTRONIC OVER - TEMP PROTECTION UNIT • THE THIRD LEVEL OVER - TEMPERATURE PROTECTION • COMPRESSOR PROTECTION TO REFRIGERANTS PRESSURE PROTECTION & OVERLOAD PROTECTION. • EXTENDED PROTECTION UNIT TO TWO SUPPLETIVE PORTS • ERROR PROTECTION TO POWER CUT OFF, ERROR REPORTS SHOWN IN LCD PANEL AND AUDIBLE ALARM STARTS • DYNAMIC HIGH AND LOW TEMPERATURE PROTECTION • AMBIENT TEMPERATURE PROTECTION TO THE INNER CHAMBER AND SPECIMENS AUTOMATICALLY RETURN BACK TO AMBIENT TEMPERATURE AFTER THE OPERATION STOP SAFETY PROTECTION • NON-FUSE PROTECTION SWITCH • OVERHEAT ALARM PROTECTION • COMPRESSOR OVERLOAD PROTECTION • PHASE SEQUENCE PROTECTION • MOTOR OVER TO CURRENT PROTECTION Learn More

1000 L STABILITY CHAMBERREFERENCE NUMBER: A-2492 1000 L STABILITY CHAMBER SPECIFICATIONS: INNER CHAMBER SIZE: 1 X 1 X 1 mm EXTERNAL DIMENSION: 1.2 X 1.97 X 2.17 mm TEMPERATURE RANGE: 70 TO 180°C HUMIDITY RANGE: 10% TO 98% RH, WHEN THE TEMPERATURE IS ABOVE 60°C, THE HUMIDITY CAN ACHIEVE 10% RH TEMPERATURE & HUMIDITY FLUCTUATION: ±0.2℃, ±0.5% RH INDICATION RESOLUTION: 0.01℃, 0.1% RH TEMPERATURE & HUMIDITY UNIFORMITY: ±2℃, ±3% RH (TESTED WITH THE EMPTY CHAMBER, 30 MINUTES AFTER STABILIZATION) HEAT UP AND COOL DOWN TIME: HEATING RATE: AVERAGE 3 ℃/MINUTES; COOLING RATE: AVERAGE 1 ℃/MINUTE (UNLOADED TEST) MATERIAL: INNER CHAMBER: SUS#304 STAINLESS STEEL EXTERIOR STRUCTURE: STAINLESS STEEL PLATE + POWDER COATED INSULATION: GLASS WOOL & PUF PERSPIRATION RESISTANT: K STYLE TUBE ACCESSORIES • TEMPERATURE RESISTANT SILICONE GASKET: 1 PC • CABLE PORT:1 PC; OD: 100 mm • WINDOW LIGHT: 1 PC • MULTIPANE VIEW WINDOW: 1 PC • LOADING SHELVES: 2 PCS REFRIGERATION & HEATING SYSTEM • ORIGINAL IMPORTED HIGH EFFICIENCY COMPRESSOR • AIR COOLING CONDENSER • FIN – TUBE HEATER • ORIGINAL IMPORTED SOLENOID VALVES • INNER SPIRAL K – TYPE REFRIGERANT COPPER TUBE • U – TYPE FINNED ELECTRO - THERMAL TUBE • HEATING & COOLING SYSTEMS SEPARATED • SINGLE STAGE REFRIGERATING SYSTEM HUMIDIFYING & DEHUMIDIFYING SYSTEM • ELECTRIC & BYTE TYPE HUMIDIFYING SYSTEM • STAINLESS STEEL HUMIDIFYING BARREL WITH VIEW WINDOW FOR WATER LEVEL • ADP DEHUMIDIFYING WAY • OVER – TEMPERATURE AND OVERFLOW PROTECTION UNITS • HUMIDIFYING & DEHUMIDIFYING SYSTEMS SEPARATED CIRCLING & DRAIN SYSTEM • CENTRIFUGAL FAN & IMPORTED MOTOR • REVERSE UNIFLOW (AIR FLOW DIRECTION) • FLOW – THROWS WIND • DRAIN SYSTEM USES SWIRL TYPE OUTLET AND U – TRAP DEPOSITION UNIT PROGRAMABLE MICRO COMPUTER LCD TOUCH CONTROLLER • PROGRAMMABLE TOUCH CONTROLLER, USER - FRIENDLY, STABLE AND EASY USE • PROGRAMS: 99 SEGMENTS PER PROGRAM, 120 PROGRAMS, 120 CYCLING PER PROGRAM • PID & SSR CONTROL WAY, STABLE AND EASY USE • HAVE SLOP CONTROL FUNCTION FOR HEATING & COOLING, LINKED PTNS CAN BE EXECUTED • PID AUTOMATIC CALCULATION • MICRO COMPUTER MULTI FUNCTION CONTROLLER, MAIN COMPONENTS ’DATA AUTOMATICALLY OUTPUT INCLUDING COMPRESSORS, SOLENOIDS, HEATING UNITS, ETC • ERRORS OF MAIN COMPONENTS APPEAR ON THE LCD PANEL • THE BRIGHTNESS OF THE LCD PANEL CAN BE ADJUSTED • TIME SEQUENCE CONTROL INTERFACE RELAYS HAVE 3 GROUPS WHICH MANAGE THE OUTPUT OF OUTSIDE LOGIC UNITS INCLUDING SIGNAL, MECHANICAL AND POWER, ETC • PROGRAMS AUTO – SAVE FUNCTION IF POWER CUT OFF SUDDENLY • HAVE HOLD & ADV BUTTONS INPROGRAMS • AUTOMATICALLY SET THE HIGH & LOW TEMPERATURE LIMITS AFTER PROGRAMS SET • PASSWORD SET FUNCTION • SD CARD SLOT, 2 GB SD CARD, RS232 OR ETHERNET (RJ45) OPERATING ENVIRONMENT • AMBIENT TEMPERATURE: +25℃ (2) RH ≤85% PROTECTION • ELECTRICITY LEAK PROTECTION • LIGHTNING STRIKE PROTECTION, ZRN LIGHTNING ARRESTER INSIDE THE CONTROLLER • SENSOR DATES TRANSFERRED INSIDE THE MICRO COMPUTER • TEMP. SENSORS TO OPEN CIRCUIT OR SHORT CIRCUIT (+ - OVER) • THE FIRST LEVEL OVER TEMPERATURE PROTECTION • ERROR DETECTED UNITS • THE SECOND LEVEL OVER TEMPERATURE PROTECTION TO ELECTRONIC OVER - TEMP PROTECTION UNIT • THE THIRD LEVEL OVER - TEMPERATURE PROTECTION • COMPRESSOR PROTECTION TO REFRIGERANTS PRESSURE PROTECTION & OVERLOAD PROTECTION. • EXTENDED PROTECTION UNIT TO TWO SUPPLETIVE PORTS • ERROR PROTECTION TO POWER CUT OFF, ERROR REPORTS SHOWN IN LCD PANEL AND AUDIBLE ALARM STARTS • DYNAMIC HIGH AND LOW TEMPERATURE PROTECTION • AMBIENT TEMPERATURE PROTECTION TO THE INNER CHAMBER AND SPECIMENS AUTOMATICALLY RETURN BACK TO AMBIENT TEMPERATURE AFTER THE OPERATION STOP SAFETY PROTECTION • NON-FUSE PROTECTION SWITCH • OVERHEAT ALARM PROTECTION • COMPRESSOR OVERLOAD PROTECTION • PHASE SEQUENCE PROTECTION • MOTOR OVER TO CURRENT PROTECTION Learn More -

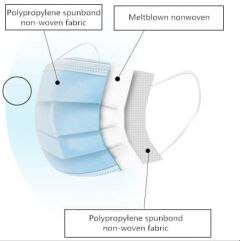

J-2765 3-LAYER FACE MASK PRODUCTION MACHINE – 150 MASKS PER MINUTE

J-2765 3-LAYER FACE MASK PRODUCTION MACHINE – 150 MASKS PER MINUTECAPACITY: 100 TO 150 MASKS PER MINUTE

PRODUCES MASKS WITH 3 LAYERS OF POLYPROPYLENE NONWOVEN MATERIAL

AIR PRESSURE: 0.6 MPa, AIR CONSUMPTION 300 LITERS PER MINUTE

CONTROLLED BY PLC, OPERATED BY LCD TOUCH SCREEN

USES ULTRASONIC WELDING FOR EAR STRAPS

VOLTAGE: AS PER CUSTOMER

TOTAL POWER: 11 KW

DIMENSIONS: 6850 x 3520 x 1990mm

WEIGHT: ≤ 5000kgMASK SURFACE LAYER, FILTER LAYER AND BOTTOM LAYER CAN BE ALIGNED AND FED TO THE MACHINE AUTOMATICALLY

BOTH SIDES ARE SYMMETRICAL WITH ULTRASONIC PROCESS STATIONS FOR EAR STRAP WELDING

AFTER WELDING, THE MASKS ARE COUNTED AND PILED TOGETHER AUTOMATICALLY

MASKS ARE DISTRIBUTED EVENLY TO TWO SETS OF EAR STRAP STATIONS BY AUTOMATIC TRANSMISSION SYSTEM, CONTROLLED BY PLC

NOSE CLIPS CAN BE AUTOMATICALLY FED, CUT AND ULTRASONICALLY WELDEDTHE CUP TYPE MASK PRODUCTION LINE CAN BE SENT BY AIR, THERE ARE TOTAL 5 WOODEN CASES, SIZES AND WEIGHT AS BELOW:

1. 2500 X 1100 X 1000mm, 1PC, 250KGS

2. 2200 X 1000 X 1500mm, 1PC, 1100KGS

3. 3000 X 1200 X 1500mm, 1PC, 1100KGS

4. 3000 X 1200 X 1500mm, 1PC, 1100KGS

5. 1900 X 700 X 1150mm, 1PC, 250KGSIF CUSTOMER NEEDS MASK BAGGING MACHINE TO CONNECT WITH DISPOSABLE MASK PRODUCTION LINE, THERE WILL BE ANOTHER TWO WOODEN CASES EXTRA, BUT WILL CANCEL THE FIFTH WOODEN CASE, SIZES AND WEIGHT AS BELOW:

1. 1580mm X 840MM X 1510 mm,1PCS, 340KG

Learn More

2. 2540 mm X 540 mm X 1510 mm,1PCS, 80KG -

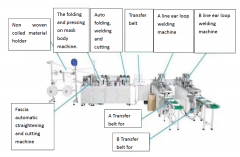

J-2733 COMPLETE AUTOMATIC PRODUCTION LINE FOR FACE MASKS – 140,000 PIECES PER 24-HOUR DAY

J-2733 COMPLETE AUTOMATIC PRODUCTION LINE FOR FACE MASKS – 140,000 PIECES PER 24-HOUR DAYPRODUCES FLAT MASKS AUTOMATICALLY: COILS STOCK, FOLDS AND PRESSES, MOLDS MASK, CUTS, LOADS AND WELDS EAR LOOPS, FINISHED PRODUCTS EXIT THE MACHINE

Learn More

MASKS ARE COMFORTABLE, NO PRESSURE, EASY TO WEAR AND PROVIDE GOOD FILTRATION

LINE FEATURES

ULTRASONIC WELDING MACHINE

HIGH SPEED PRODUCTION: 120,000 TO 140,000 PIECES PER 24-HOUR DAY

-APPROXIMATELY 90 TO 110 PIECES PER MINUTE

MODULAR AND PERSONNEL-FRIENDLY DESIGN WITH EASY MAINTENANCE

AUTOMATIC STOP AND ALARM FEATURE FOR MATERIAL BREAKAGE AND OTHER EXCEPTIONS, WITH ON-SCREEN HELP FOR CORRECTING THE BREAKAGE/EXCEPTIONS

DIMENSIONS: 6500mm LENGTH x 2500mm WIDTH x 1950mm HEIGHT

WEIGHT: </= 5000 KG

POWER: 220 VOLTS +/- 5% , 50 Hz, GROUND PROTECTION (OR AS PER CUSTOMER)

TOTAL KW: APPROXIMATELY 8.8 KW

AIR: 0.4 TO 0.6 MP (CLEAN AIR AFTER DEWATER, OIL-LESS, FILTRATION AND PRESSURE)

MAIN ACCESSORY: AIRTAC AIR CYLINDER

QUANTITY: 1 COMPLETE LINE (2 SETS CURRENTLY AVAILABLE MARCH 17TH) -

J-2375 COMPLETE CERAMIC TILE PRODUCTION PLANT, PRODUCTION 7 MILLION SQUARE METERS PER YEAR

J-2375 COMPLETE CERAMIC TILE PRODUCTION PLANT, PRODUCTION 7 MILLION SQUARE METERS PER YEARTILE FACTORY DESIGNED BY SACMI / ITALY

YEAR ESTABLISHED 2014 TO 2016

THIS PLANT IS AN ENVIRONMENTALLY FRIENDLY ENTERPRISE, WHEN IT RECYCLES 100% OF ITS EFFLUENTS AND PERFORMS HEAT RECOVERY, THEREBY SAVING ENERGY

See all pictures:

https://www.flickr.com/photos/183869481@N08/albums/72157710649767958THE PLANT:

COVERS AN AREA OF 22 THOUSAND SQUARE METERS

THE PRODUCTION CAPACITY IS 7 MILLION SQUARE METERS / YEAR

CERAMIC FLOOR TILES

CERAMIC WALL TILES

BMR POLISHING LINE

BMR SQUARING & CHANFERING LINE

THE MAIN RAW MATERIALS ARE CLAY (DB-4) - 31 %, ALBITE (STD5) - 60 %

NEPHAIIN (PN9595) - 2.5 %, KAOLIN (RHB1) - 6.5 %

ON TOP OF IT THEY ARE USING GLAZE MATERIALS AND PAINTS

•FROM THE MOMENT THE MATERIAL IS PREPARED IT IS BEING DRIED PRESSED ON ONE OF FOUR (4) PRODUCTION LINES.

•TWO (2) LINES ARE WITH SACMI PRESSES OF PH 7,500 TON EACH AND HORIZONTAL DRYERS SACMI

•TWO LINES ARE WITH SACMI PRESSES OF PH 3,590 TON EACH AND VERTICAL DRYERS SACMI

•ALL FOUR (4) LINES HAVE THEIR OWN DIGITAL PRINTING MACHINE INCORPORATED

•ALL PRODUCTS ARE BEING GLAZED AND FIRED ON 1200 DEGREES IN ONE OF THE TWO (2) KILNS, SACMI

FOUR (4) SORTING, PACKING AND PALLETIZING LINES

GLAZE PREPARATION LINE

COMPLETE INSTALLATION FOR SMALL PRODUCTION CAPACITIES

COMPLETE FOILING LINE

COMPLETE ELECTRIC INSTALLATION

POWER GENERATOR UNIT

COMPRESSED AIR INSTALLATIONMACHINES ARE MADE BY:

SACMI: ITALY

NUOVA ERA / ROBOBOX: ITALY

BMR: ITALY

IN.TE.SA: ITALY

CUCCOLINI: ITALY

SYSTEM CERAMICS: ITALY

TGMAC SR.L: ITALY

DURST: GERMANY

ROTOCOLOR MAG: ITALY

NUOVA FIMA: ITALY

OMS: ITALY

MARPAK OMS: ITALY

MESSERSI PACK: ITALYTILE SIZES

THE FACTORY MANUFACTURES TILES OF VARIOUS SIZES FROM 300 X 300 TO 1200 X 1200mm IN VARIOUS TEXTURES AND DESIGNS USING DIGITAL PRINTING MACHINES

PRODUCTION CAPACITY IS 7 MILLION SQUARE METERS / YEAR

THE FACTORY IS FULLY AUTOMATED AND USING ADVANCED CONTROL SYSTEMS!HUGE AMOUNT OF ORIGINAL SPARE PARTS AVAILABLE WITH THIS PLANT

THIS PLANT IS AVAILABLE WITH THE COMPLETE ELECTRIC, AIR, GAS, RECYCLING INSTALLATIONTHIS PLANT CAN BE SOLD: WITH 4 LINES OR 2 AND 2 LINES

Learn More -

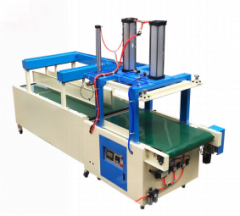

J-1948 PILLOW & CUSHION COMPRESSION PACKING MACHINE- NEW -AUTOMATIC , 12 PILLOWS PER MINUTE

J-1948 PILLOW & CUSHION COMPRESSION PACKING MACHINE- NEW -AUTOMATIC , 12 PILLOWS PER MINUTEREDUCES VOLUME FOR STORAGE AND TRANSPORTATION

USES COMPRESSED AIR AND PLASTIC COMPOSITE FILM BAGS FOR PACKAGING ITEMS AFTER COMPRESSION

EQUIPPED WITH AUTOMATIC TRANSMISSION TO COMPRESS AND FILM ITEMS UNINTERRUPTED

STANDARD MODEL EQUIPPED WITH ONE WORKSTATION WITH SINGLE SEAL (OPTIONAL ONE WORKSTATION WITH DOUBLE SEALS)

PLC TOUCH SCREEN OPERATION, USER FRIENDLY INTERFACE

CONSTANT TEMPERATURE CONTROL FUNCTION TO PREVENT BAG BURNSVOLTAGE AND POWER: 220 V SINGLE-PHASE, 0.5 KW, 50 Hz

AIR PRESSURE: 0.4 – 0.8 MPA

PACKING CAPACITY: : 8 TO 12 ITEMS PER MINUTE

PRESS BOARD SIZE: LENGTH 700mm x WIDTH 900mm

MAXIMUM COMPRESSION THICKNESS: 500mm (AIR CYLINDER TRAVEL)

SEAL LENGTH: 880mm x 10mm

OVERALL DIMENSIONS: LENGTH 3390mm x WIDTH 940mm x HEIGHT 2010mm

POWER: 1.5 KW

NET WEIGHT: 350 KG

GROSS WEIGHT: 400 KGQUANTITY: 1

Learn More -

T-2898 PP STAPLE FIBER PLANT, 6000 MTA, BRAND MOSTLY FLEISSNER , AUTEFA BALE PRESS

T-2898 PP STAPLE FIBER PLANT, 6000 MTA, BRAND MOSTLY FLEISSNER , AUTEFA BALE PRESST-2898 PP STAPLE FIBER PLANT, 6000 MTA, BRAND MOSTLY FLEISSNER , AUTEFA BALE PRESS

20 TONS PER DAYPP STAPLE FIBER SYSTEM

Learn More

6000 MTA (LINE-1+LINE-2)

EXTRUTION & SPINNING PACKAGE