Search results for: 'Edge tr'

-

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More -

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSES

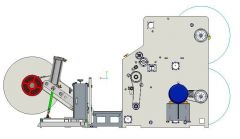

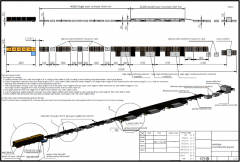

V-1468 COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTON GAUZE COMPRESSESREFERENCE NUMBER: V-1468

SURGICAL GAUZE COMPRESSING, FOLDING, AND BAGGING MACHINE

COTTON GAUZE MEDICAL COMPRESS FOLDING AND BAGGING MACHINE, WHICH AUTOMATICALLY FOLDS COTTONG GAUZE, COMPRESSES, AND THEN PACKS THEM INDIVIDUALLY OR IN GROUPS INTO SACHETS.

FEATURES

USEFUL WIDTH: 45 CM

NUMBER OF TRACKS: MAXIMUM 2 (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

SIZE:

MINIMUM DIMENSIONS OF COMPRESSES: 5 CM X 5 CM

MAXIMUM DIMENSIONS OF COMPRESSES: 10 CM X 20 CM (16 PLIES)

ALL THE USUAL OR INTERMEDIATE SIZES CAN BE PRODUCED ON THE MACHINE BY SIMPLE ADJUSTMENTS.

NUMBER OF PLIES 8 / 12 / 16 / 20 / 24 / 28 / 32 PLIES (VARIES ACCORDING TO THE SIZE OF COMPRESSES)

FOLDING: THE CONVENTIONAL FOLDING IS THE 5-FOLD "SURGICAL" OR "AMERICAN" TYPE, WITH EDGES AND CORNERS TUCKED-IN, HOWEVER BY OFFSETTING FOLDS OTHER COMBINATIONS ARE POSSIBLE.

STACKING: STACKING IS CARRIED OUT IN THE CHANNELS WHERE THE COMPRESSES ARE COUNTED AND READY TO BE MANUALLY INSERTED INTO PAPER BAGS.

PRODUCTION :

EXAMPLES OF THEORETICAL PRODUCTIONS:

5 CM X5 CM 8 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

7.5 CM X 7.5 CM 12 PLIES (2 TRACKS) 13200 COMPRESSES PER HOUR

10 CM X 10 CM 12 PLIES (2 TRACKS) 12000 COMPRESSES PER HOUR

OPTIONS:

BARIUM FIXING TRACK BY TRACK

GAUZE ROLL LOADING BY PNEUMATIC CYLINDERS"

FEATURES LIST:

MATERIAL SUPPORT ADJUSTABLE IN WIDTH,

POSITIVE UNWINDING WITH TENSION CHECK ADJUSTABLE TRACK BY TRACK,

MULTIPLE LENGTH FOLDING DEVICE ADJUSTABLE TRACK BY TRACK,

SPRAY HUMIDIFYING SYSTEM,

SUCTION SYSTEM,

ANTI-STATIC BARS,

ADJUSTABLE FLY CUT MODULE MOTORISED WITH BRUSHLESS MOTOR,

THREE CROSS FOLDING MECHANISMS WITH INDEPENDENT ADJUSTMENT OF EACH FOLD,

TRANSFER BELTS FOR THE COMPRESSES,

MOTORISED LATERAL UNWINDING OF THE PAPER ROLL MODULE,

DEVICE FOR INDIVIDUAL, IN MULTIPLES OR IN SHINGLED FORM PACKAGING - WITH A CHANGEABLE

NUMBER OF COMPRESSES BY SACHET,

CHECK OF FOLLOWING OPERATIONS TRACK BY TRACK:

. END OF FABRIC,

. PRESENCE OF SEAM,

. PRESENCE OF CROSS-FOLDED COMPRESS,

. JAM PREVENTION BEFORE PACKAGING.

COLD SEALING BY PRESSURE AND CUTTING OF SACHETS IN PRINTED AND ZONED PAPER,

POWER SYSTEM OF PACKAGING BY BRUSHLESS MOTOR ALLOWING FOR FLY ADJUSTMENT OF:

. THE COMPRESS POSITION IN THE SACHET,

. THE CROSSWISE KNURLING POSITION,

. THE CROSSWISE CUTTING OF SACHETS.

ACCELERATION RAMP BY FREQUENCY VARIATION,

MACHINE OPERATION BY TOUCH-SENSITIVE SCREEN:

. STORABLE CONFIGURATIONS,

. CLEAR LANGUAGE FAULT DISPLAY,

. COUNTERS : TOTALIZER, PRE-SELECTION, ETC.,

. SOUND AND VISUAL ALARMS,

. "INCIDENT" STATISTICS.

STARTING, STOPPING, STEP BY STEP - BY REMOTE CONTROL.

* CONTINUOUS, TRACK BY TRACK INTEGRATION OF ULTRASONIC BARIUM FIXING.

* PAPER ROLL LOADING BY PNEUMATIC CYLINDERS.

* INK JET MARKING UP TILL 8 LINES.

* SACHETS QUALITY CONTROL DEVICE: EITHER A CHECK BY PHOTO CELLS, OR BY CAMERAS,

* FAULTY SACHET EJECTION DEVICE.

* TABLE WITH CONVERGING BELTS.

Learn More -

YY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEMYY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEM INCLUDES: 1 PALLET CONVEYOR ROLLER LINE 1 SINGLE-LAYER ASSEMBLY ROLLER LINE 1 DOUBLE-LAYER CONVEYOR ROLLER LINE 1 GRAVITY-FED ROLLER LINE 1 SINGLE-LAYER QUALITY INSPECTION CONVEYOR LINE PRESS MACHINE INLET AND OUTLET ROLLER LINE TOTAL 2 SECTIONS TOTAL ROLLER POWER HEAD ASSEMBLY PARTS: 52 SETS EACH FUNCTIONAL PART IS EQUIPPED WITH CORRESPONDING START SWITCH AND CONTROLLING POWER BOX, AND EQUIPPED WITH MICROCOMPUTER TO CONTROL THE PROCESSING Learn More

YY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEMYY-1485 COMPLETE CONVEYORIZED TAPE EDGE LINE WITH DOUBLE CONVEYORS AND STACKING SYSTEM INCLUDES: 1 PALLET CONVEYOR ROLLER LINE 1 SINGLE-LAYER ASSEMBLY ROLLER LINE 1 DOUBLE-LAYER CONVEYOR ROLLER LINE 1 GRAVITY-FED ROLLER LINE 1 SINGLE-LAYER QUALITY INSPECTION CONVEYOR LINE PRESS MACHINE INLET AND OUTLET ROLLER LINE TOTAL 2 SECTIONS TOTAL ROLLER POWER HEAD ASSEMBLY PARTS: 52 SETS EACH FUNCTIONAL PART IS EQUIPPED WITH CORRESPONDING START SWITCH AND CONTROLLING POWER BOX, AND EQUIPPED WITH MICROCOMPUTER TO CONTROL THE PROCESSING Learn More -

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More -

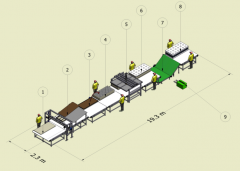

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

TRANSFER PRINTING RANGETRANSFER PRINTING RANGE, CONSISTING OF; A. JACK STAND AND STAINLESS J-SCRAY WITH EDGE SENSORS B. OPERATOR PLATFORM C. SINGER(?) TRANSFER MACHINE WITH 36" DIA. X 149" FACE WIDTH HOT-OIL CYLINDER INTERNALLY HEATED OIL BATH BY CHROMALOX ELECTRIC HEATING RODS, 126" FACE NOMEX BLANKET, CONTROLS. D. DSI A-FRAME WINDER, DIRECT COUPLING TO SPLINE SHAFT, 7.5-HP Learn More

TRANSFER PRINTING RANGETRANSFER PRINTING RANGE, CONSISTING OF; A. JACK STAND AND STAINLESS J-SCRAY WITH EDGE SENSORS B. OPERATOR PLATFORM C. SINGER(?) TRANSFER MACHINE WITH 36" DIA. X 149" FACE WIDTH HOT-OIL CYLINDER INTERNALLY HEATED OIL BATH BY CHROMALOX ELECTRIC HEATING RODS, 126" FACE NOMEX BLANKET, CONTROLS. D. DSI A-FRAME WINDER, DIRECT COUPLING TO SPLINE SHAFT, 7.5-HP Learn More -

A-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mmA-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600mm PRODUCTION SPEED: 24 TO 30 M/min EXTRUDER DIAMETER IN mm: 90mm EXTRUDER MOTOR IN KW: 45 KW PRODUCT WEIGHT RANGE: 8000 TO 1000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 1500 TO 1800 KG / 24 HOURS DIMENSION: 20000 X 8000 X 9000 mm WEIGHT: 8000 TO 1000 KGS POWER (TOTAL KW): 575 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 + 1 X 20 PRODUCTION TIME: 45 DAYS Learn More

A-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mmA-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600mm PRODUCTION SPEED: 24 TO 30 M/min EXTRUDER DIAMETER IN mm: 90mm EXTRUDER MOTOR IN KW: 45 KW PRODUCT WEIGHT RANGE: 8000 TO 1000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 1500 TO 1800 KG / 24 HOURS DIMENSION: 20000 X 8000 X 9000 mm WEIGHT: 8000 TO 1000 KGS POWER (TOTAL KW): 575 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 + 1 X 20 PRODUCTION TIME: 45 DAYS Learn More -

TT-6784 DILO NEEDLELOOM NONWOVEN LINE, WORKING WIDTH 5000mm, YEAR 1999 TO 2010TT-6784 DILO NEEDLELOOM NONWOVEN LINE, WORKING WIDTH 5000mm, YEAR 1999 TO 2010 1. DILO NEEDLELOOM NONWOVEN LINE 2. BRAND: TEMAFA / TRUTZSCHLER / FOR / AUTEFA / DILO / ETF/ MENZEL 3. WORKING WIDTH: 5000mm 4. YEAR: 1999 TO 2010 QUANTITY: 1 Learn More

TT-6784 DILO NEEDLELOOM NONWOVEN LINE, WORKING WIDTH 5000mm, YEAR 1999 TO 2010TT-6784 DILO NEEDLELOOM NONWOVEN LINE, WORKING WIDTH 5000mm, YEAR 1999 TO 2010 1. DILO NEEDLELOOM NONWOVEN LINE 2. BRAND: TEMAFA / TRUTZSCHLER / FOR / AUTEFA / DILO / ETF/ MENZEL 3. WORKING WIDTH: 5000mm 4. YEAR: 1999 TO 2010 QUANTITY: 1 Learn More -

TT-3595 SML COEX CAST FILM EXTRUSION LINE, FILM WIDTH RANGE 1600 TO 2110mm, YEAR 2011TT-3595 SML COEX CAST FILM EXTRUSION LINE, FILM WIDTH RANGE 1600 TO 2110mm, YEAR 2011 BRAND: SML EXTRUDERS CONDITION: USED YEAR: 2011 QUANTITY: 1 Learn More

TT-3595 SML COEX CAST FILM EXTRUSION LINE, FILM WIDTH RANGE 1600 TO 2110mm, YEAR 2011TT-3595 SML COEX CAST FILM EXTRUSION LINE, FILM WIDTH RANGE 1600 TO 2110mm, YEAR 2011 BRAND: SML EXTRUDERS CONDITION: USED YEAR: 2011 QUANTITY: 1 Learn More