Search results for: 'Order n'

- Related search terms

- Order

- Order no

- Order no 3

- Order no 30

- ORDER 13 RULE 4

-

TT-8137 KRONES AND OTHERS CONTIFORM, MECAFILL, VARIOPAC LINE FOR NON-RETURNABLE PET BOTTLES, YEAR 2002TT-8137 KRONES AND OTHERS CONTIFORM, MECAFILL, VARIOPAC LINE FOR NON-RETURNABLE PET BOTTLES, YEAR 2002 1. YEAR: 2002 2. CATEGORY: COMPLETE FILLING LINES 3. MANUFACTURER: KRONES AND OTHERS 4. MODEL: CONTIFORM, MECAFILL, VARIOPAC 5. AVAILABILITY: 31/08/2025 6. THIS COMPLETE PET BOTTLING LINE WAS MANUFACTURED BETWEEN 1999 AND 2007 BY KRONES (GERMANY) AND OTHER EUROPEAN SUPPLIERS. 7. IT IS CURRENTLY STILL IN OPERATION AND USED FOR FILLING CARBONATED WATER AND LEMONADES INTO 1.5L PET BOTTLES. THE LINE HAS AN OUTPUT CAPACITY OF UP TO 16,000 BOTTLES PER HOUR. 8. IT HAS BEEN REGULARLY SERVICED AND REMAINS IN GOOD WORKING ORDER. AVAILABILITY: END OF AUGUST 2025. QUANTITY: 1 Learn More

TT-8137 KRONES AND OTHERS CONTIFORM, MECAFILL, VARIOPAC LINE FOR NON-RETURNABLE PET BOTTLES, YEAR 2002TT-8137 KRONES AND OTHERS CONTIFORM, MECAFILL, VARIOPAC LINE FOR NON-RETURNABLE PET BOTTLES, YEAR 2002 1. YEAR: 2002 2. CATEGORY: COMPLETE FILLING LINES 3. MANUFACTURER: KRONES AND OTHERS 4. MODEL: CONTIFORM, MECAFILL, VARIOPAC 5. AVAILABILITY: 31/08/2025 6. THIS COMPLETE PET BOTTLING LINE WAS MANUFACTURED BETWEEN 1999 AND 2007 BY KRONES (GERMANY) AND OTHER EUROPEAN SUPPLIERS. 7. IT IS CURRENTLY STILL IN OPERATION AND USED FOR FILLING CARBONATED WATER AND LEMONADES INTO 1.5L PET BOTTLES. THE LINE HAS AN OUTPUT CAPACITY OF UP TO 16,000 BOTTLES PER HOUR. 8. IT HAS BEEN REGULARLY SERVICED AND REMAINS IN GOOD WORKING ORDER. AVAILABILITY: END OF AUGUST 2025. QUANTITY: 1 Learn More -

TT-5532 LAVAMPOSTO LANDING CRAFT, 6.3M – NEW BUILDTT-5532 LAVAMPOSTO LANDING CRAFT, 6.3M – NEW BUILD NEW BUILD - 6.3M LANDING CRAFT DATE LAUNCHED: BUILT TO ORDER LENGTH: 6.30M (20FT 8IN) BEAM: 2.46M (8FT) DRAFT: 0.28M (11IN) 1 X 115 HP OUTBOARD ENGINE INCLUDED. LAVAMPOSTO IS AN EXPERIENCED BUILDER OF ALUMINIUM AND STEEL BOATS FOR PROFESSIONAL USE. ITS PRODUCTION INCLUDES LANDING CRAFTS AND WORKBOATS OF DIFFERENT TYPES. QUANTITY: 1 Learn More

TT-5532 LAVAMPOSTO LANDING CRAFT, 6.3M – NEW BUILDTT-5532 LAVAMPOSTO LANDING CRAFT, 6.3M – NEW BUILD NEW BUILD - 6.3M LANDING CRAFT DATE LAUNCHED: BUILT TO ORDER LENGTH: 6.30M (20FT 8IN) BEAM: 2.46M (8FT) DRAFT: 0.28M (11IN) 1 X 115 HP OUTBOARD ENGINE INCLUDED. LAVAMPOSTO IS AN EXPERIENCED BUILDER OF ALUMINIUM AND STEEL BOATS FOR PROFESSIONAL USE. ITS PRODUCTION INCLUDES LANDING CRAFTS AND WORKBOATS OF DIFFERENT TYPES. QUANTITY: 1 Learn More -

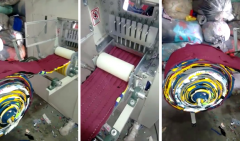

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTER

J-2326 QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERREFERENCE NUMBER: J-2326

QUILTER FOR RAGS, 12 INCH WIDTH – NEW – RAG QUILTERQUILTING MACHINE FOR RAGS

SEWS RAGS CONTINUOUSLY

SEW HEAD: 7 NEEDLES AND 7 LOOPERS

MAKES A CHAIN STITCH ON THE CONVEYED RAGS

USES OVERLOCK THREAD

DISTANCE BETWEEN NEEDLES: 250mm (ENSURES THAT EVEN SMALL RAGS ARE SEWN)

1 HP MOTOR, 3-PHASE, 220 VOLT

WITH FREQUENCY INVERTER TO ADJUST THE ROTATION SPEED OF THE MOTOR AS NEEDED

HEIGHT: 1800mm

WIDTH: 960mm

DEPTH; 370mm

CONVEYOR WIDTH: 200mm

CONVEYOR LENGTH: 1560mm

MACHINE TOTAL LENGTH WITH CONVEYOR: 2800mmAFTER SEWING, THE QUILT IS TRANSPORTED OUT INTO ROLLS WHICH CAN BE CUT ACCORDING TO CUSTOMER NEEDS

Learn More

OPERATION: PLACE A LARGER RAG AS THE BOTTOM LAYER, SMALLER RAGS AS FILLING, AND ANOTHER LARGER RAG AS THE TOP LAYER. OPERATION REQUIRES 2 TO 3 OPERATORS.

TO REDUCE THE NUMBER OF OPERATORS REQUIRED, A FIBER ROLL AS CAN BE USED AS THE LOWER LAYER. THIS ALSO INCREASES THE PRODUCTION RATE.

DAILY PRODUCTION: VARIES BETWEEN 300 TO 500 KG PER 8 HOURS OF OPERATION

FOR KNIT FABRICS SUCH AS COTTON, VISCOSE, SWEATSHIRT FLEECE, NYLON STRETCH-FABRIC, PIQUET AND POPELINE

THERE IS NO MATERIAL WASTE AS THE MACHINE USES 100% OF THE RAGS

WORKING WIDTH: 12 INCHES

NEEDLE SPACING: 1 INCH

WITH LOOPER STRUCTURE SIMILAR TO THE DIAGRAM BELOW (REDUCES BOTTOM THREAD BREAKAGE)

MACHINE IS NEW, MADE TO ORDER

LEAD TIME: 10 DAYS -

M-5009 ROSSO 025 + ULTRATURNREFERENCE NUMBER: M-5009 (121265KZ11RX) L ROSSO 025 + ULTRATURN ROSSO 025 + ULTRATURN ALL MACHINES ARE ON PALLETS READY TO START ON PRODUCTION DELIVERY: 2 WEEKS AFTER A DOWN PAYMENT PAYMENT: 50% AT ORDER + 50% BEFORE SHIPMENT BY SWIFT BANK T/T QUANTITY: 1 Learn More

M-5009 ROSSO 025 + ULTRATURNREFERENCE NUMBER: M-5009 (121265KZ11RX) L ROSSO 025 + ULTRATURN ROSSO 025 + ULTRATURN ALL MACHINES ARE ON PALLETS READY TO START ON PRODUCTION DELIVERY: 2 WEEKS AFTER A DOWN PAYMENT PAYMENT: 50% AT ORDER + 50% BEFORE SHIPMENT BY SWIFT BANK T/T QUANTITY: 1 Learn More -

TT-3122 WAUKESHA GAS GENERATOR SETS, 3360.8 KW (4201 KVA), 50 HzTT-3122 WAUKESHA GAS GENERATOR SETS, 3360.8 KW (4201 KVA), 50 Hz ITEM 001 WAUKESHA GAS GENERATOR 3360.8 KW (4201 KVA), 11000 VOLT, 220.5 AMP, 3 PHASE, 50 Hz GAS ENGINE DRIVEN ELECTRICAL GENERATOR ENGINE MANUFACTURED BY WAUKESHA (DRESSER) MODEL #16VAT27GL ITEM 002 WAUKESHA GAS GENERATOR 3360.8 KW (4201 KVA), 11000 VOLT, 220.5 AMP, 3 PHASE, 50 Hz GAS ENGINE DRIVEN ELECTRICAL GENERATOR ENGINE MANUFACTURED BY WAUKESHA (DRESSER) MODEL #16VAT27GL Learn More

TT-3122 WAUKESHA GAS GENERATOR SETS, 3360.8 KW (4201 KVA), 50 HzTT-3122 WAUKESHA GAS GENERATOR SETS, 3360.8 KW (4201 KVA), 50 Hz ITEM 001 WAUKESHA GAS GENERATOR 3360.8 KW (4201 KVA), 11000 VOLT, 220.5 AMP, 3 PHASE, 50 Hz GAS ENGINE DRIVEN ELECTRICAL GENERATOR ENGINE MANUFACTURED BY WAUKESHA (DRESSER) MODEL #16VAT27GL ITEM 002 WAUKESHA GAS GENERATOR 3360.8 KW (4201 KVA), 11000 VOLT, 220.5 AMP, 3 PHASE, 50 Hz GAS ENGINE DRIVEN ELECTRICAL GENERATOR ENGINE MANUFACTURED BY WAUKESHA (DRESSER) MODEL #16VAT27GL Learn More -

T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988 ITEM 001 HERGETH CARDING MACHINE PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 ITEM 002 HERGETH CROSS - LAPPER PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 Learn More

T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988T-7944 HERGETH CARDING MACHINE AND CROSS LAPPER, WIDTH 2500mm, YEAR 1988 ITEM 001 HERGETH CARDING MACHINE PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 ITEM 002 HERGETH CROSS - LAPPER PRESENT STATUS: DECOMMISSIONED IN WORKING ORDER QUANTITY: 1 Learn More -

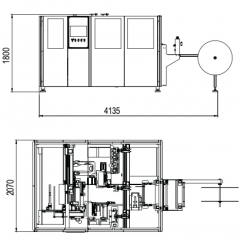

YY-3034 FULLY AUTOMATIC VERTICAL MATTRESS HANDLE ATTACHING MACHINE INCLUDING THE LABEL ATTACHMENT AND END SEWING TOGETHER, SEWING WIDTH 120 TO 450mmYY-3034 FULLY AUTOMATIC VERTICAL MATTRESS HANDLE ATTACHING MACHINE INCLUDING THE LABEL ATTACHMENT AND END SEWING TOGETHER, SEWING WIDTH 120 TO 450mm TECHNICAL PARAMETERS: SEWING WIDTH: 120 TO 450mm (4.7 INCHES TO 17.7 INCHES) SEWING THICKNESS: ≤25mm (ONE INCH) PRODUCTION CAPACITY: 4~6M/MIN (7 TO 8 YARDS PER MINUTE) TOTAL POWER: 8KW POWER SUPPLY: 220V QUANTITY: 1 Learn More

YY-3034 FULLY AUTOMATIC VERTICAL MATTRESS HANDLE ATTACHING MACHINE INCLUDING THE LABEL ATTACHMENT AND END SEWING TOGETHER, SEWING WIDTH 120 TO 450mmYY-3034 FULLY AUTOMATIC VERTICAL MATTRESS HANDLE ATTACHING MACHINE INCLUDING THE LABEL ATTACHMENT AND END SEWING TOGETHER, SEWING WIDTH 120 TO 450mm TECHNICAL PARAMETERS: SEWING WIDTH: 120 TO 450mm (4.7 INCHES TO 17.7 INCHES) SEWING THICKNESS: ≤25mm (ONE INCH) PRODUCTION CAPACITY: 4~6M/MIN (7 TO 8 YARDS PER MINUTE) TOTAL POWER: 8KW POWER SUPPLY: 220V QUANTITY: 1 Learn More -

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More -

TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011 QUANTITY: 1 Learn More

TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011 QUANTITY: 1 Learn More -

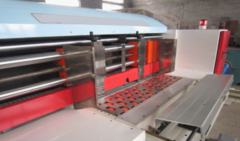

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More