Search results for: 'Textile ma'

- Related search terms

- textile

- textile mach

- textile machi

- Textile m

- Textile d

-

TT-3339 OPENING CARDING MACHINE SMALL WOOL COTTON YARN COMBING SPINNING MACHINE, CAPACITY 2 TO 8 KG PER HOUR, WIDTH 360mmTT-3339 OPENING CARDING MACHINE SMALL WOOL COTTON YARN COMBING SPINNING MACHINE, CAPACITY 2 TO 8 KG PER HOUR, WIDTH 360mm BRAND: PENGHUI CARDING MACHINES CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT QUANTITY: 1 Learn More

TT-3339 OPENING CARDING MACHINE SMALL WOOL COTTON YARN COMBING SPINNING MACHINE, CAPACITY 2 TO 8 KG PER HOUR, WIDTH 360mmTT-3339 OPENING CARDING MACHINE SMALL WOOL COTTON YARN COMBING SPINNING MACHINE, CAPACITY 2 TO 8 KG PER HOUR, WIDTH 360mm BRAND: PENGHUI CARDING MACHINES CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT QUANTITY: 1 Learn More -

G-6398 HEAVY DUTY PILLOWING FILLING MACHINE (1 OPENER & 4 STUFFERS) 1400LBS/HOURREFERENCE NUMBER: G-6398 HEAVY DUTY PILLOWING FILLING MACHINE(1 OPENER & 4 STUFFERS) 1400LBS/HOUR THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP. SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More

G-6398 HEAVY DUTY PILLOWING FILLING MACHINE (1 OPENER & 4 STUFFERS) 1400LBS/HOURREFERENCE NUMBER: G-6398 HEAVY DUTY PILLOWING FILLING MACHINE(1 OPENER & 4 STUFFERS) 1400LBS/HOUR THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUILTS - ADJUSTABLE FOOT SWITCH CONTROLLING FOR THE MATERIAL INSIDE OF THE STUFFER HOPPER THAT AVOIDS THE MATERIAL TO BALL UP. SO THAT THE FINISHED PRODUCT IS RETAINS GOOD ELASTICITY - LOW AIR PRESSURE REQUIRED. - HIGH PRODUCTIVITY QUANTITY AVAILABLE: 1 Learn More -

G-6402 AUTOMATIC PILLOWING FILLING MACHINE WITH AUTOMATIC SEALINGREFERENCE NUMBER: G-6402 AUTOMATIC PILLOWING FILLING MACHINE WITH AUTOMATIC SEALING THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUANTITY AVAILABLE: 1 Learn More

G-6402 AUTOMATIC PILLOWING FILLING MACHINE WITH AUTOMATIC SEALINGREFERENCE NUMBER: G-6402 AUTOMATIC PILLOWING FILLING MACHINE WITH AUTOMATIC SEALING THE PILLOW MACHINE LINE IS ASSEMBLED WITH A FIBER OPENER AND MINI BLOWER STUFFING MACHINES THAT MAINLY USED FOR TEXTILE STUFFING PRODUCTIONS SUCH AS BIG PLUSH TOYS, CUSHIONS AND PILLOWS ETC. IT CAN BE ALSO USED FOR FIBER QUILTING FILLING AFTER THE STUFFING SLOTS OF DUVET TYPE QUANTITY AVAILABLE: 1 Learn More -

TT-3341 FOR DOUBLE DOFFER CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1998TT-3341 FOR DOUBLE DOFFER CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1998 CONDITION: USED CATEGORY: CARDING MACHINES SUBCATEGORY: TEXTILE MACHINERY QUANTITY: 1 Learn More

TT-3341 FOR DOUBLE DOFFER CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1998TT-3341 FOR DOUBLE DOFFER CARDING MACHINE, WORKING WIDTH 2500mm, YEAR 1998 CONDITION: USED CATEGORY: CARDING MACHINES SUBCATEGORY: TEXTILE MACHINERY QUANTITY: 1 Learn More -

TT-6914 CUTTING NONWOVEN FABRICS - TEXTILE FABRICS - NATURAL AND ARTIFICIAL LEATHER, YEAR OF CONSTRUCTION 2017, COMPLETELY RENOVATED AT THE END OF 2023TT-6914 CUTTING NONWOVEN FABRICS - TEXTILE FABRICS - NATURAL AND ARTIFICIAL LEATHER, YEAR OF CONSTRUCTION 2017, COMPLETELY RENOVATED AT THE END OF 2023 QUANTITY: 1 Learn More

TT-6914 CUTTING NONWOVEN FABRICS - TEXTILE FABRICS - NATURAL AND ARTIFICIAL LEATHER, YEAR OF CONSTRUCTION 2017, COMPLETELY RENOVATED AT THE END OF 2023TT-6914 CUTTING NONWOVEN FABRICS - TEXTILE FABRICS - NATURAL AND ARTIFICIAL LEATHER, YEAR OF CONSTRUCTION 2017, COMPLETELY RENOVATED AT THE END OF 2023 QUANTITY: 1 Learn More -

TT-3085 LABORATORY CARDING MACHINE 3KA, WORKING WIDTH 500mm, YEAR 1997TT-3085 LABORATORY CARDING MACHINE 3KA, WORKING WIDTH 500mm, YEAR 1997 LABORATORY CARDING MACHINE 3KA CONDITION: USED YEAR: 1977 QUANTITY: 1 Learn More

TT-3085 LABORATORY CARDING MACHINE 3KA, WORKING WIDTH 500mm, YEAR 1997TT-3085 LABORATORY CARDING MACHINE 3KA, WORKING WIDTH 500mm, YEAR 1997 LABORATORY CARDING MACHINE 3KA CONDITION: USED YEAR: 1977 QUANTITY: 1 Learn More -

TT-4873 CIBITEX SANFOR, WORKING WIDTH 1800mm, YEAR 1991TT-4873 CIBITEX SANFOR, WORKING WIDTH 1800mm, YEAR 1991 CIBITEX SANFOR YEAR 1991 SUPPLY VOLTAGE THREE-PHASE 400 V BUT POWER SUPPLY BY DC MOTORS MAX WORKING WIDTH 1800mm MAX WORK SPEED 50 M/MINUTE TEXTILE FINISHING SANFOR QUANTITY: 1 Learn More

TT-4873 CIBITEX SANFOR, WORKING WIDTH 1800mm, YEAR 1991TT-4873 CIBITEX SANFOR, WORKING WIDTH 1800mm, YEAR 1991 CIBITEX SANFOR YEAR 1991 SUPPLY VOLTAGE THREE-PHASE 400 V BUT POWER SUPPLY BY DC MOTORS MAX WORKING WIDTH 1800mm MAX WORK SPEED 50 M/MINUTE TEXTILE FINISHING SANFOR QUANTITY: 1 Learn More -

YY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINEYY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINE THE PLANT WAS USED IN FULLY CONTINUOUS OPERATION WHICH MEANS 24 / 7 FOR 350 DAYS PER YEAR. BULK MATERIALS OF ALL TYPES (PET BOTTLE FLAKES, RESINS / GRANULE CHIPS, REGRINDS OF VARIOUS TYPES OF MATERIALS AND AGGLOMERATES) WERE USED AS INPUT MATERIAL FROM THE EUROPEAN MARKET, BUT ALSO FROM ALL OVER THE WORLD. THE REGENERATED FIBERS PRODUCED WERE BETWEEN 3 DEN AND 25 DEN AND COULD BE USED FOR MANY DIFFERENT APPLICATIONS, SUCH AS AUTOMOTIVE, GEOTEXTILES, TECHNICAL TEXTILES AND ALL GENERAL TEXTILE SECTORS – ALWAYS IN 100% RECYCLED FIBERS. PREDOMINANTLY THE LINE WAS PRODUCING A HIGH QUALITY BLACK STAPLE FIBER! Learn More

YY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINEYY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINE THE PLANT WAS USED IN FULLY CONTINUOUS OPERATION WHICH MEANS 24 / 7 FOR 350 DAYS PER YEAR. BULK MATERIALS OF ALL TYPES (PET BOTTLE FLAKES, RESINS / GRANULE CHIPS, REGRINDS OF VARIOUS TYPES OF MATERIALS AND AGGLOMERATES) WERE USED AS INPUT MATERIAL FROM THE EUROPEAN MARKET, BUT ALSO FROM ALL OVER THE WORLD. THE REGENERATED FIBERS PRODUCED WERE BETWEEN 3 DEN AND 25 DEN AND COULD BE USED FOR MANY DIFFERENT APPLICATIONS, SUCH AS AUTOMOTIVE, GEOTEXTILES, TECHNICAL TEXTILES AND ALL GENERAL TEXTILE SECTORS – ALWAYS IN 100% RECYCLED FIBERS. PREDOMINANTLY THE LINE WAS PRODUCING A HIGH QUALITY BLACK STAPLE FIBER! Learn More -

T-9752 KARL MAYER CARBON MACHINES BIAXIAL AND MULTIAXIALT-9752 KARL MAYER CARBON MACHINES BIAXIAL AND MULTIAXIAL PROPERTIES: SINCE ALL FIBERS POINT IN ONE DIRECTION, THE SCRIM CAN BE IDEALLY DRAPED GOOD SOAKABILITY WITH LITTLE RESIN CONSUMPTION CAN BE DRAPED VERY WELL AROUND CURVES AND EDGES EASY TO CUT ELECTRICALLY CONDUCTIVE, INFUSIBLE HIGH STRENGTH AND RIGIDITY DUE TO GRAPHITE-LIKE FIBER STRUCTURE BIOCOMPATIBLE TRANSPARENT TO X-RAYS LOW SPECIFIC WEIGHT IDEAL FOR SURFACE USE (LITTLE FIBER IMPRINTS) IDEAL FOR PROCESSING WITH EPOXY RESIN! TEXTILE SEMI-FINISHED PRODUCTS MADE OF PRE-SPREAD AND PLANE-PARALLEL LAID FIBERS FORM THE GROUP OF UNIDIRECTIONAL FABRICS. THE FIBERS ARE USUALLY LAID AT 0°, MORE RARELY AT 90°. BY LAYING THE UD FABRICS ALONG THE LINES OF FORCE ACTING IN THE COMPONENT, THE LIGHTWEIGHT POTENTIAL OF THE CARBON FIBER IS OPTIMALLY EXPLOITED. UD FABRICS CONSIST OF ONE OR MORE SUPERIMPOSED FIBER LAYERS FIXED WITH AN EPOXY-COMPATIBLE BINDER THREAD. THE SPECIAL SPREADING TECHNIQUE PRODUCES FABRICS WITH HIGH FIBER PARALLELISM, WITHOUT KNOTS AND FIBER TWIST. SPREAD FIBERS ABSORB THE RESIN BETTER, RESULTING IN HIGHEST LAMINATE STRENGTHS. QUANTITY: 3 LINES Learn More

T-9752 KARL MAYER CARBON MACHINES BIAXIAL AND MULTIAXIALT-9752 KARL MAYER CARBON MACHINES BIAXIAL AND MULTIAXIAL PROPERTIES: SINCE ALL FIBERS POINT IN ONE DIRECTION, THE SCRIM CAN BE IDEALLY DRAPED GOOD SOAKABILITY WITH LITTLE RESIN CONSUMPTION CAN BE DRAPED VERY WELL AROUND CURVES AND EDGES EASY TO CUT ELECTRICALLY CONDUCTIVE, INFUSIBLE HIGH STRENGTH AND RIGIDITY DUE TO GRAPHITE-LIKE FIBER STRUCTURE BIOCOMPATIBLE TRANSPARENT TO X-RAYS LOW SPECIFIC WEIGHT IDEAL FOR SURFACE USE (LITTLE FIBER IMPRINTS) IDEAL FOR PROCESSING WITH EPOXY RESIN! TEXTILE SEMI-FINISHED PRODUCTS MADE OF PRE-SPREAD AND PLANE-PARALLEL LAID FIBERS FORM THE GROUP OF UNIDIRECTIONAL FABRICS. THE FIBERS ARE USUALLY LAID AT 0°, MORE RARELY AT 90°. BY LAYING THE UD FABRICS ALONG THE LINES OF FORCE ACTING IN THE COMPONENT, THE LIGHTWEIGHT POTENTIAL OF THE CARBON FIBER IS OPTIMALLY EXPLOITED. UD FABRICS CONSIST OF ONE OR MORE SUPERIMPOSED FIBER LAYERS FIXED WITH AN EPOXY-COMPATIBLE BINDER THREAD. THE SPECIAL SPREADING TECHNIQUE PRODUCES FABRICS WITH HIGH FIBER PARALLELISM, WITHOUT KNOTS AND FIBER TWIST. SPREAD FIBERS ABSORB THE RESIN BETTER, RESULTING IN HIGHEST LAMINATE STRENGTHS. QUANTITY: 3 LINES Learn More -

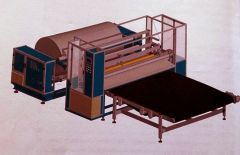

YY-1285 COMPUTERIZED CONTINUOUS EDGE FOLDING & SEWING MACHINE, PRODUCT WIDTH 1800 TO 2000mmYY-1285 COMPUTERIZED CONTINUOUS EDGE FOLDING & SEWING MACHINE, PRODUCT WIDTH 1800 TO 2000mm SUITABLE FOR CURTAIN OR OTHER HOME TEXTILES WHERE THERE IS A NEED TO SEW EDGES CONTINUOUSLY. QUANTITY: 1 Learn More

YY-1285 COMPUTERIZED CONTINUOUS EDGE FOLDING & SEWING MACHINE, PRODUCT WIDTH 1800 TO 2000mmYY-1285 COMPUTERIZED CONTINUOUS EDGE FOLDING & SEWING MACHINE, PRODUCT WIDTH 1800 TO 2000mm SUITABLE FOR CURTAIN OR OTHER HOME TEXTILES WHERE THERE IS A NEED TO SEW EDGES CONTINUOUSLY. QUANTITY: 1 Learn More