Search results for: 'fabric roll slitt'

-

TT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mmTT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mm THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON TILL CA 30%. COVERSTOK, HYGIENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN TERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTHETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250 OC. ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16 GSM TO MAX 70 GSM (DUPLEX 70 GSM) QUANTITY: 1 Learn More

TT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mmTT-2639 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, ROLLS WIDTH 30mm TO MAX 2200mm THERMOBOND LINE: POLYPROPYLENE POLYESTER POLYAMID, AND MIXTURES WITH VISCOSE OR COTTON TILL CA 30%. COVERSTOK, HYGIENE NONWOVEN FOR PADS, SLIPS, DRAPES GOWNS, FILTERS, WET WIPES, AUTOMOTIVE INDUSTRY, UPHOLSTERY TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN TERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTHETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250 OC. ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16 GSM TO MAX 70 GSM (DUPLEX 70 GSM) QUANTITY: 1 Learn More -

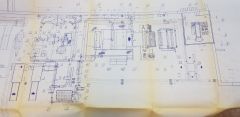

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWN

L-7129 NONWOVEN SMS PRODUCTION LINE, 1600mm, SPUNBONDED, MELT BLOWNPP CHIPS FOR MELTBLOWN: 1200 TO 2000

FABRIC WIDTH: 1600mm

2 SPINNING BEAMS FOR SPUNBOND & 1 FOR MELTBLOWN

BASIC WEIGHT: SMS 9 TO 80 GRAMS PER SQUARE METER

SS: 15 TO 100 GRAMS PER SQUARE METERPRODUCT:

SMS LAMINATED NONWOVEN FABRIC

SS SPUNBOND NONWOVEN FABRIC SS

M MELTBLOWN NONWOVEN FABRIC MTO MAKE HYGENIC FABRICS SUCH AS BABY DIAPERS, SANITARY NAPKINS, ADULT DIAPERS, MEDICAL OPERATION SUITS, OPERATION CAPS, OPERATIONS SHOES, MASKS, ETC.

CONSISTING OF:

3 X FEEDING SYSTEMS

AUTOMATIC VACUUM SUCTION FOR BOTH MAIN MATERIAL AND ADDITIVES

CAPACITY (SB + MB) 2 X 520 KGS/H, (SB) 2 X 200 KGS/HR

WITH THREE HOPPERS, THREE SUPPLIYING DEVICESSPUNBOND SYSTEM

2 X EXTRUDERS

DIAMETER: 150mm

CAPACITY: 450 KGS/HR

L/D 30:1

DRIVE POWER: 110 KW

HEATING POWER: 90 KW2 X RECYCLING SYSTEMS

DIAMETER: 105mm

CAPACITY: 100 KGS PER HOUR

L/D: 15:12 X MELT FILTERS

WORKING TEMPERATURE: UP TO 280 CELSIUS

FILTRATION CAPACITY: 520 KGS PER HOUR2 X METERING PUMPS

TYPE: GEAR PUMP

FLOW VOLUME: 250 ML/R

DESIGNING TEMPERATURE: 280 CELSIUS2 X MELT PIPELINES

WITH STATIC MIXER2 X MONOMER EXHAUSTER

INCLUDING BLOWER, CHILLER, PIPELINE, VALVE, INSULATION, ETC2 X SPINNING BEAMS

SINGLE COAT-HANGER MELT DISTRIBUTION

DESIGNING PRESSURE: 9MPA

WORKING TEMPERATURE: MAX 280 CELSIUS4 X SPINNERETS

HOLE DIAMETER: 0.45mm

L/D: 5:1

15,500 HOLESMELTBLOWN SYSTEM

1 X EXTRUDER

DIAMETER 120mm

CAPACITY: 280 KGS/HR

L/D: 30:1

DRIVE POWER: 75 KW

HEATING POWER: 80 KW1 X MELT FILTER

FILTRATION PRECISION: 20 TO 60 MICROMETERS

FILTRATION: 280 KGS PER HOUR1 X METERING PUMP

GEAR PUMP

MAX. FLOW VOLUME: 100ML/R

DESIGNED TEMPERATURE: 300 CELSIUS1 X MELT PIPELINE

WITH STATIC MIXER1 X SPINNING BEAM

INCLUDING STRETCHING CHANNEL, NOZZLE, ETC. WITH INSULATION MATERIAL

DESIGNED PRESSURE: 6 MPA2 X SPINNING DIE PACKS

COMPACT DIE PACKS

HOLE DIAMETER: 0.35mm

L/D: 12:1

# OF HOLES: 42HPI1 X SCREW BLOWER

INCLUDING MUFFLE, PRESSURE REDUCER VALVE, PIPELINE, ETC.

POWER: 200 KW1 X HOT AIR SYSTEM

FLOW VOLUME: 6000 CUBIC METERS PER HOUR

WORKING TEMP: MAX 350 CELSIUS

INCLUDING HEATER, STAINLESS STEEL PIPELINE, ETC.

POWER: 290 KW1 X OFF-LINE CONVEYOR

RANGE OF SPEED: 5 TO 100 METERS PER MINUTE1 X CONVEYOR

MECHANICAL SPEED: MAX 400 METERS PER MINUTE

BELT WIDTH AND PENETRATION

3800±10mm, 10000 CUBIC METERS PER H.M21 X CALENDAR

DOUBLE ROLLS HEATED BY OIL

PROCESS SPEED: 350 METERS PER MINUTE

EMBOSSING WIDTH: UP TO 2000mm

MAX LINEAR PRESSURE: 110 DAN/C

MAX. TEMP OF EMBOSSING ROLLER, 180 CELSIUS1 X WINDER

ONLINE CHANGING ROLL, ONLINE EDGE CUTTING, TENSION CONTROL

MAX. LINEAR SPEED: 350 METERS PER MINUTE

WIDTH: 1600mm

WIND DIAMETER: MAX 1500mm1 X SLITTER

MAX. LINE SPEED: 600 METERS PER MINUTE

MAX. WIND DIAMETER: 1200mm

MIN. SLITTING WIDE: 120mm

22 CIRCULAR BLADES1 X STEEL PLATFORM

1 X ELECTRICAL CONTROL SYSTEM

2 X OIL OVEN

1 X AIR CONDITIONING SYSTEM

1 X WATER COOLING SYSTEM

1 X CLEANING EQUIPMENTS FOR DIE PACK

1 X AUXILIARY PLATFORM

1 X AUXILIARY EQUIPMENTS

1 X LABORATORY TESTING DEVICE

Learn More -

YY-1952 TRÜTZSCHLER/HERGETH/SCHOTT & MEISSNER THERMOBOND LINE, WORKING WIDTH 2500mmYY-1952 TRÜTZSCHLER/HERGETH/SCHOTT & MEISSNER THERMOBOND LINE, WORKING WIDTH 2500mm DETAILS: WORKING WIDTH: 2500mm YEAR: 1995 TO 1998 VOLTAGE: 380 VOLTS, 3-PHASE, 50 Hz COMPLETE THERMOBONDING LINE MAXIMUM SPEED 15 METERS PER MINUTE CAPACITY UP TO 300 GSM, THROUGHPUT UP TO 300 KG PER HOUR DEPENDING ON TYPE OF FIBER CURRENTLY RUNNING A BLEND OF COTTON AND VISCOSE Learn More

YY-1952 TRÜTZSCHLER/HERGETH/SCHOTT & MEISSNER THERMOBOND LINE, WORKING WIDTH 2500mmYY-1952 TRÜTZSCHLER/HERGETH/SCHOTT & MEISSNER THERMOBOND LINE, WORKING WIDTH 2500mm DETAILS: WORKING WIDTH: 2500mm YEAR: 1995 TO 1998 VOLTAGE: 380 VOLTS, 3-PHASE, 50 Hz COMPLETE THERMOBONDING LINE MAXIMUM SPEED 15 METERS PER MINUTE CAPACITY UP TO 300 GSM, THROUGHPUT UP TO 300 KG PER HOUR DEPENDING ON TYPE OF FIBER CURRENTLY RUNNING A BLEND OF COTTON AND VISCOSE Learn More -

YY-2597 1 X 2.0M SELLERS PVC COATING LINE, YEAR 2000, WORKING WIDTH 2000mmYY-2597 1 X 2.0M SELLERS PVC COATING LINE, YEAR 2000, WORKING WIDTH 2000mm MANUFACTURER: SELLERS WORKING WIDTH: 2000mm YEAR: 2000 QUANTITY: 1 Learn More

YY-2597 1 X 2.0M SELLERS PVC COATING LINE, YEAR 2000, WORKING WIDTH 2000mmYY-2597 1 X 2.0M SELLERS PVC COATING LINE, YEAR 2000, WORKING WIDTH 2000mm MANUFACTURER: SELLERS WORKING WIDTH: 2000mm YEAR: 2000 QUANTITY: 1 Learn More -

J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020 MAKE: FUNG CHANG INDUSTRIAL CO, LTD YEAR: 2020 CONSISTING OF 2 RASCHEL KNITTING LINES: ITEM 001 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE ITEM 002 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE Learn More

J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020 MAKE: FUNG CHANG INDUSTRIAL CO, LTD YEAR: 2020 CONSISTING OF 2 RASCHEL KNITTING LINES: ITEM 001 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE ITEM 002 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE Learn More -

TT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mmTT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mm TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250°C ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16GSM TO MAX 50GSM (DUPLEX 70GSM) EXIT TRIMMED WIDTH: 2000mm Learn More

TT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mmTT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mm TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250°C ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16GSM TO MAX 50GSM (DUPLEX 70GSM) EXIT TRIMMED WIDTH: 2000mm Learn More -

TT-1127 PAILUNG CIRCULAR KNITTING MACHINES, GAUGE 18, YEAR 2012TT-1127 PAILUNG CIRCULAR KNITTING MACHINES, GAUGE 18, YEAR 2012 SLITTER FOR FABRIC ON THE WINDING UNIT CLOTH ROLLS UP ON A 60” TUBE UPGRADED CREEL WITH AIR FEED FROM PACKAGE TO FEEDER Learn More

TT-1127 PAILUNG CIRCULAR KNITTING MACHINES, GAUGE 18, YEAR 2012TT-1127 PAILUNG CIRCULAR KNITTING MACHINES, GAUGE 18, YEAR 2012 SLITTER FOR FABRIC ON THE WINDING UNIT CLOTH ROLLS UP ON A 60” TUBE UPGRADED CREEL WITH AIR FEED FROM PACKAGE TO FEEDER Learn More -

J-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mmJ-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mm QUILTING MACHINE QUILTING WIDTH: 2450mm QUANTITY: 1 PANEL CUTTER SPEED: 10 METERS PER MINUTE POWER: 3.2 KW AIR PRESSURE: 0.4 TO 0.8 Mpa VOLTAGE: 380 V / 50 Hz, 220 V / 60 Hz, 3-PHASE DIMENSIONS: 3500 x 1150 x 2300 (L x W x H mm) WEIGHT: 1150 KG QUANTITY: 1 Learn More

J-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mmJ-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mm QUILTING MACHINE QUILTING WIDTH: 2450mm QUANTITY: 1 PANEL CUTTER SPEED: 10 METERS PER MINUTE POWER: 3.2 KW AIR PRESSURE: 0.4 TO 0.8 Mpa VOLTAGE: 380 V / 50 Hz, 220 V / 60 Hz, 3-PHASE DIMENSIONS: 3500 x 1150 x 2300 (L x W x H mm) WEIGHT: 1150 KG QUANTITY: 1 Learn More -

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More -

C-4362 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (NON POP UP), WIDTH 3000mm

C-4362 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (NON POP UP), WIDTH 3000mmC-4362 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (NON POP UP), WIDTH 3000mm

Y-6 BABY WIPES FOLDING MACHINE

PRODUCTION FLOW: UNROLLING - SLITTING FABRIC INTO LANES - FOLDING - WETTING - CUTTING – PILE & COUNTING - DELIVERING

MAIN TECHNICAL PARAMETER (SUITABLE TO WET TISSUE FOR LARGE SIZE PACKING)

PRODUCT TYPE: BABY WIPES (NON CROSS FOLDING)

PRODUCT SPEED: 200 TO 270 CUTS/MIN (SET ON PLC)

SUITABLE RAW MATERIAL: AIR LAID PAPER, SPUNLACE/HOT-ROLLING NONWOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40 TO 80G/㎡

FOLDING WAY: “Z” SHAPE (NON-POP UP)

LENGTH OF WET TISSUE: 140 TO 185mm (SET ON PLC)

FREQUENCY OF RECEIVING PAPER: 14 TO 20 TIMES/MIN (SET ON PLC)

POWER SUPPLY: 380V 50HZ

POWER: 4KW

SIZE OF RAW MATERIAL: (1000 TO 1250) × Ø1000 (mm, W×DIA)

WET TISSUE UNFOLDED SIZE: (140 TO 185) × (150 TO 200) (mm, L×W)

WET TISSUE FOLDED SIZE: (140 TO 185) × (80 TO 110) (mm, L×W)

MATERIAL SUPPLY SYSTEM: SERVO MOTOR

CUTTING SYSTEM: CONVERTER MOTOR

PILING SYSTEM: SERVO MOTOR

POWER SUPPLY: 380V 50HZ

POWER: 6KW

SIZE OF MACHINE: 5200 × 3000 × 1800 (mm, L×W×H)

WEIGHT OF MACHINE: 1500 KG

OPTIONAL MAKING: Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINEQUANTITY: 1

Learn More