Search results for: 'Process+o'

- Related search terms

- Process+of+cleaning+the+a

- Process+of+cl'

- Process+of+cleaning+the+applicatio

- Process+of+cleaning+the+application

- Process+oil+uses

-

SPINNBAU DOUBLE DOFFER CARD, WORKING WIDTH 2500mm, YEAR 1994REFERENCE NUMBER: T-6844 SPINNBAU DOUBLE DOFFER CARD, WORKING WIDTH 2500mm, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: DOUBLE DOFFER CARD YEAR: 1994 WORKING WIDTH 2500mm IN OVERHAULING AND MODERNISATION PROCESS QUANTITY: 1 Learn More

SPINNBAU DOUBLE DOFFER CARD, WORKING WIDTH 2500mm, YEAR 1994REFERENCE NUMBER: T-6844 SPINNBAU DOUBLE DOFFER CARD, WORKING WIDTH 2500mm, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: DOUBLE DOFFER CARD YEAR: 1994 WORKING WIDTH 2500mm IN OVERHAULING AND MODERNISATION PROCESS QUANTITY: 1 Learn More -

P-8696 ULTRASONIC SEWING MACHINELearn More

P-8696 ULTRASONIC SEWING MACHINELearn MoreREFERENCE NUMBER: P-8696

ULTRASONIC SEWING MACHINE

CAN BE USED WITH EITHER 20 KHz, 30 KHz OR 40 KHz EQUIPMENT

LED DISPLAY FOR EASY PROCESS MONITORING

19” (483mm) THROAT

INDEPENDENT CONTROLS FOR SLITTING AND ROTARY ANVIL WELDING

DUAL SEALING CAPABILITIES WITH INDEPENDENT ADJUSTMENTS

EDGE GUIDING, REWINDING, AND FEED ROLLS CAN BE USED

CAN BE OPERATOR CONTROLLED AS A BENCHTOP UNIT OR INTEGRATED INTO AN EXISTING LINE

QUANTITY: 1

-

D-2388 What’s the Best Material for a Mask?

D-2388 What’s the Best Material for a Mask?Federal health officials have now recommended that we cover our faces with fabric during the coronavirus pandemic. But what material offers the most protection?

The Centers for Disease Control and Prevention has posted a no-sew mask pattern using a bandanna and a coffee filter as well as a video on making masks using rubber bands and folded fabrics found at home.

While a simple face covering can reduce the spread of coronavirus by blocking outgoing germs from coughs or sneezes of an infected person, experts say there is more variation in how much homemade masks might protect the wearer from incoming germs, depending on the fit and quality of the material used.

Scientists around the country have taken it upon themselves to identify everyday materials that do a better job of filtering microscopic particles. In recent tests, HEPA furnace filters scored well, as did vacuum cleaner bags, layers of 600-count pillowcases and fabric similar to flannel pajamas. Stacked coffee filters had medium scores. Scarves and bandanna material had the lowest scores, but still captured a small percentage of particles.

If you don’t have any of the materials that were tested, a simple light test can help you decide whether a fabric is a good candidate for a mask.

“Hold it up to a bright light,” said Dr. Scott Segal, chairman of anesthesiology at Wake Forest Baptist Health who recently studied homemade masks. “If light passes really easily through the fibers and you can almost see the fibers, it’s not a good fabric. If it’s a denser weave of thicker material and light doesn’t pass through it as much, that’s the material you want to use.”

Researchers say it’s important to remember that lab studies are conducted under perfect conditions with no leaks or gaps in the mask, but the test methods give us a way to compare materials. And while the degree of filtration for some homemade masks seems low, most of us — who are staying home and practicing social distancing in public — don’t need the high level of protection required for medical workers. More important, any face covering is better than none, especially if worn by a person who has the virus but doesn’t know it.

The biggest challenge of choosing a homemade mask material is to find a fabric that is dense enough to capture viral particles, but breathable enough that we can actually wear it. Some items being touted online promise high filtration scores, but the material would be unwearable.

Dressing Up for Work … at Home

Yang Wang, an assistant professor of environmental engineering at Missouri University of Science and Technology, worked with his graduate students to study various combinations of layered materials — including both air filters and fabric. “You need something that is efficient for removing particles, but you also need to breathe,” said Dr. Wang, who last fall won an international award for aerosol research.To test everyday materials, scientists are using methods similar to those used to test medical masks, which everybody agrees should be saved for medical workers who are exposed to high doses of virus from seeing infected patients. The best medical mask — called the N95 respirator — filters out at least 95 percent of particles as small as 0.3 microns. By comparison, a typical surgical mask — made using a rectangular piece of pleated fabric with elastic ear loops — has a filtration efficiency ranging from 60 to 80 percent.

Dr. Wang’s group tested two types of air filters. An allergy-reduction HVAC filter worked the best, capturing 89 percent of particles with one layer and 94 percent with two layers. A furnace filter captured 75 percent with two layers, but required six layers to achieve 95 percent. To find a filter similar to those tested, look for a minimum efficiency reporting value (MERV) rating of 12 or higher or a microparticle performance rating of 1900 or higher.

The problem with air filters is that they potentially could shed small fibers that would be risky to inhale. So if you want to use a filter, you need to sandwich the filter between two layers of cotton fabric. Dr. Wang said one of his grad students made his own mask by following the instructions in the C.D.C. video, but adding several layers of filter material inside a bandanna.

Dr. Wang’s group also found that when certain common fabrics were used, two layers offered far less protection than four layers. A 600 thread count pillow case captured just 22 percent of particles when doubled, but four layers captured nearly 60 percent. A thick woolen yarn scarf filtered 21 percent of particles in two layers, and 48.8 percent in four layers. A 100 percent cotton bandanna did the worst, capturing only 18.2 percent when doubled, and just 19.5 percent in four layers.

The group also tested Brew Rite and Natural Brew basket-style coffee filters, which, when stacked in three layers, showed 40 to 50 percent filtration efficiency — but they were less breathable than other options.

If you are lucky enough to know a quilter, ask them to make you a mask. Tests performed at the Wake Forest Institute for Regenerative Medicine in Winston-Salem, N.C., showed good results for homemade masks using quilting fabric. Dr. Segal, of Wake Forest Baptist Health, who led the study, noted that quilters tend to use high-quality, high-thread count cotton. The best homemade masks in his study were as good as surgical masks or slightly better, testing in the range of 70 to 79 percent filtration. Homemade masks that used flimsier fabric tested as low as 1 percent filtration, Dr. Segal said.

The best-performing designs were a mask constructed of two layers of high-quality, heavyweight “quilter’s cotton,” a two-layer mask made with thick batik fabric, and a double-layer mask with an inner layer of flannel and outer layer of cotton.

Bonnie Browning, executive show director for the American Quilter’s Society, said that quilters prefer tightly woven cottons and batik fabrics that stand up over time. Ms. Browning said most sewing machines can handle only two layers of fabric when making a pleated mask, but someone who wanted four layers of protection could wear two masks at a time.

Ms. Browning said she recently reached out to quilters on Facebook and heard from 71 people who have made a combined total of nearly 15,000 masks. “We quilters are very much in the thick of what’s going on with this,” said Ms. Browning, who lives in Paducah, Ky. “One thing most of us have is a stash of fabric.”

People who don’t sew could try a folded origami mask, created by Jiangmei Wu, assistant professor of interior design at Indiana University. Ms. Wu, who is known for her breathtaking folded artwork, said she began designing a folded mask out of a medical and building material called Tyvek, as well as vacuum bags, after her brother in Hong Kong, where mask wearing is common, suggested it. (DuPont, the maker of Tyvek, said in a statement that Tyvek is intended for medical apparel, not masks.) The folded mask pattern is free online, as is a video demonstrating the folding process. In tests at Missouri University and University of Virginia, scientists found that vacuum bags removed between 60 percent and 87 percent of particles. But some brands of vacuum bags may contain fiberglass or are harder to breathe through than other materials, and shouldn’t be used. Ms. Wu used a bag by EnviroCare Technologies, which has said it does not use fiberglass in its paper and synthetic cloth bags.

“I wanted to create an alternative for people who don’t sew,” said Ms. Wu, who said she is talking to various groups to find other materials that will be effective in a folded mask. “Given the shortage of all kinds of materials, even vacuum bags might run out.”

The scientists who conducted the tests used a standard of 0.3 microns because that is the measure used by the National Institute for Occupational Safety and Health for medical masks.

Linsey Marr, a Virginia Tech aerosol scientist and an expert in the transmission of viruses, said the certification method for respirators and HEPA filters focuses on 0.3 microns because particles around that size are the hardest to catch. While it seems counterintuitive, particles smaller than 0.1 microns are actually easier to catch because they have a lot of random motion that makes them bump into the filter fibers, she said.

“Even though coronavirus is around 0.1 microns, it floats around in a wide range of sizes, from around 0.2 to several hundred microns, because people shed the virus in respiratory fluid droplets that also contain lots of salts and proteins and other things,” said Dr. Marr. “Even if the water in the droplets fully evaporates, there’s still a lot of salt and proteins and other gunk that stays behind as solid or gel-like material. I think 0.3 microns is still useful for guidance because the minimum filtration efficiency will be somewhere around this size, and it’s what NIOSH uses.”

Learn More -

J-2765 3-LAYER FACE MASK PRODUCTION MACHINE – 150 MASKS PER MINUTE

J-2765 3-LAYER FACE MASK PRODUCTION MACHINE – 150 MASKS PER MINUTECAPACITY: 100 TO 150 MASKS PER MINUTE

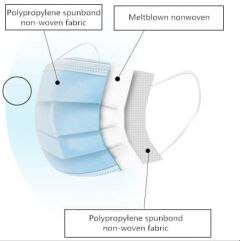

PRODUCES MASKS WITH 3 LAYERS OF POLYPROPYLENE NONWOVEN MATERIAL

AIR PRESSURE: 0.6 MPa, AIR CONSUMPTION 300 LITERS PER MINUTE

CONTROLLED BY PLC, OPERATED BY LCD TOUCH SCREEN

USES ULTRASONIC WELDING FOR EAR STRAPS

VOLTAGE: AS PER CUSTOMER

TOTAL POWER: 11 KW

DIMENSIONS: 6850 x 3520 x 1990mm

WEIGHT: ≤ 5000kgMASK SURFACE LAYER, FILTER LAYER AND BOTTOM LAYER CAN BE ALIGNED AND FED TO THE MACHINE AUTOMATICALLY

BOTH SIDES ARE SYMMETRICAL WITH ULTRASONIC PROCESS STATIONS FOR EAR STRAP WELDING

AFTER WELDING, THE MASKS ARE COUNTED AND PILED TOGETHER AUTOMATICALLY

MASKS ARE DISTRIBUTED EVENLY TO TWO SETS OF EAR STRAP STATIONS BY AUTOMATIC TRANSMISSION SYSTEM, CONTROLLED BY PLC

NOSE CLIPS CAN BE AUTOMATICALLY FED, CUT AND ULTRASONICALLY WELDEDTHE CUP TYPE MASK PRODUCTION LINE CAN BE SENT BY AIR, THERE ARE TOTAL 5 WOODEN CASES, SIZES AND WEIGHT AS BELOW:

1. 2500 X 1100 X 1000mm, 1PC, 250KGS

2. 2200 X 1000 X 1500mm, 1PC, 1100KGS

3. 3000 X 1200 X 1500mm, 1PC, 1100KGS

4. 3000 X 1200 X 1500mm, 1PC, 1100KGS

5. 1900 X 700 X 1150mm, 1PC, 250KGSIF CUSTOMER NEEDS MASK BAGGING MACHINE TO CONNECT WITH DISPOSABLE MASK PRODUCTION LINE, THERE WILL BE ANOTHER TWO WOODEN CASES EXTRA, BUT WILL CANCEL THE FIFTH WOODEN CASE, SIZES AND WEIGHT AS BELOW:

1. 1580mm X 840MM X 1510 mm,1PCS, 340KG

Learn More

2. 2540 mm X 540 mm X 1510 mm,1PCS, 80KG -

J-2752 FACE MASK PRODUCTION MACHINE – 120 PIECES PER MINUTE

J-2752 FACE MASK PRODUCTION MACHINE – 120 PIECES PER MINUTECOMPOSED OF

FACE MASK BLANK MAKING MACHINE

AUTOMATICALLY PRODUCES THE MAIN PART OF THE MASK

MACHINE HANDLES FEEDING, ALUMINUM STRIP INSERTION, CUTTING, FOLDING, ULTRASONIC WELDING, CUTTING

OUTPUT: 120 PIECES PER MINUTE

VOLTAGE: 220 VOLTS

POWER CONSUMPTION: 2.7 KW

DIMENSIONS: 3345 x 630 x 1830mm

CAN PRODUCE 3 TO 4 DIFFERENT MASK BLANKS ACCORDING TO PRODUCTION REQUIREMENTS

FOLDING LOCATION AND SIZE OF MASK IS ADJUSTABLE

COMPUTER CONTROLS AND PHOTOELECTRIC DETECTION ENSURE LOW FAILURE RATE AND HIGH RELIABILITY

FRAME CONSTRUCTED OF ALUMINUM ALLOY

QUANTITY: 1FACE MASK TRANSFERRING MACHINE

TRANSFERS THE MASKS TO THE ULTRASONIC EAR STRAP WELDING MACHINE

QUANTITY: 1ULTRASONIC EAR STRAP WELDING MACHINE

WELDS THE ELASTICS ON BOTH EDGES OF THE MASK

AUTOMATIC COUNTING

AUTOMATICALLY CONVEYS THE FINISHED MASKS TO PACKING PROCESS (PACKING BY HAND)

COMPUTER CONTROLS AND PHOTOELECTRIC DETECTION ENSURE LOW FAILURE RATE AND HIGH RELIABILITY

FRAME CONSTRUCTED OF ALUMINUM ALLOY

QUANTITY: 2PRODUCES MASKS WITH DIMENSIONS: 175mm x 95mm (ADULT SIZE)

FOR MASK TYPES: 2 LAYERS OF NONWOVEN CLOTH, 3 LAYERS OF NON-WOVEN FABRIC MASKS, 4 LAYERS OF ACTIVATED CARBON MASKS

• 2 LAYER FACIAL MASK: NONWOVEN, ALUMINUM STRIP, EAR STRAP WELDING

• 3 LAYER FACIAL MASK: NON-WOVEN, ALUMINUM STRIP, EARLOOP WELDING, FILTER COTTON (FILTER PAPER)

• ACTIVATED CARBON MASKS: NONWOVEN, ALUMINUM STRIP, EARLOOP WELDING, FILTER COTTON (FILTER PAPER), ACTIVATED CARBON CLOTHTECHNICAL PARAMETERS

OVERALL DIMENSIONS: 6500 L x 4000 W x 2000 H (mm)

PRODUCTION EFFICIENCY: 95%

PRODUCT SIZE: 175 x 95mm (ADULT SIZE)

FACIAL MASK LAYERS: 3 TO 4 LAYERS

POWER: 9 KW

AIR PRESSURE REQUIRED: 0.6 MPA

AIR CONSUMPTION: 300 LITERS PER MINUTE

WEIGHT: APPROXIMATELY 1800 KG

GROUND WEIGHT BEARING: ≤ 500KG/m2

ALL OF THE MAIN DRIVING PARTS ARE PROTECTED BY PROTECTIVE COVERQUANTITY: 1 COMPLETE LINE

Learn More -

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPE

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPEI. FUNCTION

Learn More

THE MACHINE IS FULLY AUTOMATIC EAR TO LOOP MASK MAKING MACHINE. THIS MACHINE INCLUDES ONE SET OF CS-175 AND 2 SETS CS-WD175 AND BY A UNIT OF AUTOMATED DISPENSER. MASK BODIES PRODUCED ON THE MASK MACHINE CAN BE ALLOCATED ONTO 2 SETS OF SUBSEQUENT MACHINES CONTROLLED BY PLC AT THE SPEED OF 0 TO 120 PIECES PER MINUTE. ALL OF OPERATIONS OF THE MACHINE ARE CONTROLLED THROUGH TOUCH SCREEN OR PLCS.

II. PROCESS

AFTER THE MACHINE MAKES THE MASK BODY, THE CONVEYOR BELT STRUCTURE TRANSPORTS THE MASK BODY PIECE TO THE CONNECTING CONVEYOR. THROUGH THE CONNECTION CONVEYOR MASK PLATE TO THE CONVEYOR BELT, AGAIN THROUGH THE CONVEYOR BELT THE MASK IS TRANSPORTED TO THE EAR PIECE SECTION TO THE FRONT OF THE MACHINE ABOVE THE FIRST MASK PLATE, FINALLY THROUGH THE CYLINDER DOWN THE MASK ONTO MASK EAR MACHINE DISC, FOLLOWED UP BY EAR MASKS FOR THE EARS OF THE BELT WELDING MACHINE AND THEN IT’S COMPLETE.

III. FEATURES:

1. MACHINE FRAME IS MADE OF ALUMINUM ALLOY, PREVENTED FROM RUST;

2. THE MACHINE CAN MAKE 1 TO 3 TYPES OF MASK BLANKS ACCORDING TO WHAT THE CUSTOMER REQUIRES.

3. THE SIZE OF THE MASK BLANK AND THE FOLDING LOCATION CAN BE ADJUSTED;

4. THE DIRECTION OF THE EAR LOOP IS OUTSIDE;

5. A COMPUTER PROGRAM CONTROL AND PHOTOELECTRIC DETECTION ACHIEVES A HIGH RELIABILITY AND LOW FAILURE RATE. -

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINE

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINEI. FUNCTION

Learn More

THIS MACHINE IS USED TO PACK DISPOSABLE SURGICAL FACE MASK WITH THE SIZE OF 190 X 65mm. IT CAN ALSO BE USED TO PACK OTHER PRODUCTS SUCH AS WET TISSUE.

II. FEATURES:

1. ONE SET OF INK TO INJECT PRINTER IS INCLUDED; IT CAN BE USED TO PRINT THE DATA AND OTHER INFORMATION.

2. THE AIR COMPRESSOR EQUIPMENT IS OPTIONAL.

3. PACKING MATERIAL: SINGLE TO SIDE HEAT TO SEALING PACKAGING FILM MATERIALS, SUCH AS OPP, CPP, OPP COMPOSITE PE, PET COMPOSITE PE, SINGLE TO LAYER OR COMPOSITE PACKAGING FILM MATERIALS.

4. BAG FORM: BACK TO SEALED PACKING, CAN BE CUSTOMIZED.

5. VERTICAL/HORIZONTAL SEAL: RETICULATED PACKAGING/VERTICAL AND RETICULATED PACKAGING.

III. SPECIFICATION:

NAME: PILLOW PACKING MACHINE

TYPE KD TO 350

APPLICATION: FOR ALL KINDS OF OPP HEAT TO SEALING FILM, COMPOSITE FILM, SPRAY FILM PAPER, ALUMINUM FOIL FILM, ALUMINUM PLASTIC COMPOSITE FILM

MACHINE SIZE: 4600 X 850 X 1500

PACKING SPEED: 60 TO 220 BAG/MIN

MAX. PACKING SIZE: 330mm, 150mm, 80mm. LENGTH: 330mm, WIDTH: 150mm, HEIGHT: 80mm

MIN. PACKING SIZE: 50mm, 10mm, 5mm. LENGTH: 50mm, WIDTH: 10mm, HEIGHT: 5mm

ELECTRICAL: AC220V, 2.7KW

AIR PRESSURE 0.5 TO 0.7 MPA

AIR CONSUMPTION: >0.36 (M3/H)

(DB) NOISE: 60 TO 70DB

MACHINE WEIGHT: 550KG

MOTOR FREQUENCY ADJUST: 0 TO 50HZ

AUTOMATIC CONTROL

AUTOMATIC PRINTING

STANDARD: GMP STANDARD, PACKAGING MACHINE ENTERPRISE STANDARD

APPROVAL: ISO9001:2000, CE ISO:2000 -

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILL

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILLFOR FILLING DOWN FEATHER PILLOWS

FILLING RANGE: 1 TO 120 GRAMS (70% FEATHER & 30% DOWN)

WEIGHING SYSTEM: 4 SETS

POWER: 4.5 KW

VOLTAGE: 220 / 380 V, 3-PHASE

AIR PRESSURE: 0.5 TO 0.7 MPA

ACCURATE WEIGHING RESULTS WITH TOLERANCE OF ONLY 1 GRAM

WORKING TABLE DIMENSIONS: 1200 x 2400mm (FOR CUSTOMERS FILLING PILLOWS AND QUILTS)

WORKING TABLE DIMENSIONS FOR PILLOWS ONLY: 1200 x 1200mm (EASIER TO FIT IN A 20 FOOT CONTAINER)

OPERATION CAN BE HANDLED BY ONLY 1 EMPLOYEE

INCLUDES ONE AUTOMATIC FILLING TABLE WITH FOOT SWITCH AND CLAMP DEVICE

THE WORKER STEPS ON THE FOOT SWITCH AND THE CLAMP DEVICE WILL RUN TO CLAMP THE PILLOW BAG

THE FILLING PROCESS AUTOMATICALLY STARTS TO FILL THE PILLOW AND AFTER FINISHING THE CLAMP DEVICE WILL RESET

DURING THIS PERIOD, THE WORKER MAY SEAL THE PILLOW WITH SEWING MACHINE

FOUR HOPPER SYSTEM FOR CONSTANT SUPPLY

ONE KEY FOR CHARGE AND RECHARGE REDUCES WASTED TIME

HIGH-QUALITY, RELIABLE ELECTRICAL COMPONENTS

PREPROGRAMMABLE FOR UP TO 50 GROUPS OF RECIPES WITH EACH RECIPE CONTAINING UP TO 60 SETS OF DIFFERENT FILLING PARTS FOR THE SAME PRODUCTION

FULLY ENCLOSED DESIGN TO KEEP ENVIRONMENT CLEAN AND REDUCE MATERIAL WASTE

AUTOMATIC, ACCURATE WEIGHING WITH LOAD CELL TO ENSURE PRODUCTION QUALITY

CE CERTIFICATE INCLUDED

FLOORSPACE 4000mm LONG X 3000mm WIDE X 2500mm HIGH

TABLE FOR PILLOWS IS 1200 X 1200mm

Learn More

QUANTITY: 1 -

L-6055 MAMMUT VM-7 QUILTING MACHINE, WIDTH 3200mm, YEAR 1980

L-6055 MAMMUT VM-7 QUILTING MACHINE, WIDTH 3200mm, YEAR 1980REFERENCE NUMBER: L-6055

MAMMUT VM-7 QUILTING MACHINE, WIDTH 3200mm, YEAR 1980

QUILTING MACHINE

MAKE: MAMMUT

YEAR: 1980

MODEL: VM-7

WIDTH: 3200mm

ELECTRONIC MOVING CART (FOR WEAVED STITCHING)

EQUIPPED WITH A PROCESSOR WITH DIFFERENT WAVES OR ZIG-ZAG

ALSO POSSIBLE TO STITCH SQUARES 150 AND 300mm

KNOTTED STITCHING

ONE ROW OF NEEDLES

THREAD BREAK DETECTION SYSTEM

6” BETWEEN NEEDLES

QUANTITY: 1

Learn More -

M-8007 SAMPLE COFFEE ROASTER, CAPACITY 50 TO 200 GRAMS

M-8007 SAMPLE COFFEE ROASTER, CAPACITY 50 TO 200 GRAMSREFERENCE NUMBER: M-8007

SAMPLE COFFEE ROASTER, CAPACITY 50 TO 200 GRAMS

SPECIFICATIONS:

CAPACITY: 50 GRAMS TO 200 GRAMS

POWER: 230V – 50/60HZ

GAS: NATURAL AND PROPANE OR HEATING: ELECTRICAL HEATING

EXHAUST: Ø 80mm

WEIGHT: 85KG

Learn More